International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

2 .

1PG Student, ME Structural engineering, Dept.of civil engineering, Paavai Engineering College 2Assistant professor, Department of civil engineering, Paavai Engineering college, Namakkal, Tamilnadu, India. ***

Abstract In this construction world, Geopolymer concrete is a special concrete which doesn't requires the Ordinary Portland Cement and also reduces the emission of carbon di oxide. Geopolymer Concrete (GPC), an ecofriendly material is being used as an alternative to Ordinary Portland Cement Concrete in many areas. The Geopolymer Concrete is made up of industrial by products (which contains more Silica and Alumina) and activated with the help of Alkaline solution (combination of sodium hydroxide & sodium silicate or potassium hydroxide & potassium silicate). Geopolymer concrete makes 90% utilization of fly ash and 10% utilization of steel slag powder in concrete alongwithalkalinesolutions,asabinder.Thespecimensare casted for 10M, 14M and 16M of NaOH and alkaline to fly ash + steel slag powder with using superplasticiers.Hardened properties: The compressive strength, flexural test, spilt tensile strength of specimens are casted and testing as compared to 10M, 14M and 16M at 7, 14and28days.

Keywords: Class F Fly ash, Geopolymer mortar, Alkaline activators, Sodium Silicate, Molarities Etc.,

Geo polymer was first introduced by Davidovits (1991). Geo polymer mortar does not contain Ordinary Portland Cement (OPC) instead binding material is made byreactionwithalkaliliquidwiththesourcematerialrich in alumina and silica. Silica and alumina rich materials such as fly ash, steel slag, GGBFS and metakaolin are commonly used to make geo polymers which promote excellentbehaviorandproperty.Geo polymersdependon thermally activated natural or industrial by products to produce source of Si and Al. Si and Al dissolved in the alkaline activating solution and polymerizes into molecular chains and becomes the binder. The ultimate structureofthegeo polymerdependsontheratioofSi to Al. The combination of sodium silicate (Na2SiO3) and sodium hydroxide (NAOH) has been widely used as the alkaline activator to produce geo polymer. Instead, potassium hydroxide and potassium silicate solution can also be used. But sodium is economical and widely used material as of now.Geo polymer products have high compressive strength, resistance to steel corrosion, low permeability and high durability. Fly ash is the major

material approached as the source material of geo polymer due to its commercial and performance advantage.Itisthewastematerialorresidueproducedby thecombustionofcoal.

1. As geopolymer concrete as consume less amount of water when compared to conventional concrete,soweusedselfcuringmethod.

2. While using geopolymer concrete, different types of industrial byproduct such as class f fly ash, GGBS, Steel slag, alkaline solution etc., as used as bindermaterial.

3. When geopolymer concrete were used, it will reducing carbon di oxide emission level into the atmosphere but conventional concrete produce moreco2 emissionlevel.

4. The objective of present investigation is to study thepropertiesofgeopolymerconcretealongwith differentproportionofmolaritiesconcentration.

According to SMITA SINGH(2016), from his resultsshows,thatredmudhadbeenthepotentialsource material in geopolymer concrete such as fly ash , rice hush,GGBS by using ambient temperature curing method. and finally this experimental shows good strength and well desirable stetting time while they should been grindingRedmudandflyashin45µ.

SUMAJOUW et.al (2006) studies revealed that the behavior of fly ash based geopolymer concrete at study of slender reinforced column. In his experimental has shows class f fly ash based geopolymer concrete reinforced column gases excellent potential for precast industry.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

3.1 STEEL SLAG

Table 3.1 Properties of steel slag

3.2 FLY ASH

Table 3.2 Properties of fly ash

S.No Properties Test results obtained 1 Specificgravity 2.23 3.3 M SAND

The solution of the sodium hydroxide was formed by dissolving it in water based on the molarities required. It is recommended that the NaOH solution should be made 24hoursbeforecastingandshouldbeusedwith36hours of mixing the pellets with water as after that it is converted to semi solid state. Na2SiO3 Sodium Silicate Solutionintheliquidform.

4.1 COMPRESSIVE STRENGTH TEST

Tab.no:3.5: ResultsforCompressivestrengthFor GeopolymerConcrete

Mix Molarity ofNAOH solution Curing method

Compressive strength (N/mm2)

7Days 14 Days 28 Days

In geo polymerization, alkaline solution plays an important role. Sodium hydroxide solution and sodiumsilicategelmixedtogethertogetalkalinesolution. Generally, NaOH is available in the market in the form of pellets or flakes form with 96% to 98% purity where the cost of the product depends on the purity of the material.

M1 10M

Ambient curing 25.80 28.90 35.19 26.43 29.42 35.96 26.68 28.46 36.60 Average 26.30 28.92 35.90 M2 14M

Ambient curing 27.04 29.68 38.81 28.01 31.01 39.02 28.81 31.92 38.01 Average 27.95 30.54 36.61

M3 16M

Ambient curing 28.86 30.49 36.98 29.07 31.18 35.67 30.04 32.12 37.12 Average 29.32 31.26 38.59

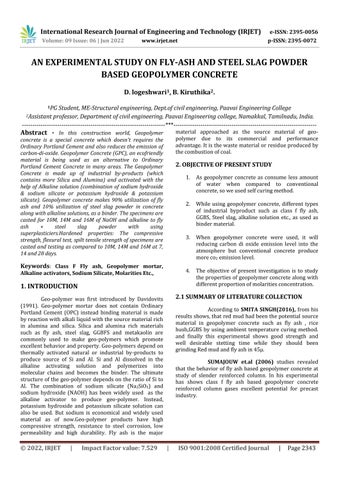

When molarity increases, the viscosity of the solution increases with increase in the compressive strength. As molarityincreases,compressivestrengthalsoincreasesup to 18M and beyond that the strength value decreases. By optimizing the molarities, 16M has given better strength valuewithincreasingworkabilityasshownintable3.5

Table no: 3.6 ResultsOfCc

Mix

Compressive Strength For ConventionalConcrete(N/mm2)

7Days 14Days 28Days

M1 24.6 28.5 34.80

M2 26.80 30.3 37.67

M3 27.11 33.40 36.86 AVERAGE 26.11 30.74 36.44

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Graph.No:1.1 Graphical Representative Of Compressive StrengthCCVs.GPC

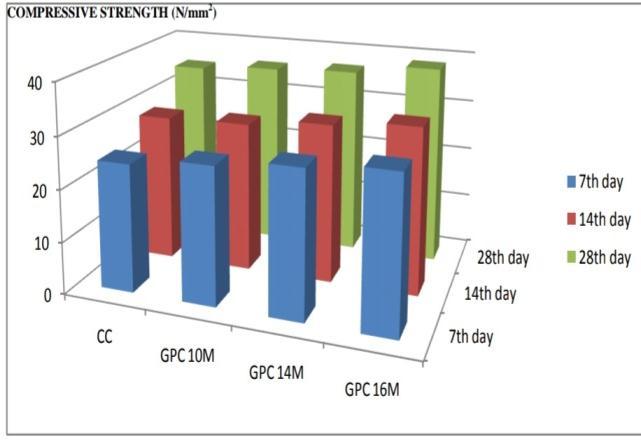

Graph.No:1.2 Graphical Representatives Of Spilt Tensile StrengthCCVsGPC

Tab.No.3.7 SpiltTensileResultsOfGeopolymerConcrete (GPC)

Mix Morality ofNAOH solution Curing method

M1 10M

Compressive strength for GPC (N/mm2)

7 days 14 days 28 days

M2 14M

M3 16M

Ambient curing

1.05 1.67 2.09 1.97 2.08 3.10 1.63 2.82 3.67 Average 1.55 2.19 2.97

Ambient curing 2.10 2.54 4.41 2.14 2.14 4.23 2.51 2.93 4.05 Average 2.25 2.53 4.13

Ambient curing 2.97 3.15 4.47 3.02 3.44 4.95 3.51 3.84 5.01 Average 3.16 3.47 4.81

Tab.No: 3.8 SpiltTensileForConventionalConcrete(Cc)

MIX

Spilt tensile Strength for conventionalconcrete(N/mm2)

7Days 14Days 28Days

M1 1.40 2.16 2.56

M2 1.46 2.26 2.67

M3 1.60 2.36 2.70 Average 1.48 2.26 2.643

Table no:3.9 FlexuralResultsforGeopolymerConcrete Mix Molarity of NAOH solution Curing method

M1 10M

Compressive strength ForGPC(N/mm2)

7 days 14 days 28days

Ambient curing 4.57 5.15 5.08 4.09 5.06 5.65 4.29 5.93 5.63 Average 4.31 5.38 5.45

Ambient curing

M2 14M

6.16 7.18 7.55 6.02 7.39 8.60 6.21 7.50 8.00

Average 6.12 7.35 8.05 M3 16M

Ambient curing 7.01 7.49 8.14 7.57 7.87 8.37 7.91 7.80 8.98 Average 7.49 7.72 8.49

Table.no:3.10 FlexuralTestResultsForConventional Concrete(Cc)

FlexuralStrengthForCc(N/mm2)

MIX

7Days 14Days 28Days

M1 4.05 5.45 6.12

M2 4.34 5.97 6.61

M3 4.86 5.23 6.92 AVG 4.41 5.55 6.56

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

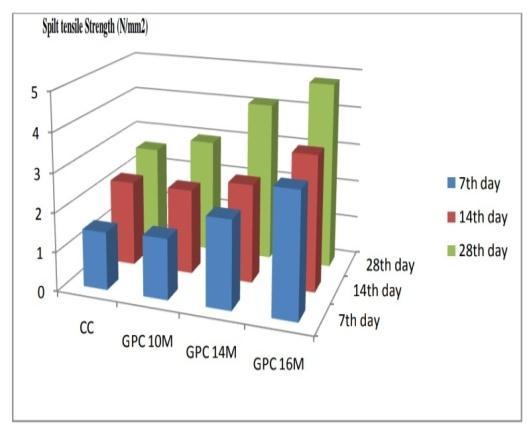

Graph. No: 1.3 Graphical Representative Of flexural strengthCCvsGPC

16MOLARITY while comparing to other molarity like10M,14M.

Geopolymer concrete strength will be get good result at 28 days because we compared to compressivestrengthofspecimenresultvalue.

Spilt tensile strength of geopolymer concrete is GRADUALLYincreasedwithrespecttomolarity

For Geo polymer mortar prism, Flexural strength test has been done. In this testing, single point load has beengivenbyplacingplaceontheprismatthecentreand thetestresultswerediscussed.

Based on the observation from the literature review,thebindertosteelslagratioisidentified.

Forconventionalconcrete,OPC53gradeconcrete was used in this project and M30 mix design was used.

For preparation of alkaline solution, Sodium hydroxide flakes and sodium silicate gel have beenusedforbondingpurpose.

Alkaline molarity is identified from the optimization process and molarity 16M gives betterstrength.

In these experimental shows, flexural and spilt tensile strength was gave better strength but compressive strength is not gave better strength comparedtoothertwostrength.

Thestrengthofspecimenisincreasedwhileaging ofthespecimens.

While when molarity ratio is increased, it also increasingthestrengthofthespecimens.

Cubesarecastedfordifferentmolarityproportion andsunlightlabcuringhasdoneforoptimization.

1. AndiArham Adam and Horianto (2014), ‘The effect of temperature and duration of curing on the strength of fly ash based geopolymer mortar’, 2ndInternational Conferenceon SustainableCivil Engineering Structures and Construction Materials,vol2,pp.410 414.

2. Abdul Alee et al (2012), Geopolymer Concrete A Review, International Journal of Engineering Sciences & Emerging Technologies, Volume 1, pp.118 122.

3. Abu Muhammad and Nidhin B. Parappattu (2015), ‘Study on Performance of Fibre Mesh Reinforced Slabs’, International Journal of Science Technology & Engineering, vol 2, pp.22 27.

The maximum compressive strength of geopolymer concrete is 38.59 N/mm2 at 28 days for 16 MOLARITY while comparing to other molaritylike10M,14M.

The spilt tensile strength of geopolymer concrete was high strength compared to conventional concreteat7days,14daysand28days.

While high molarity of NaOH was increased with strengthofspecimenalsoincreased.

The maximum flexural strength of geopolymer concrete is 8.49 N/mm2 at 28 days for

4. Arun Kumar et al 2017, 'Experimental Study on Impact Resistance of Geopolymer Ferrocement Flat Panel', International Study on Impact Resistance of Geopolymer Ferrocement Flat Panel',pp.1 5

5. A.Z. Waridwazien et al 2016, ‘Strength and density of Geopolymer Mortar Cured at Ambient Temperature for Use as Repair Material’, IOP Conference Series: Materials Science and Engineering,pp.1 6

6. Basil M. Mali and Renjan Abraham 2016, ‘Study on Geopolymer Concrete Used For Paving Blocks’, International Journal of Innovative Research in Advanced Engineering (IJIRAE), Volume3,pp.62 66

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2346

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

7. AndiArham Adam and Horianto (2014), ‘The effect of temperature and duration of curing on thestrengthofflyashbasedgeopolymermortar’, 2nd International Conference on Sustainable Civil Engineering Structures and Construction Materials,vol2,pp.410 414.

8. BrettTempestetal2009, 'CompressiveStrength and embodied Energy Optimization of Fly ash based Geopolymer concrete', World of Coal ash Conference,pp.1 17

9. Shrikant M. Harle (2017), ‘Effect Of Curing Period, Rest Period And Mix Proportion On Geopolymer Concrete’, Journal of Research in EngineeringandAppliedSciences,Vol.2,pp.105 109.

10. Padmavathy and Dharmar (2013), ‘Study on Flexural Behaviour of Flat Ferrocement Panels’, International Journal of Science and Research, Vol4Issue6,pp.1495 1498.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page