International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

1 Student Alpine Institute of Technology [AIT], UJJAIN, M.P.INDIA

2 Professor CE AIT UJJAIN, M.P., INDIA 3 Professor CE AIT UJJAIN, M.P.INDIA ***

Abstract Concreteisthemostwidelyusedmanmadematerialforconstruction.Inthisprojectworkcementwerepartially replacedbydifferentcombinationofwasteglasspowderandricehuskash.Forthatpreparednumberofcubesandbeamsby additionofwasteglasspowderandRiceHusk Ashatvariousproportions.Inthisprojectwork percentageofwasteglass powderwastakenconstantat5,10,15,20andvaryingthepercentageofricehuskashlike5,10,15and20.Conventional concretecubehavealsobeenprepared.Thecastedspecimenshavebeentestedforitscompressiveandflexuralstrengthat7 daysand28daysageandcomparethisstrengthwithconventionalconcretestrength.Testresultshowsthatthecombinationof 15%wasteglasspowderand10%ricehuskashgivesmaximumstrength.Inthisprojectworkwastematerialsareusedin concretesocostofconcreteislowthenconventionalconcrete.Itisalsoitisecofriendly.Thisstudywillhaveapositiveimpact ontheenvironment,asitwillreducethevolumeofGlassPowderandRiceHuskAshtobedisposedoffbyincinerationandland filling.Inaddition,itwillreducetheuseofcement.

Key Words: (Size10&Bold)Keyword1,Keyword2,Keyword3,etc(Minimum5to8keywords)…

Glasspowderiswasteproduct.Thekeysourcesofwasteglassesarewastecontainer,windowglasses,windowscreen, medicinalbottles,liquorbottles,tubelights,bulbs,electronicequipmentsetc.Onlysomepartofthiswasteglasscanbeusedin recycling. Thewasteglasswhengrounded toa very fine powdershowssomepozzolanicproperties.Thereforetheglass powdertosomeextentcanreplacethecementandcontributetothestrengthdevelopment.Thetypicalglasscontains70% silicaapproximately.Paststudyshowspozzoloonicpropertiesofglassarenoticeableonparticlesizesbelowapproximately 100µm.Sizeofglasspowderlessthan75µmpossessedcementitiouscapabilityandimprovescompressivestrength,resistance tosulphateattackandchlorideionpenetration.

Rice husk is an agro waste material which is produced in about 300 million metric tons in worldwide annually. Approximately, 100 Kg of rice husk are obtained from 500 Kg of rice. Rice husks contain organic substances and 20% of inorganicmaterial.Ricehuskash(RHA)isobtainedbythecombustionofricehusk.Theburningtemperaturemustbewithin therangeof600to8000C.Theashobtainedhastobegroundedinaballmillfor30minutesanditsappearanceincolourwill begrey.ThemostimportantpropertyofRHAthatdeterminespozzolanicactivityistheamorphousphasecontent.RHAisa highlyreactivepozzolanicmaterialsuitableforuseinlime pozzolanamixesandforPortlandcementreplacement.

GlasspowdercollectedfrompostconsumersourceinIndorecity.FordeterminedthespecificgravityofglassbyLe Chatelierapparatus.

ThericehuskashwascollectedfromN.K.Enterprises,Jharsuguda,Orissa,India.Thericehuskashusedinthisstudy was prepared by burning at the temperature within the range of 600 0C to 800 0C at approximately 48 hours under uncontrolledcombustionprocess.Theashobtainedwasgroundedinaballmillfor30minutesanditsappearanceincolour wasgrey.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Cement used in this experimental work is “43 grade” which is available under the commercial name “Ultra Tech cement”.Table2.1showschemicalpropertiesofbindermaterials.Table2.2showsphysicalpropertiesofvariousconcrete materials.

Table2.1Chemicalpropertiesofbindermaterials Cement % Glasspowder%

Ricehuskash%

Cao 60 67 9.79 2.51% SiO2 17 25 73.1 92.62%

Al2O3 03 08 1.36 0.49% Fe2O3 0.5 6 0.67 0.73% MgO 0.1 4 3.45 0.88% So3 1.3 3 Alkalies(K2O,Na2O) 0.4 1.3 11.1

Table2.2Physicalpropertiesofmaterials

Specificgravity Finenessmodulus Fineness

Cement 3.12 96% Glasspowder 2.95 100%

Ricehuskash 2.1 97%

Coarseaggregate 2.87 6.27 Fineaggregate 2.47 2.537

Coarseaggregateiscollectedfromnearbyquarry.Finenessofcoarseaggregateis2.805.Coarseaggregateareused withsizebetween20mm 4.75mm.Riversandconfirmingtozone2andwithfinenessmodulusof2.80wasuseinstudy.

In the present study water reducer admixture is added to reduce the water content. Plasticizer used in this experimentalworkiswaterreducertypewhichisavailableincommercialnameisfosroc.

Tofindoutpropertiesofconcretethatiscompressivestrength&flexuralstrengthwithandwithoutadditionofglass powderandricehuskash.

TofindoutsuitableproportionofGlassPowderandRHAthatprovidesgoodstrengthtooverconcretemix.

Tocalculateofeconomy.

UtilizationofIndustrialwasteinausefulmanner.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Protecttheenvironmentbytheuseofindustrialwaste.

Toprovideeconomicalconstructionmaterial.

InthisstudyanattemptismadetofindoutthehardenedpropertiesofconcretesuchascompressiveStrengthand FlexuralStrengthofM30grade(1:1.3:2.6)concretecontainingwasteglasspowderandricehuskashaspozzolana.Cement(43 grade)isusedasmainbinderinthemixes..Plasticizerdoisoptimizedtomakethemixesworkableforpavingapplication.The waterthatisavailableinlaboratoryisused.ThemixesweredesignatedasamixwiththevaryingpercentageofGlassPowder andRicehuskashsuchas5%,10%,15%,20%respectivelyandfindingoutitssuitablecombination,whichshowsthehigher compressivestrengthandhigherflexuralstrengthat7 daysand28 days.DesigningthemixasperIS10262 2009,batching, mixing,compactingofconcrete,castingthespecimenforvarioustestconsideredforthestudy,testingthespecimen,tabulation andanalysisofdataandfinallydiscussionfollowedbyconclusionbasedontestresults.

ToselectoptimallevelofreplacementofGP&RHA,the7daysand28dayscompressiveandflexuralstrengthofallthe17 combinationofconcretewereinvestigated.

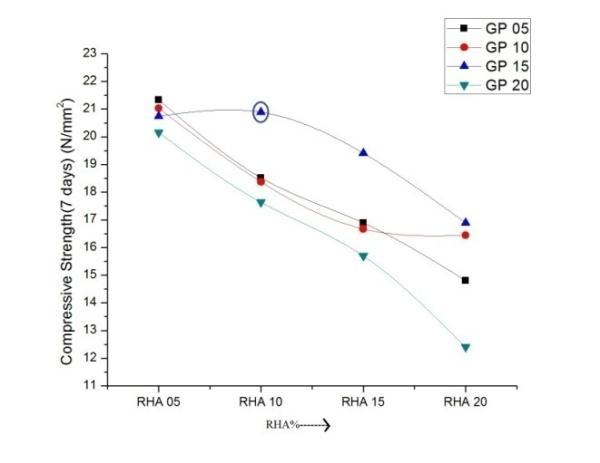

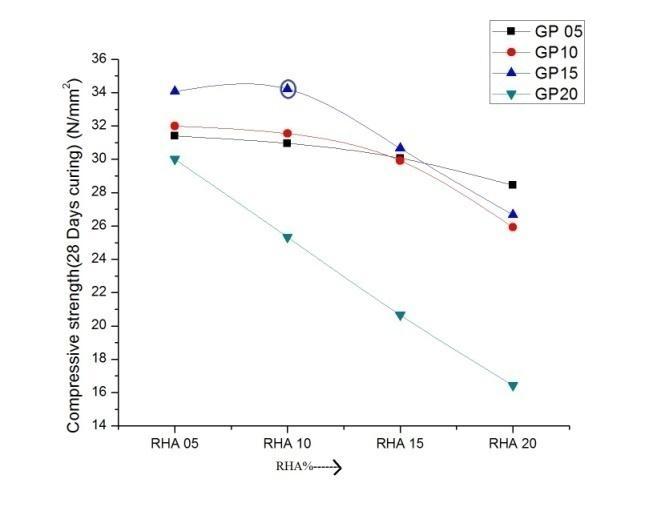

Fig.5.1andfig.5.2showscompressivestrengthofconcreteforvariouscombinationsfor7 daysand28 daysrespectively.For alltests,threespecimenswerecastedforeachcombination.GP15RHA10combinationshowsslightlylesscompressivestrength thanconventionalconcreteat7 dayscuringbutat28 dayscuringshowsmorestrengththanconventionalconcrete.Table5.1 showstheresultforcompressivestrengthofconcrete.

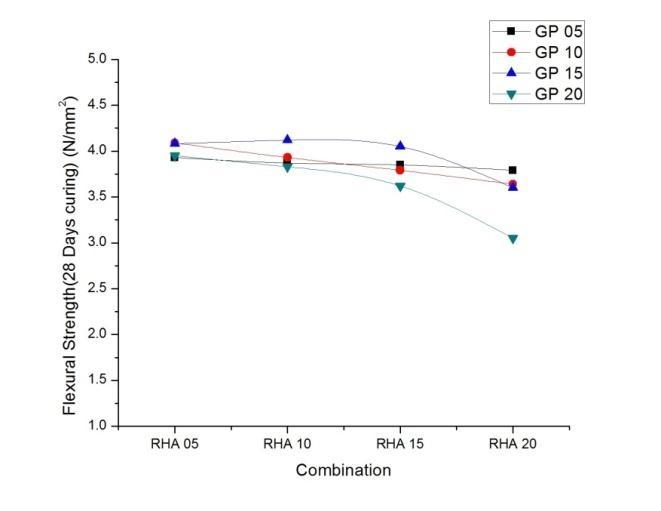

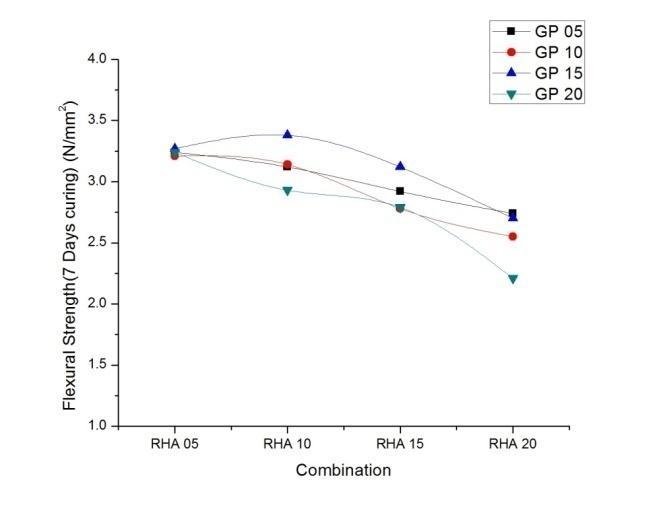

Fig.5.3andfig.5.4showsflexuralstrengthofconcreteforallvariouscombinationsandconventionalconcretefor7 days&28 dayscuringagerespectively.Table5.2numericalvaluesofflexuralstrengthforeachcombinationfor7 days&28 dayscuring age.GP15RHA10combinationshowsmoreflexuralstrengththanconventionalconcrete.

Fig.5.1 7daysCompressiveStrengthofconcreteforkeepingGlassPowderconstant&RHAvarying

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Fig.5.2 28daysCompressiveStrengthofconcreteforkeepingGlassPowderconstant&RHAvarying

Fig.5.3 7DaysFlexuralStrengthofconcreteforkeepingGlassPowderconstant&RHAvarying

Fig.5.4 28DaysFlexuralStrengthofconcreteforkeepingGlassPowderconstant&RHAvarying

GP Glasspowder

RHA Ricehuskash

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Table 5.1 CompressiveStrengthofVariousConcreteMixes

Material Mixture

Compressive strength of concrete cubes (N/mm2) Material Mixture

Compressive strength of concrete cubes (N/mm2)

7 days 28 days 7 days 28 days

GP00RHA00 22.22 32.74 GP15RHA05 20.74 34.07

GP05RHA05 21.33 31.4 GP15RHA10 20.89 34.22

GP05RHA10 18.52 30.96 GP15RHA15 19.41 30.66

GP05RHA15 16.89 30.07 GP15RHA20 16.89 26.67

GP05RHA20 14.81 28.44 GP20RHA05 20.15 30

GP10RHA05 21.03 32 GP20RHA10 17.63 25.33

GP10RHA10 18.37 31.55 GP20RHA15 15.7 20.66

GP10RHA15 16.67 29.92 GP20RHA20 12.4 16.44 GP10RHA20 16.44 25.92

GP Glasspowder,RHA Ricehuskash

Table 5.2 FlexuralStrengthofVariousConcreteMixes

Material Mixture

Flexuralstrengthofconcrete cubes(N/mm2) Material Mixture

Flexuralstrengthofconcretecubes (N/mm2) 7days 28days 7days 28days

GP00RHA00 3.3 4.05 GP15RHA05 3.27 4.08

GP05RHA05 3.24 3.93 GP15RHA10 3.38 4.12

GP05RHA10 3.12 3.87 GP15RHA15 3.12 4.05

GP05RHA15 2.92 3.85 GP15RHA20 2.7 3.6

GP05RHA20 2.74 3.79 GP20RHA05 3.24 3.95

GP10RHA05 3.21 4.09 GP20RHA10 2.93 3.83

GP10RHA10 3.14 3.93 GP20RHA15 2.79 3.62

GP10RHA15 2.78 3.79 GP20RHA20 2.21 3.05

GP10RHA20 2.55 3.64

GP Glasspowder,RHA Ricehuskash

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Withinscopeofpresentworkfollowingconclusionshavebeendrawn

AdditionofGlassPowderandRicehuskashincementconcreteforreplacementofcementsolvetheproblemofdisposalof wastematerial.

When25%ofcementisreplacedby15%GlassPowderand10%Ricehuskashcompressivestrengthofmodifiedconcrete is1.04%morethantheconventionalconcrete.

When25%ofcementisreplacedby15%GlassPowderand10%Ricehuskashflexuralstrengthofmodifiedconcreteis 1.01%morethantheconventionalconcrete.

OnadditionofGlasspowderandRicehuskashinitiallyupto7daystherateofgainofstrengthisslightlylowbutat28 daysitmeetsrequireddesignstrength.

Costofthemodifiedconcretewhen25%ofcementisreplacedby15%GlassPowderand10%Ricehuskashis16.36% lessthantheconventionalconcrete.

Themodifiedconcreteisecofriendlyascementconsumptionislow.

Useofthemodifiedconcretewillreducethecementconsumptionhencesavingofenergywilltakeplace.

Modifiedconcreteiseconomicalthanconventionalconcrete

[1] Coutinho,S.J.,2003“ThecombinedbenefitsofCPFandRHAinimprovingthedurabilityofconcretestructures”.Cementand concretecomposites:25(1):2003,pg51 59.

[2] MemonShazimAli,ShaikhMuhammadAli,AkbarHassan(2008)“Productionoflowcostselfcompactingconcreteusingrice huskash”(ICCIDC I)

[3] ChikFarahAlwaniWan,BakarBadorulHishamAbu,JohariMegatAzmiMegat&JayaRamadhansyahPutra,(2011)“Properties ofconcreteblockcontainingricehuskashsubjectedtogirha”IJRRAS8(1)

[4] KhatibJ.M.,NegimE.M.,SohlH.S.andChilesheN.(2012) “GlassPowderUtilizationinConcreteProduction”Europeanjournal ofappliedscience4(ISSN2079 2077)

[5] CelsoYojiKawahata,HolmerSavastanoJunior,JoanaSousa Coutinho(2012)“Ricehuskderivedwastematerialsaspartial cementreplacementinlightweightconcrete”Lavras,volume36

[6] Dr.PatagundiB.R.,Dr.PrakashK.B.(2012) “Effectoftemperatureonthepropertiesofconcretecontainingglasspowderas pozzolana”IJERT,ISSN2278 0181,Volume1Issue8

[7] PatilDhanarajMohan,Dr.SangleKeshavK(2013) “Experimentalinvestigationofwasteglasspowderaspartialreplacementof cementinconcrete”Internationaljournalofadvancedtechnologyincivilengineering,ISSN:22311 5721, vol.2

[8] Dr.KumarG.Vijay,MsVishalinyH.,Dr.Govindarajulu(2013)“StudiesonGlassPowderasPartialReplacementofCementin ConcreteProduction”(IJETAE,ISSN2250 2459,vol.3)

[9] VandhiyanR.,RamkumarK.andRamyaR.(2013) “Experimentalstudyonreplacementofcementbyglasspowder”(IJERT, ISSN:2278 0181,vol.2issue5

[10] Godwin A. Akeke, Maurice E. Ephraim, Akobo, I.Z.S. and Joseph O. Ukpata(2013) “Structural properties of Rice husk ash concrete”(IJEAS,ISSN2305 8269,vol.3,No.3)

[11] GambhirMLConcreteTechnology(fourthedition)

[12] Urhan,S.(1987).“Alkalisilicaandpozzolanicreactionsinconcrete”Part1:interpretationofpublishedresultsandahypothesis concerningthemechanism.CementandConcreteResearch,17(1),141 152