International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Varad Burkule1 , Vishal Choundiye2 , Devesh Kathar3

123B.tech, Second year Student, Mechanical Engineering Department, Deogiri institute of Engineering & Management Studies, Aurangabad 431001 ***

Abstract Casting is a process which allied to some defects which gives the chipper quality of the desired product To increase the quality and productivity of the any organization the casting defects Should be reduced, this paper will shows. The casting defects & remedies

Key Words: defects,remedies,casting,productivity,quality

CastingisaprocesswhichhavingamassiveHistoryof7000 yearswhichisoneoftheoldestmanufacturingprocess,even tough. Today also the initial stage of the most of the manufacturingprocessesiscasting.

In the casting process, firstly the metal is converted into liquid state by the heating process at high temperature & thenliquidsmetalpourintothemouldcavity.Andleavesto solidify,afterthesolidificationtheproducttakeout,clean& trimtogetthedesiredshape.

InthecastingprocesstherearesomedefectslikeBlow,pin hole, Drop, shrinkage & many more. It impossible to eliminatebutitcanbereduced.TheTaguchimethodisused toanalysingsomecastingdefectsLikeSand&maidrelated methodssuchasSanddroppoormould,blowbolesetc.also canusethesix sigmamethodology,astheresearcherssaid that there is a Break through improvement. In reducing defectsnearlythereisa50%.Reductionincastingdefects.

Rahul T Patil, Veena S Metri [1] In this research paper different casting defects are studied. These will help to quality control department of casting industriousness for analysisofcastingdefect.Thisstudywillsurelybehelpfulin perfectingtheproductivity.

Avinash Juriani [2] A focus on industrial case studies for castingdefectsisbandiedinthispaper.Byusingcauseand defectanalysisconceptionthevariouscausesandremedial measuresaresuggested.

Vasdev Malhotra, Yogesh Kumar [3] Casting defects are veritablyseriousfortheindustry.Thesedefectsshouldbe minimized.Inthispaperthedifferentreviewofresearchers hasbandiedregardingthecastingdefects.

Mrs.RashiP.Gaikwad,Mr.Pankaj[4]Inthisresearchwork differentcastingdefectsarestudied.Byreferringdifferent explorationpaperscausesandtheirremediesarelisted.By theanalysisthedifferentdefectthemetaltheindustrieswill improvetherequalitycontroldepartment.

AkashA.Gaware,Dr.A.K.Mahalle[5]Inthisresearchpaper research that Simulation helps to manufacture defect free casting without consuming too important time. In India, casting simulation technology is adding fleetly. Besides perfectingthebeingcasting,thistechnologycanalsobeused forrapid firedevelopmentofnewproducts.

Vaibhav Ingle, Madhukar Sorte [6] In the paper, a new bracket of defects and imperfections or Al amalgamation castingshasbeenpresented.threeordersofcastingdefect havebeenlinkedstuffing relatedblights,lossblights,shape relatedblights,thermal affiliateddefects.

NDMehta,AVGohil [7]Fromthereviewofliteratureit's perceivedthatresearchhasbeencarriedoutaboutvarious casting blights, their causes and remedies to be taken to amend casting defect. Research has also been done for optimizationofcolorfulcastingdefectminimization.

Pradip Kumar Ganguly [8] In this exploration Understand currentscriptoffoundryassiduity.innowaday’sfoundry assiduityproduceproductdifferenttypeslikeferrous and non ferrous,thiscasestudysubstantiallyfocusesonsword foundry.

Anil B Ghubade [9] Defect free casting is necessary in the manufacturingsectorascastingisoneofthemostpromising manufacturing processes to produce complex part with intricatedetails.Defectfreecastingisthemainchallenged presentlyfacedbyassiduityowingtodifficultytocontrolthe processparameters.

Chelladurai,N.S. Mohan [10] In this review several casting defects and their occurrence cause were linked. This will help in assaying the disfigurement and remedies to overcomethem.CastingRejectiononthebaseofthecasting blights should be as minimal as possible for advanced quality.Castingblightsareveritablyseriousfortheassiduity. Theseblightsshouldbeminimized.

NiravMehta,A.V.Gohil[11]Theresearchcarriedoutinthe presentarticleprovidesknowledge groundedintertwined

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

module to help casting defect analysis process in medium andsmallscaleindustries.Thedatabasestructureforcasting defect analysis is been strengthened considering both industrialandtheoreticalapproaches.

Vishal Choundiye [12] The research carried out in the present article provides knowledge of sand casting and various defects can develop during manufacturing, depending on factors such as raw material quality, mold designandcontrolofmachiningparameters.

It is undesirable irregularities occurs in the casting process,therearevariousfactorsresponsibleforthat,inthat inthispaperwewilldiscussthevarioustypeofdefectsand itsremediestogetthedefectfreeproduct.

Thedefectscanbeclassifiedintothe5stepsasfollows

Gas porosity: blowhole,openhole,pinhole

Shrinkage defects: Shrinkage

Mold material defect: cut&washes,swell,drops, Metalpenetration,rattail.

Metal pouring defect: coldshut,misrun,slaginclusion.

Metallurgical defects: hottears.

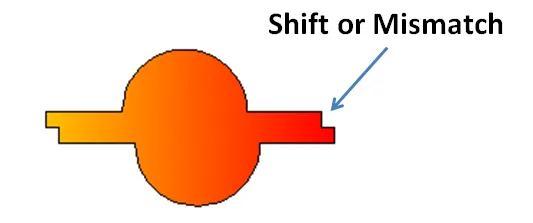

i. Shift or mismatch: shift or mismatch defect can occurduetomisalignmentofdrag&copebox

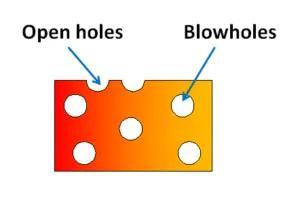

ii. Blow holes: it Blow holes i it is a large circular Cavitycreatesduetothegasofmoltenmetal. This typeofdefectcavityformsincopeorSurfacepartof mold

Fig .2 Blowhole

Causes:

1)Immoderatemoistureinsand. 2)FinegrainsofSand 3)ToomuchrammedSand. 4)Improperventing,

Remedies:

1)ControlthemoistureofSand. 2)Sufficientrammingshouldbedone 3)Providepropervents. 4)useproperanddesiredsand

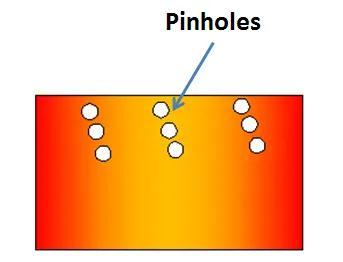

iii. Pin holes: pin holes are the very small holes are about the 2 3 mm in size. Which can occur on surfaceofcasting

Thisdefectoccursatthetimeofsolidificationion, &Solubilityofhydrogengasdecrease&startsrun offmoltenmetal&createssmallholescardpinhole.

Fig .1 shiftormismatch

Cause: 1)Misalignmentofcope&dragbox 2)Misalignmentinpatternplates.

Remedies: 1)Dothecorrectalignmentofdrag&copebox 2)Checkpatternplates. 3)Alignaflask

Remedies:

Fig .3 Pinholes

1)usemoderatemoisturecontentsand 2)usepropermaterial. 3)pourthemoltenmetalincorrectway. 4)increasepermeabilityofsand

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Causes:

1) highmoistureContent

2) hydrogengassolubility

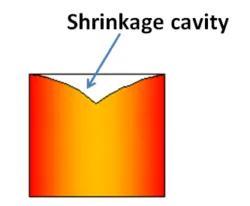

iv. Shrinkage: itisa.formationofthe cavitybecauseofinsufficientmoltenmetal pouringoritisavolumetriccontraction calledshrinkage.

Remedies:

1) Pouringtemperatureshouldbedesirable

2) MakepropergettingSystem.

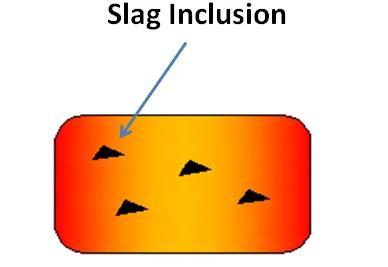

vi. Slag Inclusion: this defect is caused. when the moltenmetalcontainssomeImpurities&itpoured incavityandgetsolidify.

Causes:

1)highpouringtemperature.

2)undesirableSolidificationofmetal

Remedies:

1)pourrequiredamountofmoltenmetal 2)Makepropervents

3)Risershouldbeatproperlocation

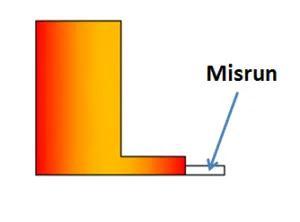

v. Misrun: Whenever there is a solidification before the required molten metal filled, Because of pre solidification,thespaceisCreatesinmoldcavity& thisdefectisCalledasmisrun.

Causes:

1)presenceofimpuritiesinmoltenmetal 2)Impuritiesinmold/sand

Remedies:

1)RemoveImpuritiesfrommoltenmetal 2)Checkimpuritiesbeforemetalmelts 3)CheckImpuritiesinmoldcavity/sand.

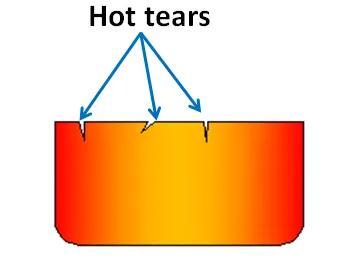

vii. Hot tears or hot cracks: Whenthemoltenmetalis hot that is weak and because. of residual stresses castingfails.Asmoltenmetalbecomescool,&cracks comesonSurfaceCalledhottearsorcracks.

Causes:

1) undesirableorlessfluidityofmoltenmetal

2) lesstemperatureofthemoltenmetal.

3)Impropergettingsystem.

Causes

1) Impropermolddesign

2) Residualstresses

3) Hightemperature

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Remedies

1) makepropermolddesign

2) TrytoreduceResidualstressesmelt

3) Pouringtemp.Shouldbedesirable.

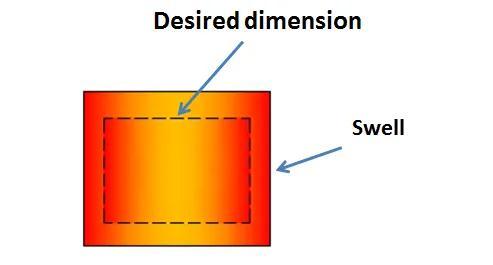

viii. Swell: Swellistheenlargementofthecavity, &Moltenmetalpressure Becauseofthisthere Isoverallenlargementofcasting

Remedies:

1) makeproperramming

2) usecorrectcompositionofsand

3) usepropermoisturecontentsand,

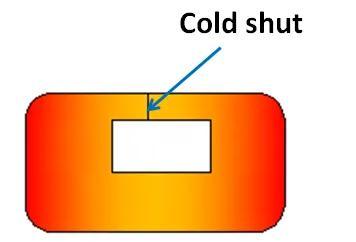

x. Cold Shut: itisacrossinginmoldcavitywhentwo metal streams does not intermix & having round edgescalledcoldshut.

Fig

Fig 10. ColdShut

Causes:

1) Improperdesignofcavity.

2) Improperramming. 3) Rateofmoltenmetalpouring.

Remedies:

1) Makepropermolddesign. 2) makeproperramming 3) pourmoltenmetalwithUniformSpeed

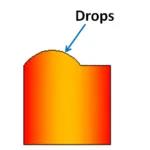

ix. Drop: Whenever there is a cracking on upper surface of sand, the sand particles fall ino molten metal

Causes:

1) Improperramming(soft) 2) lessmoisturecontentinsand 3) Compositionofsand

Fig.9 Drop

Causes:

1) Impropergettingsystem 2) thinsectionsinCasting 3) Lessfluidityofmoltenmetal

Remedies:

1) makethepropergettingsystem. 2) usedesired&hotmoltenmetal

5. Conclusion:

In this study of the defects by referring the research papers or review papers. the defects and remedies are suggested,thispaperwilldefinitely helptothefoundries/ Industries to reduce or to eliminate the casting defects, it willalsohelpforqualitywork,andtoImproveproductivity andminimizetherejection,IncaseofImprovementwecan use six sigma method to reduce or eliminate the casting defects, As the researchers said there is a breakthrough improvementthtis50%toeliminatethecastingdefects,by usingthedifferentanalyzingaswellasdesigningsoftware’s canalsohelptoreducethecastingdefects.

[1]Rahul TPatil,Veena SMetri,CausesofCastingDefects with Remedies, International Journal of Engineering Research&Technology,Vol.4Issue11,November 2015.

[2]AvinashJuriani,CastingDefectsAnalysisinFoundryand TheirRemedialMeasureswithIndustrialCaseStudies,IOSR Journal of Mechanical and Civil Engineering (IOSR JMCE), Volume12,Issue6Ver.I(Nov. Dec.2015).

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

[3] Vasdev Malhotra, Yogesh Kumar,casting defects: an literature review,International Journal of Design and Manufacturing Technology (IJDMT), Volume 7, Issue 1, January April2016.

[4]Mrs.RashiP.Gaikwad,Mr.Pankaj,Studyofcastingdefects and their remedies a review,International Journal of AdvancedResearch,November2016.

[5] AkashA. Gaware,Dr.A.K. Mahalle, A Review on Investigation of Casting Defects with Simulation,International Journal of Innovations in EngineeringandScience,Vol.2,No.5,2017.

[6]VaibhavIngle,MadhukarSorte,Defects,RootCauses in CastingProcessandTheirRemediesReview,International JournalofEngineeringResearchandApplication,Vol.7,Issue 3,March2017.

[7] N D Mehta, A V Gohil, Innovative Support System for Casting Defect Analysis A Need of Time,Science Direct,Proceedings5(2018).

[8] Pradip Kumar Ganguly, A review on reducing casting defectsandimprovingproductivityinasmallscalefoundry usingdmaicapproach,Internationaljournalofengineering sciences&researchtechnology,July,2018.

[9] Anil B Ghubade, Review on casting defects and methodologiesforqualityimprovement,JournalofEmerging Technologies and Innovative Research, Volume 6, Issue 4, April2019.

[10]Chelladurai,N.S.Mohan,Analyzingthecastingdefectsin smallscalecastingindustry,ScienceDirect,13May2020.

[11]NiravMehta,A.V.Gohil,Developmentofcastingdefect analysismodulethroughintegratedapproachforsmalland mediumscaleindustries,ScienceDirect,8September2020.

[12]VishalChoundiye,IntroductionofSandCastingProcess anOverview,InternationalResearchJournalofEngineering andTechnology,Volume9Issue6S.No68,June2022.

Varad Burkule PursuingtheBachelorof Technology Degree [Mechanical] From Deogiri Institute of Engineering and Management Studies, Aurangabad, Maharashtra,India

Vishal Choundiye Pursuing the Bachelor of Technology Degree [Mechanical]FromDeogiriInstituteof EngineeringandManagementStudies, Aurangabad,Maharashtra,India

Devesh Kathar PursuingtheBachelor of Technology Degree [Mechanical] From Deogiri Institute of Engineering andManagementStudies,Aurangabad, Maharashtra,India.