International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

1

2,3,4,5,6,

Abstract The effect of different brands of OPC 53 grade cement on compressive strength of M25 SCC Mix is not investigated as per the literature. The present investigation finds the effect of different brands of OPC 53 grade cement on compressive strength of M25 SCC Mix. The Nan Su mix design is used. The present work identifies the need to use different mix design for different brand of cement for optimal design. Also establishes the use of Cooper Slag, an an industrial by product which is used in the Madurai Tuticorin industrial corridor project, as mineral admixture to concrete.

Key Words: SelfCompactingConcrete(SCC),GGBS,Copper Slag,DifferentBrandsofOPC53GradeCement,Nan SuMix Design, EFNARCGuidelines,SlumpFlowTest,J RingTest,V FunnelTestandL BoxTest.

Self Compacting Concrete (SCC) is highly flowable, non segregating, fill the formwork and encapsulate the reinforcement without any mechanical consolidation. The fresh properties of SCC can be characterized by the three properties(EFNARC,2002):fillingability,passingabilityand segregation resistance. Additional properties, such as robustnessandconsistenceretention,arealsoimportantin applicationsofSCC.

The effect of different brands of OPC 53 grade cement on compressivestrengthofM25SCCMixisnotinvestigatedas per the literature. Five different brands (Dalmia Cement, PriyaCement,ZuariCement,JSWCement,ChettinadCement) ofOPC53Gradeareconsideredforinvestigation.

***

ThematerialsusedintheSCCare

i. Different brands of OPC (Dalmia Cement, Priya Cement, Zuari Cement, JSW Cement, Chettinad Cement)

ii. GGBS iii. FlyAsh iv. FineAggregate v. CopperSlag vi. CoarseAggregate(12.5mmand20mm) vii. MasterGleniumSky8233(SuperPlasticizer)

Thepropertiesofmaterialsaredeterminedandareshownin Table 1, 2, 3 & 4. Table 5 shows the super plasticizer propertiesasgivenbythemanufacturer.

ThestepsusedinNan SuMixDesignaregivenbelow.

Step 1: Calculation of Coarse and Fine aggregate contents:

=917.70kg/m3 (1) =713.30 kg/m3 (2)

Where,

Wfa:contentoffineaggregatesinSCC(kg/m3), Wca :contentofcoarseaggregatesinSCC(kg/m3), fa:unitvolumeweightoflooselypiledsaturatedsurface dryfineaggregatesinair(kg/m3),=1545.99kg/m3

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Table 1: Properties of Different Brands of Cement

Different Brands Of 53 Grade Cement

Specific Gravity Of Cement

Initial Setting Time

Final Setting Time Standard Consistency Fineness of Cement

DalmiaCement 3004 2hrs36min 6hrs49min 31% 2%

PriyaCement 3.110 2hrs16min 6hrs24min 35% 2%

ZuariCement 3.029 2hrs42min 6hrs39min 33% 3% JSWCement 2.970 2hrs10min 7hrs15min 31% 2%

ChettinadCement 3.004 2hrs38min 7hrs15min 31% 2% Ranges 3.00 3.15 >30min <10hrs <10%

Table 2: Properties of Coarse Aggregate (IS: 383 1970)

Properties Size Standard range 20 mm 12.5 mm 30% of 20 mm & 70% of 12.5 mm

SpecificgravityofCoarseAggregate 2.875 2.84 2.85 2.5 3.0

BulkDensityofCoarseAggregatetightlypacked (Kg/m3) 1554.7 1441.4

BulkDensityofCoarseAggregatelooselypacked (Kg/m3) 1471.9 1305.3 1355.0

Crushingtest 14.07%

a)FlakinessTest 13.85% 33.65% <35%

ShapeTests

b)ElongationTest 24.98% 38.56% <40% ImpactTest 14.05% <35%

Table 3: Properties of Fine Aggregate (IS: 383-1970)

Properties

Property Value Standard range

SpecificGravity 2.6 2.5to3

BulkDensity,(kg/m3)FreelyPoured 1545.99 FinenessModulus 2.60(Zone II) 2.2 2.6(FineSand)

Properties

GGBS Fly Ash Copper Slag

SpecificGravity 2.85 2.24 3.805

BulkDensityofCoarseAggregatetightlypacked(Kg/m3) 2091.995

BulkDensityofCoarseAggregatelooselypacked(Kg/m3) 1912.350 Fineness 6% 26% Consistency 36% 64%

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2077

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Table5:MasterGleniumSky8233(SuperPlasticizer)

Properties Test Results of Manufacturer Catalogue

Appearance ReddishBrownLiquid pHValue >6 Solubility ReadilySolubleInWater RelativeDensity 1.08+0.02at25oC ChlorideContent 0% Solid 50+1%

ca:unitvolumeweightoflooselypiledsaturatedsurface drycoarseaggregatesinair(kg/m3),=1355.054kg/m3 PF:packingfactor,theratioofmassofaggregatesoftightly packedstateinSCC tothat oflooselypackedstateinair,= 1.12(Assumed) :volumeratiooffineaggregates(sand)tototalaggregates, whichrangesfrom50%to57%.=53%(Assumed)

Step 2: Calculation of Cement Content: ) 20( ' Concrete OPC for f C c =229.163kg/m3 (3)

Where, C=Cementcontent(kg/m3); f’c = designed compressive strength (psi). =4583.264 psi (31.6MPaTargetMeanStrengthObtainedfromIS:10262 2019)

Step 3: Calculation of mixing water content required by cement: C C W W wc =96.249kg/m3 (4) Where, Wwc =contentofmixingwatercontentrequiredbycement (kg/m3), =thewater/cementratiobyweight=0.42(Assumed)

Step 4: Calculation of SP dosage DosageofSPusedWsp =n%×WC (5) Where, n%=DosageofSP=0.7%(Assumedandfixedaftertrials) Wc=Cementcontentinkg/m3 AmountofwaterinSPWwsp=(1 m%)Wsp=0.802kg/m3 (6) Where, m%=AmountofbindersanditssolidcontentofSPtakenas 50%

Step 5: Calculation FA and GGBS contents:

Where, w =densityofwater, Gca=specificgravityofcoarseaggregates, Gfa=specificgravityoffineaggregates, Gc =specificgravityofCement, Gw =specificgravityofwater, Va =aircontentinSCC(%).

AsperNansuMixDesigntheformulaforcalculatingWPM is (8)

WhereA%=percentageofFlyAsh(Weightbasis)

B%=percentageofGGBS(Weightbasis)

But,themodifiedformula1 (8.a)forcalculatingWPMisused (8.a)

Where,GG,GFA, areobtainedfromtestsand =0.42and =0.42areassumed, A% =25%andB%=75%are assumedandVPF +VPG obtainedfromEq.(7)

WPM = 264.261kg/m3

WF=A%×WPM =66.065kg/m3 (9) WG=B%×WPM =198.196kg/m3 (10)

Mixingwatercontentrequiredforflyashpasteisobtained fromEq(11)

WWF= ×WF =27.747kg/m3 (11)

MixingwatercontentrequiredforGGBSpasteisobtained fromEq(12)

WWG= ×WG =83.242kg/m3 (12)

Step 6: Calculation of mixing water content needed in SCC:

The mixing water content required by SCC is the total amountofwaterneededforcement,FAandGGBSinthemix. Therefore,itcanbecalculatedfromEq.(14)

Ww =Wwc +WWG +WWF Wwsp =206.436kg/m3 (13)

=0.210m3 (7)

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2078

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

ConcretegradeM25isconsidered,andmixesaredesigned for different brands (Dalmia Cement, Priya Cement, Zuari Cement, JSWCement,ChettinadCement) aspertheabove Nan Su mix design Target mean strength as per IS 10262:2019 is used for the mixes in Eq. 3 in place of f’c ThefineaggregatecontentcalculatedfromEq.1isreplaced with20%ofcopperslag.BasedontrialmixesW/Cratioand SPdosageisfixedsatisfyingEFNARCguidelines.TheSCCmix proportions for different brands of cement are shown in Table6

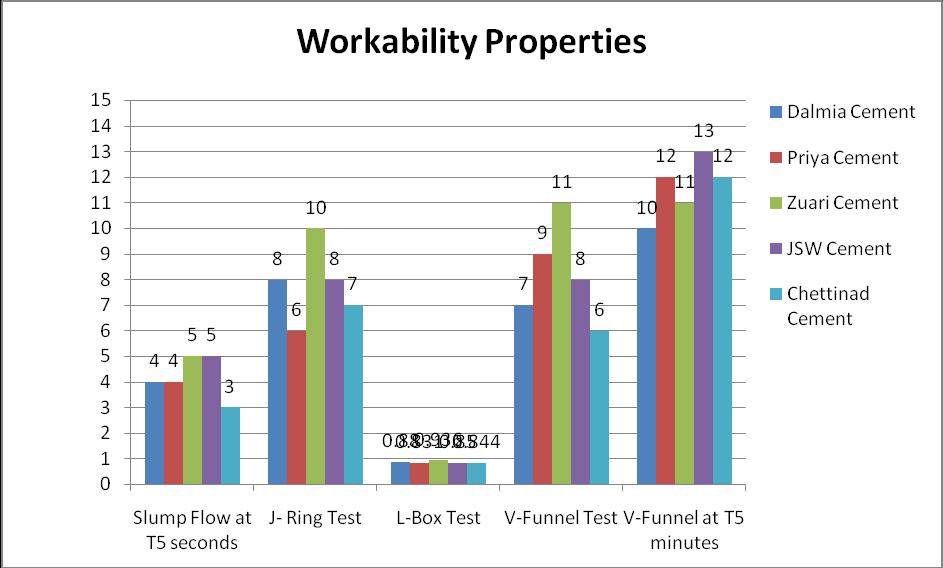

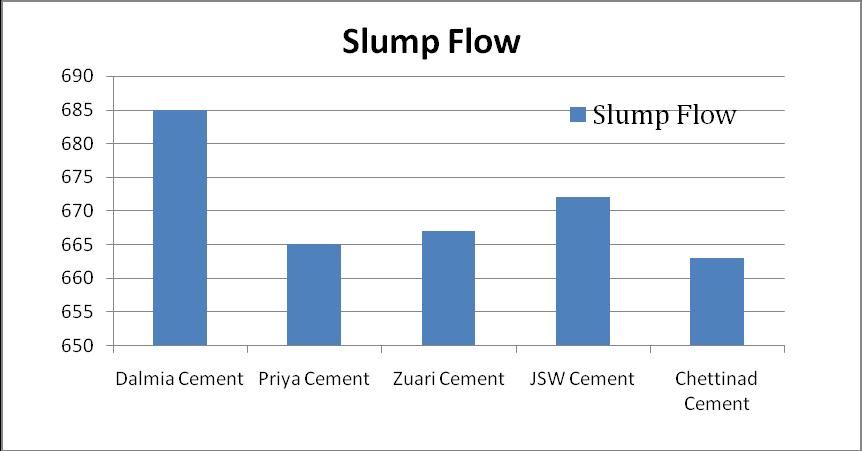

SlumpflowtestandthenJ Ringtestisconductedinorderby using6litresofconcrete.Vfunneltestisconductedbyusing 14 litres of concrete. L Box test is conducted by using 17 litresofconcrete.Freshpropertiesaredeterminedforthe mixes.TheresultsareasshowinTable7andalsoinFig.1& 2.AllthetestresultsareconformingtoEFNARCguidelines forSCC.

S.No Different Brands of OPC

53

Sand (80%)

Grade Cement Water (kg) (as per mix design) Water (kg)(actually added ) Sp content (%) GGBS(kg) 75% of Admixtures Fly Ash(kg) 25% of Admixtures W/p Ratio W/c Ratio Packing factor Cement Content FineAggregate (kg) Coarse Aggregate (kg) Copper Slag (20%)

1 Dalmia Cement 207.28 206.4 0.7 198.1 66.06 0.42 0.42 1.12 229.163 183.54 734.16 713.3 0

2 Priya Cement 208.64 207.8 0.75 200.6 66.88 0.42 3 Zuari Cement 207.63 206.7 0.8 198.7 66.26 0.42 4 JSW Cement 206.83 205.9 0.8 197.3 65.79 0.42 5 Chettinad Cement 207.29 206.1 0.8 198.3 66.11 0.42

Table7:WorkabilityProperties

S.NO DifferentBrandsofOPC 53GradeCements JRingTest (mm) L Box Test V Funnel Test(sec) T50 Slump FlowTest(sec) SlumpFlow Test(mm) V funnel at T5minutes

1 DalmiaCement 8 0.88 7 4 685 10 2 PriyaCement 6 0.831 9 4 665 12 3 ZuariCement 10 0.963 11 5 667 11 4 JSWCement 8 0.85 8 5 672.5 13 5 ChettinadCement 7 0.844 6 3 663 12 EFNARCGuidelines 0 10 0.8 1.0 6 12 2 5 650 800 +3

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2079

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Fig.1:WorkabilityPropertiesofDifferentBrandsofCements

Fig2:SlumpFlowofDifferentBrandsofCements

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2080

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

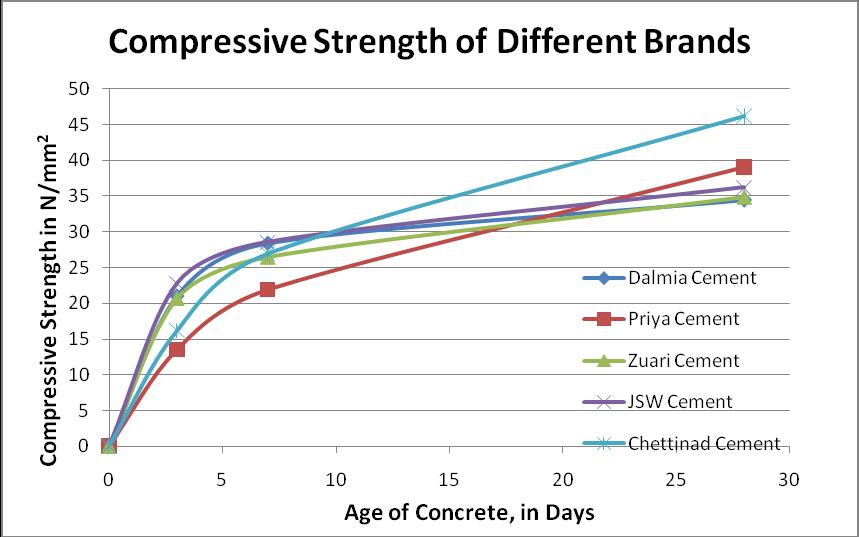

Cubesarecastedforeachmixtodeterminethe3,7and28 days compressive strength. The compressive strength of differentbrandsofcementfor3,7and28dayswithnormal curingisshowninTable8andthevariationofcompressive strengthis showninFig3. Forall the brandstarget mean strength of 31.6 N/mm2 is achieved. The 3 and 7 days compressivestrengthismoreforJSWCement.The28days compressivestrengthismoreforChettinadCement.

Table3:3,7and28DaysCompressiveStrengthofM25 SCCforDifferentBrandsofCement

S. No DifferentBrandsof OPC53Grade Cement

CompressiveStrength(N/mm2) 3Days 7Days 28Days

1 DalmiaCement 21 28.37 34.43

2 PriyaCement 13.52 21.87 39.02

3 ZuariCement 20.68 26.44 34.83

4 JSWCement 22.803 28.55 36.19

5 ChettinadCement 16.176 26.94 46.20

4. The compressive strength variation is more between somebrands,hencedifferentmixdesignisrequiredfor differentbrandofcementforoptimalmixdesign.

5. Copper slag can be used as mineral admixture for partialreplacingfineaggregate.

1. G. Asif Hussain et.al (2020), “Properties of M60 High Performance Self Compacting Concrete by usingBlendsofDifferentSizesofCoarseAggregate”, National Virtutal Conference on Recent Trends in CivilEngineering 2020(RTCE’20),September2020 pp31 36,ISBN:978 81 942685 2 9.

2. Bhosale Mahesh Bhimarao, et.al(2020), “Replacement of Copper Slag with Fine Aggregate”, InternationalResearchJournalofEngineeringand Technology(IRJET),Vol.07,Issue.03,March2020, pp.4201 4204

3. B. Chandraiah, et. al. (2017) “Variation Of Compressive Strength And Split Tensile Strength Of M40SelfCompactingConcreteWithDifferentSizesOf Coarse Aggregate”, International Journal of Engineering Technology Science and Research (IJETSR),Vol.4,Issue8,August2017,pp.279 285

4. N. Shanmuga Nathan, E.Ambrish, et.al,(2017) “Partial Replacement of Copper Slag as Fine Aggregate”, SSRG International Journal of Civil Engineering(SSRG IJCE),Vol.4,Issue3,March2017, pp.18 23.ISSN:2348 8352.

Fig3.VariationofCompressiveStrengthwithAgeof ConcreteforDifferentBrandsofCement

1. Forallthebrandsthecompressivestrengthobtainedis more than the target mean strength(31.6 N/mm2) as perIS10262 2019.

2. The3and7daysCompressiveStrengthofmixwithJSW Cementandthe28daysCompressiveStrengthofmix withChettinadCementismorecomparedtoallother brands.

3. The percentage increase in Compressive Strength for Chettinad mix is 84.8% more compared to CharacteristicCompressiveStrength.

5. Bhavani,C.KrishnamaRaju,S.TalhaZaid(2016), ” Effect on Mechanical Properties of M25 SCC with Variation of Class F Fly Ash & GGBS”.International Journal of ChemTech Research, Vol. 11, No. 07, 2018, pp. 70 77, DOI= http://dx.doi.org/10.20902/IJCTR.2018.110709

6. S. Dhiyaneshwaran, et. al. (2013), ”Study on Durability Characteristic of Self Compacting Concrete with Fly Ash” Jordan Journal of Civil Engineering,vol.7,No.3,May2013,pp.342 353.

7. S. Venkateswara Rao, M.V. Seshagiri Rao, P. Rathish (2010), ”Effect of Size of Aggregate and Fines on Standard and High Strength Self CompactingConcrete”, JournalofAppliedSciences Research,pp.433 442.

8. NanSu,Kung ChungHsuandHis WenChai(2001) proposed a ” Simple Mix Design Method for Self Compacting Concrete”JournalofCementConcrete

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2081

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Research , Vol. 31, No. 12, pp. 1799 1807., Dec. 2001.

9. IS:2386(Part i,Part iii,Part iv) 1963, ”Methodsof TestforAggregateforConcrete”.

10. IS:383 2016, ”SpecificationsforFineaggregateand Coarseaggregate”.

11. IS: 10262 2019, ”Concrete Mix Proportioning Guidelines”.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page2082