International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1M.E. Student, Department of Civil Engineering and Applied Mechanics, Shri G.S. Institute of Technology and Science, Indore, Madhya Pradesh, India

2Dean R & D and Professor, Department of Civil Engineering and Applied Mechanics, Shri G.S. Institute of Technology and Science, Indore, Madhya Pradesh, India ***

Abstract Plastics are used in various industries for varied purposes. With rapid urbanization this use is continuously increasing, with this increase is important to find sustainable ways to use and discard plastic waste. This study focuses on the impact of plastic waste particle size on the performance of plastic waste modified asphalt bituminous concrete. The various parameters analyzed are, Marshall stability, flow and Marshall Quotient for different percentages of plastic wastes (2,4,6,8 and 10%) . The plastic waste particles were classified into two categories i.e. coarse and fine graded plastic waste and the properties of these were compared to give the results. Through the results of all the parameters it was inferred that using fine graded plastic waste particles leads to overall enhancement in the strength and durability characteristics of the mixtures.

Key Words: Marshall stability, flow, Marshall Quotient(MQ), Fine Graded (FG) and Coarse Graded (CG) plastic particles.

Theuseofplasticinroadconstructionisnowbeingdonefor quite some time. There is sufficient research available on varioustypesofplasticsusedasmodifiersforpavementand their impact on various engineering properties of the bituminous concrete. The various methods used for preparing plastic waste modified asphalt bituminous concreteareasfollows:

In the dry process the plastic is used as binder to the bituminous mix. In this process Plastic is mixed with hot aggregateat170℃whichcoatstheaggregateonwhichhot bitumen is added to form the plastic bitumen aggergate mixture.

Therearefourstepsinthisprocess:

a) Collectionofwasteplastic

b) Cleaningandshreddingofwasteplastic

1.2

c) Mixingofshreddedwasteplastic,Bitumenand aggregateatcentralmixingplant

d) Layingofbituminousmix

In the wet process plastic is used as a modifier to the bituminous mix.Inthisprocesstheplasticismixedtohot bitumen, which is followed by mixing with hot aggregate. Thisprocessisnotusedaswidelyasthedryprocess.

2.1

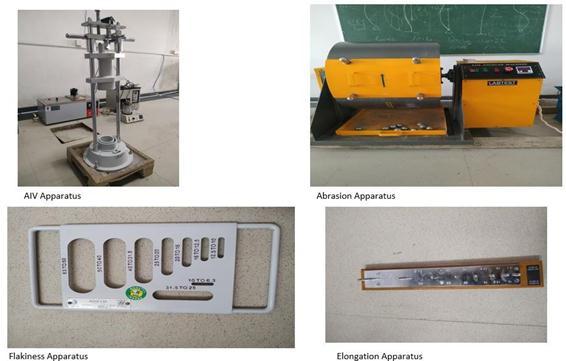

Inthisstudycrushedquartzaggregatewereused.Various laboratoryexperimentswereperformedwhichincludethe cleanliness,Grainsizedistribution,Bulkspecificgravity,Los Angeles Abrasion, flakiness and elongation index, impact strengthandwaterabsorptionwerecarriedoutwhichhave beenshownintabularformintable2.1.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Test results

Cleanliness(Dust)(%) 3

BulkSpecificgravity(g/cm3) 2.68

%wearbyLosAngelesabrasion 10.6

%SoundnesslossbyNa2SO4 solution 3.4

%SoundnesslossbyMgSO4 solution 3.7

Flakiness&elongationindex

20mm 10mm 27.93 32.13

ImpactStrength(%) 20mm 10mm 4.15 5.91

Waterabsorption 1.67

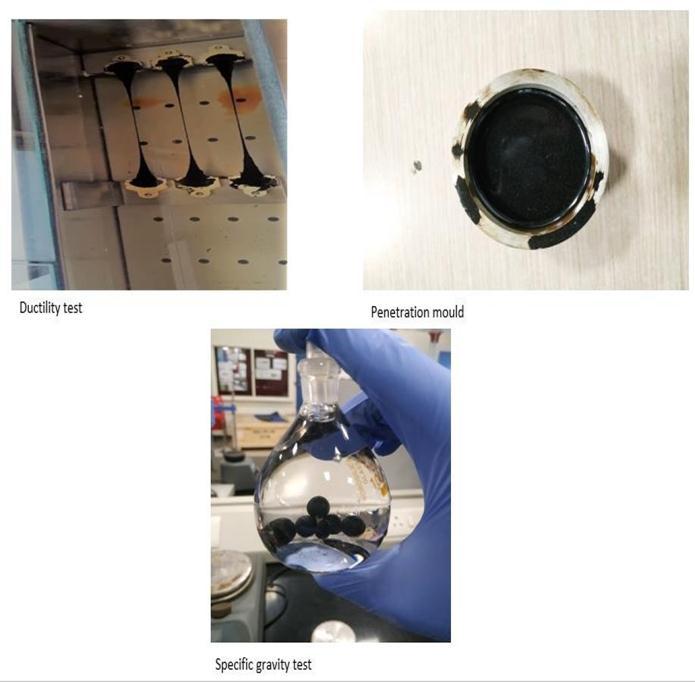

VG 30 grade bitumen was used in this study. The binder properties were assessed by carrying out flash point, penetration,softeningpoint,solubility,viscosityandspecific gravity

Flashpoint,Clevelandopencup,℃,Min 304

Absoluteviscosityat60°Cpoises 2855 Kinematicviscosityat135°CcSt,Min. 392 Penetrationat25°C,100gm,5sec,1/10mm, Min 49

Softeningpoint(R&B),°C,Min 48 MatterSolubleinTrichloroethylene,%by mass,Min. 99.45 Viscosityratioat60°C,Max 1.3 Ductilityat25°C,cmafterTFOTmin. 75 SpecificGravitygm/cc 0.987

Table

The plastic waste was obtained and used in this study throughthefollowingprocedure:

i)Thewasteplasticwascollectedfromdiscardeddrinking waterbottles.

ii)The collected plastic waste was then crushed into finer particlesusingaspecializedcrusher.

iii)Plasticwasteparticlesweresievedtochecktheeffectsof particlesize.

iv)Theparticlespassingthrough2.36mmsieveandretained on1.18mmsievewereusedasCoarsegraded(CG)plastic wastes and the particles passing through sieve 0.595 mm and remaining on sieve 0.295 mm were classified as Fine Graded(FG)plasticwaste.

Density(g/cm3) 1.35

Moistureabsorption(%) 0.2 MeltingPoint(℃) 240

Tensilestrength 850 Coarsegradedplasticwaste(% passing) 2.36mm 1.18mm 100 5 FineGradedplasticwaste(%) 0.595mm 0.295mm 100 5

Figure 2.2 Bitumen testing

Table 2.3 Size distribution of plastic waste used

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Thebituminousconcretemixtureswerepreparedthrough dryprocessbythefollowingsteps:

i) The optimum binder content of the control mixture (withoutplasticwaste)wasfoundtobe4.5%byusingthe Marshallmixdesignmethod.

ii) The aggregates were heated for 4 hours and bitumen were heated for 150℃ and 170℃ respectively and then mixedfor5minutesusingalabmixer.

iii)Afterthisplasticwastewastewasaddedandmixeduntil theaggregateandplasticwastewerefullycoatedwiththe binder.

Thismethodwasusedtoretaintheplasticinitsnaturalstate (semicrystallineresin) with minimal changestoitsshape andproperties.

Thepreparedmixwaspouredoncylindricalspecimensof67 mmthicknessand102mmthicknessandwerecompacted with75blowsoneachside.Thesemixeswerethenairdried for4hoursandfinallykeptina waterbathat60℃for 30 minutesprior toMarshall testing.TheguidelinesofASTM D6927 2015 were adhered for the testing The following processwasfollowedforMarshalltesting:

i) Three specimens of each type of mix were prepared to investigatetheeffectofrepeatabilityandmeanresultswere computedalongwithstandarddeviation.

ii)Themaximumloadresistanceandrespectivedeformation weremeasuredandrecordedusinga100kNloadcellanda 50mmLVDTwitha data acquisitionsystemata constant strain rate of 50.4 mm/min. The results were reported as Marshall'sStability,FlowandQuotient

The volumetric properties are the most important parameters for evaluating the performance of asphalt bituminousconcrete.Inthisstudyvariouspropertieslikeair voidcontent(Va),VoidsFilledwithAsphalt(VFA),Voidsin mineralaggregate(VMA)wereanalyzedandtheirvariation withdifferentcontentsofplasticwastewerecomparedto completely understand the performance of plastic waste modifiedasphaltbituminousconcrete.

Mixture

Plastic content % (by weight of bitumen) Binder Content (%)

Fine Grade

Control 0

Air Voids Conte nt (%)

VMA( %) VFA( %) Coars e Grade

4.5 4.15 13.29 68.787

CG 2 2 4.5 4.256 13.526 68.550

CG 4 4 4.5 4.362 13.756 68.312

CG 6 6 4.5 4.468 13.985 68.075

CG 8 8 4.5 4.574 14.215 67.837

CG 10 10 4.5 4.68 14.445 67.599

FG 2 2 4.5 4.28 13.547 68.431

FG 4 4 4.5 4.41 13.798 68.077

FG 6 6 4.5 4.54 14.049 67.720

FG 8 8 4.5 4.67 14.299 67.366

Thefollowingobservationscanbemadethroughtheresults ofvolumetricproperties:

i)TheairvoidcontentandVMAincreaseswiththeincrease in plastic waste content. This is because of decrease in binder to fill the voids as it is consumed for coating the plastic waste. Another reason is due to the elastic deformation of plastic waste particles under compaction effort.

ii)TheairvoidcontentandVMAofcombinationscontaining finegradedplasticwastearehigherthanthosecontaining coarseplasticwaste.

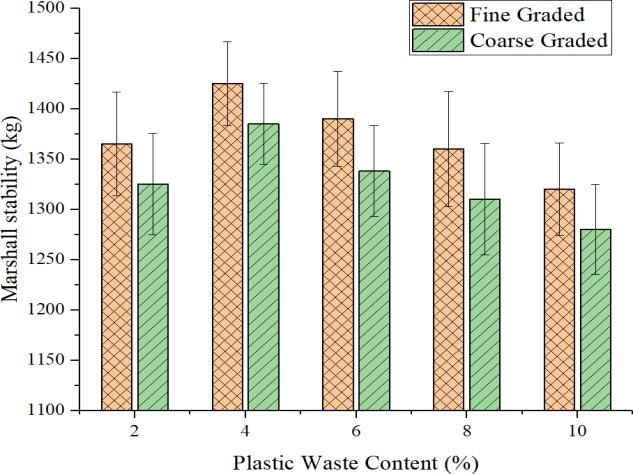

Figure 3.2 Effect of plastic waste on Marshall Stability

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

The effect of plastic waste on Marshall stability can be summarisedasfollows:

a) The Marshall Stability (MS) for both fine and coarse graded plastic wastes increases with increase in plastic waste content upto 4% beyond which the MS values start decreasingwithincreasingplasticcontent.

b) Theplasticwastewasaddedtothemixtureatthefinal stageofmixingtheaggregatewiththebinder,thisresultsin preservingthesemicrystallinenatureofplasticwasteinthe mixtureandthusweseetheincreaseinMSvalues.

c) From the results it is clear that the stability of Fine Graded(FG) plasticwasteismorethanCoarseGradedplastic wastethisisduetotheshapeoftheplasticwasteparticles. TheFGplasticwasteparticlesareuniforminshapeandare mostlyflatwhichresultsinlowdeformationunderloading.

d)TheFGplasticwasteparticlescanbewelldistributedin themixtureascomparedtotheCGplasticwasteparticles, duetothisreasontheyfillthevoidseasilyandincreasethe stiffness of the mixture. The FG plastic particles also have lowmeltingpointduetowhichmorecrystallinepartofthe plasticremainsinthemixturetherebyincreasingstiffness.

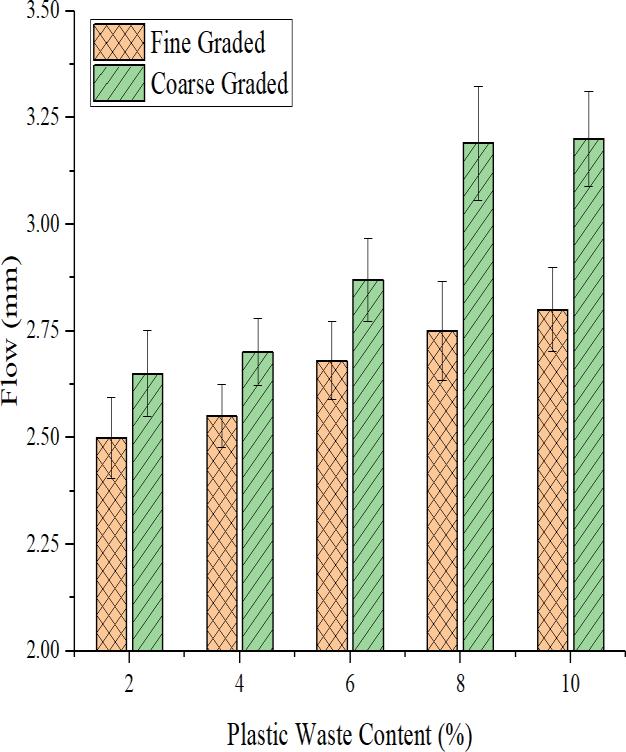

Flowisameasureofdeformationresistance,andmixtures with a higher flow are more likely to deform under load. Mixtureswitha low Marshall flow,ontheotherhand,are considered to be stiff and prone to cracking. Therefore, minimumandmaximumflowarespecifiedforbituminous concretemixtures.

The following results were found on the effect of plastic wasteonflowvaluesofthemixtures:

a)Marshallflowisreducedwithincreasingtheplasticwaste contentofmixturescontainingbothfineandcoarseplastic wasteparticlesupto4%,afterwhichitbeginstoincrease withincreasingtheplasticwastepercentageofthemixtures.

b) It can be observed that, for any plastic waste content valueforthemixturescontainingfineplasticwasteparticles, and the mixtures containing up to 6% of coarse graded plastic waste particles, the flow is lower than that of the controlmixturewith0%ofplasticwastecontent,indicating thatinclusionofplasticwasteincreasesthestiffnessofthe mixtures.

c) From Figure 3.3 it is clear that the flow of fine graded plasticwasteparticlemixturesislowerthanthatofcoarse gradedplasticwasteparticlemixtures.

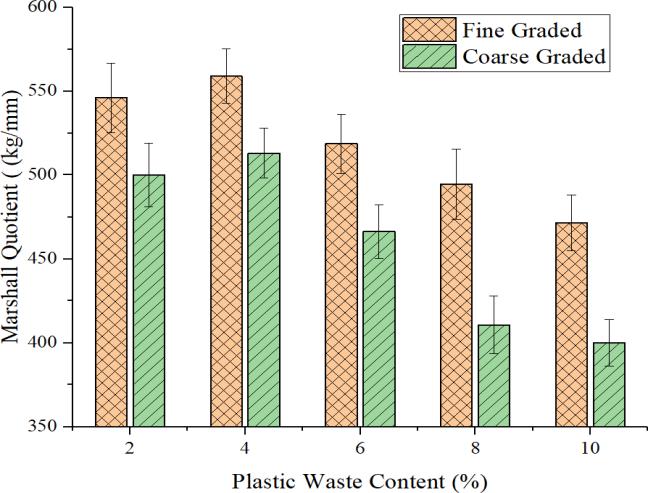

MarshallQuotientisanindicationofabituminousmixture's resistancetoshearstressandpermanentdeformation.

a) The MQ for mixtures containing both fine and coarse gradedplasticwasteparticlesincreasestill4%plasticwaste content after which it starts decreasing with increasing plasticwastecontent.

b)TheMQforallmixturesexcepttheonecontaining10% plasticwasteparticlesishigherthanthecontrolmixture.

c) Fine graded plastic waste mixtures have higher MQ as comparedtothecoarseplasticmixturesandthedifference between the two keeps on increasing with increasing the plasticwastecontent.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Inthisstudy,plasticwasteparticlesofdifferenttwodifferent sizes were mixed with bituminous concrete and various volumetricandengineeringpropertiesofthemixtureswere analyzed.Theresultsareasfollows:

i)Forbothfineandcoarsegradedplasticwasteparticles,a similar pattern was observed , the Marshall stability and MarshallQuotientofthemixturesincreasedwithincreasing theplasticwastecontentupto4%,beyondthislimitthey startdecreasingwithincreasingplasticwastecontent.

ii)At4%plasticcontentthelowestflowvalueofmixturesis obtained.

iii)Withtheincreaseinplasticwastecontenttheresistance topermanentdeformationofbituminousmixturesincreases.

iv)Overall,finegradedplasticwasteparticlesarefoundto bemoreeffectivethancoarsegrainedplasticwasteparticles forimprovingthepropertiesofthemixtures.

[1]Modarres,A.,&Hamedi,H.(2014).Effectofwaste plastic bottles on the stiffness and fatigue properties of modifiedasphaltmixes.Materials&Design,61,8 15.

[2] Ahmadinia,E.Zargar,M.,Karim,M.R.,Abdelaziz,M.,& Shafigh,P.(2011).Usingwasteplasticbottlesasadditivefor stonemasticasphalt. Materials & Design, 32(10),4844 4849.

[3]Ponnada, S., & Vamsi Krishna, K. (2020). Experimental investigation on modification of rheological parameters of bitumen by using waste plastic bottles. MaterialsToday:Proceedings,32,692 697.

[4]ASTMD69272015Pageno.4

[5] Pareek A. ,Gupta T. (2012). Performance of polymer modified bitumen for flexible pavements. International JournalofStructuralandCivilEngineeringResearch

[6]Nouali,M.,Derriche,Z.,Ghorbel,E.,&Chuanqiang,L. (2019). Plastic bag waste modified bitumen a possible solutiontotheAlgerianRoadPavements.RoadMaterialsand PavementDesign,21(6),1713 1725.

[7] Abtahi, S. M., Sheikhzadeh, M., & Hejazi, S. M. (2010). Fiber reinforcedasphalt concrete areview.Construction and Building Materials, 24(6), 871 877. https://doi.org/10.1016/j.conbuildmat.2009.11.009

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |