International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Sugan V1,Gokulkannan S2, Elayaraja R3

1,3 Assistant Professor, Department of Mechanical Engineering, Mahendra Engineering College(Autonomous), Mallasamudram,Namakkal,Tamilnadu,India

2 PG Scholar, Department of Mechanical Engineering, Mahendra Engineering College(Autonomous), Mallasamudram,Namakkal,Tamilnadu,India

***

Abstract During the casting process, many complicated phenomena supporting metal solidificationoccur,suchascast metal flow, thermal gradient, and heat transmission between the cast metal and the mould. Both of these events, as well as the geometrical parametersandthermo physicalpropertiesof the metal and the mould, determine the grain size and mechanical properties of cast metal. Convectional heat loss from the mould to the environmentcanimpactthemechanical characteristics of cast metal. Using the finite element approach and the ANSYS software programme, two dimensional numerical simulations of pure iron solidification in industrial AI 50/60 AFS greensandandmullitemouldswere performed in this study. For this aim, the thermo physical characteristics of iron were assumed to be temperature dependent, whilst the properties of sand and mullite were assumed to be constant, and the convection phenomenon was also studied on the mold's external surface. Metallurgical parameters such as the assault zone in the feed head and the hot top were not included in this study since they have no bearing on the metal's heat transmission to the mould. This type of problem is nonlinear because of the temperature dependent thermo physical characteristics of iron. The heat transfer data, as well as the thermal flux, thermal gradient, and convergence curves that determine the feasibility of the Newton Raphson algorithm calculationprocess,aredisplayed in two dimensions. The heating and cooling curves in the mould, as well as the cooling curves at various sites of the solidified specimen, were also exhibited. These findings were deemed important.

Key words: Numerical simulation; finite elements; solidification of iron; sand and mullite mold

Casting is the process of producing metal into a determined shape by melting solid metal into liquid form, pouringitintoamoldandlettingitsolidifyintothedesired shape.Themoldisanegativecopyoftheshapeofthecasting. There are many other methods of shaping metals, such as machining, forging, welding, stamping and hot working. Casting has many advantages over the other methods of metalshapingforproducingsomeparticularshapesofmetal andtypesofmetal.

Castingcansimplifyproductionbycastingasingle complexshapepieceinsteadofmanufacturingaproductthat requiresassemblingseveralpiecestogether.Massproduction of products can be done by casting; a large number of products in a single mold or in other cases by reusing the mold.Verylargeheavyobjectscanbecastwhichwouldbe extremelydifficultoreconomicallyimpossibletoproduceby othermethods.Someengineeringpropertiesincastingare betterthanobjectsproducedbyothermethods.Forexample, uniformpropertiesthroughoutthecastingcanbeachievedif properly cast. Casting can give an economic advantage resultingfromoneormoreoftheadvantagesshownwhich may help in the competition against other types of manufacturing.(Heineet.al.,1995)

Therearesituationswhereothershapingmethods aremoresuitable.Forexample,machiningcanachievebetter surface finish and dimensional accuracy not achievable by casting; welding can join metal objects which may be produced by wrought or casting into more complex structures,stampingproduceslightweightsheetmetalparts; and forging helps improve the strength and toughness of steel,etc.Anengineerwithknowledgeofthepossibilitiesof eachshapingmethodmayselectamethodoracombination ofmethodswhichbestsuitshisorherworkachievinghigh quality,lowpricedproducts(Heineet.al.,1995).

Therearemanyprocessesforproducingacasting depending on size, type of metal, complexity, dimensional allowance,qualityandwhatsoever.Oneoftheoldestmethods knownissandcasting.Sandismixedwithbindersandwater sothesandgrainsholdshape,compactedinaflaskwhichcan beseparatedintotwoormorepieceswithapatterninthe middle.Thispatternwillhaveapproximatelythesameshape and size (or may be slightly different depending on the dimensionaltolerance,shrinkage/expansionofthemetalor machining allowances) of the desired casting. The mold is thenparted,thepatternisremovedandthecompactedsand willhaveanegativeshapeofthepattern.Themoldmaybe assembledwithcorestogivethecastinghollowshapes,and thegatingsystem,includingrunners,ingates,risers,sprues, etc.,willbemadeinthemold.Theliquidmetalwouldthenbe pouredintothemold.Afterthecastinghascooleddown,the moldisbroken to remove the casting. Thecasting's gating

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2657

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

systemandriserswouldbebrokenoff,thecastingcleaned andthenmachinedintothedesiredproduct.

Sandcastingmaybeseparatedintogreen sandmold casting,no bakesandmoldcastingandshell moldcasting. Green sandmoldcastingissilicasandandclaymixedwith water,no bakesandmoldissilicasandmixedwithresinthat hardenswithinminutesaftershapingandshell moldcasting issilicasandmixedwithresin,shapedandbakedtoformthe wantedmoldshape(SocietyofManufacturingEngineers).

Sand casting may be classified as Expendable Mold/Reusable Pattern process. Other Expendable Mold/Reusable Pattern process casting methods are the plaster mold casting process, and ceramic mold casting process(SocietyofManufacturingEngineers).Thelostwax castingmethodorinvestmentcastingprocesswasusedby AsianIndianstomakesculpturesofgodsandgoddessesfor hundredsofyears.

Full mold casting or evaporative foam casting is done by packing loose silica sand around an expanded polystyrene(EPS)pattern. Moltenmetalisthenpouredinto the mold through the gatingsystem, burning out the foam pattern as it fills the mold. It is called full mold casting because the pattern is not removed, hence the name full mold.Thismethodissuitableforevenintricatecastingsand requireslesslaborandskillcomparedtosandcasting.Amold mustbeusedtomaketheEPSpatternsandthemoldshould properlyventoutthegasesgeneratedfromburningthefoam.

Anothervariationisvacuumcasting,whichalsouses loose sand but held between two thin plastic sheets by vacuum applied to a pattern with a number of vent holes (Ravi,2005).

Investmentcastingandevaporative foamcastingcan be classified as Expendable Mold/Expendable Patterns Process. Another classification of casting process is PermanentMold/NoPatternsProcess.Thecastingprocesses inthisclassificationarepermanentmoldcasting,diecasting andcentrifugalcasting(SocietyofManufacturingEngineers).

Gravitydiecasting(alsocalledthepermanentmold process)isamethodwhichmoltenmetalispouredintoacast iron mold coated with a ceramic mold wash. Cores can be madefromsandormetal.Afterthecastinghascooleddown, themoldispartedandthecastingisremoved.Thismethodis suitable for non ferrous metals with medium sizes and moderatecomplexityandthickness(Ravi,2005).

Pressurediecastingisaprocesswhichmoltenmetal isinjectedintoahardenedsteeldieunderpressure.Usually thistypeofdieiswater cooledandmetalcoresmustbeused insteadofsandcores.Thecastingisremovedbypartingone halfofthedieandthecastingisremovedbyejectorpins.This process is suitable for non ferrous castings with small to mediumsize,varyingcomplexityandthinwalls(Ravi,2005).

Centrifugalcastingisaprocesswhichmoltenmetal is poured into a horizontal rotating mold where the centrifugalforcewouldpushthemoltenmetaltothemold wall.

Tool Costs

Lab or Cost s

Typical Tolera nces

Surface Finish Typical Volume

Permanent Mold High Low +/ .01 .03in Good Medium High

Greensand Low Low +/ 0.03 0.06in Average Low High

Die Very High Low +/ 0.01 0.15in Very good VeryHigh

Thismethodcanproducepipesoftubeswithoutusing cores (Ravi, 2005) and the thickness of the casting wall depends on the amount of molten metal poured into the mold(SocietyofManufacturingEngineers).Analternativeto this process is the semi centrifugal casting process which axis symmetricalcastings,likepulleys,gearsandrotorscan be produced while rotating about a vertical axis rotating mold. Another variation called the centrifuge casting is a processwhichmoldcavitiesarearrangedaroundacentral axis.Thismethodusestherotationofthemoldtogetbetter fillingcharacteristics(Ravi,2005).

Squeeze casting or semi solid casting is a process whichsemi solidmetalisforcedunderpressureintoametal mold.Thismethodwouldgiveacastingfinemicrostructure free from dendrites. The mechanical properties of these castingsareclosetothoseofforgings.Thismethodisuseful fornon ferrousmetalsandcompositesandisalsoappliedfor aerospaceandautomotiveparts(Ravi,2005).

Thecastingprocessstartsfromreceivinganorder fromacustomerwhichmayincludethedesign,dimension, physicalproperties,etc.,thenthefoundrymustplanhow to makethecastings,whatmethodsmustbeused,thenproduce aprototypeofthecasting,modifythecastingmethodstoget rid of the defects, produce the product, and last of all, the sendthefinalproducttothecustomer.Figure1.1showsthe mainproceduresofacastingprocess,buttheproceduresin eachcastingfacilitymaydifferindetail.

Casting Process Cost Production rate (Pieces/Hour) Die Equipment Labor

Sand L L L M 20

Investment M H L M H 1000

Die H H L M 200

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2658

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Guharaja etal.(2018) usedTaguchi'sapproach to determine the ideal green sand casting parameters for attainingthebestqualityattributesofspheroidalorductile castiron.Greenstrength,moisturecontent,permeability,and mouldhardnesswereallexaminedasprocesscharacteristics. Theeffectoftheselectedprocessparametersandtheirlevels on casting defects, as well as the subsequent optimal parametersettings,wereachievedusingTaguchi'sparameter designapproachandconfirmedwithactualtrials.

There must be studies and researches into the features of each component in each process in order for a casting simulation software programme to anticipate the resultsofacasting.Becausecastingpressureconditionsin diecastinghaveasignificantimpactoncastingdefectssuch asgasporosity,shrinkageporosity,andgasholes,Liuetal. (2015)investigatedtheeffectsofcastingpressure,loading time, and piston position of pressure intensification on pressure variation and casting quality. Casting pressure, loadingtime,andpistonlocationofpressureintensification werediscoveredtohavesignificanteffectsonmouldpressure variances,castingquality,andcastingperformance.

Metalsusuallyshrinkwhentheyloseheat,whichis similartohowacastingshrinkswhenitsolidifiesinamould, but depending on the material, the casting may start to expand when it cools down to a specific temperature. The heat transfer rate is determined by the heat transfer coefficient(h)between twotypesofsurfaces,whichinthe case of casting are the casting and the mould. However, because a casting may shrink during the solidification process,thehvaluemaychangeduetothegapofaircreated by the casting shrinkage. The interfacial heat transfer coefficient(h)betweenhightemperaturecastingalloysand moulds was measured by Wang et al. (2013) during the castingprocessduetogapcreation.Itwasdiscoveredthatat thestartofthecasting,ahighvalueofinterfacialheattransfer coefficient is attained, then the value lowers abruptly, increasestoaspecificvalue,andthenprogressivelyfalls.The heat transfercoefficient (h) value is also controlled by the mouldmaterialratherthanthecastingalloys;castingswith ceramic moulds have a h value between 22W/m2 K and 350W/m2 K,whereassandmouldshaveahvaluebetween 40W/m2 Kand90W/m2 K.

DeLooze(2015)investigatedhowtheoperational parametersofalowpressurediecast(LPDC)machineand thequalitylevelofthealuminiummeltinfluencedthecasting coolingrateand/ormicrostructure.Microporositygeneration anddispersioninthecastingswereemployedasindicatorsof casting quality and solidification conditions, and experimentalevidenceforburstfeedinginlowpressuredie castingwasdiscovered.Diecoolingresultedinconsiderable directional solidification improvements as well as micro structural refinement. Wong (2018) studied how to manufacture high quality aluminium castings using

Campbell's10castingcriteria(Campbell,2004).Campbell's criteria wereusedtocreatetherunnerandgatingsystem, with proper runner and gating system designs including bottomfilling,lowfillingrate,andgoodpouringbasin,riser, andventingdesigns.Thedesignswerethenconfirmedusing CAE software. Three castings were manufactured and examined in this study, all of which passed X ray and fluorescencepenetrationinspections.ACVDheaterwascast usingthesandcastingmethod,agatevalvebodywasformed using the permanent mould die casting method, and an aerospacehousingwascastusingtheQuickcastmethod.

Filipic(2014)investigatedtheuseofanoptimization tool that included an optimization algorithmand a casting process simulator. It was used to optimise spray coolant flowsinanindustrialcastingmachine.Themanualcontrolof coolantflowwasgreatlyenhanced.

1. Toevaluatethecastmaterialandmouldmaterial deformationanditsdurabilitywiththehelpof Ansys.

2. Tostudythethermalstressofthecastmaterialand mouldmaterial.

3. TointerpretthetemperatureandLiquidfractionat each second of the cast material and mould material.

4. To analyze theheat flux from thecontainer to the atmosphere.

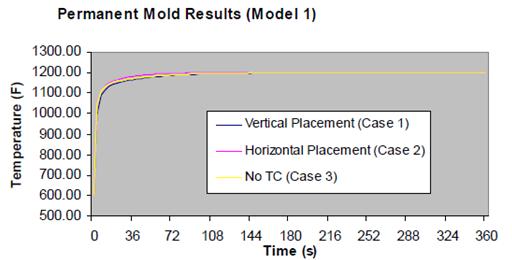

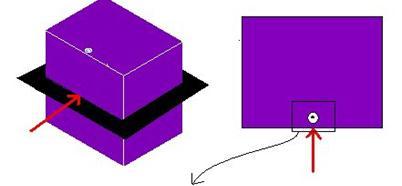

Figure 1depicts the data collected from the simulations created to approximate the temperatures measured by vertically and horizontally mounted thermocouples.

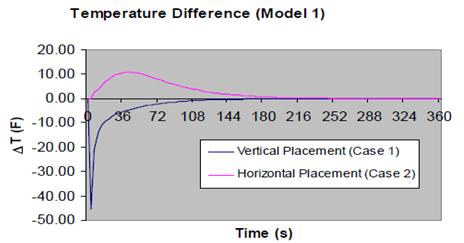

Figure2showshowthetemperaturesmeasuredby vertically and horizontally mounted thermocouples differ fromthetemperatureresult.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2659

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

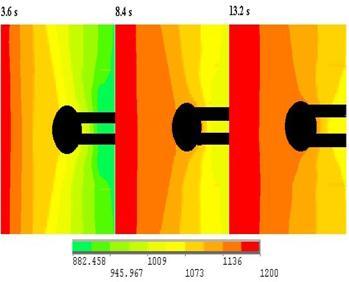

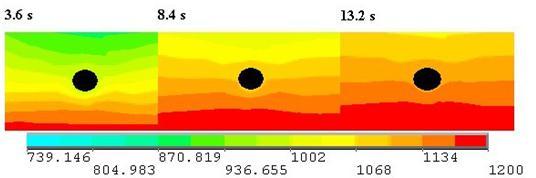

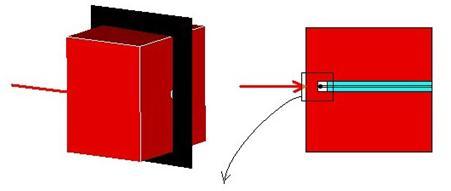

The temperature field distortion can be seen by cuttingaplanethroughthethermocouplebead(Figures3 and 4). To show how the distortion progresses, a contour plotisgivenfordifferentpointsintime.

The necessity of thermocouple placement when recording transient temperatures is highlighted by the FE analysisdiscussedabove.Inpermanentmoulds,aholemust beboredtoappropriatelylocatethethermocouple,andthe hole, regardless of its contents, becomes a source of distortion.Asaresult,thetemperatureatthebottomofthe hole will be different than it would be in an undamaged mould. As a result, even a perfect thermocouple would generateinaccuratetemperaturereadings.Aholemustbe drilled to accommodate the thermocouple and insulator when the thermocouple is positioned vertically. The temperaturefieldisplainlyalteredasaresultofthehole's entrance. As a result, readings from a thermocouple bead placed at the bottom of the hole will be off from the real temperature. Continuing our consideration of permanent moulds, the hole itself has a substantial effect on the temperature when the thermocouple is positioned horizontally (perpendicular to the isotherms). As a result, the horizontally positioned thermocouple readings differ somewhatfromtherealtemperature.

When using thermocouples to obtain transient temperature data, the placement of the thermocouple relative to the isotherms is crucial. By appropriately positioning the thermocouple, the error caused by temperature field distortion can be greatly decreased. In permanentmoulds,thelengthofthethermocoupleshould be perpendicular to the isotherms. This arrangement improves overall temperature measurement accuracy by allowing you to adjust the distance between the interface and the thermocouple bead. In sand moulds, the thermocoupleshouldbeparalleltotheisotherms,resulting inlessconductionthroughtheleadwiresandmoreaccurate temperaturemeasurements.

1. Maria JosMarques,(2006). CAETechniquesforCasting Optimization,INEGI,P.4465 4591.

Figures 3 and 4 show a close up view of the temperaturefieldaroundthethermocouplebeadatacertain point in time, with the arrow representing the step temperatureappliedtothefrontfaceofthemouldmaterial. ThetemperaturescaleisinFahrenheitunits.

2. Rabindra Behera, Kayal, S. Sutradhar. G. (2001). Solidfication behaviour and detection of Hotspots in AluminiumAlloycastings:ComputerAidedAnalysisand experimentalvalidation,InternationalJournalofApplied EngineeringResearch,ISSN09764259.

3. Ravi,B.(2000).ComputerAidedDesignAndAnalysisFor ZeroDefects,InternationalConferenceonAluminium,p. 1 6.

4. Joshi. (2008). Durgesh Joshi and Kamalesh Singh Part ToolingandMethodOpti misationDrivenbyCastability AnalysisandCostModel,WorldFoundryCongress7 10 Feb,p.261 266.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

5. Reis, A. Houbaert, Y. Zhian Xu, Rob Van Tol, (1999). Modeling of shrinkage defects during solidification of long and short freezing materials, Journal of Materials ProcessingTechnology95,p.428 434,1999.

6. Shamasundar, S., Ramachandran, Damayanthi., Shrinivasan,Si YoungKwak,JieChengandJeong KilChoi, (2007). Impact analysis of casting parts considering shrinkagecavitydefect,chinaFoundryVol.8No.1,p.1379 1385.

7. N.S.,Junatha,M.T.M.(2007).ComputerSimulationAnd AnalysisOfInvestmentCastingProcess,TexmoPrecision Castings,p.1 19.

8. J.C.Chen,J.H.Kuo,andW.S.Hwang:“Measurementof interfacial heat transfer coefficient for the evaporative pattern casting of A356 aluminum alloy,” International JournalofCastMetalsResearch,2002,vol.15,pp.93 101.

9. W.D.Griffiths:“TheHeatTransferCoefficientduringthe Unidirectional Solidification of an Al Si Casting,” Metallurgical and Materials Transactions B, 1999, vol. 30B,pp.473 482.

10.K. Narayan Prabhu and W. D. Griffiths, “Metal/mould interfacialheattransferduringsolidificationofcastiron in sand moulds,” International Journal of Cast Metals Research,2001,vol.14,pp.147 155.

11.K.NarayanPrabhuandJohnCampbell,“Investigationof casting/chill interfacial heat transfer during the solidificationofAl 11%Sialloybyinversemodelingand real time x ray imaging,” International Journal of Cast MetalsResearch,1999,vol.12,pp.137 143.

12.M. H. Attia and L. Kops, “Distortion in Thermal Field Around Inserted Thermocouples in Experimental InterfacialStudies,”JournalofEngineeringforIndustry, 1988,vol.110,pp.7 14

13.G.Paniagua,R.Denos,M.Opresa,“ThermocoupleProbes for Accurate Temperature Measurements in Short Duration Facilities,” Proceedings of ASME Turbo Expo, 2002,pp.209 217.

14.M. H. Attia and L. Kops, “Distortion in Thermal Field Around Inserted Thermocouples in Experimental Interfacial Studies Part II: Effect of the Heat Flow ThroughtheThermocouple,”JournalofEngineeringfor Industry,1986,vol.108,pp.241 246.

15.R.W.Ruddle,TheSolidificationofCastings,Instituteof Metals,London,England,1957,pp.14 35.

16.X. Xue, R. Luck,B. Dawsey,and J.T. Berry, “Modeling of Temperature Measurement Process with a Thermocouple:AComprehensiveParametricStudyand

some Experimental Results,” AFS Transactions, 2004, Paper04 044,pp.37 54.

SuganV, AssistantProfessor/Mech, Mahendra Engineering College, Mallasamudrdam,Namakkal 637408

ElayarajaR, AssistantProfessor/Mech, Mahendra Engineering College, Mallasamudrdam,Namakkal 637408

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2661