Design and Analysis of Jet Nozzle in Laser Cutting Machine

Mr. C Mohankumar1 , B Arun2 , N Ponmugil3 , J Santhoshkumar4

Mr. C Mohankumar1 , B Arun2 , N Ponmugil3 , J Santhoshkumar4

1 Assistant Professor, 2,3,4 UG Scholar, 1,2,3,4 Department of Mechanical Engineering, Sengunthar Engineering College(Autonomous), Tiruchengode, Namakkal, India. ***

Abstract: Due to the ultra flexibility of the cutting conditions, high quality end product, quick set up, non mechanical interaction between the work piece and the tool, and tiny size of the heat affected zone, lasers are frequently utilised in industry for cutting tools. Copper is a common material for nozzle manufacturing. Because copper is a moreexpensive material, the material selection process is done tofind the most cost effective material for the nozzle. the various materials (Brass and Nickel) based on the temperature and heat flux values obtained from the thermalanalysis The optimal material for jet nozzle is determined based on the thermal analysis results, and the material is advanced through the implementation phase.

1.INTRODUCTION

In the 1970s, lasers were initially employed for cutting. Laser cutting is more commonly utilised in current industrial manufacturing in sheet metal, plastics, glass, ceramics, semiconductors, and materials such as textiles, wood, and paper. Theuseoflasercuttinginprecisionmachiningandmicro machiningwillexpandsignificantlyinthenextyears.

Theirradiationregionwarms upquicklyas theconcentratedlaser beam meets the work item, melting or vaporising the material. The cutting process begins when the laser beam penetrates the work item; thelaser beam proceeds along the contourandmeltsthematerial.Ajetstreamistypically employedtoblowthemeltawayfromtheincision,leaving onlya smallgapbetweenthecuttingsectionandtheframe.

2. LASER CUTTING METHOD

2.1 Fusion cutting

Theworkpieceispartiallymeltedduringlaserfusioncutting,andthemoltenmaterialisexpelledbyairflow.Theprocedure isknownaslaserfusioncuttingsincethematerialisonlytransferredinitsliquidcondition.Thelaserbeamisaccompanied byahighpurityinertcuttinggasthatallowsthemeltedmaterialtoexittheslot,butthegasdoesnotcut.Laserfusioncutting cancutatafasterratethangasification. Gasification requires more energy thanmelting.Thelaserbeamisonlypartially absorbedinlaserfusioncutting.

2.2 Vaporization cutting

Thesurfacetemperatureofthematerialgetstotheboilingpointsoquicklyduringlasergasificationthatitavoidsmelting duetoheatconduction.Someofthematerialvaporisesintosteam,whileothersareblastedawaybythesupplementarygas flow from the slit's bottom. A very highlaser power is necessary in this instance. The thickness of the material must not exceed the diameter of the laser beam to avoid material vapour from condensing into the slit wall. This method is only appropriateforapplicationsthatneedtheremovalofmoltenmaterial.Itisonlyusedinafewplacesforferrousalloys.

2.3. Fracture-controlled cutting

Fracture controlled cutting uses high speed and controllable laser beam heating to cut fragile materials prone to heat damage. The following is the primary element of this cutting procedure: The laser beam warms asmall area of fragile material, generating a significant thermal gradient and severe mechanical deformation in thearea, leading to material cracking. The laser beam can guidethe fractures in any desired direction as long as the balanced heating gradient is maintained.

2.4 Oxidation melting cutting

Inmostcases,aninertgasisusedformeltingcutting.Whenemployingoxygenoranyreactivegas,thematerialwas lighted by the laser beam and violently reacts chemically with oxygen, producing another source of heat and furtherheating the material. This is known as oxidation melting cutting. Because of this effect, cutting speed for structural steel of the same

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

thicknessisfasterthanfusioncutting.Cuttingincision,ontheotherhand,maybeworse.Itwill,inreality,resultinbroader cutseams,visibleroughness,greaterthermalimpactzones,andpooredgequality.Precisionmodelsandsharpcornersare not suitable for laser flamecutting (risk for burn sharp corners). The pulsemodelasercanbeutilised toreducetheheat effect,andthecuttingspeedis determined bythe laser's power. Thesupplyofoxygenandthethermalconductivityofthe materialarethelimitingfactorsforparticularlaserpowers.Thesearethefourmostprevalentlasercuttingtechniques.The cuttingplancanbedeterminedbythepowerofthecuttingmachine,processingneeds,andmaterialparameters.

3.MATERIAL SELECTION

3.1 Copper Material

Copperisoneoftheworld'soldestmetals.Thegreatheatconductivityofcopperisoneofthekeyreasonsforitsuse.Itisa native metal, which means it may be found naturallyin useable form and has excellent metallurgical qualities. Malachite, cuprite,azurite,bornite,andchalcopyriteareallmineralsthatincludeit.

3.2 Nickel Material

Nickelisanaturalelementproducedfromthecoreoftheplanet.It'ssilverwhiteincolour,withagleamingfoundationand agoldentint.Nickelisclaimedtobebeneficialduetoitsductileandcorrosion resistantqualities.Nickelisrecoveredfrom magmaticsulphidesandlaterites,twotypesofores.

3.3 Brass Material

Nickelisanaturalelementproducedfromthecoreoftheplanet.It'ssilverwhiteincolour,withagleamingfoundationand agoldentint.Nickelisclaimedtobebeneficialduetoitsductileandcorrosion resistantqualities.Nickelisrecoveredfrom magmaticsulphidesandlaterites,twotypesofores.

3.4 Heat Transfer Calculations

The temperature of a substance will change by a specific amount when heat energy is applied to it. Every material's connection between heat energy and temperature isunique, and the specific heat is a value that indicates how they interact.(massofsubstance)(specificheat)=heatenergy(changeintemperature)

Q = mc∆T

Q=standsforheatenergy(Joules,J)m=asubstance'smass(g) cisthespecificheat(inJ/g°C).

∆T=temperaturechange(DegreeCelsius)

ForCopperMaterialSpecificheat(c) 0.385J/g°CMass(g) 29.853

Changeintemperature(∆T) 2.2

Q=mc∆T

=29.853x0.385x2.2

Q copper=25.285491JForNickelMaterial

Specificheat(c) 0.444J/g°CMass(g) 29.743

Changeintemperature(∆T) 9.6

Q=mc∆T

=29.743x0.444x9.6Q nickel=126.7765632J

ForBrassMaterial

Specificheat(c) 0.380J/g°CMass(g) 28.73

Changeintemperature(∆T) 7.8

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

4.PROBLEM IDENDIFICATION

The nozzle is generally accessible in the market in copper material, although at a high cost. To provide the most cost effective nozzle with high performance quality in the manufacturing industry. As a result, any other materials must be usedtoreplacethecopper.

Objective:

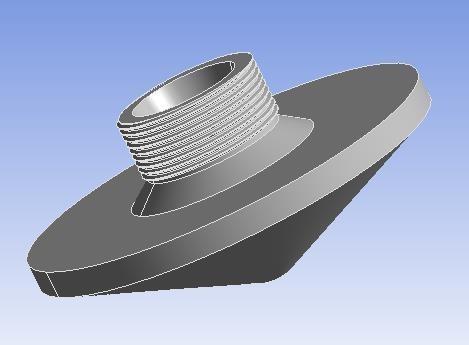

The major goal of this research is to design and analyse several types of jet nozzles (copper, nickel and brass). Temperatureandtotalheatflowvaluesfromthe thermal study areusedtocompareanddeterminetheoptimal material forthenozzleusingAnsyssoftware.

5.INTRODUCTION OF FEM

5.1 Introduction of FEM

TheFEMisamathematicalmodelforpredictingcloseexperimentalsolutionsinavarietyofcomputingfields. FEM based numericalanalysisisgenerallyreferredtoasfiniteelementanalysis(FEA).

5.2 FEA Works

Asamachinetoolforperformanceartsengineeringanalysis,FEAcouldbevaluableinengineering.Itentailstheuseofmesh construction techniques to break down a complex problem into little pieces, as well as the usage of asoftware package programmethatfollowstheFEMrule.

5.3 Advantages of FEA Software

1. Itreducesthenumberofprototypetests,savingbothmoneyandtime.

2. Itshowsagraphicaldepictionoftheanalysis'results.

3. Thefinite element modelling and analysis aredonein the pre processor and solution phases, which would take a longtimeand,insomesituations,beimpossibletoexecutemanually.

4. Itaidsintheoptimizationofadesign.

6. THERMAL ANALYSIS

Thermal analysisisa discipline of materialssciencethat studies how materials' properties vary as temperature changes. Several techniques are regularly employed. The property that is measured distinguishes them from one another. The temperature and heat movement within and between components in your design, as well as between them and their environment, are calculated using thermal analysis. Because many goods and materials have temperature dependent qualities, this is a significant design concern. Product safety is also a factor to consider. You may need to design a guard overaproductorcomponentthatbecomestoohot.Theheatflowthrough thecomponentscanbeeitherconstant(where theflowdoesnotfluctuateovertime)ortransient(wheretheflowchangesovertime).

7. PROCEDURE ANALYSIS

ANSYS is a finite component modelling software system that may be used to solve a wide range of mechanicalproblems numerically. It will do structural (linear and non linear), thermal, magnetic attraction, and fluid analysis, among other things.

Theuserinterfacetechniquemakesitsimpletodoanalysis.A graphical interface is created, making the software system simpletouse.

7.1 Pre-processing stage

7.3 Results

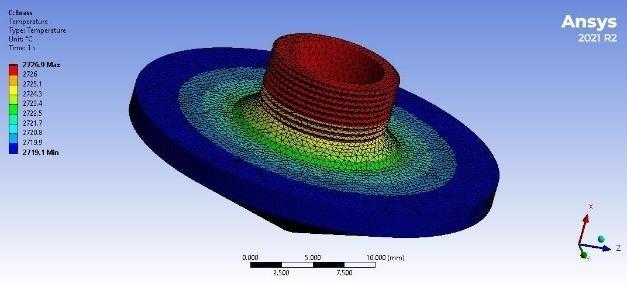

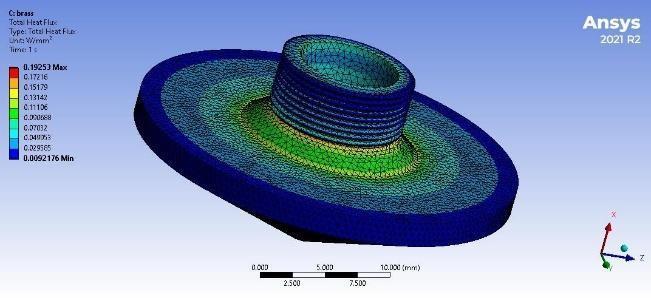

Fig-3: Temperaturedistributionofnozzlewithbrassmaterial

8.CONCLUSIONS

Laser cutting is a crucial aspect of the manufacturing process. This research presents an effective nozzle configuration estimationforhigh pressurelaserjetting.Solidworkssoftwarewasusedtomodelthejetnozzle,whileANSYSworkbench softwarewasusedtodothethermalanalysis.Allaspectsoftheboundaryconditions canbeaddressedusingsteadystate thermal analysis. A nozzle made of nickel was chosen as the best thermal performance and economically acceptable material based on the temperature distribution and total heat flux data. Based on the heat transfer on the nozzle with various materials, it appears that nickel has a substantially higher heat transfer (126.7765632 J) than other materials (25.285491Jand85.15572Jrespectivelyforcopperandbrass).

ACKNOWLEDGEMENT

We wish to express our sincere thanks to our honourable chairman Thiru. JANSONS.T.S. NATARAJAN, Sengunthar Institutions, Tiruchengode for providing opportunity to do this project. We wish to extend our heartfelt thanks to our honourableSecretaryandCorrespondentProf.A.BALADHANDAPANI,M.A.,M.Phil.,andotherrespectedTrustmembersfor providinguswithallthefacilitiestodeveloptheprojectsuccessfully.

WewouldliketoexpressoursinceregratitudetoourbelovedPrincipalDr.K.UMADEVI.M.Tech.,Ph.D.,forhavingrendered usmoralsupportinourendeavor.

WefeelelatedbytheencouragementofourMr.N.THIRUSENTHILADHIBAN,M.E.,HeadoftheDepartmentofMechanical Engineeringformotivatingusthroughoutthecompletionofthisproject.

REFERENCES

[1] Anil Varkey, Shajan Kuriakose, Narayanan Unni (November 2014), “Optimization of Edge Quality during co2 Laser CuttingofTitaniumAlloy”InternationalJournalofInnovativeResearchinAdvancedEngineering,Volume1,Issue11, pp110to117.

[2] KadamVijay,DhumalKetan,FegadeHemant,KadlagRanjit,Roundal,Deshpande,(April2017)“DesignofSheetMetal ProfileGasCuttingMachinebyUsingScrap”7thInternationalConferenceonRecentTrendsinEngineering,Science& Management,pp.340to346.

[3] LeonardoOrazi,Mohamed DarwishandBarbaraReggiani(November2019)“InvestigationontheInert Gas Assisted LaserCuttingPerformancesandQualityUsingSupersonicNozzles”,Metals,pp.1to16.

[4] MartinAmarRaj,RameshChandraPanda,MohammadIsrar,ItishreeMohanty(August2019)“Experimental Analysis of Heat Affected Zone by Laser Beam Machining” International Journal of Engineering and Advanced Technology, Volume8,Issue6,pp.5261to5267.

[5] Nigade&Jadhav(June2016),“LaserBeamCuttingParameterOptimizationforMildSteel”JournalofMaterialScience andMechanicalEngineering,Volume3,Issue3,pp.258to261.