International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Student, NITRA TECHNICAL CAMPUS, GHAZIABAD, India ***

Inaweavingloomtherearethreeprimarymotionsnamelyshedding,pickingandbeatup.Inaloomspeedofpickingis importantsinceitdeterminestheproduction.Therearevariouspickingmechanismswhicharecommerciallyavailablein marketsuchasjetmachinesbothwaterandair,rapier,projectileandmultiphaselooms.Inthispaperdesignedanewpicking mechanismknowsasmagneticpickingmechanism.Inmagneticprocessbyusingmagneticlevitationconceptpickingcanbe done.Theproblemoccurswitholdsystemsareenergyuses,speed,productionandthestressonwarpyarnswhileshedding andpickingdevicesize.Itcanbeintroduceandconventionalorexistingloominlowcost.

Firstloomwasdevelopedin4400BCinEgyptforweaving,inChinasilkiswovenaround2600BC andlaterinRomanitis usedtowovewoolandlinenforEuropeanpeople[1].DuetoslowproductionandrequirementEdmundCartwrightdesign thefirstmechanical loomwhichincreases production[2].Followingisthechart1. ofdifferentloomfromconventionalto unconventional it can be classified according to picking method or supply package used in weft and according to automationinloom[3].Nowaboutprimitiveloomsinthispitandloomsareusedwhereapitismadeasframeloomsfor exampleNagagamchaaremadeinIndia.Otherloomisframeloomorflyshuttleloomwherewoodenloomismadeasin picture.Nowcomestosemiautomaticloomwheremostofthemotionisautomaticlike beatupisdoneasinpicture.And in power loom all the motion are control by mechanical parts like gears etc. in automatic loom like Pirn changing is introducedwhereshuttlepirnischangedwithintheloom [5]. Inunconventionalloom/shuttlelessloomnewmethods ofpickingareintroducedlikerapier,projectile,jetandmultiphaselooms.Inrapiertwocarriersareusedknownasrapier whereonecarriercarriestheyarnfromthepackagetothehalfwaythroughshedandotherhalfiscarriedoutbyanother carrieracompletecyclemakesapicking.Inprojectilebyusedofprojectilewhichisabulletlikewheretorsionbarisused togivemotiontothegripperwhohelpinpicking.Injettwomethodsareusedwaterandairwherewaterandair areused topassthepickfromoneendoftheloomtoanotherside[6].Inmultiphaseelectromagneticshuttleisusedwhichmakeit pickinsertionratehigh. Themainobjectiveofthisnewdevelopmentistoreducetimeconsumption,increaseinspeed,quality,flexibilityinsenseof yarnetc,lesssoundproduced,simplemachineforuseI.e.easyhandlinglesscomplicated. Byusing electro magnets, it canbe achieved whichwill helpinfull filing thedrawback ofthe previous generationlooms. Mainlythecostofthemachineistohighandcomplicatedmachinepartsareused[7].

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |Page209

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Fig.1:

There are basically three motions in a loom primary motion, secondary motion and auxiliary motion. In primary motion (shedding, picking, beat up), secondary motion like take up and let off, in auxiliary motion various stop motion. Mainly primary motion is most important motion without which a loom cannot run. Secondary motion is motions which are essentialbutpartiallyimportant.Auxiliarymotionismotionwhichmainfocusistoimprovequalityoftheproduction[4]. Pickingisapartofprimarymotionwhereayarnis passingthroughashedorwarpsfromonesidetoanothersideofthe loom by using various methods. In recent development of picking the main objective is to increase production with less energyuses,lesssoundandgreatflexibilityofloomandimprovequality.Therearevariouspickingmechanismsbut,inthis paper,mainlyfocusingonshuttlelessmechanism.

There is various unconventional picking mechanism which are commercializedlike Rapier loom, projectile, air jet, water jetand multiphaseloom.Discussionofpickingmechanismisinbelow Rapier

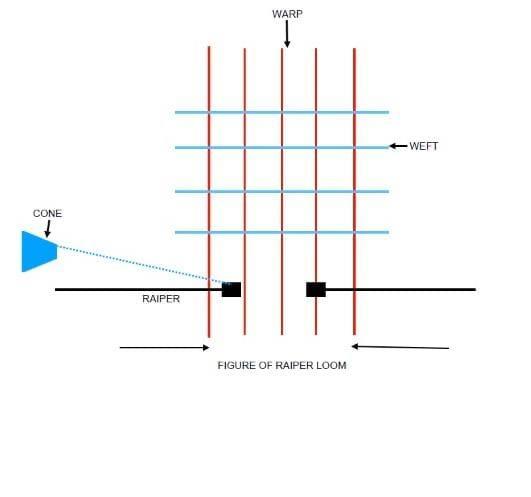

In this type of loom two carriers known as rapiers are given in figure 1. are used one half uses to bring the pick to the half way through the shed and then it is pass to the other carrier which carry the pick to the other half of the loom which complete the picking[5].

Typeofrapierlikeflexiblewheretapewheelsareused,rigid where rapiers are in rigid form and telescopic where the extralengthgoesinsideliketelescope. Number of rapiers double picks with single rapier, single pickwithsinglerapierandtwophaseortwin.

MethodofweftinsertionthatisDewasandgablersystem Pickingmechanismposition.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

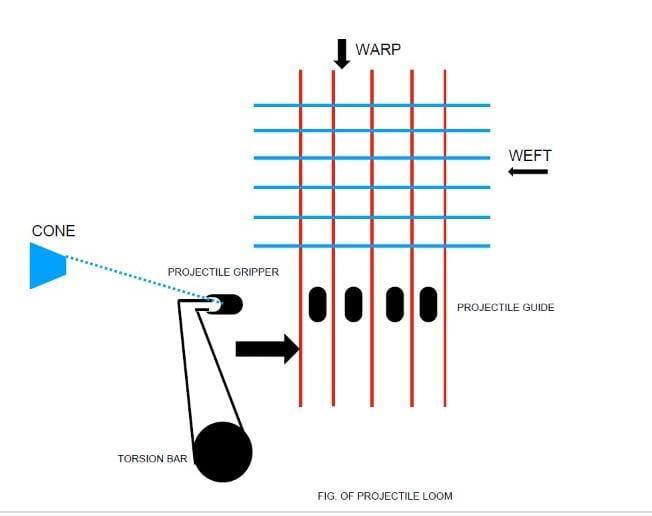

This was invented by Sulzer brother and introduce in market in 1953. Here a Bullet like shuttle known as gripper projectile was used whichdiameteris90mmlong,weightisaround 40 grams. The main feature of this loom is the picking mechanism which does not touch the warpbecauseoftheuseofguidethroughwhich the gripper is moved from one part to another of loom [6]. The projectile is accelerated with thehelpoftorsionbar Fig.3.

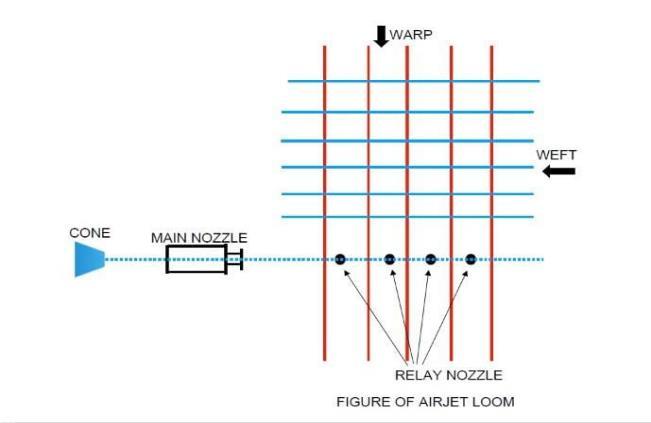

Inthispickingmethodairusedbecauseofwhichsoundproduce was less fig.4. Nowadays relay nozzles are used. First there is a mainnozzlefromwheretheairispassedwithhighvortexofair which carries the weft after that by using relay nozzles and profile reed the weft is passing to other side of the loom and pickingtakesplaces[7].

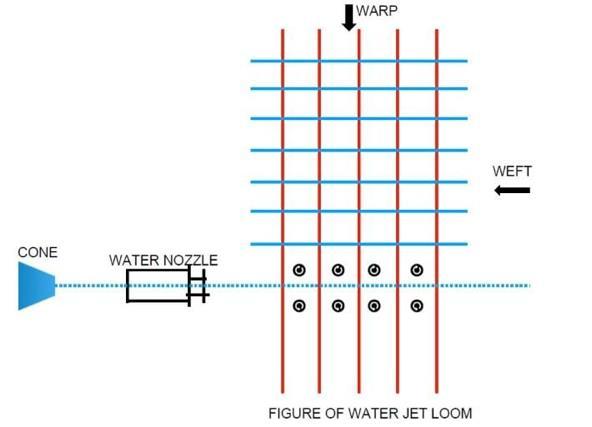

Inthissystemfig.5incaseofair,waterisusedforpickingwherewater is pumped through nozzles at high pressure which pass the weft from one position to other side of the loom. It was developed by Svaty and wascommercializedin1955[8].

Fig.3: Projectile loom

Fig.4: Air jet loom

Fig.5: water jet loom

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |Page211

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

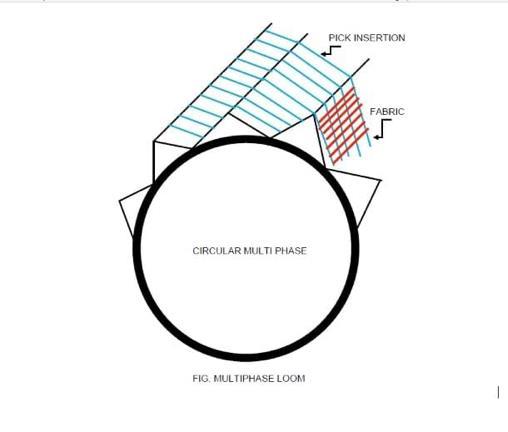

Theconcepttothisloomisthatinsinglephaseloomall the primary motion that is shedding, picking and beat up is on warp direction but According to multi phase bothwarpandweftdirectionsheddingcanbeachieved. There are two types of machine flat i.e. rectilinear or circular[8].

In mention all above picking system there are drawbackslike Inrapiernoiseishighandproductionisless Inprojectilecostishigh,complicated,noiseishigh Injet machine in air jet machinepicksare broken dueto pressureofair,pillingupofyarnduetoair resistance and in water loom only hydrophobic Fibrescanbeweave Inmultiphaseloom moiré effectisproduced,light fabriccanbeproduced,costishighetc. Therefore, to overcome these drawbacks a new picking methodisrequiredwhichwillworkonelectromagnetic.

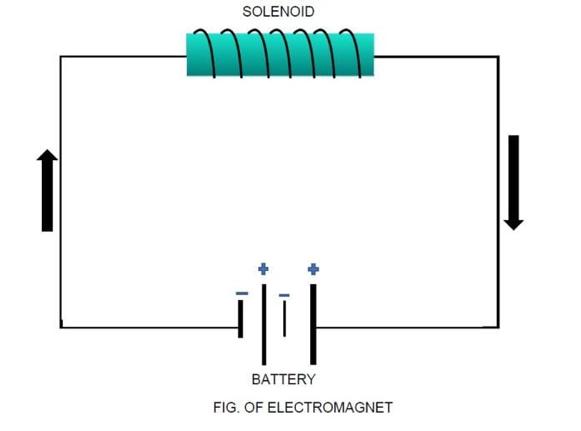

Electronics magnets are made of number of wire coils which has electricity passing through it which make the core magnetised. Engineers use solenoids by using length of metal around a template mainly round. And the electromagnet powercanbeadjustbyusingformulasis Force = charge * velocity of charge *(magnetic constant * number of turns in solenoid * current)

Calculationforforceofelectromagnetfig.7. J= (n*i) 2 * magnetic constant * a/ (2* g2)……………………………………………………..(Eq.1) Where, jistheforce iisthecurrent gisthelengthofgapbetweenthesolenoidandapieceofmetal aisthearea nisthenumberofturnsthesolenoidandmagneticconstant=4*PI*10 7 Byusingthismethodinthepickingmotionthereisadvantages

1. Duetoitssmallpickingmethodnoshedispossibletheweftcarrieriscanbeusemuchsmallerthanprojectilegripper. 2. Thespeedofthepickingisdeterminedbymagneticfieldproduced

3. Duetonouseofmovingmechanismtorsionetcthesoundcanbereduced

4. Flexibilityisalsoincreasedduetoitsversatilityeveryfibrecanbeused

5. Due to small carrier delicate yarn or fine count can be produced due to less opening of warp with high speed and qualityisalsoimproved.[9]

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |Page212

Fig.6: Multiphase loomInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Therearemanyadvantagesofthispickingmethodandcanreplaceotherpickingmechanismsdrawbacks.

Fig.7: Electromagnet

Inpresentscenariotherearethreemethods:

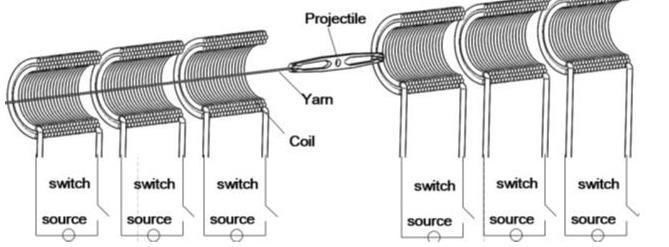

1. Electromagneticprojectile 2. Magnetictimingbelt 3. FOR Maglev Electro Magnetic Projectile In this method electromagnetic method fig. 8 is use where the carrier is moved by electromagnetic force direction. Here only two main components coil and the carrier. After a pick the motion is reversedforanotherpick.Itisatwowaysdirectionascomparetoconventionalprojectileloom.

Fig.8:ElectromagneticProjectile[10]

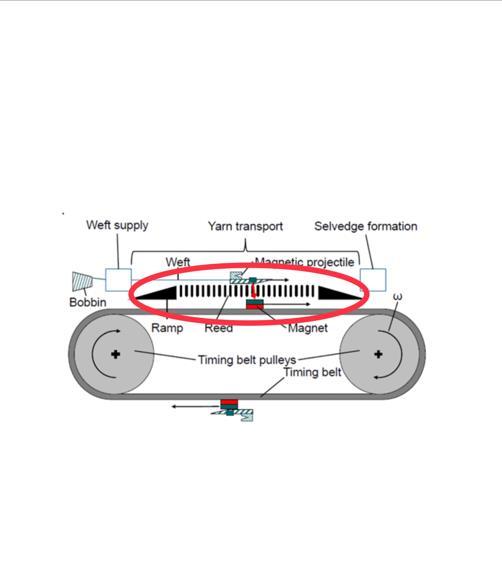

Magnetic Timing Belt inthismethodtwopulleysandabeltisusedwheretwopermanentmagnetsareusedwhichmove alongwithmagneticprojectilewithaspecialkindofreed. Fig.9.Bothsideofthereedthereisrampssothattheweftcan movefreelyoverthereed.Afterpickingthepickisreleasedandbeatuptakesplace.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |Page213

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

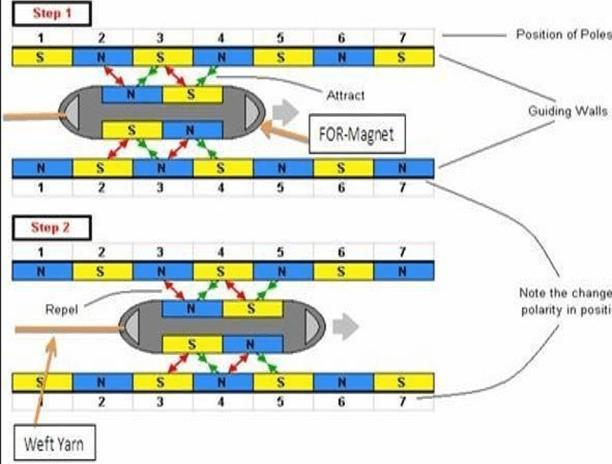

For Maglev: In this method fig. 10 basic magnetic concept is used where like poles repels and unlike pole attract. It is like the maglev train concept by changing the polarity of the electromagnet so that the carrier moves in forward and backward movement. Special kind ofreedisusedsothatpolesdoesnotinfluenceeachother.[10]

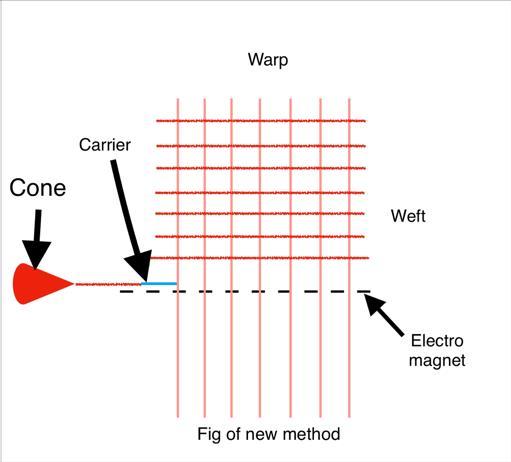

Asperabovediscussionaboutalltypesofloomandstudiedthe technologybasedonalltheseloomscreateanewideathatwillbe differentfromtheseexistingloomitwillbecreated,innovativeand sameproductionwillbedeliveredinshorttime.Thisloomwillbe known as “NO SHED LOOM or ALLURING LOOM”. The line diagram of the new concept loom is given in figure 11. It will solve the problem occurs with old systems are energy uses, speed, production and the stress on warp yarns while shedding and picking device size. Since the size of the carrier will be small the shedopeningisnexttonoshed.

Fig. 10 FOR maglev [10]

FIG.11OFNEWPICKINGMECHANISM

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Thisisconcludedfromthestudythattheproblemwhichisfindoutinthecurrentloompickingmechanism canbereduce by using newly developed electro magnetic mechanism. The main motive is to make a picking mechanism which reduce thecomplicationinmodernloomswithhighspeedthanotherpickingmethod.Andalsotoreducethesoundornoisethat is made by the existing loom and much more production. The versatility is also important which can make according to fabricwidthwhetherwideornarrowitcanbeproduceeasily. Attheendthenewmechanismcansolvemanyproblemsandcanuseitforfuturedevelopment.

1. wikipedia.(2022,April3).Retrievedfromhttps://en.wikipedia.org/wiki/Loom

2. Atkins, W. A. (n.d.). encyclopedia. Retrieved from encyclopedia.com: https://www.https://www.encyclopedia.com/history/encyclopedias almanacs transcripts and maps/power loom inve nted.com/history/encyclopedias almanacs transcripts and maps/power loom invented

3. Sobuj, M. S. ( 2015, February 10). textilestudycenter. Retrieved from www.textilestudycenter.com: https://textilestudycenter.com/classification of loom

4. Kiron, M. I. (2014 , November 23). textilelearner. Retrieved from www.textilelearner.net: https://textilelearner.net/primary secondary and stop motions of loom/

5. Diary, J. (n.d.). textileschool4u.blogspot. Retrieved from www.textileschool4u.blogspot.com: http://textileschool4u.blogspot.com/2013/11/looms classification of looms brief.html

6. raja, D. (2014, april 20). slideshare. Retrieved from www.slideshare.net: https://www.slideshare.net/Danish110/unconventional method of weft insertion

7. AMBURE, S. (March 2, 2020, March 2). textilestudycenter. Retrieved from www.textilestudycenter.com: https://textilestudycenter.com/modern techniques weft insertion projectile weaving machine/

8. TALUKDAR, D. M., SRIRAMULU, P., & AJGAONKAR, D. weaving machine *mechanisms*management. MAHAJAN PUBLISHERSPRIVATELIMITED.

9. Banas, T. (2018, March 13). sciencing. Retrieved from www.sciencing.com: https://sciencing.com/calculateforceelectromagnet5969962.html

10. Atkins, W. A. (n.d.). encyclopedia. Retrieved from encyclopedia.com: https://www.https://www.encyclopedia.com/history/encyclopediasalmanacstranscriptsandmaps/powerloominvent ed.com/history/encyclopediasalmanacstranscriptsandmaps/powerloominvented

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |Page215