International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Kumar1, Sucharu Sharma2

1 M.Tech. Scholar, Department of Civil Engineering. SSCET, Badhani, Pathankot, Punjab, India. 2Assistant Professor, Department of Civil Engineering. SSCET, Badhani ,Pathankot, Punjab, India. ***

Abstract The Construction Industry's key materials are mortar and concrete mix in which Cement acts as binder. In cement production, CO2 gas is eminently evolved as a by product, which adversely affects our environment. Waste materials can be used in the manufacture of concrete mix to minimize negative consequences and natural resource utilization. In Present Study, Various strength properties of concrete mix are evaluated with the effects of partially replacing the Cement and Coarse aggregates with Ground Granulated Blast Furnace Slag (GGBFS) and Ceramic Waste Tiles (CWT), respectively along with Jute Fiber (JF) inaddition to mix. Various Strength Properties such as Slump values, Compressive Strength, Split Tensile Strength and Flexural strength are thus evaluated in this study with the percentage variations of materials used as GGBFS constantly replacedthe cement content by 40%, Ceramic Waste Tiles as 0%,15%,20% and 25% replaced the Coarse aggregates along with Jute Fiber as 0.1%,0.2% and 0.3% All specimens were cured for 7days, 14 days and 28 days before testing. From the study it has been observed that the results shows optimum proportion for M30 grade concrete is GGBFS as 40%, Ceramic Waste Tiles (CWT) as 20% and Jute Fiber (JF) as 0.3%. The Test results of this study are within acceptable limits.

Key Words: Jute Fiber, Ground Granulated Blast Furnace Slag (GGBFS), Ceramic Waste Tiles (CWT), Mechanical Properties, Concrete.

The Construction Industry makes extensive use of mortar and concrete mix. Concrete is largely used human made material that ranks almost after water as most consumed materialofaboutsixbilliontoneseveryyear.Itisahardened masswhichispreparedbymixingappropriateproportionof cement, fine aggregates, coarse Aggregates, water and admixtures. The concrete cost is corresponds to its ingredientscostwhichisscarceandexpensive,andleading to usage of economically alternative materials in its production. This requirement is drawn the attention of investigatorsandexplorenewreplacementsofIngredients. The major problem is that the original conventional materials are depleted and our research for alternate materials results the usage of Ground Granulated Blast FurnaceSlag(GGBFS),CeramicWasteTilesandJuteFiber. Beingaby productandwasteusingiteffectivelyuptosome

extentservesasastepforagreenenvironmentandatthe sametimekeepinginmindthatthestrengthoftheconcrete can’tbedegradebytheusageofGGBFS.TheCeramicWaste Tilesarenotrecycled;howevertheceramicwastetilesare durable,hardandhighlyresistanttodegradationforcesso, weselectedthesewastetilesasareplacementmaterialto thenaturalaggregatetoreusethemandtoreducethesolid wasteproductionfromconstructiondemolition.JuteFiber hasbeen recognized; the addition of closely spaced and uniformlydistributedFibersinconcretewouldactascrack arresterandwouldsubstantiallyimprovestaticanddynamic properties Thus,thecurrentstudywillfocusontheeffectof Ground Granulated Blast Furnace Slag (GGBFS), Ceramic Waste wall and floor tiles as aggregate with Jute fiber in additiontoconcretemix

Veeresh Karikatti et.al (2016) thepresentreportsurveys the research carried out on Geo Polymer Concrete (GPC) withflyash(FA)andGroundGranulatedBlastFunaceSlag (GGBS)forambientconditions.Thereviewalsoincludesthe workthathasbeencarriedout,todate,accountingforthe effectsofvariousingredients,ratiosandstructuralaspects on the behaviour of geopolymer concrete and present applicationsinconstructionindustry.

R. Nagesh Kumar et.al.(2018) presents the strength properties of M30 grade concrete mix with alternate materialsforPortlandCementandCoarseaggregateasGGBS and Broken tiles. Portland cement is replaced GGBS, and coarseaggregateisreplacedwithbrokentilesas10%,20%, 30%,40%and50%proportioningratios.Theinfluenceof mineraladmixtureandinertaggregateontheworkability, compressive strength, split tensile strength and flexural strengths of SCC is examined for M30 grade SCC. The test resultsshowsthattheoptimumproportionforthisgradeis foundat30%andarewithinacceptablelimits.

S.M. Leela Bharathi et.al.(2019) worked on the flexural behaviourofNaturalFiberReinforcedconcretewithpartial replacement of Flyash and GGBFS. It is noticed that Jute Fiber Reinforced Cement Concrete (JFRCC) mix with 30% GGBFShasmaximumcompressivestrengthwhichis8.8% higherthannormalconcreteand15.8%higherthanJFRCC with30%Flyash.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Pramodini Sahu et al. (2020) proposedastudyoneffectof JuteFiberorientationandpercentageonstrengthofJFRCC. In this research, the experiments related to Jute Fiber reinforced concrete are done by taking different Fiber percentage and the compressive strength and modulus of rupturevalueobserved

Madhurima Dass et.al.(2020) concludedthattheindustrial wasteGGBFSwillbeutilizedtopartiallyreplacethecement content in the concrete mix. Cement was supplanted by GGBFS within range of 0 to 40% cement weight for M30 grade mix. Fresh concrete properties like workability and hardconcretepropertieslikecompressivestrength,tensile strengthandflexuralstrengthwascalculatedfor7,28and56 days results average compressive strength and flexural strengthby40%GGBFSsubstitutionasCement.

WateravailableinthelaboratorywithpHvalueof7.0and confirming the requirements of IS 456 2000 is used for making concrete mix and curing the specimens as well. Waterisanimportantingredientofconcreteasitactively participatesinchemicalreactionwithcement.

TheordinaryPortlandCement(OPC43grade)confirmingto IS 12269 1987. The physical properties of the cement are testedinaccordancewithIS:4031 1988andaresatisfied.

Fine aggregate should pass through I.S sieve 4.75 mm. Standardfineaggregatesandistobeusedfromthenearby riverandtheclassificationofsandaccordingtoIS383 2016 codeconfirmsthezone 2.

Outoftotalaggregates,theaggregatesthatareretainedon 4.75mm sieve are termed as coarse aggregates. The local availablecoarseaggregates(naturalstoneAggregates)are usedinthepresentwork.Thecoarseaggregateswithsizeof 20mmwillbeusedinthispresentwork.

Granulated Blast Furnace Slag is produced from blast furnaceslag,theironsteelcompany.Thegranulatedslagis ground to desired fineness for producing GGBFS. The chemical composition of GGBFS contributes to the productionofsuperiorcement.

Figure 3.1 Ground Granulated Blast Furnace Slag (GGBFS)

Table 3.1: Chemical Properties of GGBFS

Chemical components %age of chemical components

SiO2 33.6942

CaO 21.9869 Fe2O3 23.7346 Al2O3 8.6925

JuteFibersareofsilkytexture,thesearebio degradableand eco friendly.ThecommonstructuralpropertiesoftheJute Fibersarehavinghightensilestrengthandlowextensibility. InthepresentstudyrawjuteFiberscuttoalengthof10mm are used. The content of Jute Fibers is determined with respecttotheweightofcement.

Figure 3.2: Jute Fiber (JF)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Brokentileswillbecollectedfromthesolidwasteofceramic manufacturing unit and from demolished building sites. Ceramic Waste can be used in concrete to improve its strengthanddurabilityfactors.Inthisstudy,itcanbeused toreplacethecoarseaggregates

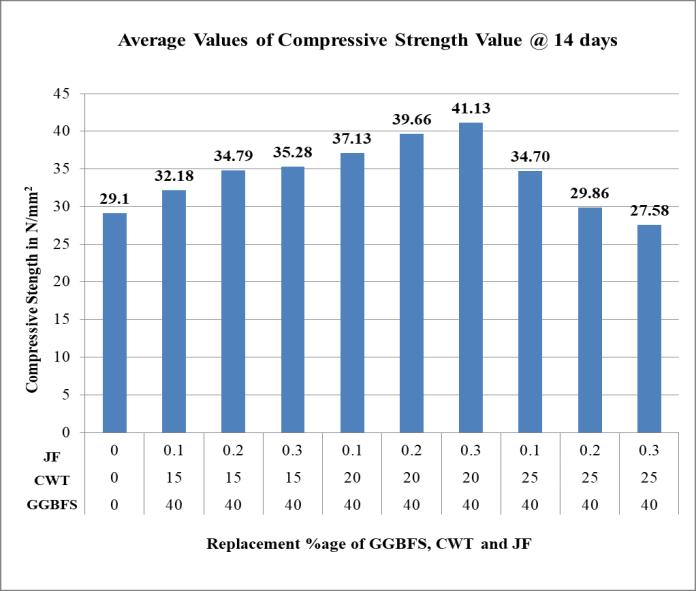

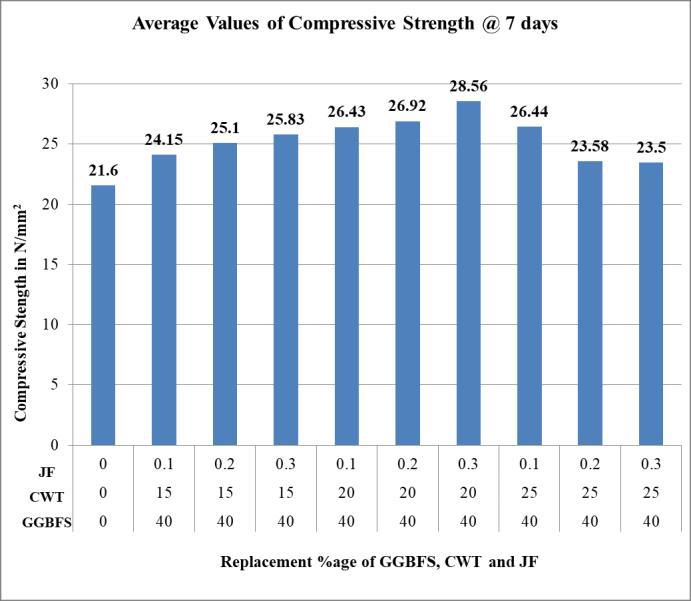

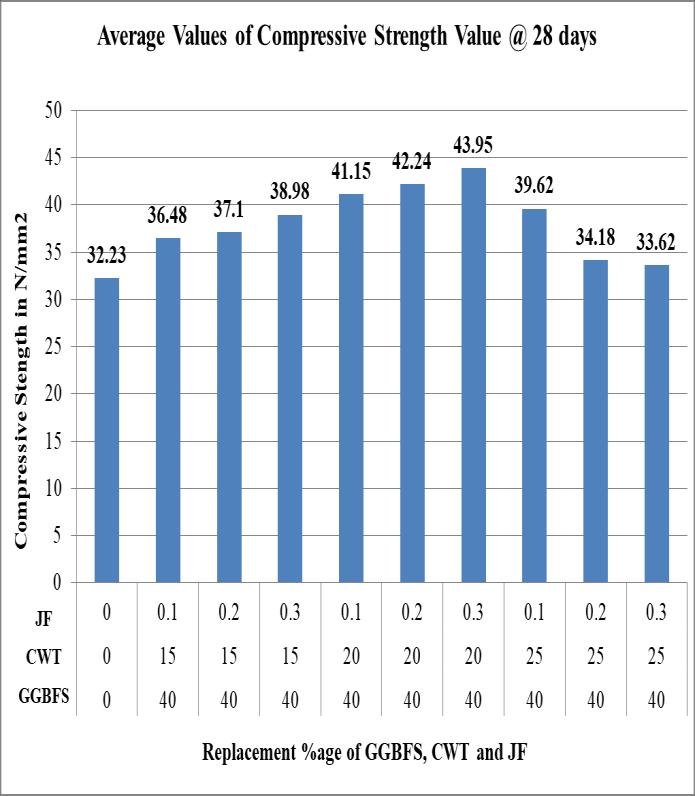

TheCompressiveStrengthTestiscarriedoutbytestingof cubesofsizes(150x150x150)mmfor7days,14daysand 28 days. The highest compressive strength of cubes is achieved with 40% of Ground Granulated Blast Furnace Slag(GGBFS),20%ofCeramicWasteTiles(CWT)and0.3% of Jute Fiber (JF). The graphical representation of compressivestrengthofcubesfor7days,14daysand28 daysareshowninfigure4.2,figure4.3andfigure4.4

Figure 3.3: Ceramic Waste Tiles (CWT)

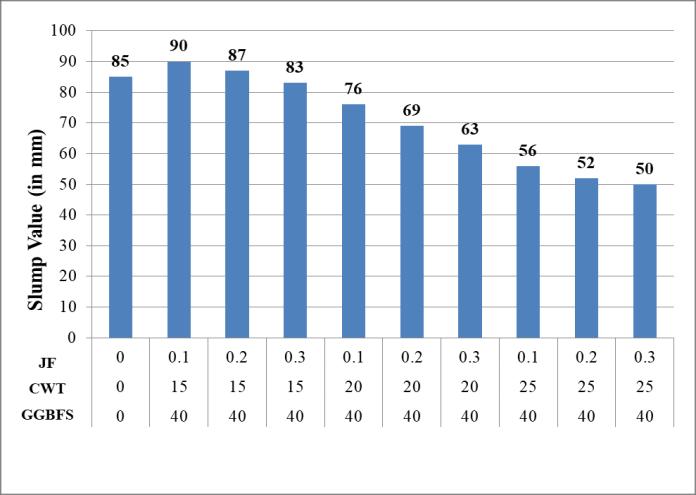

The Slump Cone test is performed to determine the workability in terms of consistency of the concretemix of M30gradeonvarioussamples.Workabilityistheabilityof concrete to be easily mixed, transported, placed and compacted The Slump of 85 mm initially are noticed on conventionalmixandthemaximumslumpofabout90mmis noticeable at combination of 40% GGBFS, 15% CWT and 0.1%JF.ItsgraphicalrepresentationisshowninFigure4.1.

Figure 4.2: Compressive Strength of Concrete Mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 7 days of curing.

Figure 4.1: Slump Values of Concrete Mixe Using GGBFS, Ceramic Waste Tiles and Jute Fiber.

Figure 4.3: Compressive Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 14 days of curing.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Figure 4.4: Compressive Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 28 days of curing.

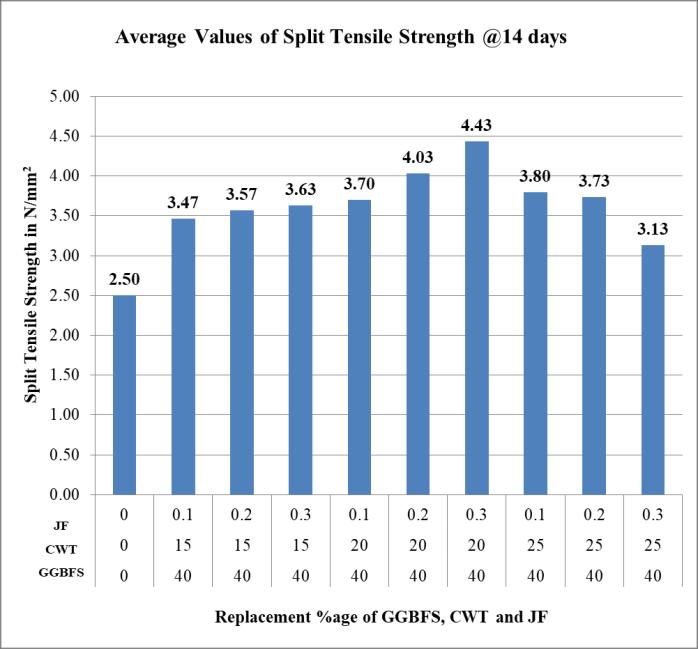

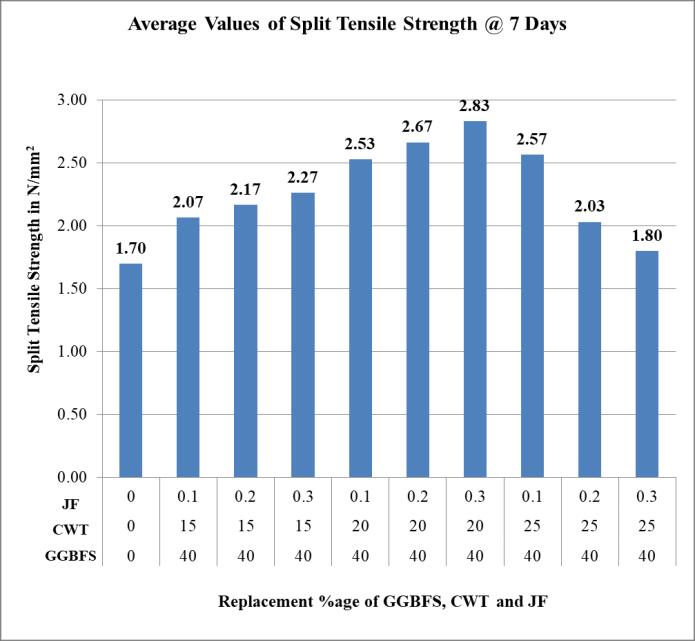

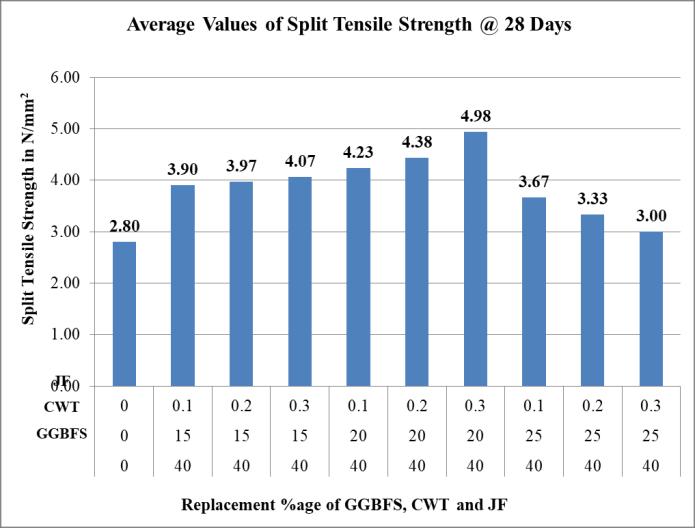

SplitTensileStrengthofCylindersincreasesgraduallyand attainedmaximumstrengthvaluesatthecombinationof 40%GGBFS,20%CeramicWasteTilesand0.3%JuteFiber intheconcretemix ThegraphicalrepresentationofSplit Tensile strength of cylinders for 7 days, 14 days and 28 daysareshowninfigure4.5,figure4.6andfigure4.7

Figure 4.6: Split Tensile Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 14 days of curing.

Figure 4.5: Split Tensile Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 7 days of curing

Figure 4.7: Split Tensile Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 28 days of curing.

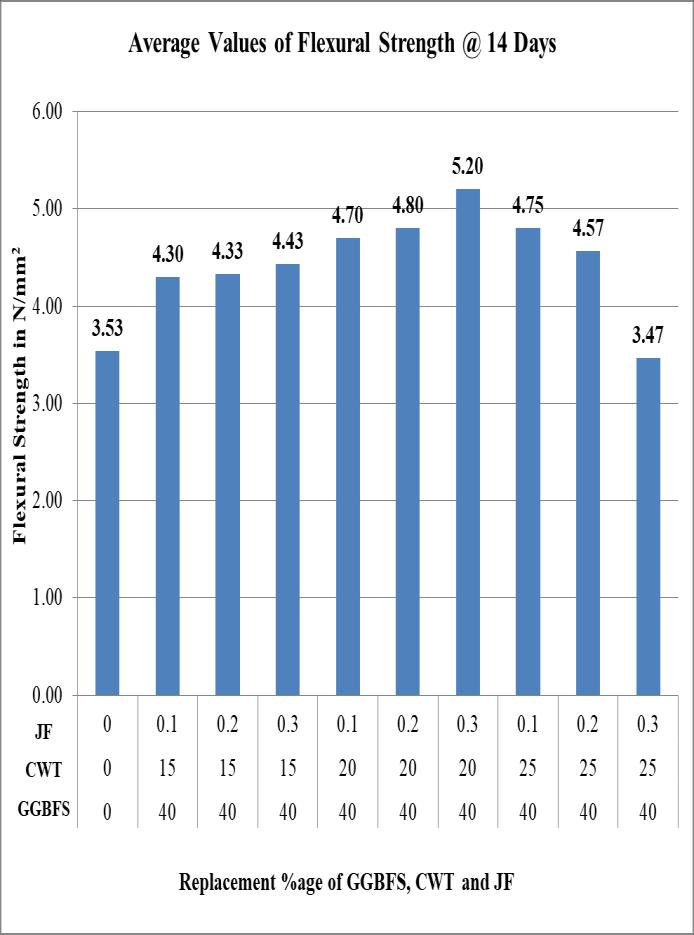

Flexural Strength or Ultimate Moment (Strength) for reinforcedbeamsisdefinedasthemomentthatexistsjust prior to the failure of the beam. The maximum flexural strength of beams is achieved at the percentage of 40% GGBFS, 20% CWT and 0.3% Jute Fiber. The graphical representationofFlexuralStrengthofbeamsfor7days,14 days and 28 days are shown in figure 48, figure 49 and figure410

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Figure 4.8: Flexural Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 7 days of curing.

Figure 4.10: Flexural Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 28 days of curing.

Presentstudyconcludesthefollowing:

1. TheCompressiveStrengthofConcretemixafter7days, 14daysand28daysofcuringincreasesgraduallyby replacement of cement and coarse aggregates with GGBFS and Ceramic Waste Tiles, respectively along with addition of Jute Fiber becomes maximum as 28.56N/mm2,41.13N/mm2 and43.95N/mm2 when GGBFSis40%,CWTis20%andJuteFiberis0.3%.

2. The Split Tensile Strength of concrete mix achieves maximumvalueof2.83N/mm2,4.43N/mm2and4.98 N/mm2 when GGBFS is 40%, CWT is 20% and Jute Fiberis0.3%.isaddedtoconcretemixafter7,14and 28daysofcuring,respectively.

3. The Ultimate Flexural Strength observed maximum with40%GGBFS,20%CWTand0.3%ofJuteFiberi,e. 4.20N/mm2,5.20N/mm2and5.88N/mm2ofmixafter curingof 7days,14daysand28days,respectively.

Figure 4.9: Flexural Strength of Concrete mix using GGBFS, Ceramic Waste Tiles and Jute Fiber after 14 days of curing.

4. Concrete mix G40C20J0.3 can be used as structural concrete without compromising its strength properties as it is the optimum mix in terms of strengthandeconomy.

5. The Slump value increases 85 mm to 90 mm due to additionofGGBFSat40%.MaximumSlumpof90mm was observed at G40C15J0.1 Combination in concrete mix.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1. KimmiGarg(2016)Analysisofstrengthcharactersticof GGBFSconcrete,InternationalJournalofLatestResearch inScienceandTechnology.

2. N.NaveenPrasad(2016)PartialReplacementofCoarse aggregatebyCrushedTilesandFineaggregatebyGranite Powder to improve the Concrete Properties in IOSR JournalofMechanicalandCivilEngineering(IOSR JMCE).

3. Mohammad Zakaria et.al. (2016) “Scope of using jute fiberforthereinforcementofconcretematerial”Zakaria etal.TextilesandClothingSustainability(2016)2:11DOI 10.1186/s40689 016 0022 5.

4. QianJueshiet.al.,"Highperformancecementingmaterials fromindustrialslags areviewResources" Conservation and Recycling 29,1June2017,195 207

5. Ganesh Babu, K et.al "Efficiency of GGBFS in concrete Cement.Concrete"Res.,2017,1031 1036.

6. M.N. Soutsos et al, "Fast track construction with high strengthconcretemixescontainingGroundGranulated Blast Furnace Slag", International Journal of Civil Engineering and Technology,255 263.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal