International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Power in Rolling-A Review

Devesh Kathar1 , Varad Burkule2 , Vishal Choundiye3

B.tech, Second year Student, Mechanical Engineering Department, Deogiri institute of Engineering & Management Studies, Aurangabad 431001 ***

123

Abstract On the basis of classic rolling theory, during manufacturing of rolling based products and to develop a newrollingmillthereisaproblemofaccuratecalculationof powerparametersofrolling.itsnecessarytocalculatepower parameters an improved calculation method for rolling pressure and load torque for proper production and developmentofnewrollingmills.Inthispaperpowerand requiredtorqueformulasstudied

Key Words: RollingTheory,rollingprinciples,terminologies, Torque,power

1. INTRODUCTION

Rollingistheprocessofreducingordecreasingthethickness or changing the cross section of a long workpiece by compressivetypeofforcesappliedwithhelpofsetofrolls

Powerparametersofrollingmillsclassifiedaccordingtothe numberofmill standrolls,whichmakethegeometryofthe deformationzone.Accordingly,thesecanbecategorizedby thetypeofrollgrooveandtherolltransmissionpath.

Themostcommongroovesaretriangular formedbythree smoothrolls;rectangular formedbyfourrolls; hexagonal formedbysixsmoothrollsorthreegroovedrolls

To determining the power parameters, improvement of calculationmethodswillprovideanopportunitytosimulate orimprovetherollingprocess.

Thecalculationofpowerandforceparametersisapplicable eitherforthebuildofnewmillsorattheextensionofthe rolledproductrangeoftheexistingones.

Overthepastdecades,therehavebeensignificantchangesin thedesignofrollersandtechnologicalstrategyforrolling,as wellasindraftingways

Continuouslygrowingmarketrequirementsformetalgoods andproductsorderabouttheneedtoexpandtherangeof rolledassortment.

Nowdays, Modernstand design proceduresare based on thegatherexperienceofusingvariousgroovesystems.

[

2. LITARETURE REVIEW

1] P. O. Aiyedun1, O. S. Igbudu Torque performs a totally great roll at some stage in rolling operation. Therefore, there'sthewanttolimitthemtobeabletolesseneachvalue and weight, which in the long run interprets into low strength dissipation and consumption. It became located that.

[2] Huang Changqing, Deng Hua the mounted version of rolling pressure calculation, primarily based totally at the traditionalrollingconceptandbyusing3sub fashionsofthe elasticflattenrollradiusversion,thepressurekingdomthing version and material deformation resistance version, became regressed primarily based totally on real manufacturing information and get excessive precision mathematicalversion.

[3] Mahdi Bagheripoor, Hosein Bisadi ,A mathematical versionprimarilybasedtotallyattheFEapproachhasbeen evolved to simulate warm rolling of business natural aluminum strips. The predominant innovation of this paintingsisaprecisionevaluationoftherollpressureand torque and their fluctuations at some stage in the rollingtechnique. The results of fundamental technique parameterswhichincludesrollingpaceandstripdiscount areconsidered.

[4]VRGasiyarov,AARadionovAnalyticaldependencefor rollingstressatsomestageinrollingofsheetslabsthicker than 250 mm are given. When growing a brand new approach, particularity of rolling mill expanded motion becameconsidered.Angle ofutility factorofrollingstress resultantpressureinrollingmill5000standbecamedecided experimentally.

[5]VoroninS.S.,MaklakovaE.A,tosummarizethisstudies paper, it could be concluded that the direct utility of the simplified approach of instructional A.I. Tselikov is inadmissible at some stage in tough on warm plate mill 5000,asitoffersmiscalculationswithinsidethefirstpasses to 38%. With the discount of the sheet thickness miscalculationisdecreasedto2...6%.

[6]ElenaSorochan,ViktorArtiukh Onthepremiseoftwo dimensionalFEMmethodandnumericalrecurrentanswers of finite differential kinds of the circumstance of static equilibriumofindifferentbasicvolumes,receivedbyusing

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

fragmentationofthestripalongsidetherollinglineandthe evaluation of the location of plastic deformation, mathematical fashions have been evolved for stressed deformedmetallickingdomatwarmrollingofsheets,plates and strips, which made it feasible to improve dynamic fashionsofdrive’sstrainsoftherunningstands.

[7]MarinaN.Samodurova,OlgaI.KarandaevaTheauthors accomplishedacomplicatedoftheoreticalandexperimental researchofenergy parametersfor rolling generators with four rollbyskipstands.Thereceivedoutcomesmaybeused because the preliminary information for improvement of latestassortmentsforrolledmerchandiseorwithinsidethe layoutoflatestgenerators.Thepaperanalysestheaccuracy of figuring out the energy parameters through the recognizedanalyticaldependences,givingtipsforhisorher utilityincalculations.

[8] O.M. Ikumapayi, E.T. Akinlabi There are preferred and operationaldefectsthatariseinrolling.Generaldefectsare speciallyduetoimperfectionswithinsidethestartingand give up merchandise of rolling. Operational defects are becauseofdeformationsanddeflectionoftherollsatsome stage in rolling, which outcomes ultimately merchandise having defects. The gift article had focused on rolling operations as a metallic forming exercise in business productionoperation

4. What is rolling process?

Rolling is that the process of reducing the thickness or changing the cross section of an extended workpiece by compressiveforcesappliedthroughagroupofrolls.Rolling isthatthemostsignificantmetalformingprocess.over95% offerrousandnon ferrousmetalsandalloysareprocessed totheirusableshapesbyrolling.

TheRollingProcessconsistsoftwoopposingrollersanda metalsqueezinginbetweenthem.theessentialisthatthe thickness between the rollers should be but the Metal's (Ingot)InitialThickness

Intherollingprocess,permanentdeformationisachievedby subjectingthefabrictohighcompressive

5. Principles of rolling process

Rollingmaybeaprocesshabittoshapeessenceintoasmall long subcaste bypassing it through a niche of two rolls rotatinginmultitudinous direct ions(clockwiseandanti clockwise)Thegapbetweenthetwobreakersismeanttobe lowerthantheconsistenceoftheworkingpieceoffabricto be formed. When the essence piece is put between the breakers, it experiences a force of disunion and com pression from the breakers compressing it to be thin and elongated,orlongerthanitsoriginallengthWhenthepiece completesitswaythroughthegapbetweenbreakers,itmust

have lower thick ness than the original bone with an increased length and range. This drop in consistence is mentioneddraftandthustheincreaseinlengthandrangeis named an absolute extension and spread respectively the system of rolling could be a technical variety of metal formingforshapinglargebulkmaterialintofurtherdetailed partsandenormouslengthcrosssectionalaccoutrements,as well.Thediffer entkindsofrollingprocessthatresultsin increased functional per formance and product inflow is bandied supported the various techniques. The rolling operation must conform to the work com ponent figure being rolled, to confirm uniformity of the fabric and the changeinpropertybecauseofthedistortionprocess.

3.TERMINOLOGIES OF ROLLING

1 Ingot it'stheStartingEssencethatishandedInputto the Rolling Process. The Rod could be a forging language, where essence is taken out from the cast with colorful defects.

2 Bloom it's the primary rolled product of Ingot, with a samplingareaofrelatively230cm

Fig. Bloom

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

3 Billet thewaresisattainedbyfartherrollingofBloom, havingaquarterofsamplinglesserthan1600mm

6 Foil it's a skinny strip, with a range of 300 mm, and a maximumconsistenceof1.5mm.

Fig. Billet

4 Plate it'stheMillproduct,withconsistenceover6mm.

6.Hot Rolling

Fig. Foil

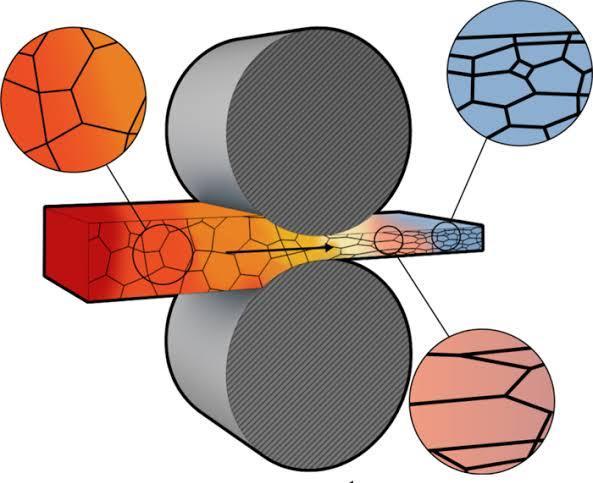

Hot rolling is a metalworking process in which essence is hottedabovetherecrystallizationtemperaturetoplastically distortitintheworkingorrollingoperation.Thisprocessis usedtoproduceshapeswiththeaskedgeometricalconfines andmaterialparcelswhilemaintainingthesamevolumeof essence. The hot essence is passed between two rolls to flattenit,outstretchit,reducethecross sectionalareaand gainainvariantconsistence.Hot rolledswordisthemost common product of the hot rolling process, and is extensively used in the essence assiduity either as an end productorasrawmaterialforposterioroperations.

Fig. Plate

5 Strip it'saMillproductwithconsistencebut6mm,and rangebut600mm.

The non uniform original grain structure of substance consistsoflargecolumnargrainsgrowinginthedirectionof solidification. This is generally brittle with weak grain boundaries and may contain scars analogous as loss depressions,porositycausedbyfeasts,andforeignmaterial analogous as metallic oxides. Hot rolling breaks the grain structures and destroys the boundaries, giving rise to the conformation of new structures with strong boundaries havingsteadygrainstructures.

StartingAccoutrementssimilarasbloomsorcrossbeamsat an elevated temperature inflow from the nonstop casting process directly into the rolling manufactories. In lower operationstheaccoutrementsstartatroomtemperatureand mustbehotted

either in a soaking hole, or by induction heating before beingfedintothemill.Hotrollingimproves

Toughness and strength, Ductility, Resistance to vibration andshockFormability,Weldability

Fig. Strip

Fig. Hot Rolling

7. Cold Rolling

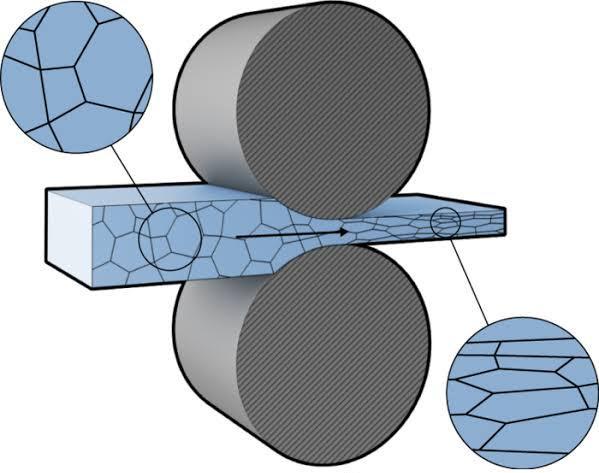

Coldrollingisafashionwhereasubstancestripordistance is passed between two combers and also squeezed and compressed.Thepositionofstrainpresentdeterminesthe parcelsandhardnessofthefinishedmaterial.Thisprocessis considerably used for face finish and high quality dimensionaldelicacy,whichcanhelpmaterialdamageand corrosion.

Coldrollingcanincreaseaessence'shardnessandstrength byashighas20%.Thisfashionalsoenhancesthefacefinish of essence and promotes advancedtolerances. Typically, cold rolled accoutrements are compressed during the process. Due to their lower confines, they've advanced strength compared to products that have been cluster mulledorhotrolled.Stripsthatarecoldrolledareavailable in conditions similar as full hard, skin rolled and quarter hard.

Coldrollingofessencestripisaspecialmemberwithinthe metalworking assiduity. The purpose of this process is to produce thinner essence strips with a good dimensional delicacy and a devoted face quality for a variety of operations.

During the cold rolling process, when the essence is put undermechanicalstress,it causesaendlesschangetothe liquidstructureoftheessence.Thiscausesanincreaseinits strengthandfrequentlyimproveserosionresistance.Along with perfecting its face finish, another advantage of cold rollingisbetterdimensionaldelicacy.

Fig. Cold Rolling

8.Rolling Materials

The introductory conditions for roll accoutrements are strengthandresistancetowear.Commonrollaccoutrements arecastiron,castsword,andforgedsword;tungstencarbide isalsousedforsmall peripheryrolls,similarastheWorking rollintheclustershop.Forged swordrolls,althoughmore expensivethancastrolls,haveadvancedstrength,stiffness, anddurabilitythancast ironrolls.Forspecialoperations, theyalsoarepolished.Rollsmadeforcoldrollingshouldn't beusedforhotrolling,becausetheymaycrackfromthermal cycling(heatchecking)andspelling(crackingorunloading offacelayers).Recallalsofromearlierconversationsthatthe elastic modulus of the roll influences roll Deviation and leveling. Note that the nethermost face of an aluminum libation can, for illustration, has what appear to be longitudinalscrapesonit.Thisisexplainedbythefactthat the face is a replica of the face finish of the roll, which is producedbygrinding.InthisWay,therollingdirectionofthe originalaluminumdistancealsocanbedeterminedfluently. Lubricants.Hotrollingofferrousblendsgenerallyiscarried outWithoutlubricants,althoughgraphitemaybeused.

Essence like titanium, aluminum, and nickel blends, along with pristine sword can all be cold rolled. Though cold rollingessencesimilaraspristineswordcoilincreasesthe strengthoftheessenceanditsfacefinish,itdoesdropthe rigidity. The same applies to essence line which has been colddrawnorrolled.still,oncetheessenceisannealed,it's readytobeusedinmultipleways.

Water grounded results are used to cool the rolls and to breakupthescaleontherolledmaterial.Nonferrousblends arehotrolledwithavarietyofcompoundedcanvases,mixes, and adipose acids. Cold rolling is carried out with water answerable canvases or low density lubricants, similar as mineral canvases, mixes, paraffin, and adipose canvases.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

The power in rolling process is expended principally in four ways

• Theenergyneededtodistortthematerial

• The energy needed to control frictional force in bearings.

• Theenergylooseinpowertransmissionsystem.

• Theenergylooseintheformofelectricallossesin themotor.

9.Torque in Rolling

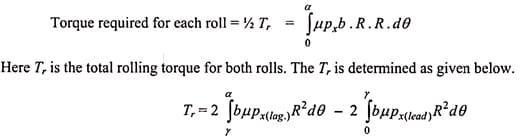

The torque is getting by integrating the frictional force multiplybyrollradiusofarcofcontact

Where, T:Torque

F:RollForce

L:Contactlength

10.Power

in Rolling

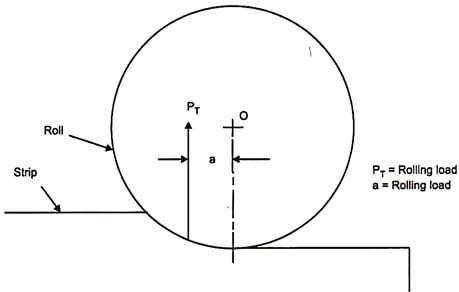

ThetorqueinrollingprocessismultiplicationofFanda.the powerisrequiredinrollingcanbegotbyassumingtheFis actatmiddleofarcofcontacttherefora=L/2

Therefore,thetotalpower(fortworolls)inS.I.unit

• Power(inKW)=2πFLN 60,000

Where,Fisinnewtons Linmeters

NinRevolutionsperminuteofrolls

Intraditionalunitpowercanbeexpressedby

Negative sign after first term is because in leading zone metal goes faster than the roll so that it helps to roll the rollersthegivenequationleadscomplexequation

ForeasyweconsideredthatPTisrollingloadactatdistance ‘a’fromcenterofrollsthatdistancecalledleverarmand‘L’ islengthoffrictionofcontact

• Power(inhp)=2πFLN 33,000

Where,FinpoundanLinfeet.

Reducing roll force

Rollforcescanbegetsignificantdeviationandlevelingofthe rolls(asitdoesinarubbertire).similarchangesinturnwill affect the rolling operation. Also, the columns of the roll stage(includingthecasing,chocks,andcomportments)may redirectunderhighrollforcestosuchanextentthattheroll gapcanopenupsignificantly.Accordingly,therollshaveto besetnearthanfirstlycalculatedinordertocompensatefor thisdeviationandtogaintheaskedfinalconsistence.

Decreasingfrictionatrollworkpieceintersection

Using lower periphery rolls to reduce the contact area

Fig. lever arm for rolling torque

Thevalueofλhasbeencalculatedbycalculatingtorqueby Equation for a huge range of rolling. For hot rolling λ changesbetween0.49to0.45.Lowervaluesareforhigher reductions.Forcoldrolling,thevalueofλchangesbetween 0.36 to 0.45. if we make the correction for elastic deformation of rolls and the increase in contact length, accuratecalculationscanbegot.

Thetorqueinrollingcanbealsocalculateby T=0.5*F*L

Taking lower reductions per pass to reduce the contactarea

Rollingatraisedtemperaturestolowerthestrength ofthematerial

CONCLUSION

Hence,inthisreviewwehaveconcludebasicofrollingand its working principal base on rolling theory and its types withintroductionanalsodefinetherollingtorquewithits diagramandhowpowerparametersdecided.Howtoreduce

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

rolling force. With help of this review, we can gain introductoryknowledgeofrollingprocess.

REFERENCES

[1]P.O.Aiyedun,O.S.Igbudu,SimulationofTorqueduring RodRollingofHCSS316atLowStrainRateUsing“Phantom Roll” Method, Journal of Minerals & Materials Characterization&Engineering,Vol.10,No.15,2011.

[2]HuangChangqing,DengHua,Researchonrollingforce model in hot rolling process of aluminum alloys, Elsevier Ltd,2011.

[3] Mahdi Bagheripoor, Hosein Bisadi, an investigation on therollforceandtorqueFluctuationsduringhotstriprolling process,Production&ManufacturingResearch,2014.

[4]VRGasiyarov,AARadionov,Methodofloadcalculation of electrical drives of rolling mills during heavy plate manufacturing, IOP Conf. Series: Materials Science and Engineering,2014.

[5] Voronin S.S., Maklakova E.A, The determination of energy power parameters of hot plate mill mechatronic system,ElsevierLtd,2015.

[6]ElenaSorochan,ViktorArtiukh,MathematicalModelof Plates and Strips Rolling for Calculation of Energy Power ParametersandDynamicLoads,MATECWebofConferences 73040097,04009,2016.

[7]MarinaN.Samodurova,OlgaI.Karandaeva,Calculating Power Parameters of Rolling Mill Based On Model of DeformationZonewithFour RollPasses,Multidisciplinary DigitalPublishingInstitute,13November2020.

[8]O.M.Ikumapayi,E.T.Akinlabi,Rollingoperationinmetal forming: Process and principles A brief Study, Elsevier Ltd,29February2020.

[9] A reference book of Manufacturing Engineering and technology,author SeropeKalpakjain,StevenR.Schmid Sixthedition

BIOGRAPHY

Devesh Kathar PursuingtheBachelor of Technology Degree [Mechanical] From Deogiri Institute of Engineering andManagementStudies,Aurangabad, Maharashtra,India.

Varad Burkule PursuingtheBachelor of Technology Degree [Mechanical] From Deogiri Institute of Engineering andManagementStudies,Aurangabad, Maharashtra,India. Vishal Choundiye Pursuing the Bachelor of Technology Degree [Mechanical]FromDeogiriInstituteof EngineeringandManagementStudies, Aurangabad,Maharashtra,India.