International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

2

1M.Tech. Scholar, Dept of Mining Engineering, College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur, Rajasthan, India

2 Professor and Head, Dept of Mining Engineering, College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur, Rajasthan, India ***

Abstract An unmanned aerial vehicle (UAV), often known as a drone, unmanned aerial system (UAS), or by a variety of other names, is an air plane that does not have a human pilot on board. UAVs can fly with varying levels of autonomy: under remote control by a human operator, or totally autonomously by onboard computers. UAVs are frequently selected over manned aircraft for operations that are "too dull, unclean, or dangerous" for people. The goal of this study was to see if using UAV for topographic mapping andsurveying may reduce the cost and time required to do the same task using conventional methods while still reaching acceptable accuracy. This study analyses and contrasts the deployment of unmanned aerial vehicle (UAV) in the surveying and mapping sector with traditional and recognised methods.

Key Words: Drone, GNSS, GPS, Survey, 3D Mapping, Monitoring etc

Drones have been employed for a number of civilian and military applications and tasks, including unmanned air vehicles(UAVs)andmicroairvehicles(MAVs).Depending onthesortofmission,theseunmannedaircraftsystemscan carry a variety of sensors, including acoustic, optical, chemical, and biological sensors. Researchers have concentrated on the design optimization of drones to improvetheperformanceandefficiencyofdrones,whichhas resultedintheinventionandmanufactureofmanytypesof aerialvehicleswithdiversecapacities.Droneshaverecently piqued the mining industry's interest for everyday operationsinsurfaceandundergroundmines.Thegoalof this research is to look at how drone technology is being used in the mining business. Previous research and information from companies that provide drones to the miningindustryarealsousedforthisaim.

Minesaretypicallyfoundinhuge,inaccessiblemountainous environments.Asaresult,monitoringminesandassociated infrastructures is a difficult operation that necessitates a largeamountofpeople.Asaresult,traditionaltechniquesof monitoringminesaretimeandmoneyexpensive.Dronescan

be useful in monitoring, surveying, and mapping the area aroundminesifusedcorrectly.Dronescanbeusedtotrack mineactivitiesandtopographychangesintheminingarea, resultinginbettermineplanningandsafetyrules.Adrone equippedwithahyperspectralframecamera,forexample, wasutilisedtomonitorthesafetyoftheproductionpitin.In open pit mines, slope angle optimization is critical for loweringcostofproduction,increasingmineperformance, andrecyclingresources.

Drone use in deep mines has been limited despite advancesindronetechnology.Thisisduetothecomplexity of using drones in belowsurface mines. Drones flying in harsh subsurface conditions have numerous challenges. Flyingadroneinundergroundworkinglocationsisdifficult due to confined space, poor sight, air velocity, dust concentration,andthelackofawirelessconnectionsystem. Also, a drone operator's access to inaccessible and dangerous regions in deep mines is almost impossible. Dronesinundergroundminescouldbeusedforavarietyof healthandsafetypurposes.Surfaceroughnessmapping,rock massstabilityanalysis,ventilationmodelling,hazardousgas detection,andleakagemonitoringaresomeoftheseuses.

i. Geotechnicalcharacterizationofundergroundmine

ii. Rock size distribution analysis in underground mines

iii. Gasdetectioninundergroundcoalmines

iv. Minerescuemissioninundergroundmines.

v. Common sensing methods for drones in undergroundmining.

Surveyingplaysanimportantroleintheminingsectorsince itprovidesvitalinformationtoallotherminingdisciplines. Surveyingallowsforprecisemeasurementofminedareas and volumes, as well as accurate portrayal of surface and subterraneanconditionsonminingplans.Thefollowingare theconventionaltechniquesofSurveyinginMining.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1921

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

i. Theodolite.

ii. TotalStation.

iii. Photogrametry.

iv. Differentialglobalpositioningsystem(DGPS)

Surface mines Underground mines Abandoned mines

MinesOperation

3DMapping

Slopestability

Minesafety Construction monitoring Facility management

Geotechnical characterization

Rocksizedistribution

Gasdetection

Minerescuemission

Subsidence monitoring Recultivation

Landscapemapping

Gas storage detection

Acid drainage monitoring

Thisstudywasconducted ina Soapstone mine Thestudy area is situated in the Dingri Nathara ki pal region of Udaipur,Rajasthan.Thearealiesabout40kmSouth Eastof Udaipur.Theareaofthestudysiteis22Hectare.Themethod ofextractioninthemineisShovel Dumpercombination, blasting is done to remove the overburden. Here the soapstone is found alongside talcose schist and dolomitic limestone from the Aravalli period. Soapstone is found as lensesandveinswithlengthsrangingfrom18to90meters andthicknessesrangingfrom2to15metres.Soapstoneisa large,foliatedstonethatrangesincolourfromwhitetopale green in appearance. The above study was carried out in order to assess the applications UAVs in mining industry. ThisassessmentwasdonebycarryingoutUAVsurveyofthe chosenmines.

Step 1: Assembling of the drone and the communication box

Thefirstandforemoststepistoassemblethedroneproperly. Forthis,thefollowingprocedurewasadopted:

i. Firstthepropellerwasassembledwiththedrone. There are two type propeller provided with the package,oneissilvercolormarkedandanotheris black color marked. The black color marked propeller was mounted on black color marked motorandsilvercolormarkedpropellermounted onsilvercolormarkedmotor.

ii. Then the lithium battery was assembled with the drone using Velcro straps on the drone. It was ensuredthatthebatterywastighteningthebattery properly.

iii. Thebattery’scablewastightenedwithlandinggear usingthehelpofVelcroattachedwiththelanding gear.

iv. Antennawasassembledintothedroneatdesignated portandsnappeditondrone’sbody.

v. Camera was mounted on the drone at designated slotandtherubberwaspushedback.

vi. The communication box was mounted on tripod withthehelpofthetripodconnector.Thetripod’s heightwasadjustedaspertherequirement.

vii. The battery power port was connected with designatedportonthedrone.Makesuretheportis tight.Thescrewdriversuppliedwithmaintenance kitwasusedtoincreasethediameterofcontactsof thedrone’sport.

viii. The button on the communication box was long pressedtoswitchiton.

ix. After 90 seconds, the standard boot time for the dronetwogreenlightsinfrontandtworedlightsin backstarted blinkingat1Hzrate.1Hz means,itwouldonforonesecondandthenofffor onesecond.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

a) TheApplicationwasopenedinanAndroidmobile phone.

b) Firstloggedin.

c) Once the drone has booted up, a camera and connectionselectionsweremade.

d) Thecameramodelwaschosen.Cameradetailswere entered for GoPro 10 black or GoPro 9 Black as payloadandclickedon“QuickApp”buttontomake cameraBluetoothvisible.

e) Clicked on confirm button on App. It took few seconds for camera to connect with the drone wirelessly.Onsuccessfulconnection,itwasnotified on the App saying “Camera Wi Fi Connected” and alsoabeepsoundwasheardoncamera.

f) Althoughmostofthesettingsaredoneautomatically onthecamerabydrone,fewthingsmustbechecked tohaveasuccessfulsurvey.Theyare:

g) Checkingofzoomlevelofcamera.Forwhich“photo linear”buttononcamerawasused,thenclickedon edit icon, and scrolleddownto see how muchthe zoomlevelis?Ifitwasn’t1x,itwaschangedto1x.

h) CheckedwhetherthecameraGPSislockedornot. Tocheck it,scrolleddownthesettingscreenfrom home screen. Saw that if the GPS icon is of white colorornot.Ifitisnotofwhitecolour,waitedfor sometimeforGPStolock.Ifitdidn’tlockforlong time,thecamerawasrestarted.

i) The camera icon of the App was clicked to see if cameraisclickingimagesornot.Ifitisnotclicking theimages,everythingwasreconnectedagainfrom thestart.

j) Clicked on “Plus icon” on right side bottom of the camera to plan the mission. After giving desired altitude,angleandoverlap.

k) Clicked on “Arm” button on top of the screen to checkwhetherthemotorsareworkingfineornot.

l) Aftercheckingeverythingsuccessfully,swipedthe “swipetofly”button.Themissiongotuploadedonto the drone and drone took off to complete the mission.

m) Oncetheflightwascompletedanddronehadlanded ontotheground,clickedonphotoicononAppand checkedwhetherthecameraisclickingphotoornot.

Tosatisfythedatagoalsof workormission,droneflight planning entails setting the flying schedule, pattern, altitude, andimage or image capturing parameters,as well as any weather related needs (e.g. temperature, light, or irradiance constraints). Failure to design the properflightplancanresultinnotonlyawasteoftime and resources, but also serious implications such as damagetothedroneorendangeringthesafetyofothers. For this study purpose the following flight plan was adopted.

i. HeightofFlightwassetto100m.

ii. Thechosenoverlappingwas70%.

iii. Flightspeed35km/h.

iv. Camerasettolinearphotomode.

The flight is planned after the KML import. Figure showstheflightplanforthisstudy.

i. Thebroadyellowlinepolygonrepresents theimportedKMLboundary.

ii. The green drop pin represents the start position of the drone, the red drop pin representstheendpointoftheflight.

iii. Thegreenarrowrepresentsthedroneand itsdirection.

iv. Thethinyellowlines(insidethepolygon) representsthepathonwhichthedrone willfly.

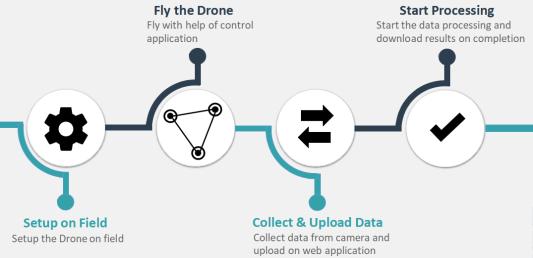

AfterthecompletionoftheFlightaccordingtotheFlight plan,theobtaineddatawassentforprocessing.Forthis studytheDronedataprocessingwasdonethroughH.K. &Associates,Udaipur.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1923

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

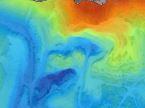

Thefollowingresultantimageswereobtained:

i. Theimageofthewholepitshowingallthebenches, pitareaandleasearea(ifrequired).

Fig 4 Orthomosaicimageofarea

ii. Elevation profile of the pit, where blue region represents deeper location and reddish shades representhigherpitarea.Deepestpointofthepoint isat578m,whilehighestisat691m.

The following images were obtained by drone surveying, whichcanbeusedtocalculate:

i. Mine(pit)area.

ii. Benchheight iii. BenchSlope

iv. Volumetricanalysis.

v. LeaseAreaandDemarcation

Allthisdatawasobtainedbyasingledrone,performingonly oneflight.Thedurationtocarryoutthissurveyof22hectare minepitwasabout30minutes&anadditionaltimeof24 hoursisspentinprocessingthedata.Comparingthiswith theconventionalsurveyingmethodofDGPS,itwouldhave takenapproximately4daystosurveythesameareasize

Fig 5 ElevationProfile

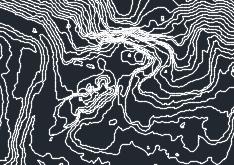

iii. The Contour profile depicting the points of same elevationinthepit.

Also,themanpowerrequiredtoperformDronesurveyis2 persons, while it requires 4 persons to carry out a survey throughDGPS.Thedronewasabletocapturehardtoreach areas, while the DGPS would was not able to acquire data fromthoseregions.

Fig 6 ContourFileofthePit

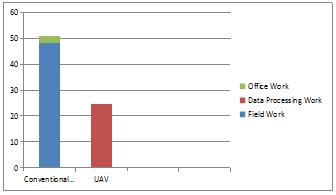

Financebeinganimportantpartofminingindustry,thusthe costofcarryingoutthesesurveysalsoneedtobeevaluated.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

During thisstudy, industry sourceswere reviewed.It was foundthat:

i. TheDronesurveyingcostsaboutINR10000/hectare.

ii. TheSurveyingthroughDGPScostaboutINR800/pillar. Thenumberofpillarsdependonthesizeofmine.

According to business to cost ratio, the UAVs are cheaper thantheconventionalmethods.

The primary purpose of this research was to assess the applicationofUAVsinmining.Thesecondarypurposewas to make recommendation regarding the utilizing the maximum potential of UAVs in mining industry. In this regarda survey wascarried outina Soapstonemine.The obtainedandprocesseddatawasthencomparedwiththe conventionalsurveymethods.Themajorfocusofthisstudy istohighlighttheeaseofdataacquisitionbyUAVsinhard terrainsofminingindustry. Withhighriskfactorinmining industryandminingbeingprimarilyasafetyorientedsector requiresthesafetyofitsworkforce.Thissafetyfactorcanbe achieved ifall the working areasareobserved, monitored and surveyed efficiently. This can be done using efficient toolslikeUAVsinvarioussectorsofmining.Inthisregard thecurrentstudywasconductedwithfocusonUAVsurvey andfollowingconclusionsweremade:

i. ItwasobservedthattheDronesurveywasefficient in saving time taken to acquire images. Drone survey took about half the time to present the resultascomparedtotheconventionalmethods.

ii. The overall cost to carry out the Drone survey is cheaper compared to conventional methods with respecttothesizeofarea.

iii. ThemanpowerrequiredinDronesurveyisabout half the manpower required in conventional method.

iv. The resulting data and images can be used to calculatearea,stockpileanalysis,stopestability.

WiththeseaforementionedmeritsUAVsshowedgreatscope in mining industry with further development in UAV technology,UAVscanbemoreefficientintheminingfield

I would like to thank my Head of the Department and my guideDr.AnupamBhatnagar,foryourvaluableadviceand technicalassistance.

[1] AlvaradoM..,GonzalezF.,FletcherA.&Doshi,A.2015. Towards the Development of a Low Cost Airborne SensingSystemtoMonitorDustParticlesafterBlasting atOpen PitMineSites. Sensors, 15,19667 19687.

[2] Bamford T., Esmaeili K. & Schoellig A.P. 2017, A real time analysis of post blast rock fragmentation using UAV technology. International Journal of Mining, Reclamation&Environment;Volume31(6),p439 456.

[3] Carvajal,F.,Aguera,F.andPerez,M.,2011,Surveyinga Landslide in a Road Embankment Using Unmanned AerialVehiclePhotogrammetry,InternationalArchives of the Photogrammetry, Remote Sensing and Spatial InformationSciences,Volume3822,p201 206.

[4] DunningtonL.,NakagawaM.,Fastandsafegasdetection from underground coal fire by drone fly over. EnvironmentalPollution,Volume229,p139 145.

[5] Esposito G., Mastrorocco G., Salvini R., Oliveti M. and StaritaP.2017,ApplicationofUAVphotogrammetryfor the multi temporal estimation of surface extent and volumetricexcavationintheSaPigadaBiancaopen pit mine, Sardinia, Italy. Environmental Earth Science; Volume76(3),103.

Faisal Sheikh, completed the B.Tech. degree from RTU Kota in 2018. He is currently a final year M.Tech. student of College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur,Rajasthan,India

Dr Anupam Bhatnagar, Associate Professor & HEAD, College of Technology and Engineering, Maharana Pratap University of Agriculture and Technology, Udaipur, Rajasthan, India, Ph.D. (Marble Waste Minimization), M.Tech.(Mining)IITKharagpur,B. E.(Mining).