International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Swaraj Ramdhave1 , Mr. Pritish. G. Chitte2 , Sanskar Shrawane3 , Abhinav Fating4 ,

Prajwal Kahate5

1234Student, Dept. of Mechanical Engineering, Walchand Institute of Technology, Solapur, Maharashtra, India 5Professor, Dept. of Mechanical Engineering, Walchand Institute of Technology, Solapur, Maharashtra, India ***

Abstract - In the past twenty years, various in pipe scrutiny robots (IPIRs) are designed and used. per the propulsion mechanism quantity, these in pipe scrutiny robots (IPIRs) will be summarized into 2 classes, i.e. single locomotion system and multiple locomotion system.

This paper presents the classic structure options and characters of the 2 classes of IPIRs, and moreover compares their own benefits and limitations, further as performances of every kind IPIR. Ultimately, it's finished that the multiple locomotion kind In pipe scrutiny golem has become more and more current developing trend.

Key Words: Robot, Pipes defects, Electronics control systems,Digital video.

Roboticsis oneofthefastest growingengineeringfieldsof today. Robots are designed to remove the human factor from labour intensive or dangerous work and also to act in inaccessible environment. The inspectionof pipes may be relevant forimprovingsecurityand efficiencyinindustrialplants.Thesespecificoperationsasinspection,maintenance,cleaningetc. areexpensive,thustheapplicationofrobots isappearing tobeoneof the mostattractivesolutions.Thepipelinesarethe major tools for transporting of drinking water, effluent water, fuel oils and the gas. A lot of trouble is caused by piping networks aging, corrosion, cracks, and mechanical damages are possible. So, continuously inspecting, maintaining and repairing are strongly demanded. With a considerable history behind the development in robotics, in pipe robots can be classified into seven different sub categories, based on their applications. These are named as pig type robot, wheel type robot,caterpillartyperobot,wall pressrobot,walkingtyperobot,inchwormtyperobotandscrewtyperobot

Recently,theusingofin pipeinspectionrobothasgrownincreasinglypopularinengineeringfieldsincludingnuclearpower plantindustry,sewagesystem,andpetroleum industry etc.Withcarryingvarious sensors, thesein pipeinspectionrobots (IPIRs), walkingalongthepipelineinside,areappliedtoinspectdefects,cracksanderosioncausedbystrainageing, creep deformation,watererosion,etc.Duringthelatest20years,numerousin pipeinspectionrobots(IPIRs)havebeendesigned andfabricatedbasedonseveralelementaryformsaccordingtothelocomotionpatterns.

StudyexistingmodelofPipeTraversingRobot.

Toanalyzedifferenttypesofrobotsandtheirdifferentpositionsforoptimizedresultssuitablefortheindustry.

DesignanddevelopmentofPipeTraversingRobot.

Toaddresstheproblemoftheweightofrobot&increasingefficiencyof machine atlowcost.

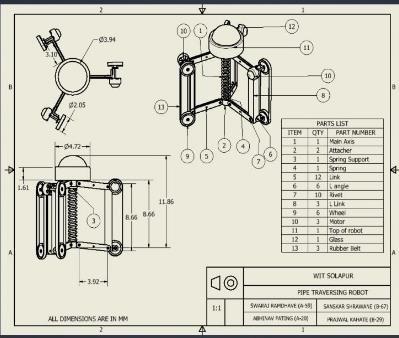

Development of the prototype model using CADsoftware.

Investigatingpre existingPipeTraversingRobotwiththehelpofresearchpaperandmanufacturersCatLog.

StudyingandselectingtheoptimumcombinationofpartsforIn pipeinspectionrobot.

Designing pipe traversing robot by performing various mathematical calculations to reach out maximum output fromthemachineandcarryoutstaticstructuralanalysistosupportthemathematicalcalculations.

SelectingpartsfromthemanufacturersCatLogthatarebestoptimizedaccordingtothecalculationsandthefactorof safety.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

ModellingthedesigninCADsoftwareforthebestpossibledepictionoftheactualmachine.

Abatteryisanelectrochemicaldevicethatmaybechargedanddischargedasneededwithanelectriccurrent.Smallelectric devicessuchascellphones,remotecontrols,andflashlightsaretypicallypoweredbybatteries.Inthepast,theterm"battery" wasused to refer to the combination of twoormoreelectrochemicalcells.Wehaveused12V,12Ah batteryinourproject tocarryouttheoperationssuchastopowertheArduinoUno,theDCmotorsetc.

A DC motor, conjointly referred to as an on the spot current motor, is AN electrical machine that converts power into energy by making an on the spot current force field. supported following calculations the motors area unit being designated

Technicalspecification

The 12V DC Geared Motor can be used invariety of robotics applications and is available with wide range of RPM and Torque. Length:80mm Torque:1.5kg.cm Weight:130.00gm Speed:10RPM

The Arduino board contains variety of controllers and microprocessors. The Arduino Uno could be a microcontroller board that uses the ATmega328P microcontroller. There square measure fourteen digital input/output pins, 6analogue inputs, a16 megahertz ceramic resonator, a USB instrumentality, an influence jack, associate degree ICSP header, and a pushonthisboard.Thehardwarecouldbeaprogrammableboardandthereforethesoftwaresystemwehaveatendency touseisnamedthe“ArduinoIntegratedDevelopmentEnvironment”.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page197

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Fig -3:ArduinoUno

4. DistanceMotor

Advanceddigitcounter,whichhavefivedigitcounters.Theseareespeciallymadeforlowcosthandwindingmachines.Our Digital Counters are equipped with left/right lever reset & both side drive shaft extension. Along with this, these are equippedwithtopgoingortopcomingdrivedirection.Furtherspecificationsareasthefollowing:

•Overallsize(mm):L 166,W 66,H 70

•Mountingholes:4hole,5mmX 98.5mm,Y 16.5mm.

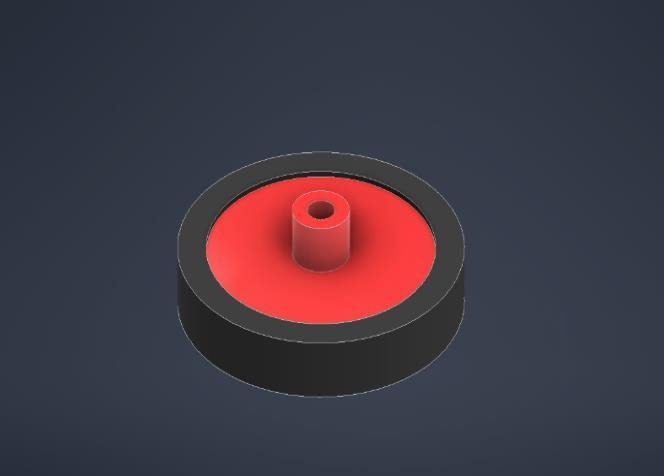

5. Wheels

Diameter 72mm

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

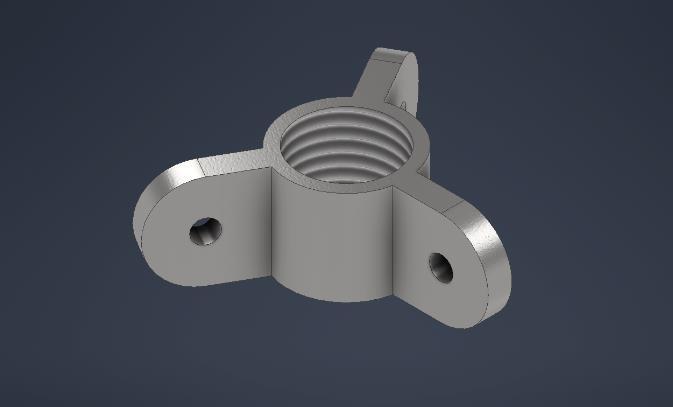

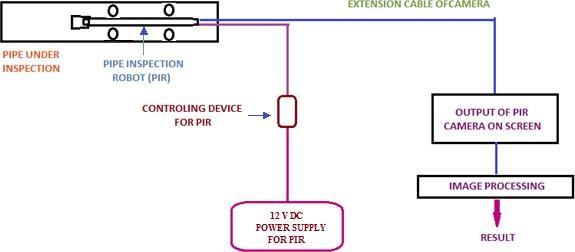

WorkingofPIRisstartsfromitsinsertioninpipe.Thefront3armsiscompressedbyhandandsoinsertedwithinthepipe andsoback 3arms isinserted bypushingthePIR. The motors driven artheprimarysixarms mentionedhere, theypull wholesetup.PIRisregardingahundredseventyfivecmlongandtomaneuveritfreelywithinthebendpipes,atwodegree of freedom connection is provided at the center in order that it will flip simply. As switch is on and current is flowing throughwires,wheelsstartsmovingandforcesPIRtopropelforward.exploitationthefrictionbetweenwheelsandpipe, themotionofwheelsbecomeattainable.

PIRmayhavequite3armsforhigherjudgmentandperfectionhoweverit'dincreasetheloadandpriceofproducingand thus we'd like to try to to trade off between cash involvement and perfection. PIR wheel motion is given ten revolutions perminute,twelveVDCmotorsthusitsspeedareoftenmaintainedbetween 10totenrevolutionsperminute.theability providedtomotorsisfromsingle12Vdcadapterthusloadoneverymotoraregoingtobeminimumthatexpected.

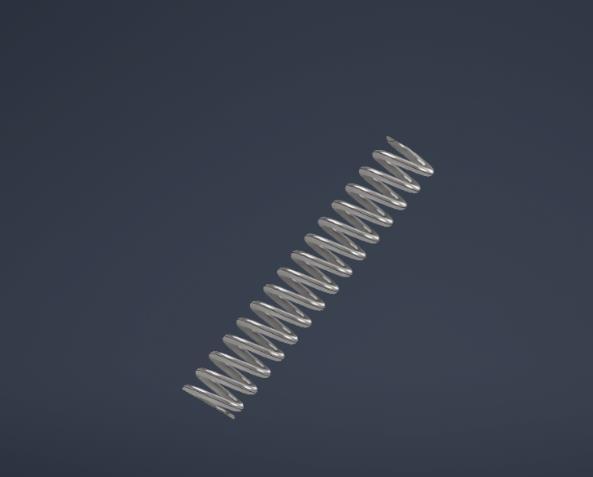

As we tend to mentioned earlier that PIR are going to be able to move within any diameter travel between 203mm to 254mm,wetendtohadtoproduceautomobileadjustingmechanismwhichwillexpandandgetintouchwithasPIRmoves within the pipe Spring of appropriate stiffness is mounted aboard rod, as seen in figure, in order that as arms gets contracted thanks to load of compression against pipe, spring get compressed and have a tendency to expand outward attemptingtopusharmsbacktotheirtraditionalpositionhoweveraspipeprohibitthem,theycan'tmove.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Thesystemuses12Vbatterytopowerthevehiclemovementmotors.

Pipe scrutiny robots ar accustomed examine varies pipeline components like straight pipelines, elbow, and branches internally.

Theautomatonisintendedtohandlediameterofonehundredtwentyfivemillimetretoa hundredandeightymillimetre. theoveralllengthoftheautomatonisthreehundredmillimetre,andthereforetheweightis840grams.

ThevehiclemotorsarinterfacedtoArduinoUnothroughmotordriverthatcontrolstheoperatingofthemotors.

Theforeandrearlegsarconnectedsoastobeparalleltoeverydifferentintheirmutualpositions.Ontheoppositehand, the gap and shutting angles of the legs is unbroken at an equivalent price. moreover, this automaton contains a giant foldingvary becauseofthat automaton will move freely withinpipesofvariousdiameters.ACCDcamera isputinatthe frontapartoftheforelimbsystemtoobserveandvaluatethedefectsofthepipe

The pipe inspection robotinspects situation inside the pipe which will be recorded and display on the monitor screen,italsofacilitatesworkingpersonnelforeffectiveobservation,detection,quickanalysisanddiagnosis.

Savecomprehensiveinvestment,improveworkefficiency,moreaccuratedetection.

Reducethefrequencyofenteringintothetestingenvironment.

Operatingcostrelatedtoothermethodandmodelislow.

Highercakesolidconcentrationswhencomparedtoabeltfilterpress.

Costofmanufacturingofthisrobotisrelativelylow.

Robotsplayavitalroleinwithinpipe networkmaintenanceandtheirrepairing.anumberofthemweredesignedto comprehend specific tasks for pipes with constant diameters, and alternative could adapt the structure operate of thevariationoftheinspectedpipe.

• Inthis project within pipestandard roboticsystemarea unit planned. a vital stylegoal ofthoseroboticsystemsis thattheabilitytotheinnerdiametersofthepipes.Thegivenmodelpermitstheusageofamini camforvisualimage ofthein piperevieworalternativedevicesrequiredforfailuredetectionthatseemwithintheinnerapartofpipe (measuringsystemswithopticalmaser,deviceetc).

• Themajoradvantageisthatitmaybeutilizedincaseofpipediametervariationwiththeeasymechanism.wetend to developed a pipe review automaton which will be applied to 203mm 254mmpipeline. a true model was developedtocheckthefeasiblenessofthisautomatonforreviewofin housepipeline.

• Thevarietiesofreviewtasksareaunitterriblycompletelydifferent.Astandardstylewasthought aboutforsimply custom made to new environments with little changes. Presence of obstacles inside the pipeline could be a troublesome issue. within the planned mechanism the matter is solved by a spring effort and increasing the flexiblenessofthemechanism.

Flocculationtankcanbeinstalledformaximumefficiencyofthemachinewhichcancontrolthewaterconcentration ofthefeedsludge.

Automated pressure plate can be implemented for adjusting the clearance at the discharge end to control the dewateringratebutthismightcomeasthecostofincreasedprice.

Movingfilterplatescanbeinstalledinsteadofmeshformaximumdewateringofthesludge.

Consideringvariablefeedsludgewaterconcentration,acomputerizedsystemcanbegeneratedthatcancontrolthe

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

clearance between the pressure plate and the screw for maximumdewatering depending upon the type of sludge input. Modulardesignscanbeusedforeasyrepairandmaintenance.

[1] Ref@BiogasPotentialinHouseholdWasteafterScrewPressPre treatment(Chalmers)byHarunUluyol

[2] https://en.wikipedia.org/wiki/Dewatering_screw_press

[3] https://www.linkedin.com/pulse/what dewatering screw press sludge treatment disposal victor qiu

[4] HTTPS://AOSTS.COM/WHAT IS A SLUDGE DEWATERING SCREW PRESS/ [5] https://www.linkedin.com/pulse/what dewatering screw press sludge treatment disposal victor qiu [6] https://www.researchgate.net/publication/3266971