International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

PORTABLE AND EASY TO USE 3D PRINTER

1,2,3Student, dept. Electronics and Telecommunication AISSMS IOIT, Maharashtra, India 4Professor, dept. Electronics and Telecommunication AISSMS IOIT, Maharashtra, India ***

Abstract The Additive manufacturing market is constantly growing in everything from the automotive industry to ceramics. However, the vast majority are in traditional areas such as prototyping using plastics. 3D printing has benefits such as faster and slower over conventional production, this makes it easy to reproduce when needed. As a tool of Industrial 4.0, Intelligent Manufacturing, and enable technology, 3D printing technology, has made fast progress incurrent years and is extensively used in many areas of public life. In addition, 3D printing technology is a high quality form of production, which plays a transformative role in industrial growth. So, in the interest of determine the nature of the research and growth of 3D printing technology, this project orderly analyses some common methods and applications in other fields, and predicts its future development trends based on a brief introduction of the 3D performance policy.

Key Words: FDM, Additive technology, 3d printer,

1. INTRODUCTION

The additive manufacturing or fast prototyping 3D printing machinery is a new manufacturing techniquethat is being employedworldwideasalow wastetechnology.The3Dprintingtechnologyisbasedonthemodelfile,connectingsome adhesive type materials together in solid form such as metals or plastics. And then through the layer by layer printing method, it is possible for two dimensional data to transform into 3D materials. [1]. The 3D printing technology allows you to do this, and it has much more complicated applications in science and industry,italsoshowsthatitcanbezero release,zerowaste technology.[2]. Further, the3D printing method leads tothe redesign of sometoolsand products,it pushesthelimitsoftraditionalprocessingmethodsandleavesplentyofroomforinnovativedesign[1].

As mentioned earlier, 3D printing technology is known as AM by designing CAD data and adopting a method of incrementally increasing materials to create parts of an entity. It is a manufacturing method that adds materials from bottomto top comparedto conventional material removaltechniques(machining,etc.).Withdevelopmentinlate1980s, AMwasalsoknownasmaterial enhancement, rapidprototyping,stackedmanufacturing,solidfreeform manufacturing, and3Dprintingmethod.Differentdesignationsrefertospecialfeaturesofmanufacturingtechnology.[1]

2. REVIEW OF LITERATURE

2.1 Yiran Yuan, “Research Status and Development Trend of 3D Printing Technology”,presented at IOP Conf. Series: Materials Scienceand Engineering VOL. 711, Hefei, China, September 2019.

3D printing technology plays a great part in industrial growth. Due to high productivity and lowcost, 3D printing technology brings great old schoolconversion production, which can be considered a drive for economic and social growthinChina.

However,therearealsoother3Dprintingproblems isa brightfutureheretechnology,sothewhole worldisconnectinggreatnoticetoit.Inshort,3D printingtechnologywillcreateaneweraofnationalproduction.[1]

todealwith,suchaswithoutwarrantyproduction rate,highdemand for production technology, solid staff training and pollution of rubbish, etc. Althoughthe bottle of technology is still availabletoday,there

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

2.2 SAMER MKHEMER, SAED MAKHOOL, QAIS SAMARA, “3D PRINTING TECHNOLOGY”, PRESENTED AT 3D PRINTING BIRZEIT UNIVERSITY, BIRZEIT, PALESTINE, NOVEMBER2014. PP-3.

Scientists and engineers fascinate us every day withever changing technologies what has recently beenconsidered a science fiction or unimaginable futureis a reality, making it ours it lives easily and is veryinteresting. For example, you thought you could doit Your framed mirror frame, children's toys, and any other image in your home using green buildingmaterials and a single machine? 3D printing technology enables you to do this and more the most complex applications in science and industry.This is an analytical research paper in which the student is introduced to 3D printingtechnology,itsmeaning,history,basiccomponents,andoperatingtheory.

So,whatisthistechnology?Therearemanysimilarmeaningsandwordsusedtodescribe3Dprinting suchas:additional production,andfasterprototyping.However,allofwhichdefinethemaindividingconceptinthemostcommonmethods of subtraction Additional productivity. In general, 3D printing: a process in which solid 3D piece of any shapeor x ray type can be created from a slicer file.Creation is obtained by placing down the consecutive layers of something up to everythingis created. Each of these covering constitute a horizontal section cut slightly (similar a output of astandard printer, this hence the so called print) of the object at the end, in contrast to the standard output production methods thatdependontheextractionofgoodsinordertocreatesomething.[2]

2.3 HIDEO KODAMA, " BACKGROUND OF MY INVENTION OF 3D PRINTER AND ITS SPREAD”, IN PATENT MAGAZINE OF JAPAN PATENT ATTORNEYS ASSOCIATION,

VOL.67, NAGOYA, JAPAN, , NOVEMBER 2014 NO.13, PP.109 118

Increased productivity can have a huge impact on the environment. For example, unlike conventional manufacturing, whenparts arecutfrom large cubes of material, AM makes a layer of product and prints only the wanted parts, using very little material and thus less energy to produce the required materials. The production of additives can also contribute significantly to the reduction of energy consumption and greenhouse gas emissions to vehicles and other modes oftransport by simply fulfilling the structural requirements of products. For example, a case studyof an aircraft component using additive manufacturing found that partial use resulted in optimal energy and carbon dioxide emissionssavingsof63% over thelifeoftheproduct.Additionally,previous experimentsinthemanufacturinglifecycle had predicted that using of the technology could reduce Carbon dioxide emissions are reduced because 3D printing allows for local manufacture and eliminates the need for products to be transported long distances to their final destination.

However, continuing to adopt additive manufacturing creates a downturn. Despite the fact that additive manufacturing reduces waste from extra production processes by 90%, it also generatesother sorts of waste, such as non recyclable material dust. Additional productivity has yet to reach your 97% active visual capacity, but may come closer as technologycontinuestoincreaseproductivity.[3]

2.4 AN OVERVIEW ON 3D PRINTING TECHNOLOGY: TECHNOLOGICAL, MATERIALS AND APPLICATIONS. N.SHSHRUBUDIN, T.C.LEE, R.RAMLAN

In this review, there are rich landscape of 3D printingin manufacturing industry. At present, 3D printing technology is beginning in the manufacturing industries, it offers many benefits to the people, company, and government. Therefore, more information is needed to progress on ways to enhance the adoption of 3D printing technology. The more information about 3D printing technology will help the company and government to upgrade and improve the infrastructureof3Dprintingtechnology.Thus, thispaper istooverview thetypesof3Dprintingtechnologies,materials usedfor 3Dprinting technologyinmanufacturingindustryandlastly,the applicationsof3Dprinting technology.Inthe future, researchers can do some study on the type of 3D printing machines and the suitable materials to be used by everytypeofmachine.[4]

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

2.5 GERALD C. ANZALONE1, CHENLONG ZHANG1, BAS WIJNEN1, PAUL G. SANDERS1,AND JOSHUA M. PEARCE2, “A LOW-COST OPEN-SOURCE METAL 3-D PRINTER”, PRESENTED AT IEEE ACCESS, DECEMBER 5 2013, DOI: 10.1109. PP 1 6

Thisarticlehassuccessfullyprovidedaproofof conceptof70,000opensourcemetal3Dprinters. What3dprintobjects or models using metal as filament, solid carbon steel ER70S 6, open source microcontroller and a low cost commercial gas metal arc welder (GMAW)? shape. This allows for the printing or fabrication of a variety of metal components, althoughtheprintermayrequirefurtheradjustmentsinresolutioninprints.Thereissignificantpotentialforthecreation of an entirely new and large market for weld like products to be used in the manufacture of user specific metal components in the wider consumer market. This technology is likely to follow an evolutionary path similartopolymer open source3 Dprinting.[5]

3. METHODOLOGY

1. Aspertheresearchmadebyusbystudying variousresearchpaper,wegotideasrelatedtoimprovingprevious methodologiesandtechnology.paperswhicharerelevanttothistopic.

2. Our aim was to make low budget, affordable, 3d printer. In this proposed system we used Arduino mega, RAMPS,Nema17steppermotorsforcontrollingx,yandzaxiswhichareconnected.

3. Inthis3dprinterweareusingadditivetechnology(AM)orFDMforprintingmodels.

4. Once all parts are connected, 3d model is madeusing 3d modelling software’s like CAD, Catiya, Blender etc. whichisthenconvertedintoG codeusing‘slicer’whichbasicallyslicesthe3dmodellayerbylayer.

5. Thisisnormal3dprocedure,butweadded LCDandSDcardportthroughthatusercanselectthegcodewhich willbeintheSdcardwhichcanbeconnectedtoSDcardport.Thisis somethingnew,sowhichmakesiteasiertouse the systemandmakingitmoreefficientandtimesavingsystem.

6. Afterselectingwhenuserwillclickprintthemachinewillstartprintingmodelasperthegcode.Thenafter requiredtimeispassedthe3dmodelisreadyuse.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

4. Working

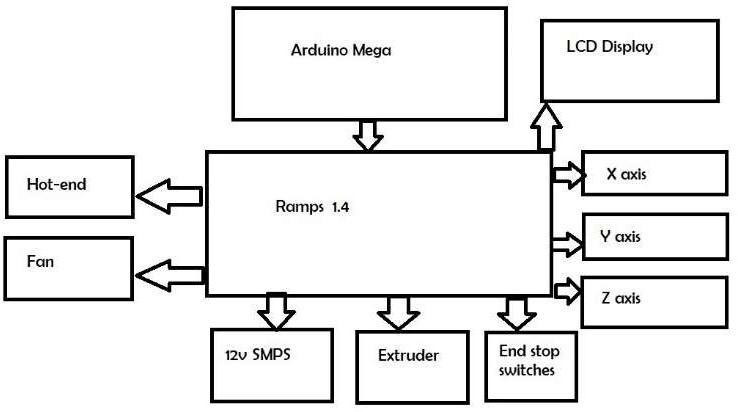

Step 1: Arduino mega needs interface to connect with all the other components so RAMPS 1.4 is the interface which helps Arduinotoconnectwithallothercomponents.Nowthebedispreparedusingacrylic sheetandalignedproperly.Which areXandYaxis.

Step 2: ThenExtruderisconnectedwhichguidesthefilamenttothehot end.Hot endmeltstheplasticfilament,andthe smallfanhelpsitmaintaintheappropriate.Temperaturethrough outtheprocess.

Step 3: Arduinomegaisnowprogrammedwhichishexfileisuploaded.Nowrunthemachine.

Step 4: Nowdesired3DmodelismadeusingPronterfacesoftware,theoutputisaSTLfilewhichisconvertedintoGcode usingultimakercura.

Step 5: Now3Dprinterwouldmakethe3dmodel.

5. HARDWARE AND SOFTWARE DESIGN

Todesigna3Darchitectureofselectedapplication usingAutoCADsoftware.Thenafileisgeneratedby AutoCADhaving .STL extension. This file is then uploaded into the slicer software. The slicer softwaresliced the 3D architecture into 2D layersandgenerates the co ordinates of the 3D architecture. This co ordinatesareprovidedtothecontrollerwhichhelps toprintthe3Dobject.

A. Hardware Design

1. Arduino

Arduino Mega2560 is an ATmega2560(data center)basedmicrocontrollerboard.Thereare54digitalI/pO/ppins(can be used as 14 PWM outputs), 16 analog inputs, 4 UART (hardware serial ports), 16 MHz crystal oscillator, USB connection,powerinput,ICSPheaderandresetbutton.

2. Ramps

RAMPS stands for RepRap Arduino Mega Pololu Shield. It's made to fit all of the electronics needed for RepRap into a tiny, low cost package. RAMPS is a versatile interface that connects an Arduino Mega to the powerfulArduino MEGA platform.Italsoprovideslotsofpotential for expansion. For easy repair, components replacement, upgradeability, and extension, the modular design features pluggablestepperdrivers andextruder controlelectronics in an Arduino MEGA shield. Additionally, as long as the main RAMPS boardis remained at the top of the stack, a set of Arduino extension boardscanbeaddedtothesystem.

3. SDcard

TheSDHCcardreaderallowsthecardtobe usedincompatibledeviceswithaUniversalSerialBus(USB)port,suchasa computer.SDHCmemorycard.

4. LCD

In this project I will show you how to interface128X64 Graphic LCD with Arduino mega. This particular LCD Module is based on the ST7920LCD Controller. Therefore, we will first know alittle about the Graphic LCD Module and its LCD ControllerST7920.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

5. PROCESSOR

It is a 32 bit processor based on the Harvard architecture.Ithas a3 step pipeline,fetch, decode,and execute. The main control chip used in the processor is LPC 1768, which supports the G code file format. This processor is cost effective, usedtoreduceprocessorspace,andhasextensiveoptimizationinterrupthandlingandsystemdebuggingcapabilities.

TEST RESULTS

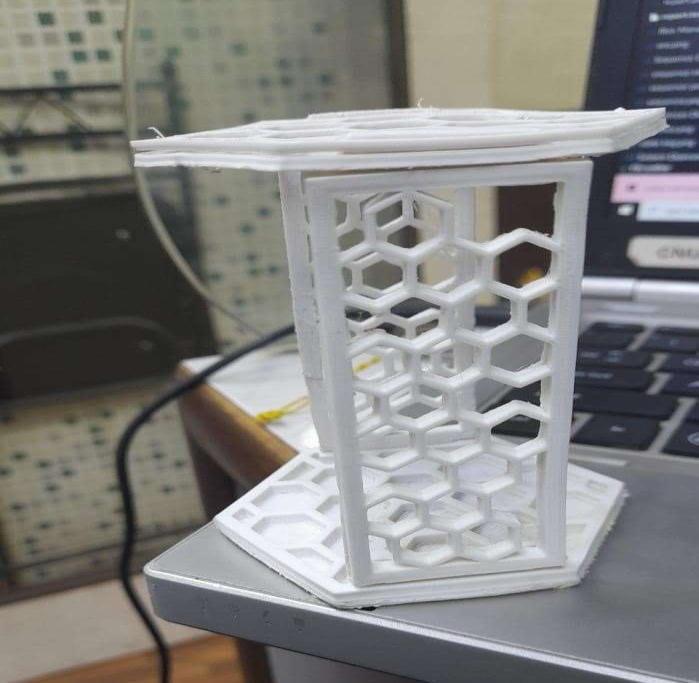

We are expecting a 3D printer to make a small scale prototype which can be put into a use of mechatronics based industries which have an accuracy up to 90% and is of very cost efficient. Firstly, the prototype is tested to check whethereverymotorisworkinginx,yandzaxisincorrect directionrespectivelyfollowedbytheendstopis triggering ornot,thentheheatbedischecked,whichisproperlyheatingat50 110degreecentigrade.Tomelttheplasticfilament, thehotendstartedheatingatrange200 240degreecentigrade.Asinweusealuminumextrusiontherewasnovibrations inthemechanicalpartoftheprinter.

Conclusion

3D FDM printer is designed and manufactured. For precise printing in geometric dimensions, this printingprocess ensuresthatthemachinemeetsallrequired specifications.SomeABSplasticpartsassembledona3D FDMprinterwere printed to replace some metal parts. This project presents the results of the design and production of the 3D printer using the FDM printing method, which provides the necessary technicalspecifications.Ideal printingparameters willbe doneasfurtherresearchtomakesuretheproductqualityfordifferentplastics.

REFRENCES

[1]. Yiran Yuan, “Research Status and Development Trend of 3D Printing Technology”, presented at IOPConf. Series: Materials Science and Engineering VOL. 711, Hefei, China, September 2019, doi:10.1088/1757899X/711/1/012014. Pp2.

[2].SamerMkhemer,SaedMakhool,QaisSamara, “3DPrintingTechnology”,presentedat3DprintingBirzeitUniversity, Birzeit,Palestine,November2014.Pp 3.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page273

[3]. Hideo Kodama, " Background of my invention of3D printer and its spread”, in Patent Magazine of Japan Patent AttorneysAssociation,vol.67,Nagoya,Japan,November2014no.13,pp.109 118.

[4]. N.shshrubudin, T.C.LEE, R.Ramlan, “An overview on 3d printing technology: technological, materials and applications.”, presented in International Conference on Sustainable Materials, Processing and Manufacturing (SMPM 2019)

[5]. Gerald C. Anzalone1, Chenlong Zhang1, Bas Wijnen1, Paul G. Sanders1, And Joshua M. Pearce2, “A Low Cost Open SourceMetal3 DPrinter”,presentedAtIEEEAccess,December52013,DOI:10.1109.pp1 6.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page274