International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1 M.Tech second year, Department of Textile Technology, Jaya engineering college, Tamil nadu, India 2&4 Assistant professor, Textile Technology/ Department of Chemical Engineering, VFSTR, Andhra Pradesh, India 3Assistantprofessor,DepartmentofTextileTechnology,Jayaengineeringcollege,Tamilnadu,India ***

Abstract A needle punching process using Cotton, Kapok,andArecafibresata consistentpunchdensity(300), an eco friendly nonwoven fabric was developed. The effect of cotton, kapok, and areca fibre content (45:10:45, 60:10:30, 30:10:60, and 40:20:40) on the tensile, thermal conductivity, air permeability, and sound absorption characteristics of needle punched non woven textiles was studied. The tensile strength of nonwoven fabric was observed to be higher, with a tensile strength of 2.56 CN/Tex. The non woven fabric has a greater thermal conductivity and air permeability than the other nonwoven fabric. In the reverberation time technique, the highest sound absorption coefficient is 0.923 was observed in this study. The nonwoven fabric created in this study can be utilised as a sound insulation material in commercial settings such as theatres, malls, and auditoriums, among otherthings.

Key Words: Thermal conductivity, Air permeability, and Sound absorption, Sound Absorption Coefficient, ReverberationTime…

In today's world, noise has a significant impact on human health. Noise pollution, in particular, has a significant negative impact on the environment as a result of development. Noise pollution from several technologies and industrial uses has resulted in a slew of issues that have harmed people's live1.Unknowingly, noise or unpleasantsounddisruptspeople'severydayroutinesand health. After conducting a study and survey, the National Institute of Occupational Safety and Health (NIOSH) set a maximumof85decibelsforeighthoursperday2

According to the World Health Organization, more than 30%ofthepopulationinEUcountriesisexposedtonoise atnight.Thegrowinginterestinengineeringandresearch todevelopsound absorbingmaterialsfornoisereduction. Textile is a key component of sound absorbing materials. Bulk density, thickness, and fibre arrangement all had a substantial impact on sound absorbing material. Sound absorbingmaterialsareoftencomprisedofsyntheticfibre, which uses a lot of energy during the manufacturing process. Sustainable materials, on the other hand, are effective sound absorption materials.3.One of the main engineering procedures used to control environmental noiseistheuseofsound absorbingmaterials4 .

The development of renewable source acoustical materialsasviablealternativestomineralwool,fibreglass, and other synthetic fibres has gotten a lot of attention, especially in acoustic applications.5. Natural fibres are biodegradable in general, and processing them may be made more cost effective and environmentally beneficial. Naturalfibreshavealsobeenshowntobesaferforhuman health than most mineral synthetic fibres because they don'trequirespecialcare.Recentresearchhasfocusedon theutilisationofnaturalfibres,suchasvegetalandanimal fibres,tocreateeco friendlysound absorbingmaterials.

Several natural fibers suitable as bases for sound absorption materials, such as bamboo6, ramie 7, coir and fiber from date palm8, fiber from oil palm empty bunch9,flax10, bagasse11, corn husk12, pineapple leaf 13 , broom fibers14, chicken feathers15, sisal16, kenaf 17and othersustainablefibres.

Areca is grown for its fruit nuts in India and other Asian nations.ArecanutshavebeenutilizedinIndiaformedical purposes,aswell aspaint,chocolate,andchewable gutka. Areca fiber makes up 60 to 70% of the entire weight and volume of the areca fruit. Areca fibers have an average lengthof3to6cm.Thefibermightbeusedtomakevalue added goods like thick boards, soft pillows, non woven textiles, and thermal insulators, among other things.Because of its high absorption coefficient, Areca Nuts fibre composite is an effective sound proofing materialatlowandmediumfrequencies18

Hollowstructureaffectsthebuoyancybehaviourofkapok fibre. Because of these characteristics, kapok fibre has a high porosity, which improves sound absorption properties. The large cross sectional diameter of kapok fibre increases friction resistance between air and fibre, resulting in energy dissipation.19In both the lateral and longitudinal parts of the fibre, the cell wall of kapok fibre differsfromthatofcottonfibres.20

Cotton has an excellent cohesive property and may be utilisedtomakenonwovenfabricsbecauseofitsincreased cohesiveness and quietness. Sound absorption increases witha decrease in fibre diameter, resulting in anincrease inairflowresistance.Thequantity,size,andtype ofpores on the material's surface are other factors that allow soundtobedissipatedthroughfriction.Sothatthecotton

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page258

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

hasbeenselectedminimumamounttofindthequalitiesof otherfibres.

In this study, the sound absorption properties of areca, kapok and cotton fiber blends different proportions are measured and Sound absorption coefficients and Noise Reduction Coefficient are measured for the different combinations of fiber mixture by reverberation time method.

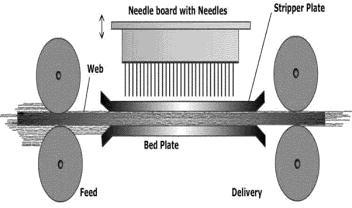

Nonwoven fabrics have micron and submicron holes, making them ideal for sound absorption21. Many elements, such as fibre characteristics, process parameters, and physical parameters, can increase the sound absorptive capabilities of nonwoven fabric22.The followingprocesseswereusedtoprepareneedle punched nonwoven fabric. The lab model blow room machines from Trytex were utilised to make homogenous mixing and cleaning in the first stage. To increase the blend's homogeneity,thefibremixeswereranthroughtheopener twotimes.Blendedfibreswerecardedinthesecondstage withalabmodelcardingmachinetoremovedirtparticles, align fibres, and generate webs. The needle punching process is used to create nonwoven fabric consolidation. This approach involves repeatedly piercing through the fibrewebwithanarrayofbarbedneedlestomechanically connectfibres.

The sound absorption property is measured by the reverberationtimemethodwiththespecificationofASTM C 423. The acoustic characterization of the samples is testedunderstandardtestingconditions.

Sabine's reverberation formula is still widely acknowledged as a very practical evaluation method for the reverberation time in rooms, and it is used to determine the material absorption coefficients with the help of reverberation rooms. Sabin is a measurement of sound absorption that measures the area of an open window in square meters. The method's primary idea is that sound energy travelling into an open window in a room is not reflected at all; yet, it completely vanishes in the open air outside. If the open window is replaced with 100 percent absorbent material in the same sizes, the sameeffectwillbeattained23

Where V is the chamber volume, S is area of the sample, TRisthesoundreceivingtimewiththetestsampleinside the chamber, TR0 is the sound receiving time without the testsampleinsidethechamber.

Sabinealsocameupwithadefinitionforthetime it takes for residual sound to decline below detectable levels, T, by starting with a 1,000,000 times larger initial amount,asseenintheequationbelow.

T=0.163V/A

Where V is the room volume in m3 and A is the total absorptionareainm224

The experimental setup is shown in fig We used a loudspeaker system, a microphone for generating sound signals,asoundpressurelevel meter,andareverberation room chamber of volume 64 cubic feet (1.81228 m3). The

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

testing is carried out under two conditions without sample(empty room absorption) and with samples(full roomabsorption).

tabulated in table 1.The relationship between air permeability and heat conductivity is seen in Figure 4. According to this research, when air permeability is high, thermalconductivityishigher.Thereverberationtime RT 60,asshowninfigure5,isdependentonthethicknessand areal density of the material used in nonwoven manufacture

Table1:

Sam ple ID

First, the reverberation time of the empty room withoutsampleismeasuredbythefollowingprocedure.A bandofrandompinknoise, a1/3octavebandnoiseat 90 dB, was used as a test signal and was turned on long enough for the sound signal to stabilize. When the signal was turned off, the sound pressure level decreased (90 60=30dB) and each frequency band’s decay rate was determinedbymeasuringtheslopeofastraightlinefitted to the average decay curve’s sound pressure level. The absorption of the empty room was calculated from the Sabineabsorptionformula,

The specimen of size 18 x 18 inches (0.209032 m2)(Areca,kapok,cotton blended nonwoven) was installed and the same procedure is repeated for measuring full room absorption. The specimen’s absorption coefficients werecalculatedasfollows:

Thearithmeticmeanoftheabsorptioncoefficients in 1/3 octave frequency ranges is used to compute the noise reduction coefficient (NRC). This number has been roundedtotheclosest0.05multiple.Theperfectreflection is shown by the NRC value of zero. The NRC number 1 indicates that perfect absorption has occurred. This parametercanalsobemeasuredusingreverberationroom techniques25

This chapter summarises all of the test results as well as the nonwoven fabric samples that were investigated. The test results and details have been examined, and an attempt to explain the findings has been made. All of the chosen fibres include the largest quantity of cellulose components, and they are all biodegradable waste from agricultural applicationsDuring the purpose testing, each sampleistested10timesandtheaverageiscalculatedand

Blen d rati o

Thick ness mm

GS M Rt6 0 sec

ACK 1 45:1 0:45 5.315 4 4 2

ACK 2 60:1 0:30 5.195 4 5 6

ACK 3 30:1 0:60 4.967 4 2 7

ACK 4 40:2 0:40 5.505 4 4 8

� Tena city CN/t ex

Air permea bility m3 m 2.min 1

Therma l conduct ivity, W/m.K

0.1 89 0.9 23 1.34 40.89 0.02991

0.1 92 0.8 91 1.51 47.31 0.04288

0 .19 5

0.7 37 2.56 46.63 0.03177

0.1 98 0.6 48 1.32 48.29 0.03643

Tenacity, Airpermeability, Thermal conductivity

50

40

30

20

10

Figure 4:Airpermeabilityandthermalconductivity 0 1.34 1.51 2.56 1.32

60 0 1 2 3 4 5 6

40.89 47.31 46.63 48.29 0.02991 0.04288 0.03177 0.03643 0

Tenacity Air permeability

Thermal conductivity, W/m.K

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page260

2.5

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

5 Arenas, J.P. Applications of Acoustic Textiles in Automotive/Transportation. In Acoustic Textiles; Padhye,R.,Nayak,R.,Eds.;Springer:Singapore,2016; pp.143 161.

1.5

0.5

2

1

1.34 1.51

0.923 0.891 0.737 0.648

0.189 0.192 0 0.198

2.56 1.32 0

3 0 1 2 3 4 5

RT 60 , α, Tenacity Rt60 sec �� Tenacity

The Areca, Kapok, Cotton blended nonwoven was produced with four different blend ratios of 45:10:45, 60:10:30,30:10:60 and 40:20:40. The effect of fibre content on tensile strength, thermal conductivity, air permeability, and sound absorption qualities was investigated.Theresultsshowthatwhenmixedwithkapok fibre,arecafibrenonwovenfabrichasthemaximumtensile strength. Because of the kind of fibre and changes in composition, the thickness and areal density of the nonwoven material varies.This study's needle punched non wovenclothcanbeemployedforacousticapplications inindustries.

1 Development of Acoustic Material using Kapok Fibre for Automotive Application Ashwin Thakkar1 Dharmendra Bihola2 Kishan Sangani ; IJSRD International Journal for Scientific Research & Development| Vol. 5, Issue 09, 2017 | ISSN (online): 2321 0613

2 Navy Environmental Health Center, “Man MadeVitreous Fibers,”vol.12,no.October,p.110,1997.

3 Asdrubali F, Schiavoni S, Horoshenkov, K.V. 2012. A review of Sustainable Materials for Acoustic Applications.BuildingAcoustis.Vol19.P.283 312

4 Crocker, M.J.; Arenas, J.P. Use of sound absorbing materials. In Handbook of Noise and Vibrations; Crocker,M.J.,Ed.;JohnWileyandSons:NewYork,NY, USA,2007;pp.696 713.

6 Koizumi,T.;Tsujiuchi,N.;Adachi,A.Thedevelopmentof sound absorbing materials using natural bamboo fibers. High performance structures and composites. WITTrans.BuiltEnviron.2002,59,157 166.

7Yang, W.D.; Li, Y. Sound absorption performance of natural fibers and their composites. Sci. China Technol.Sci.2012,55,2278 2283.

8 Taban,E.;Khavanin,A.;Faridan,M.;Samaei,S.E.;Samimi, K.; Rashidi, R. Comparison of acoustic absorption characteristics of coir and date palm fibers: Experimental and analytical study of green composites.Int.J.Environ.Sci.Technol.2020,17,39 48.

9 Or, K.H.; Putra, A.; Selamat, M.Z. Oil palm empty fruit bunch fibres as sustainable acoustic absorber. Appl. Acoust.2017,119,9 16.

10 Zhang, J.; Shen, Y.; Jiang, B.; Li, Y. Sound Absorption Characterization of Natural Materials and Sandwich StructureComposites.Aerospace2018,5,75.

11Malawade,U.A.;Jadhav,M.G.Investigationoftheacoustic performanceof bagasse.J.Mater.Res.Technol.2020, 9,882 889.

12 Tang, X.; Zhang, X.; Zhang, H.; Zhuang, X.; Yan, X. Corn husk for noise reduction: Robust acousticabsorption and reduced thickness. Appl. Acoust. 2018, 134, 60 68.

13 Putra, A.; Or, K.H.; Selamat, M.Z.; Nor, M.J.M.; Hassan, M.H.; Prasetiyo, I. Sound absorption of extracted pineapple leaffibres.Appl.Acoust.2018,136,9 15.

14 Berardi, U.; Iannace, G.; Di Gabriele, M. The acoustic characterization of broom fibers. J. Nat. Fibers 2017, 14,858 863.

15 Kusno,A.;Sakagami,K.;Okuzono,T.;Toyoda,M.;Otsuru, T.; Mulyadi, R.; Kamil, K. A pilot study on the sound absorption characteristics of chicken feathers as an alternative sustainable acoustical material. Sustainability2019,11,1476.

16 Oldham, D.J.; Egan, C.A.; Cookson, R.D. Sustainable acoustic absorbers from the biomass. Appl. Acoust. 2011,72,350 363.

17 Lima, Z.Y.; Putra, A.; Nor, M.J.M.; Yaakob, MY Sound absorptionperformanceofnaturalkenaffibres.Appl. Acoust.2018,130,107 114.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page261

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

18 MTaufik1,ADoyan,Susilawati,SHakimandLMuliyadi Acoustic characteristics board of areca nuts fiber composites. Journal of Physics: Conference Series 1572 (2020) 012004 IOP Publishing doi:10.1088/1742 6596/1572/1/012004.

19 Xiang,H.,Wang,D.,Liu,H.2013.InvestigationonSound Absorption Properties of Kapok Fibers. Chinese JournalofPolymerScience(EnglishEdition).

20 Simona Vasile,Lieva van Langenhove; “Automotive IndustryahighpotentialMarketfornonwovensound Insulation,Journaloftextileandapparel”,Technology andmanagement.Vol3,Issue4,2004.

21 Shahani,Fereshteh.dkk.2014.TheAnalysisofAcoustic Charactheristics and Sound Absorption Coefficient of Needle Punched Nonwoven Fabrics. Journal of EngineeredFibersandFabrics.

22 Puranik, P.R., Parmar, R.R., Rana, P.P. 2014. Nonwoven Acoustic Textiles Review. International Journal of Advanced Research in Engineering and Technology (IJARET)

23 TaşcanM.Acousticaltestmethodsfornonwovenfabrics.

In: Padhye R, Nayak R, editors. Acoustic Textiles, Textile Science and Clothing Technology. Singapore: Springer; 2016. DOI: 10.1007/978 981 10 1476 5. ISBN:978 981 10 1476 5.

24 Atmajan A, Tessy I, Abin M, Pisharady SK.Chapter 7: Acoustics. In: A Textbook of Engineering Physics. New Delhi: Acme Learning Private Limited; 2011. p.107. ISBN:8121908175,9788121908177

25 Padhye R, Nayak R.Acoustic textiles: An introduction. In:PadheR,NayakR,editors.AcousticTextiles,Textile Science and Clothing Technology. Singapore: Springer; 2016. DOI: 10.1007/978 981 10 1476 5. ISBN: 978 981 10 1474 10

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page262