International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1M.Tech, Production and Industrial Engineering, Integral University, Lucknow, India.

2Associate Professor, Department of Mechanical Engineering, Integral University, Lucknow, India. ***

Abstract This review paper studied to increase the strength of the Acrylonitrile ButadieneStyrenefilamentwitha different technique, and a summary of all research papers is available in the literature survey. The demand for 3D printed materials has increased as the number of people using 3D printers has grown. Several materials have been used to experiment with the printingprocesssincetheinventionofthis technology. The materials that can be printed range from polymers to biological tissues. According to a Forbes survey from 2018, plastics are the most widely used 3D printing materials, accounting for around 88 percent of all materials used globally. This is due to the low cost and widespread availability of plastics. Plastics have a better processability than most other 3D printing materials.

ABS is appropriate for 3D printing because to its thermoplastic nature. ABS has unique mechanicalcapabilities due to its composition, including excellent toughness, impact resistance, stiffness, and strength. As a result, ABS is used in a wide range of products, from everyday things to automobile parts and complex medical gadgets. The challenge of how to recycle and dispose of the material arose as a result of the increased demand and consumption of the material. Any incorrect disposal of ABS poses a significant environmental risk. As a result, there is more room for study on ABS recycling patterns.

Key Words: 3D printer, filament, Strength, Acrylonitrile Butadiene Filament, the strength of the filament.

Market statistics suggest that income from 3D printer vendingandservicesquadrupledbetween2009and2013, and maintain to expand significantly (Park, 2014). Even thoughthesetechnologies"wereinitiallymeantprimarilyfor (heavy)industrialusage,""continuouscostreductionshave broughtthemwithinreachof[subjectmatterexperts]SMEs and individual entrepreneurs". Moreover, client markets uncoverAssociateinNursingexpandingpropensitybyand largedealsinorganizationslikeStaplesandWalmart(Rayna andStriukova,2016).on lineretailerslike3DXTech(2017a), Stratasys (2017), and Makerbot (2017) sell restrictive materials along with their synthetic substances, while Amazon,eBay,andvariousmerchantsselloutsidermaterials and3Dprintingadministrationstoordinaryclientsandhuge producers(RaynaandStriukova,2016,).Throughalayering

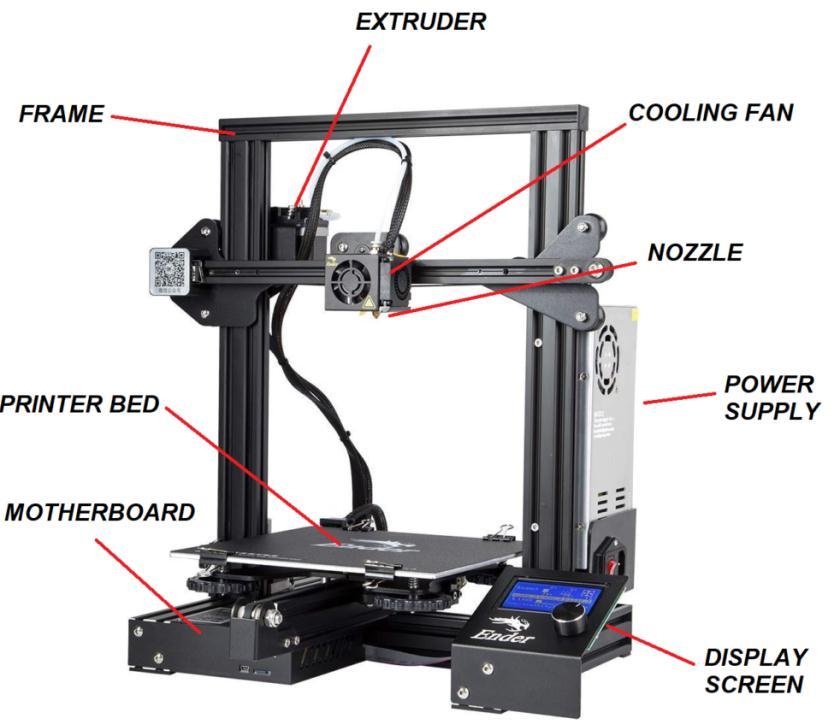

approach, 3D printing employs computer aided design (CAD)to buildthree dimensional things.3D printing, also knownasadditivemanufacturing,istheprocessofstacking materials such as plastics, composites, or bio materials to makeitemsthatvaryinshape,size,stiffness,andcolour.The figureofthe3Dprinteraregivenbelow:

3D printers are part of the additive manufacturing family and work in a similar way to inkjet printers, although in threedimensions.Tomakeathree dimensionalthingfrom scratch, you'll need a combination of top of the line software,powder likematerials,andpreciseequipment.

ABSismanufacturedfromthemonomersAcrylonitrile,1,3 Butadiene,andStyrene,aswellaspetroleum.Thiskindof plasticisnotedforitsstrengthandresistancetoimpact.This filament will allow you to print long lasting 3D items that willwithstandalotofuseandwear.

WhiteisthecolourofarawversionofABSmaterial.Itmay simply be dyed to your prefered hue throughout the productionprocessbecause toitsneutral colour.TheABS filamentfigureisasfollows:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

3Dprintingaretwoofthesetechnologies.3Dprinting"refers toaclassoftechnologiesforthedirectfabricationofphysical productsfroma3Dcomputer aideddesign(CAD)modelbya layered manufacturing process" 3D printing "alludes to a classofinnovationsfortheimmediatecreationofanactual productfroma3Dpchelpedstyle(CAD)model byaslept withdeliveringprocess"(Huang,etal.,2012).AMisutilized to make a virtual 3D model of an item that might be 3D composed. Successive level cross segments are arranged exploitationprogrammingbundles,andeachcrosssegment isimaginedasasecondmathematicalitemwithafirmlevel.

The relevant literature has looked into fused deposition modelling(FDM),ABSwithadiscussionoftensilestrength, carbonfibrereinforcinginABSwithadiscussionoftensile strength,CFRABSproducers,andtensilestrengthchanges dependentontheorientationof3Dprintedstrands.

According to Brooks, Kinsley, and Owens (2014), S. Scott Crump, who co founded Stratasys, introduced FDM in the 1980sandbegandevelopingitintowhatweknowasFDM today. Since the patent on FDM expired, the cost of commercial3Dprintershasdroppeddramaticallyasmore businessesandopen sourcecommunitiesembracetheidea ofcreatingamachineormaterialforone.Accordingtothese academics, "businesses are now beginning to grasp the possibilityofemployingthistechnologyinsidetheirbusiness model for competitive advantage" since FDM's inception. Companiescan,forexample,utilizeawiderangeofmaterials toserviceagreaterrangeofclients.

FDMtechniquesmaymakeabroadvarietyofitemssuchas "prototyping,tooling,andmanufacturedgoods"fromseveral materials such as "paper, nylon, wax, resins, metals, and ceramics," according to Bhargava, Bhargava, and Jangid (2014). "A wide range of sectors, including automotive, aerospace, medicinal, consumer, electrical, and electronic devices,canbenefitfromFDM,"theresearchersconclude(p. 4). FDM has this benefit because, "unlike certain additive productiontechniques,FDMrequiresnospecificequipment or ventilation and includes no toxic chemicals or by products."Furthermore,partscreatedwithFDMarereadyto usewith"verylittledelayandwork,"whilealsoremoving expensivecomponentsliketooling"Additivemanufacturing (AM)" (Fudali, Witkowski, & Wydrzyski, 2013) refers to "production systems that generate products through a sequential layering process." Fused Filament Fabrication (FFF),alsoknownasfuseddepositionmodeling(FDM),and

Byexpellingathinstrandofasemi moltenthermoplastic, typicallyABS,throughanintensitysafespout/opening,a3D printerproduces(ordevelops)structuresforeachlayerin turn (Berman, 2007; NovakovaMarcincinova and Kuric, 2012).Theflatthincutofthemodelmadebyprogramming bundle is constructed utilizing a spooled fiber of thermoplastic, typically.07 inches (1.75 mm) or.12 in. (3 mm) in width. The fiber is warmed to an arranged temperaturedegreeandexpelledusingalittlespout(witha roundaboutopeningusually.0079in.(.2mm)to.28inches (.7mm)inbreadth)togetdownastrandofplasticontoa form stage to that the underlying layer of plastic rapidly joins.furthercoursesaremadetillthelayerisfinished.Shell strandsareunexceptionallyputdownontheborderofevery layer of the model. Inside locales are normally molded of strandssetdownataframedpoint,(forexample,+45°tothe build platform's x axis, which runs left and right) if the model is mentioned to be made with a strong inside (NovakovaMarcincinovaandKuric,2012).whenthemachine advancestotheresultinglayerbytrickytheformingstage somewherenearthenumbersimplebyeachlayerthickness, the ensuing layer is huge opposite to and on prime of the past layer (for instance, at 45° to the x axis), any place it sticks.Insidezonesincertainmodelsaren'tstronganyway typify honeycomb or option mathematical material directions to try not to squander material utilization, developmenttime,ormodelthickness.

Upholdsarelikewisemadeoncethereareessentialshadesof 3Dcomposedmaterialorontheotherhandontheoffchance thatasuperiorlayerisineffectivelyupheldincertainareas by the layer underneath it (at times with dissolvable or generallybasicallyremovablematerials).whenthemodel's bondtotheformingstageislean,aspecificarrangementof establishmentlayersknownasapontoonoranedgeismade (asapristinestageforthemodeltobeplannedon)tokeep away from it from getting unstuck all through creation. Pontoons overflow, and supports are eliminated once the modelhashuge.thetexturefollowstheCADmodel'scross sectionalstructurelayerbylayerallthroughtheexpulsion strategy,atlonglastchangingintotheconcludeditem.

ThebeginningsofABSplastic(chemicalformulamentioned above)maybetracedback tothemid 1940s,accordingto

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Olivera,Muralidhara,Venkatesh,Gopalakrishna,andVivek, (2016). The initial formulation omitted butadiene (C4H6), which produced problems in the acrylonitrile styrene copolymer.Bulletproofarmor was manufacturedin World WarIIaftercombiningthisrubbermonomerandformingthe terpolymerwenowknowasABS,whichhadstrongimpact resistance and "poor thermoplastic flow characteristics." "Great toughness (even in freezing circumstances), acceptable stiffness, strong thermal stability, and high resistance to chemical assault and environmental stress crackingcharacterizeABSpolymers."ABSisahighlysought after thermoplastic in engineering, according to Ghanbari (2014),becauseofitsnumerousdesirableattributes,which include but are not limited to: "acceptable mechanical properties, chemical resistance, and adequate processing characteristics."

(C8H8 C4H6 C3H3N)n

Numerousfarandwidepropertiessemiconductordiodeto thereceptionofABSinfieldsliketrim,anyplacepartslike lines were made, following Olivera et al. (2016). In the NineteenFifties,ABSmadeitsmethodologyintofieldslike "materials,style,toys,andprivatepurposes."ABSwasstarted usedin3DprintinginsidetheNineties,asaresultofadded substance delivery systems. "Common ABS consolidates a dissolvingormellowingreasonsomewhereintherangeof 401and473degreesGabrielDanielFahrenheit(205and245 degrees Celsius), that considers direct utilization in many business3Dprinters,"Satches(2015)composes.

"ABSmightbeafarandwidedesigningthermoplastic,and it's the chief successive material used in amalgamated statement demonstrating (FDM) innovation," composes Savvakis (2014). ABS is open in a real type of synthetic structures, as well as expulsion grade, plating grade, and shapedgrade(Matweb,2017a);subsequently,asatisfactory compoundsynthesisofABSshouldbepickedforaspecific expulsionapplication.relaxstreamfile,waterassimilation, lastingness,andwarmconductionarealargenumberofthe requirements which might disallow these gifts (Mat web, 2017b). once referencing, Savvakis et al. (2014) give understandingintotheacknowledgmentofstudydesignated onthissubstance.

ABSisbroadlyutilizedinanextremetypeofareabecauseof its particular capacities, which encapsulate pleasant mechanicalreactions,syntheticobstruction,finesurfaceend, andexceptionalcyclequalities.Thus,differentinvestigations areledtogaugethemechanicalattributesofthismaterialand its composites underneath various things and to build up thosecharacteristics.

These attributes will be worked on in an extreme type of ways that. Vairis, Petousis, Vidakis, and Savvakis (2016) examinedtheimpactofstrainrateonthelastingnessofABS andABSmodelsandfoundthataspecialistlayerthickness(in contrast with any or all various models assessed) was the

leastdifficultoptionforgreaterlastingnessdiscoveries.The objectiveofthisstudywasto"assessanywaychangedcheck speeds influence the mechanical strength of 3D composed things." Solid ABS three dimensional composed examples with a 45 degree infill point had rigid qualities beginning from3,190psi(22MPa)tofive,221psi(36MPa).

According to Tymrak, Kreiger, and Pearce (2014). "The fundamental tensile strength and elastic modulus of produced components under realistic environmental circumstancesforstandardusersofavarietyofopen source 3D printers," these experts said. "The link between deposition pattern orientation and layer height to tensile strength, strain at tensile strength, and modulus" was investigatedinthepaper.Theyclaimedafinalaveragetensile strengthof4,133psifortheir3DprintedABSpieces(28.5 MPa).Whencreatingitemson3Dprinters,theresearchers pointedoutthatvariousoptionsandotherfactorsmustbe considered."Settings,tuning,andoperationofeachunique printer, as well as the kind, age, and quality of polymer filamentused"areonlyafewofthem."Withinthelimitations oftheirmechanicalqualities,functionallystrongcomponents may be manufactured with open source 3D printers," the researchersconclude.

Carbonfibersareanisotropicandcontainatleast92wt percent carbon (Huang, 2009, p. 2369). Graphite fiber is a fiber that contains at least 99 percent carbon by weight. Anisotropic properties may improve the strength of 3D printingmaterialsinparticularorientations.Somephysical characteristics of carbon fibers that refer to anisotropy include, but are not limited to, being brittle or easily damaged,notabsorbingwater,notchangingdimensionsin humidenvironments(Vasiliev&Morozov,2013),and"yields differentvaluesofmechanicalandthermalcharacteristicsin thelongitudinalandtransversedirections."

These researchers "examined the potential for load bearing components in particular...results reveal that composites with highly dispersed and highly orientated carbonfibersmaybemanufacturedusingtheFDMtechnique [sic]," according to the researchers. They discovered that within test samples, fibers are primarily orientated in the directioninwhichthematerialisdepositedonthe3Dprinter buildplatform,enhancingtensilestrength.

AsindicatedbyTekinalpetal.(2014),carbonfilaments have a brilliant potential for load support, though the thermoplasticframeworkties,encompasses,andsafeguards the carbon strands while conjointly moving the strain to them.Carbonfiberincorporatesamoregroundedlastingness than ABS (Fernandez Vicente, Calle, 2014) and would so legitimatelyworktohelpitonceextratoitsscience."Oneof thepossiblemethodsisembeddingreinforcedmaterials(like carbonstrands)intoplasticmaterialstomakethermoplastic

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2441

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

frameworkcarbonfiberfortifiedplastic(CFRP)composites," Carbonfiberfortificationsinthermoplasticssquaremeasure utilized in area designing, the auto area, medical procedure/otherclinicalactivities,andpropertydrives,per Biron(asreferencedinNingetal.,2015).

Afterstudyingalltheaboveresearchpapers,thefollowing conclusionfoundwhicharegivenbelow:

Theincreasing biomassloadingcaused a decrease in melt flow and impact strength and an increase in flexural modulusforbothbiodegradablepolylactide/hemphurdand biodegradable polylactide/BP biocomposites, increased tensile strength and flexural strength for biodegradable polylactide/hemphurdwhereasdecreasedcorresponding propertiesforbiodegradablepolylactide/bamboopowder, attributed to the reinforcement by hemp hurds with fibrillary structure and enhanced interfacial adhesion between hemp hurd and polymer matrix. The surface roughnessoffuseddepositionmodeling printeditemswas negligibly affected by the particle size of biomass when it was less than the printing layer thickness. Only when the particlesizewaslargerthantheprintinglayerthickness,the surfaceroughnesswouldincrease.

[1] T. Pereira, J.V. Kennedy, J. Potgieter, A comparison of traditional manufacturing vs additive manufacturing, the bestmethodforthejob,ProcediaManuf.30(2019)11 18. https://doi.org/10.1016/j.promfg.2019.02.003.

[2] B.P. Conner, G.P. Manogharan, A.N. Martof, L.M. Rodomsky, C.M. Rodomsky, D.C. Jordan, J.W. Limperos, Making sense of 3 D printing: Creating a map of additive manufacturing products and services, Addit. Manuf. 1 4 (2014) 64 76. https://doi.org/10.1016/j.addma.2014.08.005.

[3] T. Peng, K. Kellens, R. Tang, C. Chen, G. Chen, Sustainabilityofadditivemanufacturing:Anoverviewonits energydemandandenvironmentalimpact,Addit.Manuf.21 (2018) 694 704. https://doi.org/10.1016/j.addma.2018.04.022.

[4]A.García Dominguez,Claver,M.A.Sebastián,Integration of Additive Manufacturing, Parametric Design, and Optimization of Parts Obtained by Fused Deposition Modeling(FDM).AMethodologicalApproach,Polymers.12 (2020)1993.https://doi.org/10.3390/polym12091993.

[5] A. Haleem, M. Javaid, Additive Manufacturing ApplicationsinIndustry4.0:AReview,J.Ind.Integer.Manag. 04 (2019) 1930001. https://doi.org/10.1142/S2424862219300011.

[6] J. Faludi, C. Bayley, S. Bhogal, M. Iribarne, Comparing environmental impacts of additive manufacturing vs traditional machining via life cycle assessment, Rapid Prototyp.J.21(2015)14 33.https://doi.org/10.1108/RPJ 07 2013 0067.

[7]M.Attaran,Theriseof3 Dprinting:Theadvantagesof additivemanufacturingovertraditionalmanufacturing,Bus. Horiz. 60 (2017) 677 688. https://doi.org/10.1016/j.bushor.2017.05.011.

[8] D. Bourell, J.P. Kruth, M. Leu, G. Levy, D. Rosen, A.M. Beese,A.Clare,Materialsforadditivemanufacturing,CIRP Ann. 66 (2017) 659 681. https://doi.org/10.1016/j.cirp.2017.05.009.

[9]D.Han,H.Lee,Recentadvancesinmulti materialadditive manufacturing:methodsandapplications,Curr.Opin.Chem. Eng. 28 (2020) 158 166. https://doi.org/10.1016/j.coche.2020.03.004.

[10] S. Upcraft, R. Fletcher, The rapid prototyping technologies, Assem. Autom. 23 (2003) 318 330. https://doi.org/10.1108/01445150310698634.

[11]A.Bandyopadhyay,B.Heer,Additivemanufacturingof multi materialstructures,Mater.Sci.Eng.RRep.129(2018) 1 16.https://doi.org/10.1016/j.mser.2018.04.001.

[12]I.Ribeiro,F.Matos,C.Jacinto,H.Salman,G.Cardeal,H. Carvalho, R. Godina, P. Peças, Framework for Life Cycle Sustainability Assessment of Additive Manufacturing, Sustainability. 12 (2020) 929. https://doi.org/10.3390/su12030929.

[13] J. Liu, A.T. Gaynor, S. Chen, Z. Kang, K. Suresh, A. Takezawa, L. Li, J. Kato, J. Tang, C.C.L. Wang, L. Cheng, X. Liang, Albert.C. To, Current and future trends in topology optimizationforadditivemanufacturing,Struct.Multidiscip. Optim. 57 (2018) 2457 2483. https://doi.org/10.1007/s00158 018 1994 3.

[14]M.Orme,I.Madera,M.Gschweitl,M.Ferrari,Topology OptimizationforAdditiveManufacturingasanEnablerfor Light Weight Flight Hardware, Designs. 2 (2018) 51. https://doi.org/10.3390/designs2040051.

[15] V. Kandemir, O. Dogan, U. Yaman, Topology optimization of 2.5D parts using the SIMP method with a variablethicknessapproach,ProcediaManuf.17(2018)29 36.https://doi.org/10.1016/j.promfg.2018.10.009.

[16] G.W. Melenka, J.S. Schofield, M.R. Dawson, J.P. Carey, Evaluationofdimensionalaccuracyandmaterialproperties of the MakerBot 3D desktop printer, Rapid Prototyp. J. 21 (2015) 618 627. https://doi.org/10.1108/RPJ 09 2013 0093.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2442

[17]U.M.Dilberoglu,B.Gharehpapagh,U.Yaman,M.Dolen, TheRole ofAdditiveManufacturinginthe Era ofIndustry 4.0, Procedia Manuf. 11 (2017) 545 554. https://doi.org/10.1016/j.promfg.2017.07.148

[18] T.D. Ngo, A. Kashani, G. Imbalzano, K.T.Q. Nguyen, D. Hui, Additive manufacturing (3D printing): A review of materials, methods, applications, and challenges, Compos. Part B Eng. 143 (2018) 172 196. https://doi.org/10.1016/j.compositesb.2018.02.012.

[19] K.R. Ryan, M.P. Down, C.E. Banks, Future of additive manufacturing:Overviewof 4Dand3D printedsmartand advancedmaterialsandtheirapplications,Chem.Eng.J.403 (2021).https://doi.org/10.1016/j.cej.2020.126162.

[20] L. Hirt, A. Reiser, R. Spolenak, T. Zambelli, Additive ManufacturingofMetalStructuresattheMicrometerScale, Adv. Mater. 29 (2017) 1604211. https://doi.org/10.1002/adma.201604211.

[21]S.Lim,R.A.Buswell,T.T.Le,S.A.Austin,A.G.F.Gibb,T. Thorpe, Developments in construction scale additive manufacturing processes, Autom. Constr. 21 (2012) 262 268.https://doi.org/10.1016/j.autcon.2011.06.010.

[22] H. Bikas, P. Stavropoulos, G. Chryssolouris, Additive manufacturingmethods,andmodelingapproachesAcritical review, Int. J. Adv. Manuf. Technol. 83 (2016) 389 405. https://doi.org/10.1007/s00170 015 7576 2.

[23] A.A. Bakır, Atik, S. Özerinç, Mechanical properties of thermoplasticpartsproducedbyfuseddepositionmodeling: a review, Rapid Prototyp. J. 27 (2021) 537 561. https://doi.org/10.1108/RPJ 03 2020 0061.

[24]N.Volpato,J.AguiomarFoggiatto,D.CoradiniSchwarz, TheinfluenceofsupportbaseonFDMaccuracyinZ,Rapid Prototyp. J. 20 (2014) 182 191. https://doi.org/10.1108/RPJ 12 2012 0116.

[25] G.P. Kumar, S.P. Regalla, Optimization of Support Material and Build Time in Fused Deposition Modeling (FDM), Appl. Mech. Mater. 110 116 (2011) 2245 2251. https://doi.org/10.4028/www.scientific.net/AMM.110 116.2245.

[26] J. Vanek, J. a. G. Galicia, B. Benes, Clever Support: Efficient Support Structure Generation for Digital Fabrication, Comput. Graph. Forum. 33 (2014) 117 125. https://doi.org/10.1111/cgf.12437.

[27]S.L.Messimer,A.E.Patterson,N.Muna,A.P.Deshpande, T.RochaPereira,CharacterizationandProcessingBehavior ofHeatedAluminum PolycarbonateCompositeBuildPlates fortheFDMAdditiveManufacturingProcess,J.Manuf.Mater. Process. 2 (2018) 12. https://doi.org/10.3390/jmmp2010012.

[28]K.Singh,Experimentalstudytopreventthewarpingof 3D models in fused deposition modeling, Int. J. Plast. Technol. 22 (2018) 177 184. https://doi.org/10.1007/s12588 018 9206 y.

[29]A.S.deLeón,A.Domínguez Calvo,S.I.Molina,Materials withenhancedadhesivepropertiesbasedonacrylonitrile butadiene styrene(ABS)/thermoplasticpolyurethane(TPU) blendsforfusedfilamentfabrication(FFF),Mater.Des.182 (2019) 108044. https://doi.org/10.1016/j.matdes.2019.108044.

[30] T. M. Wang, J. T. Xi, Y. Jin, A model research for prototypewarpdeformationintheFDMprocess,Int.J.Adv. Manuf. Technol. 33 (2007) 1087 1096. https://doi.org/10.1007/s00170 006 0556 9.

[31] R. Polak, F. Sedlacek, K. Raz, Determination of FDM PrinterSettingsaboutGeometricalAccuracy,inB.Katalinic (Ed.), DAAAM Proc., 1st ed., DAAAM International Vienna, 2017: pp. 0561 0566. https://doi.org/10.2507/28th.daaam.proceedings.079.

[32] M.S. Alsoufi, A.E. Elsayed, How Surface Roughness PerformanceofPrintedPartsManufacturedbyDesktopFDM 3DPrinterwithPLA+isInfluencedbyMeasuringDirection, Am. J. Mech. Eng. 5 (2017) 211 222. https://doi.org/10.12691/ajme 5 5 4.

[33]R.Singh,S.Singh,I.P.Singh,F.Fabbrocino,F.Fraternali, InvestigationforsurfacefinishimprovementofFDMparts by vapor smoothing process, Compos. Part B Eng. 111 (2017) 228 234. https://doi.org/10.1016/j.compositesb.2016.11.062.

[34] I. Gajdoš, E. Spišák, L. Kaščák, . Krasinskyi, Surface Finish Techniques for FDM Parts, Mater. Sci. Forum. 818 (2015) 45 48. https://doi.org/10.4028/www.scientific.net/MSF.818.45.

[35] N. Jayanth, P. Senthil, C. Prakash, Effect of chemical treatmentontensilestrengthandsurfaceroughnessof3D printedABSusingtheFDMprocess,VirtualPhys.Prototyp. 13 (2018) 155 163. https://doi.org/10.1080/17452759.2018.1449565.

[36]F.Rayegani,G.C.Onwubolu,Fuseddepositionmodeling (FDM)processparameterpredictionandoptimizationusing group method for data handling (GMDH) and differential evolution(DE),Int.J.Adv.Manuf.Technol.73(2014)509 519.https://doi.org/10.1007/s00170 014 5835 2.

[37]R.CoelhodeMacedo,R.T.L.Ferreira,K.Jayachandran, DeterminationofmechanicalpropertiesofFFF3Dprinted materialbyassessingvoidvolumefraction,coolingrateand residual thermal stresses, Rapid Prototyp. J. 25 (2019) 1661 1683.https://doi.org/10.1108/RPJ 08 2018 0192.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2443

[38] A.A. Bakır, Atik, S. Özerinç, Effect of fused deposition modelingprocessparametersonthemechanicalproperties ofrecycledpolyethyleneterephthalateparts,J.Appl.Polym. Sci.(2020)49709.https://doi.org/10.1002/app.49709.

[39]M.Schouten,G.Wolterink,A.Dijkshoorn,D.Kosmas,S. Stramigioli, G. Krijnen, A Review of Extrusion Based 3D PrintingfortheFabricationofElectro andBiomechanical Sensors, IEEE Sens. J. 21 (2021) 12900 12912. https://doi.org/10.1109/JSEN.2020.3042436.

[40]I.Calafel,.H.Aguirresarobe,M.I.Peñas,A.Santamaria, M. Tierno, .I. Conde, B. Pascual, Searching for Rheological Conditions for FFF 3D Printing with PVC Based Flexible Compounds, Materials. 13 (2020) 178. https://doi.org/10.3390/ma13010178.

[41] M. Vaezi, S. Chianrabutra, B. Mellor, S. Yang, Multiple materialadditivemanufacturing Part1:areview,Virtual Phys. Prototyp. 8 (2013) 19 50. https://doi.org/10.1080/17452759.2013.778175.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2444