International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

2

1Student, Dept. Of Civil Engineering, Rajarambapu Institute of Technology, Maharashtra India. 2Professor, Dept. Of Civil Engineering, Rajarambapu Institute of Technology, Maharashtra India. ***

Abstract For the Indian Financial development the sugar industries performs the essential role. Sugar industry play a significant role in India's economicdevelopment.However,the wastewater generated by these enterprises is very polluted. For every tons of sugar cane crushed in India, around 1,000 litres of effluent are produced. It causes pollution if sugar industry waste water is dumped without treatment, it cause pollution. Both aquatic and terrestrial ecosystems are impacted. The wastewater from the sugar industry is examined in this article. Sources of generation, features, and recent advances in the aerobic, anaerobic, and physico chemical treatment technologies. The reuse of treated wastewater was also looked at. The majority of the study Anaerobic treatment was used to treat wastewater from the sugar industry processes. On the otherhand,oilandgreaseare to decompose via anaerobic processes. Anaerobic processes destroy nutrients to some extent, whereas aerobic processes burn more energy. Organics can be entirely removed using anaerobic aerobicmixedsystems.Unfortunately,therearefew studies on anaerobic aerobic combination systems accessible, and further research is needed in this area.

Key Words: Effluent Treatment Plant, Sugar Industry, Wastewater, Aerobic / Anaerobic treatment, Physicochemical properties.

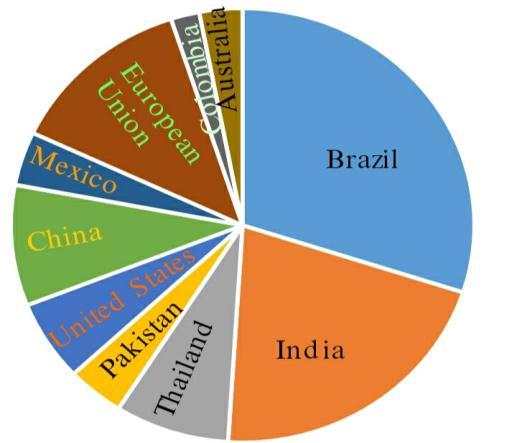

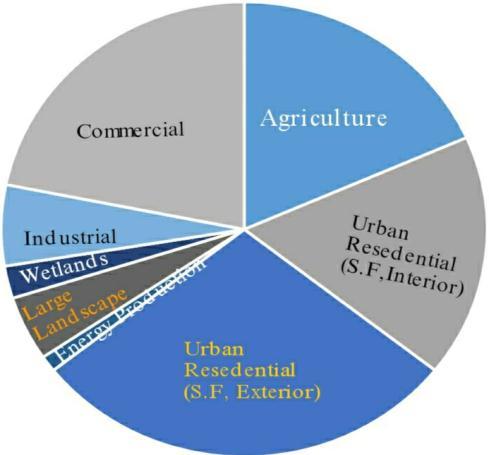

Indiaistheworld'slargestsugarconsumerandsecond largest sugar producer. The sugar industry landscape in Indiaisdepictedbytheriseofsugarfactoriesandthesugar industries (figure 1)[3].Amongst many agro based industries,thesugarindustryisthemostcommonindustry inover130countries,particularlyindevelopingcountries. At present, this industry contributes significantly to economic development and is the main source of job creation in many developing countries in Asia, Africa and SouthAmerica.Theindustryisinvolvedintheprocessingof sugarcanetoproducerawsugarfrommorethan70%ofthe world'ssugarcaneproduction[1].Around85%(688BCM)of wateruseisdivertedforirrigation(Figure1),whichcould increase to 1072 BCM by 2050.The primary source of irrigationisundergroundwater.Waterconsumptioncanbe the amount of water used in a household or country [2].India'sfarmingindustryhas43%ofIndia'sgeographic

region,andcontributes16.1%ofIndia'sGDP. Agriculture continuestomakeasignificantcontributiontoIndia'sGDP despiteitsfallingshareofGDP[4].

Fig1.SugarcaneWorldwideDistribution[3].

The cane growing areas have expanded to 5,086,000 hectaresin2011 12,upfrom5,055,000hectaresin2007 08. Anadditional516industrieswereactivein2007 2008.In 2011 12, this number has risen to 529, producing 26.0 milliontonnesofsugar[5].Asaresult,thequantityofwaste waterproducedbytheseindustrieshasalsoincreased.

Sugarfactoryproducebothsugarandalotofeffluent. They produce one cubic metre of effluent per tonne of crushed cane, on average. The discharge of effluent from sugar mills into surface water bodies with high TDS has a negativeimpactonaquaticlife.Duringthesugarproducing period in November April, the irrigation water for the majorityoftheRabicropgotunsuitablewatersurrounding thesugar mill locations.The terribleimpactsofuntreated sugarindustryeffluentsalsodamagehumanlife[9].Waste water in the sugar industries is characterised by high biologicaloxygendemand(BOD),chemicaloxygendemand (COD) and total dissolved solids. The carbohydrates, nutrients, oil and grease, chlorides, sulphates and heavy metalsarepresentinthesugarwastewater[6 8].

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Fig.2.Sugarcaneworldwidedistribution[4].

Furthermore, in order to safeguard the environment, the Indiangovernmentimplementedhighlyrigorousnormsand regulationsregardingeffluentdisposal(Table1).Toachieve the effluent discharge regulations, appropriate treatment technologiesarenecessary.

Table1.Standardslimitssuggestedfordischargeofeffluents fromthesugarindustry

Parameter Maximumvaluemg/l World Bank Guidelines CPCBIndia

pH 6 9 6.5 8.5 BOD5 30 for disposal in surfacewater 100fordisposalon land COD 150 250 250 TSS 50 1000 OilandGrease 10 10

Therefore,goalofthisstudywastoreviewtheliteratureon the sugarcane industrial process, including water consumption rates, effluent characteristics, and environmentalconsequences.Thereportalsoassessesthe mostprevalentwastewatertreatmenteffortsmadetoreduce theenvironmentalimpactofeffluent.

The sugar production process in the cane factory includes juice extraction, clarification, evaporation, crystallisation,andcentrifugaloperations. Hence,Wateris usedforcleaningpurposesinvarioussectionsofthesugar industry,resultinginwastewater.Therearenosingleunits

that generate wastewater, but wastewater is produced primarily by washing on the milling house floor, boiling house units such as evaporators, clarifers, vacuum pans, centrifugation,andsoon.Additionally,periodiccleaningof lime water and SO2 producing houses, as well as periodic descalingofheatexchangersandevaporatorsusingNaOH, Na2CO3, and HCl for heater descaling and neutralisation, contributetothemassivevolumeofwastewater[11].Sugar industry wastewater contains wash water with lost cane juicefromvariousoperations,detergents,bagasseparticles, lubricantoilandgrease,andlostsugarsolidsinprocess.Itis distinguishedbyhighnutrientconcentrations,organicand inorganiccontent[12].Millhouseandprocesshousearethe two primary portions of wastewater generated in a sugar production, respectively. The mill house wastewater is primarily contaminated with oil and grease as well as suspendedsolids,whereastheprocesshousewastewateris contaminatedwithhighorganicmattersuchasCOD,BOD5, and pH [13].Due to the complicated nature of the wastes generated and the limited technology to remove all contaminants at once, inappropriate management of industrial wastewater is one of the most serious environmental concerns facing emerging countries. Sugar factoriesmakecontributionsdrasticallytowaterandland pollutants via way of means of discharging tremendous quantities of wastewater as effluent, which incorporates excessive ranges of solids, BOD5, COD, chloride, sulphate, nitrate,calcium,andmagnesium.

ItcanbeobservedthatthereissignificantvariationinCOD (11012,211.44mg/L)andBOD(605,103mg/L).Mostofthe COD loading to wastewater is owing to the lost cane juice andsugarsolids.ThepHandtotalsolids(TS)concentration variesintheextentof4.510and6,06262mg/L,respectively [23];andconsiderableamountofnutrients,1540mg/Lof totalKjeldahlnitrogen(TKN)[17]and1.312mg/Loftotal phosphorous are also observed in sugar industry wastewater.Exceptthis,extremelyhighquantityofchlorides (483,195 mg/L), ca (CaCO3), SO4 + , Na+ , K+ , and heavy metals(Zn2+,Ni2+,Cu2+,Mn2+,Pb2+,Cd2+,Cr3+,andFe2+) [20]havealsobeendescribedinliterature.

Toreducetheamountofsuspendedsolids(SS)insugar industry wastewater, screening, grit removal, flow equalisation, sedimentation, or dissolved air flotation are used. For the reduction of soluble organic matter and disinfection, biological treatment methods are used [16].Aerobic and Anaerobic processes are included in biologicaltreatment.Physico chemicalmethods,inaddition to biological methods, are used for sugar industry wastewatertreatment.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Because sugar industry wastewater contains mostly sugars and volatile fatty acids, both of which are easily biodegradable, all biological (anaerobic and aerobic) treatmentprocessesareappropriate[16].

The anaerobic treatment process for concentrated wastewaterforpollutants(e.g.wastewaterfromthesugar industry)isaprocesswidelyused inindustry.Ithasseveral advantages over aerobic methods, including lower energy requirements; the production of methane due to the decompositionoforganicmatter,whichisasourceofenergy; and lower sludge production, which indirectly greatly reduces sludge disposal costs [24 26].The anaerobic treatment process for concentrated wastewater for pollutants (e.g. wastewater from the sugar industry) is a processwidelyused inindustry.Ithasseveraladvantages overaerobicmethods,includinglowerenergyrequirements; the production of methane due to the decomposition of organic matter, which is a source of energy; and lower sludgeproduction,whichindirectlygreatlyreducessludge disposal costs [24 26].With Sanchez Hernandez Travieso CordobaAFRfortreatingwastewaterfromdifferentsugar factoriesHydraulicdwelltime(HRT)(0.5,1.0,2.0and4.0d).

ItturnsoutthattheincreaseinHRTincreasesRemovalof organic matter and more than 90% COD Removal was foundonHRTonthe4th[21].Most sugarindustriesdoOnly solid matter separation pretreatment by clarification / clarification Dissolution flotation system [16] Doke et al. reportedthatplantgrowth andcropyieldwerereducedand soilhealthwasaffectedifirrigatedwithwastewatertreated withthismethodTherefore,completeremovalofpollutants is necessary[22].Nachevaetal investigatedandevaluated themesophilicUASBreactorforthetreatmentofpreviously treated sugar cane mill wastewater in this regard. They reported more than 90% COD removal at organic loading rates(OLR)ofupto16kgCOD/m3dwhileproducingalotof biogas.Finally,theyconcludedthatdischargestandardsfor COD concentration can be found if the UASB reactor is operatedatalowerOLRof 4kgCOD/m3d;however,ata higher OLR, an additional biological treatment stage is required [16] .The efficiency of anaerobic digestion is affectedbywastecharacteristics,reactorconfigurations,and operational parameters [18].Co digestion is one of the alternativesusedtoimprovetheanaerobicdegradationof wastes with different characteristics if the waste characteristicsareunsuitableforanaerobictreatment.

In general, aerobic biological treatment involves the degradationoforganicsinthepresenceofoxygen.Activated sludge,tricklingfilters,aeratedlagoons,oracombinationof these are used in conventional aerobic treatment [19].Wastewaterfromthesugarindustry,withtheexception

of fats and oils, is biodegradable and is not easily decomposedbyanaerobicprocesses[27].Theoilproduces long chain fatty acid during the hydrolysis step, causing a delayinmethanogenesis[28].Long chainfattyacidshave beenshowntobe inhibitorsofmethanogens[29].

AhmadandMahmoud[30]ledtestsinclusterreactorto show whether the oxygen consuming treatment for sugar industrywastewaterisadequate.Itwasaccountedforthat the oxygen consuming biodegradation of wastewater is pleasing.ItwasadditionallyrevealedthattheCODdecrease canbeanticipatedatgivenboundarieswiththeassistanceof relationship recommended by Tucek et al. [33].To investigate the contamination of stream because of this movement, Moses' et al [inspected the examples for temperature,pH,Body,COD,TDS,andTSSandreasonedthat the qualities were well above than release limits characterizedbyNEMAandtheWorldWellbeingAssociation (WHO) [34] . Hamoda and Al Sharekh inspected the exhibition of a system,aerated submergedd fixed film (ASFF), in which bio film was connected on lowered fired tileswithdiffusedaircirculationcondition.Itwasreasoned thattheASFFcycleisequippedfortakingcareofextreme natural loadings of 5 120 g Body/m2 d with minute lesseningfrom97.9to88.5%inBodyexpulsionproficiency and from 73.6 to 67.8% in COD evacuation effectiveness. Nitrification rate was additionally diminished however at higherrates[31].

Nothingunlessthereareotheroptionsstudiesshowed totally/almostcompleteorganicsevacuation.Subsequently, an extra organic treatment stage is required. Half breed frameworksofcontaininganaerobicandoxygenconsuming medicines have been supported fit for giving high COD expulsion proficiency with more modest required energy [5,10,14].Yangetal.detailedajoinedanaerobic(UASB)and oxygen consuming (EAFB) treatment framework for emanating from essential treatment of sugarcane plant wastewaterforitsapplicationfordribblewatersystem,and P99%organicsandsolidsevacuationwereaccountedforat HRT of 2 d. This treated wastewater hold better water qualityfordribblewatersystem[21].

Coagulation/flocculation with inorganic coagulants furthermore, adsorption are broadly utilized for the expulsionofsuspended,colloidal,anddisintegratedsolids (DS) from wastewaters. By and large, coagulation/flocculationisutilizedintheessentialfiltration of modern wastewater (now and again as optional and tertiary treatment)[27].In coagulation process, insoluble particlesorpotentiallydisintegratednaturalmaterialstotal tobebigger,andareeliminatedbysedimentation/filtration stages.

Electro compound (EC) treatment process is an arising wastewater treatment innovation. EC treatment strategy

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

includes electro oxidation, electrocoagulation, and electrofloatation.Inelectrooxidation(EO)treatment,natural materials are oxidized to carbon dioxide and water or different oxides by electrochemically created receptive oxygenorpotentiallyoxidizingspecialist.Though,electro coagulation process includes age of anode material hydroxides orpotentiallypolyhydroxideswhicheliminate the organics by coagulation. Electro buoyancy process eliminatestoxinswiththeassistanceoflightgasesbubbles createdduringelectrolysis,whichtakewiththemthepoison materialstotheouterlayeroffluidbody[32].

Only one study of lime coagulation followed by activated carbonadsorptionhasbeenreportedinpublishedliterature .BODandCODremovalefficiencieshavebeenreportedtobe 96%and95%,respectively [12].Inanotherreview,Guvenet al. channeled EC examinations to treat reproduced sugar beetindustrialfacilitywastewater.Theimpactofdifferent functional factorslikeappliedvoltage, electrolytefixation, andsquanderfixationwasreadupforrateCODexpulsion and starting COD evacuation rate. Most elevated COD evacuation and COD introductory expulsion rate were accountedforas86.36%and43.65mg/Lmin,individually, after8hattheappliedvoltageof12V,100percentsquander concentration with 50 g/L NaCl. At upgraded set of interactionfactorsandat100percentsquanderfocus,rate CODevacuationandCODintroductoryexpulsionratewere viewed as 79.66% and 33.69 mg/L min, separately. In EC process,thecathodematerialplaysaverysignificantjobin natureoftreatment[33].

However,anaerobicprocessesarecommonlyused.This for the treatment of wastewater from the sugar industry ProcessislimitedduetotheproductionoflongchainsFatty acid in the hydrolysis of fats and oils. Similarly, Do not completely eliminate the anaerobic process Nutrients / Organics; Therefore, they are treated anaerobically Waste waterneedsfurthertreatment.AerobicSBRPromisingsugar processingtechnologyIndustrialwastewaterduetoaerobic SBRReportedly,itprovidesexcellentremovalefficiencyin thefollowingways:Bothnutrientsandotherorganicmatter. Membrane assistedtreatmentisveryeffectiveWherehigh quality wastewater needs to be produced Reuse. But the wastewaterfromthesugarindustryisheavilypolluted.For DSandSS,thisleadstoalotofmemorypollution.Therefore, from the point of view of good quality manufacturing Treated wastewater for reuse, including hybrid systems .Membraneofaerobic/anaerobictreatmentmethod And/ orphysicochemicalmethodsmaybepromising.

1.PradeepKumarPoddar,OmprakashSahu(2015),"Quality andmanagementofwastewaterinsugarindustry",Springer ,Volume7,461 468.

2. Rakesh Singh Asiwal, Dr. Santosh Kumar Sar, Shweta Singh, Megha Sahu (2016),"Wastewater Treatment by EffluentTreatmentPlants",SSRG IJCE,Volume3,Issue12, 2348 8352.

3.OmprakashSahu,DubasiGovardhanaRao,RichaGopalb, Anurag Tiwari b, Dharm Pal (2017),"Treatment of wastewater from sugarcane process industry by electrochemicalandchemicalprocess:Aluminum(metaland salt)",ScienceDirect,Volume7,50 62.

4. M. Rais , A. Sheoran (2018),"Treatment of Sugarcane Industry Effluents: Science & Technology issues ",IJERA , Volume5,Issue1(Part2),11 19.

5.Availablefrom:http://www.indiansugar.com/Statics.aspx (accessedon22March2013).

6. Mr. Khalid Iqbal, Prof.F.IChavan, Prof.Dr.M.Husain, Prof.Yakub Ansari (2017),"Wastewater Management in a SugarFactory",IJCRT,2320 2882.

7. Jemal Fito,Nurelegne Tefera , Stijn W. H. Van Hulle (2019),"Sugarcanebiorefnerieswastewater:bioremediation technologies for environmental sustainability",Springer , Volume6,Issue6.

8. Aijaz Panhwar,Dr. Khalida FaryalDr. Aftab Kandhro,Kamran Ahmed,Mansoor Iqbal (2020),"Chemical treatmentofsugarcaneindustryeffluent",JCBPS,Volume10 ,Issue2,221 227.

9.M.A.Rahim,M.G.Mostafa(2021),"Impactofsugarmills effluent on environment around mills area",AIMS EnvironmentalScience,Volume8,Issue1,86 99.

10. Thalyne de Almeida Ferreira Rocha,Altair Marques da Silva (2022) ,"Thermal Evaluation of Shell and Tube Heat Exchangers in the Sugar Industry: Case Study", Springer , Volume24,585 592.

11. A.Ingaramo , H Heluane , M Colombo , M Cesca (2009),"Water and Wastewater Eco Efficiency Indicators FortheSugarCaneIndustry",JCP,Volume17,487 95.

12.M.Khan,U.Kalsoom,T.Mahmood,M.Riaz,A.R.Khan (2007),"Characterization and Treatment of Industrial EffluentFromSugarIndustry",JCSP,Volume25,Issue3, 242 247.

13. A.R. Memon , S.S. Ahmed , A.A. Khaliq (2006)," Sugar Industry Effluent Characteristics and Chemical Analysis", JAES,Volume1,156 7.

14. J. Fito , N. Tefera , Van Hulle SWH (2018)," Physicochemical Properties of the Sugar Industry and Ethanol Distillary Wastewater and Their Impact On The Environment",SugarTech.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

15. S. Samuel , Muthukkaruppan SM (2011)," Physicochemical Analysis of Sugar Mill Effluent, Contaminated Soil and it's Effect on Seed Germination of Paddy",IJPBA,Volume2,1469 72.

16. P.M.Nacheva,G.M.Chavez,J.M.Chacon,A.C.Chuil(2009) ,"Treatment Of Cane Sugar Mill Wastewater in an Upflow Anaerobic Sludge Bed Reactor", WST, Volume 60 Issue 5, 1347 1352.

17. U.S. Hampannavar, C.B. Shivayogimath (2010)," AnaerobicTreatmentofSugarIndustryWastewaterbyUASB ReactoratAmbientTemperature,IJEAS,Volume1,Issue4, 631 639.

18. E.Alkaya,G.N.Demirer(2011),"AnaerobicMesophilic Co DigestionofSugar beetProcessingWastewaterandBeet pulpinBatchReactors",RE,Volume36,971 975.

19. F. C Escobar, J. P Marin, P. A Mateos, F.R Guzman, M.M.Barrantes,F.BMateos (2004),"AerobicPurificationof DairyWastewaterinContinuousRegime,PartI:Analysisof theBiodegradationProcessinTwoReactorConfigurations", BEJ,Volume21,183 191.

20. M. Khan, U. Kalsoom, T. Mahmood, M. Riaz, A.R. Khan (2003), " Characterization and Treatment of Industrial Effluent from Sugar Industry ", JCSP , Volume 25, Issue 3, 242 247.

21.E.P.Sanchez,L.Travieso,"AnaerobicTreatmentofSugar Mill Wastewater in Downflow Fixed bed Reactors ", BT , Volume48,179 181.

22. K.M. Doke, E.M. Khan, J. Rapolu, A. Shaikh (2011) ," Physico chemicalAnalysisofSugarIndustryEffluentandIts Effect on Seed Germination of Vigna Angularis, Vigna CylindricalandSorghumCernum",AES,Volume5,7 11.

23.E.Alkaya,G.N.Demirer(2011),"AnaerobicAcidification of Sugar beet Processing Wastes: Effect of Operational Parameters",BB,Volume35,32 39.

24. F.Y. Cakira, M.K. Stenstromb (2005)," Greenhouse Gas Production:AComparisonbetweenAerobicandAnaerobic WastewaterTreatmentTechnology",WR,Volume39,4197 4203.

25A.Wheatley," AnaerobicDigestion:AWasteTreatment Technology",EAS,London.

26. J.P. Kushwaha, V.C. Srivastava, I.D. Mall (2010)," Treatment of Dairy Wastewater by Inorganic Coagulants: ParametricandDisposalStudies",WR,Volume44,Issue20 ,5867 5874.

27. J.P. Kushwaha, V.C. Srivastava, I.D. Mall (2011)," An OverviewofVariousTechnologiesfortheTreatmentofDairy Wastewaters",CRFS,Volume 51,Issue5,442 452.

28.K.Hanaki,T.Matsuo,M.Nagase(1981),"Mechanismof Inhibition caused by Long chain Fatty Acids in Anaerobic DigestionProcess",BB,Volume 23,1591 1610.

29. I. Koster (1987)," Abatement of Long chain Fatty acid Inhibition of Methanogenic by Calcium Addition ", BW , Volume25,51 59.

30. S.Ahmad,T.A.Mahmoud(1982),"Wastewaterfrom a SugarRefiningIndustry",WS,Volume16,345 355.

31M.F.Hamoda,H.A.Al Sharekh(1999),"SugarWastewater Treatment with Aerated Fixed film Biological Systems ", WST,Volume40,313 321.

32.J.P.Kushwaha,V.C.Srivastava,I.D.Mall(2010),"Organics Removal from Dairy Wastewater by Electrochemical TreatmentandResidueDisposal",SPT,Volume76,Issue2, 198 205.

33. G. Guven, A. Perendeci, A. Tanyolac (2009)," ElectrochemicalTreatmentofSimulatedBeetSugarFactory Wastewater",CEJ,Volume151,149 159.

34. A.N. Moses’, N.N. Destaings, N.F. Masinde, J.B. Miima (2011),' Effluent Discharge by Mumias Sugar Company in Kenya:AnEmpiricalInvestigationofthePollutionofRiver Nzoia",SJES,Volume1,Issue1,1 30.

35. Tucek,J.Chudoba,V.Madera(1971),"UnifiedBasisfor Design of Biological Aerobic Treatment Processes ", WR , Volume5,647 680.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal