International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p-ISSN: 2395-0072

1 (M.tech Scholar) 2nd year, Department of Civil Engineering, Ganga Institute of Technology and Management, Jhajjar Haryana (India)

2Assistant Professor, Department of Civil Engineering, Ganga Institute of Technology and Management, Jhajjar Haryana (India)

3Assitant Professor, Department of Civil Engineering, Ganga Institute of Technology and Management, Jhajjar Haryana (India) ***

Abstract Our project focuses on the designing of PEBs structure and the green building aspect of the structure. In India 67 million tons of food get wasted annually accounting for 92000 crores and being a developing country there will always be a need for an industrial structure for storing and other industrial activity. With the increasing demand for industrial sheds, the structures need to be designed fast and accurately. Any discrepancy and clash in the design of structure cause wastage and the use of BIM software can easily detect and solve such problems before the work even started. The PEB structure has 21,840 m3 and consists of non prismatic members designed for bending moments at their respective nodes. The members are designed as per IS800 and connection as per AISC and IS. The project uses different software for designing such as ETABS, STAAD PRO, RAM CONNECTION and IDEASTAICA along with hand calculation following IS 875 parts 1, 2, and 3 for load calculation and IS 800

Key Words: Structure, Designing, Steel, Green Building, Pollution,wastage,BIM,Technology,software.

AdvancesinTechnologymakepossibletodesignstructure more accurately with least possible clashes with other aspectsofthestructure.Thisisnowpossiblewiththehelpof BIM and different software interoperability. With the growingdemandofindustry,housingsector,needofstorage unitsetc.ThePEBsstructureisintelligentlydesigntotake forcesandcanbeconstructedrapidly.ThePEBsplannedand members are fabricated in factory and only need to be assembled at site, this help in reducing construction time considerably.. TheadvantageofPEBstructureisthatitcan be constructed quickly with lesser amount of material in weight being used. As all the members are fabricated in factoryandmembersneedtobetransportedsoitalsocost lesserintransportationchargesandeasiertoreachplaces thatarehardertoreach.

The greenhouse gases due to steel construction is lesser comparingtoconcreteconstructionandtheneedofframing forconcreting,hydrating,andcuringperiodisnotrequired in steel construction. With the help of BIM and

interoperability of different software to create and design structurewecanreducethewastageofmaterialandtimeof construction.

Intheprojectwestudiedthatextentofintegrationpossible usingdifferentsoftware’sononeprojectsworkingonsingle point.WeuseETABStodesignmembersofstructuresand import the design file to STAAD Pro to design connection using RAM connection in STAAD pro. STAAD pro RAM connection only able to design generic connection inside STAAD PRO, so we used IDEASTATICA BIMLink to design connectionfromscratchusingsamedesignfile

Therearevarioustypesofmethodsavailableaccordingto theIndianStandardcode

LimitStateMethod(LSM)

WorkingStateMethod(WSM)

Load Factor Method (LFM) or Ultimate Load Method(ULM) HereLSMisusedformemberanalysis.

Inphilosophy,LSMissuchthatthestructuresafelycarries all the load over its entire life span without failing. The structure is unfit when its collapses or violates the serviceabilityrequirementsuchascrackinganddeflections. With the probabilistic approach design, load and design strengtharedetermined.Thisphilosophicalmethod,design structure in such a way that it remains fit for its entire designliferemainingwithinacceptablelimitsofsafetyand serviceability requirements. We use LSM methodology to designthePEBstructure.

A well designed and well planned structure has the least probabilityofitsfailure.Thestructureisdesignedbasedon thecharacteristicvaluesofitsmaterialstrengthsandapplied loadstakingaccountofvariationinmaterialspropertyand

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

loadtobesupported.Designvalueisobtainedbyapplying partial safety factors. The reliability of the design is expressedas

DesignAction(Qd)≤DesignStrength( ) ThedesignactionQdisexpressedas

And,thedesignstrengthSdisobtainedas = Where, =characteristicload =ultimatestrength =partialsafetyfactorforloads. =partialsafetyfactorformaterials.

01 ThespanofthePEB 40m

02 SpacingofthePEBframe 7.66m

03 Heightofcolumn 5m

04 Lengthofbuilding 91.1m

05 RiseofthePEB 7m

06 Slopeoftheroof(ϴ) 10degree

07 Lengthalongtheslopingroof 20.1m

08 Lengthofeachpanel(c/cspacingofpurlin) 7.66m

09 SpacingofgablefromPEBframe 7.42

Basicwindspeed(Vb) =33m/s

DesignWindspeed( )isgivenby

k1 = probabilityfactor(riskcoefficient)

k2 = terrain,heightandstructuresizefactor

k3 = topographyfactor

k4 = CyclonicFactor

Vz = 33m/s

Designwindpressure(

DesignWindPressure, WindDirectionalityFactor, =0.9 Clause7.2.1ofIS875 Part3

AreaAveragingFactor, =0.80 Clause7.2.2ofIS875 Part3

CombinationFactor, =0.90 Clause7.3.3.13ofIS875 Part3 =0.648>0.7

DesignWindPressure, =0.457KN/m2 PressureCoefficients: Areaoftheface=455

Areaoftheopening=44 PercentageAreaoftheOpening=9.65% Encloserconditionofthebuilding= Partially Enclosed

Enclosed 0.2 PartiallyEnclosed 0.5 Open 0.7 =0.125 =2.28 3/2≤ <4

ExternalPressureCoefficient Usetable4fromIS:875part3 1987

Table 2 MaterialListbySectionProperty

Section

member

Object Type No of Pieces Length Weight

m kN

700mm Beam 34 154.098 166.0928 mem_1_prismatic_ 800mm_to_700mm Beam 22 147.3982 173.1145 member_2_prismat 700mm_to_900mm Beam 22 147.3981 227.7299

Column400mm Column 21 138.6 133.8249 Columnmiddle Column 26 130 124.8399 member_3_900_to_ 700 Beam 22 73.6992 113.8653

ISMC Beam 104 791.54 273.43

ROD50 Beam 36 366.54 16.72 ROD50 Brace 12 109.83 5.08

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

FollowingarethedesignresultonPEBstructure

Table 3 Supportreaction

Horizontal Vertical MomentKN m FxkN FzkN FykN Mx My Mz

Max Fx 88.44 0.084 130.07 0 0 0 Min Fx 88.43 0.083 130.10 0 0 0 Max Fy 0 0.001 313.436 0 0 0 Min Fy 0.04 4.61 6.452 0 0 0 Max Fz 0.015 14.723 21.973 0 0 0 Min Fz 0.024 14.73 36.62 0 0 0 Max Mx 20.784 0.056 48.817 0 0 0 Min Mx 20.784 0.056 48.817 0 0 0 Max My 20.784 0.056 48.817 0 0 0 Min My 20.784 0.056 48.817 0 0 0 Max Mz 20.784 0.056 48.817 0 0 0 Min Mz 20.784 0.056 48.817 0 0 0

Table 4 BeamEndForces

Fx kN Fy kN Fz kN Mx kN m My kN m Mz kN m

Max Fx 313.436 0 0.001 0 0 0 Min Fx 14.427 0.017 0.149 1.2 1.498 0.215 Max Fy 57.543 158.13 0 0.001 0.004 523.103 Min Fy 57.543 158.13 0 0.001 0.004 523.105

Max Fz 0.839 4.892 5.04 0.038 7.611 3.625 Min Fz 2.139 8.111 5.04 0.038 9.273 9.017 Max Mx 0.697 6.392 2.116 1.923 8.024 3.288 Min Mx 0.957 3.791 2.116 1.923 9.442 0.124

Max My 0.418 3.837 0.406 1.409 14.448 1.97

Min My 0.699 6.372 0.408 1.409 14.64 3.28 Max Mz 57.543 158.13 0 0.001 0.004 523.105 Min Mz 150.85 72.991 0 0 0 364.957

X mm Y mm Z mm

Resulta nt mm

rX rad rY rad rZ rad

Max X 9.62 7 14.42 0.127 17.339 0 0 0.00 1 Min X 9.62 14.42 0.128 17.34 0 0 0.00 1 Max Y 5.56 8 2.513 0.012 6.109 0 0 0 Min Y 2.65 24.5 0.03 24.657 0 0 0.01 Max Z 0.00 3 0.037 29.56 1 29.561 0.00 4 0.00 2 0

Min Z 0.00 4 0.061 29.83 6 29.836 0 0 0

Max rX 1.2 10.48 7 5.231 11.781 0.04 6 0.00 5 0.00 1

Min rX 1.20 2 10.50 2 5.268 11.81 0.05 0.01 0.00 1

Max rY 0 0 0 0 0.00 1 0.05 1 0.00 1 Min rY 0 0 0 0 0.00 1 0.05 0.00 1 Max rZ 0.90 7 9.266 0.036 9.311 0 0 0.00 4 Min rZ 0.91 9.264 0.036 9.309 0 0 0.00 4

Max Rst 0.00 4 0.061 29.83 6 29.836 0 0 0

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

(1/16in) : 3

Connectingplate tp:Thickness : 25.4mm Material : A36

3.4.2

Material

Steel E165(Fe290)

Projectitem PurlinConnectionDesign Name Purlinconnection Analysis Stress,strain/loadsinequilibrium

Table 6 Loadeffects(forcesinequilibrium)

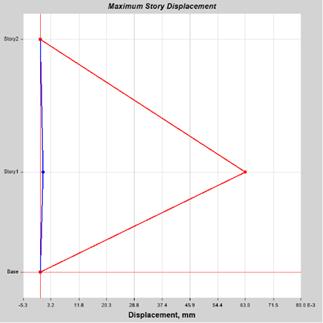

Chart1 TabulatedplotCoordinatesofDisplacement

Someoftheconnectionare

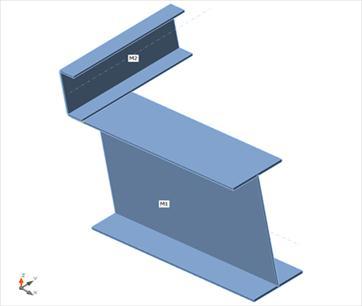

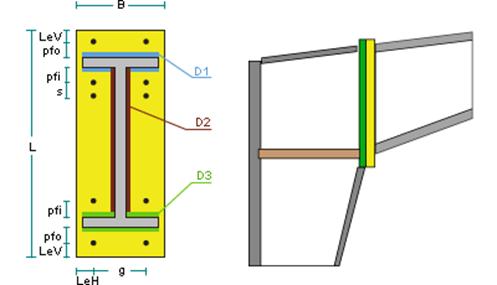

Fig1 Apextypeconnectiondetaildiagram

Configuration

Isapex : Yes

Verticalangle(deg) : 0 Rightbeam Beams

Beamtype : Tapered member

Beamsection : Taper_7

Beaminitialheight : 699.999mm

Beamfinalheight : 699.999mm

Beamlength : 3.35m

Beammaterial : STEEL_275_NMM2

Moment Flangeandwebwelded

Beamside

Topflangeweldtype : Fillet

Topbeamflangeweld: E70XX

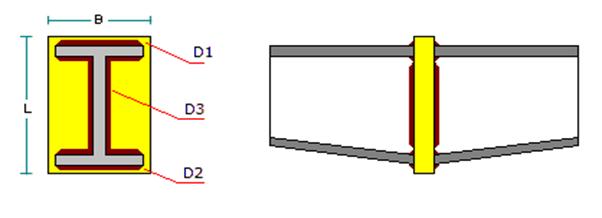

D1: Weldsizetotopbeamflange(1/16in) : 4

Bottomflangeweldtype : Fillet

Bottombeamflangeweld : E70XX

D3: Weldsizetobottombeamflange (1/16in) : 4

Weldingelectrodetobeamweb:E70XX

D2: Weldsizetobeamweb

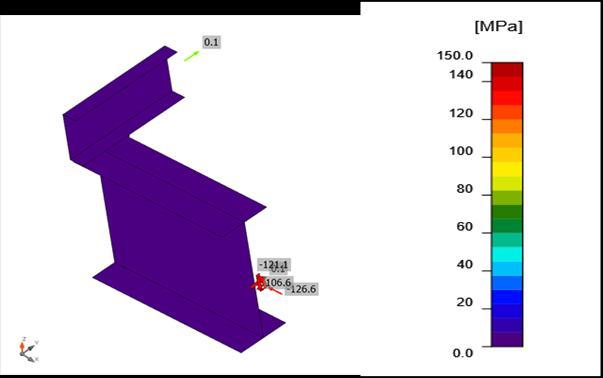

Name Mem N Vy Vz Mx My Mz

LE1 M1 126.6 0.1 121 0 106.6 0 M2 0.1 0 0 0 0 0

LE2 M1 141.8 0.1 91 0 47.1 0 M2 0.1 0 0 0 0 0

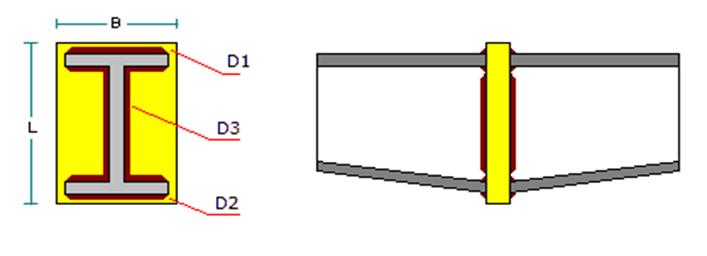

Table 7 Summaryofpurlinconnectionresult

Name Value Check status Analysis 100.00% OK Plates 0.0<5.0% OK Welds 0.6<100% OK Buckling Notcalculated

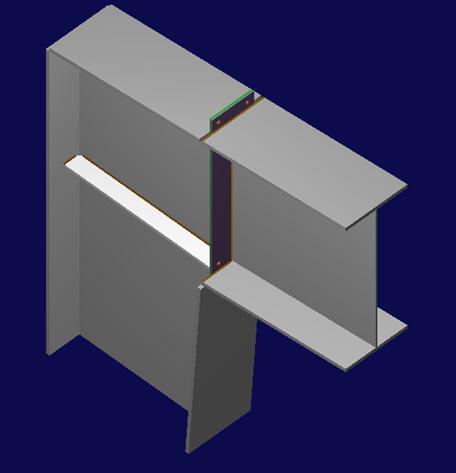

Fig2 Purlinconnection

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Fig3 PurlinconnectionequivalentstresscheckforloadLE1

Members

Configuration

Isapex : Yes

Verticalangle(deg) : 0

Rightbeam

Beams

Beamtype : Taperedmember

Beamsection : Taper_7

Beaminitialheight : 699.999mm

Beamfinalheight : 699.999mm

Beamlength : 3.35m

Beammaterial : STEEL_275_NMM2

Moment Flangeandwebwelded

Beamside

Topflangeweldtype : Fillet

Topbeamflangeweld: E70XX

D1: Weldsizetotopbeamflange(1/16in): 4

Bottomflangeweldtype : Fillet

Bottombeamflangeweld : E70XX

D3: Weldsizetobottombeamflange(1/16in):4

Weldingelectrodetobeamweb : E70XX

D2: Weldsizetobeamweb(1/16in) : 3

Connectingplate

tp:Thickness : 25.4mm Material : A36

Members

Configuration

Isapex : Yes

Verticalangle(deg) : 0 Rightbeam

Beams

Beamtype : Taperedmember

Beamsection: Taper_7

Beaminitialheight : 699.999mm

Beamfinalheight : 699.999mm

Beamlength : 3.35m

Beammaterial : STEEL_275_NMM2

Moment Flangeandwebwelded

Beamside

Topflangeweldtype : Fillet

Topbeamflangeweld: E70XX

D1: Weldsizetotopbeamflange(1/16in): 4

Bottomflangeweldtype : Fillet

Bottombeamflangeweld : E70XX

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

D3: Weldsizetobottombeamflange(1/16in):4

Weldingelectrodetobeamweb: E70XX

D2: Weldsizetobeamweb(1/16in): 3

Connectingplate

tp:Thickness : 25.4mm Material : A36

Existsoppositeconnection: No

General

Beamsection : Taper_7

Beammaterial : STEEL_275_NMM2

Beaminitialheight : 699.999mm

Beamfinalheight : 699.999mm

Beamlength : 6.7m

Verticalangle(deg) : 5.711

Includeflangestiffener: No

General

Supportsection : Taper_2

Supportmaterial : STEEL_275_NMM2

Supportinitialdepth : 749.999mm

Supportfinaldepth : 399.999mm

Supportlength : 5m

Connector

Plateextension: Extendedexternaledge Width : 203.2mm

tp: Platethickness : 6.35mm

Platematerial : A36

Fy : 0.248kN/mm2

Fu : 0.4kN/mm2

Holetypeonplate : Standard(STD)

Flushextensionlength: 25.4mm

Platealignment :Verticalalignment

Externalflangeweldtype: Fillet

Weldtoexternalflange: E70XX

D1: Weldsizetoexternalflange(1/16in): 3

Internalflangeweldtype : Fillet

Weldtointernalflange : E70XX

D3: Weldsizetointernalflange(1/16in): 3

Webweld : E70XX

D2: Weldsizetoweb(1/16in): 3

Bolts

tp: Connectionplatethickness: 6.35mm

Bolts: 1/2"A325N

g: Gage transversec/cspacing: 139.7mm

Holetype : Standard(STD)

Lev: Verticaledgedistance : 31.75mm Leh: Horizontaledgedistance: 31.75mm Boltgroup(externalextension) pfot:Distancefromboltrowstoflange:31.75mm Boltgroup(externalflange)

Boltsrowsnumber : 1 pfit:Distancefromboltrowstoflange :31.75mm Boltgroup(internalflange)

Boltsrowsnumber : 1 pfib:Distancefromboltrowstoflange:31.75mm

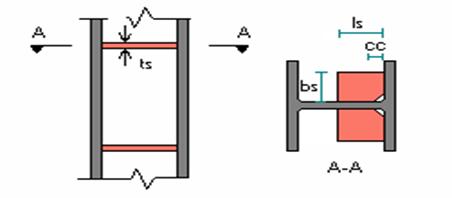

Transversestiffeners Section : PL12.7x76.2x727.65

Fulldepth : Yes Length : 727.649mm bs: Transversestiffenerswidth: 76.2mm cc: Cornerclips : 19.05mm ts: Transversestiffenerthickness: 12.7mm

Material : AS_Class4.6

Weldtype : Fillet

Weldingelectrodetosupport : ASE41XX D: Weldsizetosupport(1/16in) : 3

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

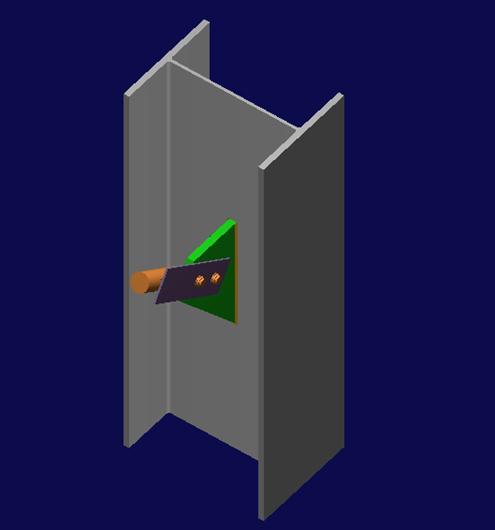

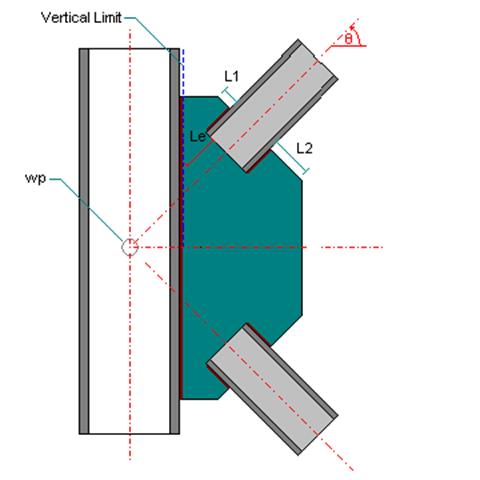

Upper right brace

Gusset General

tg: Thickness: 20mm Material : E250A LV:Lengthoncolumn: 324.458mm

Gusset to Brace connection

General Connectiontype: Bolted Bolts : M_20G8_8

Existingmembers

Rightbeam : No Leftbeam : No

Upperrightbrace : Yes

Upperleftbrace : No

Lowerleftbrace : No Lowerrightbrace : No Alignbeamstotopedge: No Bracingcleatassembly: No Column General Columnsection : Taper_2

Columnmaterial : STEEL_275_NMM2

Columnorientation : Transversal Iscolumnend : No

Upper right brace

General Section : Cir0.05_0

Material : Q345 Slopeangle(degrees) : 33.11

Additionalverticalforce: 0kN

Additionalgeometricdata wpx: WPhorizontaldisplacement: 0mm wpy: WPverticaldisplacement: 0mm

Le:Minimumdistancetoothermembers: 25mm

Le1:Leftdistance : 25mm

Le2:Rightdistance : 25mm

Holetype : STD Holetypeongusset : STD np: Numberofrowsofboltslongitudinally: 2 nc: Numberoflinesofboltstransversely: 1 sp: Longitudinalboltspacing: 70mm ae1: Longitudinaldistancetoedge: 45mm ae3: Transversedistancetoedge: 45mm Material : E250A t: Thickness: 5mm Setback : 20mm Weld : E49 Weldsize : 5mm Weldlength : 100mm Weldclearance: 5mm

Gusset to Column connection

General Connectiontypetocolumn:Directlywelded Directlywelded Weldingelectrode : E49 Weldsize : 6 mm

Members

Column Section : Taper_2 Material : STEEL_275_NMM2

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Longitudinaloffset : 0mm

Transversaloffset : 0mm

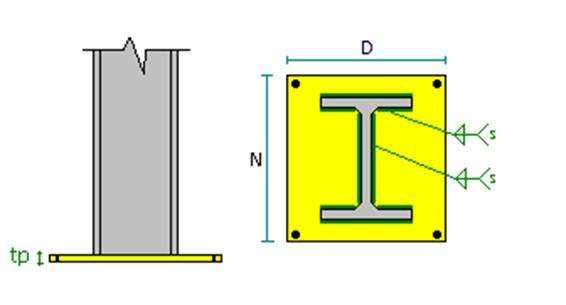

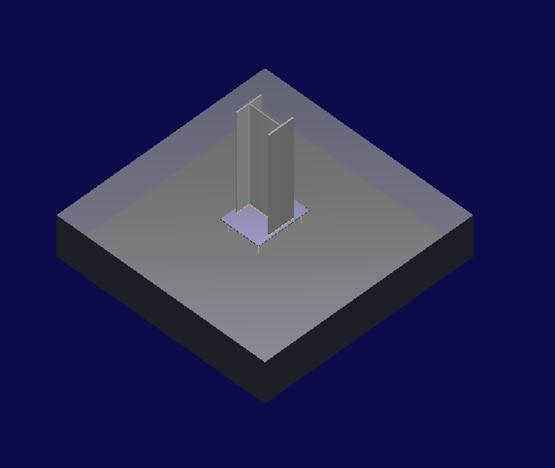

Baseplate

Connectiontype : Unstiffened Positiononthesupport: Center

N:Depth : 460mm

D:Grosswidth : 610mm tp:Thickness: 6mm Material : E250A

Columnweld: E41

s:Columnweldsize : 3mm

OverrideA1/A2ratio : No Shearkeytype : None

Withpedestal : No

Longitudinaldimension : 2500mm

Transversaldimension : 2500mm Thickness : 500mm Material : M40

Includegrouting : No Cover : 70mm Anchor

Anchorposition : Transversalposition Rowsnumberperside : 1 Anchorsperrow : 2

Longitudinaledgedistanceontheplate: 50mm Transverseedgedistanceontheplate : 50mm Headtype : Hexagonal Includelocknut : No Anchor : M 8

Effectiveembedmentdepth : 150mm

Totallength : 166.56mm

Material : Class8.8

Fy : 640N/mm2

Fu : 800N/mm2

SplittingFailure : No

Crackedconcrete : No Non ductilesteel : No

Fastenersweldedtobaseplate: No Leverarm : No

Tensionreinforcement: No Shearreinforcement : No

Fig11 Baseplateconnection

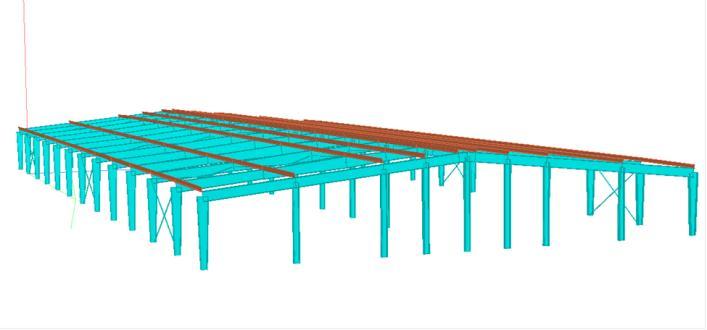

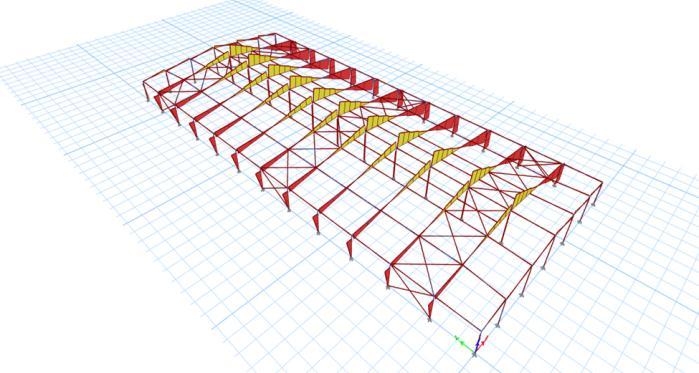

Fig12 RenderviewofthePEBstructurebySTAADpro

Fig13 Sheardiagramofthestructure

Weareabletodesignthestructureandconnectionbycodal provision and preliminary data. With the use of Etabs and Staad Pro we designed members of the structures and

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2234

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

connectionwiththehelpofRAMconnectionandIdeaStatica. Thedataofmodelistransferredfromonesoftwaretoother with help of IFC file or plugins. Both the methods for transferringthedataisn’tcompletelysuccessfulinourcase and some of the members need to redesign for further designing

Thestructureisprefabricatedanditisonlyassembledonthe site. The structure is pre planned according to the site conditions, wind conditions, earthquake forces, MEP loads andtemperaturestresses.Oncetheplanningofstructureis completed, the member is fabricated in the factory and assembledonthesiterequiringlessertimeandfewerman power.AccuracyThememberandconnectionaredesigned specifically for each node and use of Ram connection and Ideastaticaconnectioncandesignedtheconnectiontohighest accuracy. The software designed file can be shared with various software using plugin. The file shared contain designeddatafromparentsoftwarewhichcannowintegrate withotherdataonothersoftwarelikeRevittocreatehighly accurate 3d Model. Low wastage the PEBs structure after designing is fabricated in a factory part by part and only requisiteamountofmaterialiscutfrombiggersheetofrolls toformafabricatedmemberofaPEBandthescrapsfromthe sheetscanbecollectedforrecycling.

Thestructureisprefabricatedanditisonlyassembled onthesite.

[2] T.Subramani and K.Murali (2018) Analytical Study of Tall Building with Outtrigger System with Respect to SeismicandWindAnalysisUsingETABS

[3] Guangfeng Wang (2014) Research on ETABS Steel ToweraTopBuildingStructuralSystem

[4] K. Surender Kumar, N.Lingeshwaran, Syed Hamim Jeelani (2020) Analysis of residential building with STAAD.Pro&ETABS

[5] YongheWua,JianchunMub,ShengqiangLicandHuifeng Xi(2011)DynamicResponseAnalysisonSteel Concrete CompositeFrameBasedonETABS

[6] YongweiSHAN,PaulGOODRUM,CarlHAAS,andCarlos CALDAS(2012)AssessingProductivityImprovementof Quick Connection Systems in the Steel Construction IndustryUsingBuildingInformationModeling(BIM)

[7] NitinK.Dewani,SanjayBhadke(2018)STUDYOFPRE ENGINEEREDBUILDING,IRJET

[8] Mr. Vaibhav Thorat, Mr. Samyak Parekar 2022 Pre Engineering Building as a Modern Era: A Review, IJRASET

[9] Mitaali Jayant Gilbile, S. S. Mane (2020) A Review on Comparative Study on the Structural Analysis and Design of Pre Engineered Building [PEB] with ConventionalSteelBuilding[CSB],IJERT

The structure is pre planned according to the site conditions, wind conditions, earthquake forces, MEP loadsandtemperaturestresses.

Once the planning of structure is completed, the memberisfabricatedinthefactoryandassembledon thesiterequiringlessertimeandfewermanpower.

[10] Angela Acree Guggemos,A.M.ASCE; andArpad Horvath,A.M.ASCE (2005) Comparison of Environmental Effects of Steel and Concrete Framed Buildings

Accuracy The member and connection are designed specifically for each node and use of Ram connection andIdeastaticaconnectioncandesignedtheconnection tohighestaccuracy.

Thesoftwaredesignedfilecanbesharedwithvarious softwareusingplugin.

The file shared contain designed data from parent software which can now integrate with other data on other software like Revit to create highly accurate 3d Model.

[1] Geeta Mehta,BidhanSharmaandAnujKumar,(2016) Optimization of Member Size and Materials for MultistoriedRCCBuildingsusingETABS

MohdAamir,M.Tech,Department ofCivilEngineering,Ganga InstituteofTechnologyand Management,JhajjarHaryana, (INDIA)

Email.Id: aamir.ahmed433@gmail.com

Ravinder,AssistantProfessor, DepartmentofCivilEngineering, GangaInstituteofTechnology andManagement,Jhajjar Haryana,(INIA)

Email.Id: ravinderpanwar7043@gmail.com

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

SheelaMalik,AssistantProfessor, DepartmentDofCivil Enginnering,GangaInstituteof TechnologyandManagement, JhajjarHaryana,(INDIA) Email.Id: sheelamalik2209@gmail.com

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |