International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

4

1, 2, 3, 4, 5, 6 Department of Mechanical Engineering, Mangalore Institute of Technology & Engineering, Karnataka, India ***

Abstract Aluminium matrix composites find wide applications in transportation and weight saving applications. Their density is comparatively lower than those of Al alloys with the advantage that their properties can be tailored as per requirement. A number of processing routes are available for their production ranging from casting, powder metallurgy, infiltration etc. The present work provides a technical review on the Al metal matrix composites processed through stir casting. The findings of various researchers are summarized and analyzed to offer a comprehensive review on Al based composites and hybrid composites. A comparison of wear properties between Al alloys and its composites are also presented

Key Words: Aluminium, composites, alloys, wear, casting.

Tooptimizefuelconsumptionwithoutcompromisingfunctionality,reliabilityanddurabilitymodernvehiclesmustmakeuseof materialshavinghighspecificstrength.Onesuchmaterialisaluminiumanditsalloys.Theeasewithwhichsuchalloyscanbe casted,machinedandfabricatedhasmadethemthematerialsofchoiceinseveralindustrialapplications.Further,thesealloys possessrelativelyhighresistancetoenvironmentalattackduetoanadherentsurfaceoxide.However,alimitationofAlandits alloyistheirlowerabrasivewearresistancecomparedtosteels.

Wearreferstothedeteriorationofamaterialatitssurfaceduetorelativemotionincontactwithoneormoresurfaces.Alloying withSiandCuintoaluminiumhasshownsignificantincreaseinthewearresistanceofpurealuminium.Specificwearratewas reducedbyabout36%fortheAlalloyscomparedtothatofpureAlwhentestedunderidenticalwetconditions.Further,unlike pure Al, Al alloys do not show an increase in the coefficient of friction beyond a threshold load. Increased tribological characteristicsinaerospace,vehicularapplicationswarrantthedevelopmentofalightweightmaterialwhosewearresistance propertiesarebeyondthoseobtainedfromaluminiumalloys.

TheaboveissuecanbepartiallyansweredbyAluminiummatrixcomposites.Acompositematerialisonewhichismadeupofa reinforcementphaseandamatrixphase.Thereinforcementprovidesstrengthwhilethematrixphaseactsasanenvelope protecting the reinforcement from sudden loading and serves to provide shape to the material. A unique feature of such compositesisthatthepropertiescanbetailoredbyvaryingthevolumefractionofthereinforcementsrelativetothematrix. Furthermore,incorporationofreinforcementsintoAldoesnotsignificantlyalterthedensityofAl.However,theconventional aluminiummetalmatrixcompositesmakeuseofmacroscopicreinforcements.Thesereinforcementsarenotwelldispersed throughout the matrix phase and do not prohibit wear effectively. This limitation can be overcome with the help of nanocomposites.Nanocompositesarethosematerialsthathavereinforcementsinnanoscale.Thenano scaledreinforcements permitsuperiordistributioninthematrixwhichinturncouldleadtoimprovedtribologicalproperties.

ThepresentreviewprovidesanoverviewofAlmatrixcomposites.Thestate of the artprocessingmethodsandtheweartest outcomeswithvariablesaffectingtheexperimentalevaluationofwearcharacteristicsarepresentedbelow.

The unique characteristics of Al and its alloys have bolstered their use in a number of engineering applications. Pure aluminiumhasinsufficientstrengthandwear resistanceproperty.Theseshortfallsareremarkablyimprovedwiththehelpof alloyadditions.Thealloymetalsaddedformintermetalliccompoundsandofferresistancetoslipleadingtoincreasedstrength inaluminium.However,despiteoftheadvancementsinalloyformulationsAlalloysdonotsurpassconventionalsteelalloysin applicationswherewearisasignificantanddetrimentalfactor. Wearcanbeofadhesive,abrasive,surfacefatigue,frettingand

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

of erosive type. Of these, adhesive wear is the most prominent mechanism that is responsible for decommissioning of componentsmadefromAlalloys.Adhesivewearreferstotheselectivedeformationandseparationofsurfaceandnearsurface softermaterialduetoplasticdisplacement.Inadhesivewear,theinteractingsurfacesinvolvedexperiencefrictionleadingto localized heat generation and subsequently fragmentation under mechanical action. Based on the surface characteristics observed,abrasive wear maybecharacterizedasploughing,cutting, wedge formation, micro crack and fatigue type. The factors that contribute to acceleration of wear are load applied, speed, presence of hard phases between the interacting surfacesanddurationofwearstudy.

The most commonly used Aluminium alloy owing to its castability is the aluminium silicon alloy. In particular the hypereutecticalloythatcontainsmore than12%Si possessessuperior wear resistance. Otheralloying elementsthatare commonlyaddedtoAlincludecopper,magnesium,zinc,nickel,ironetc.ThewearbehaviorofSiisgovernedbytheamount, size,distributionandshapeofthesilicon[1].StudyonwearbehaviorofAl Sialloysshowedambiguousresultswithsome reportingincreasedwearbehaviorwhileothershaveshowednomarkedinfluenceofSicontentonwear[2,3,4].Athreshold loadbeyond2kgandaslidingvelocitybelow2m/swasshowntoacceleratewearinthecaseofAl 10%Si 2.4%Cualloy.The specificwearratewasfoundtobehigherforpureAlcomparedtotheAl Si Cuwhentestedunderhigherslidingspeedand reducedload.Thesefindingsfurtherindicatethathighspeedandlowloadsarepreferredoverlowspeedsandhighloadsfor minimizing material loss under slidingconditions[5].It iswell known thattherate ofwear reduces withincreasein the hardnessofamaterial.ThehardnessoftheAluminiumalloyscanbeincreasedtoalimitingextentbyprecipitationhardening heattreatmentasmostofthealloyingadditionshavelimitedsolidsolubilities(0.5to1wt.%)inaluminium.TheeffectofCr andNionthewearresistanceofAl 2%Sishowedthatadditionof4%Crand2%NiincreasedthehardnessoftheAl Sialloy andincreasedtheresistancetowearunderbothdryandlubricationconditions[6].AnexcellentreviewontheeffectsofSiinAl alloysandtheuncleareffectofmorphologicalfeaturesofSiinfluencingwearpropertiesispresentedbyShebalet.al[7].Amore prospective method to increase the hardness is by using dispersants which lead to the development of metal matrix composites.

MMC’sareformulatedbytheadditionofreinforcementsintoasoftermatrixphase.Thesecompositescanbetailoredwith therequiredconcentrationofhardphasestoobtainthedesiredmechanicalproperties.Effortshavebeenmadeinthepastto increasethelubricityofAlcompositesbytheadditionofgraphite,andmolybdenumdisulfidealongwithhardreinforcements suchasboroncarbide.Mechanicalmemberssuchascrank shafts,brakedrums,cylinderlinersarepresentlyutilizedandare madefromparticulatereinforcedcompositematerialwithAlastheirmatrixphase.

AninvestigationontheeffectofsizeandconcentrationofSiCusedasaparticulatereinforcementinAlhybridMMC was performed. The study showed improved wear resistance with higher hardness for the smaller sized reinforcements at increasedconcentrationwasobserved.Ahighesthardnessof86.6BHNforthe10μmsizedSiCat15wt.%wasseenandwas reportedtobethebestalloythatwithstoodwearatthehighestslidingspeedanddistance[3].Toprovidelubricityduringwear testMoS2 wasaddedtoAl6061alloy.Thepin on diskweartestresultsshowedincreasedwearvolumeandacceleratedwear occurringbeyondtheslidingdistanceof200mandataloadof10Nwhichintensifieswithslidingspeed[4]. Al/Al2O3/Gr hybridcompositesshowedreducedwearwithincreasedslidingspeedandincreasedAl2O3contentataconstantconcentration ofGr.Thereductioninthewearratewasattributedtotheformationofanoxidefilmwhichinhibiteddirectcontactbetween theslidingsurfaces[5].ThewearbehaviorofAl7075compositeswereassessedasafunctionofTiB2 concentration,applied load,andspeed.Al7075alloyexhibitedhigherwearlosscomparedwiththecompositesofAl7075.Thewearrateshowed reductioninitsmagnitudewithincreasedamountofTiB2reinforcement.Thebehaviorofthewearratewithslidingspeedwas foundtobeakintothatoftheTiB2 additions.Thewearrateshowedupto18%reductionat3Kgsofloadatspeedsranging between200to400rpmforthe15%TiB2comparedtothatofthe5%composite[8].TheCOFandwearratewereindependent oftheslidingspeed(600to1500rpm)fortheAl 2%Licompositeat1kgload.Deviationswithrespectofspeedwereobserved whentheloadwasincreasedbetween1.5to2kg.AdditionofSi3N4 causedincreasedwearratewhileadditionofLitothe Al/Si3N4 compositeprovidedhigherwearresistancecomparedtoAl/Si3N4.Further,thespecificwearratewasfoundtobe nearlyconstantfortheAl/Si3N4/Licompositeatappliedloadsof1.5and2Kgsfora givenspeedunderconsideration[9]. Reducedweightloss(20%less)occurredintheAl/15%B4CcomparedtoAl/5%MoS2underidenticaltestconditionsabove2 m/sofslidingspeed[10].Areductionofabout45%inthewearratewasfoundforafivefoldincreaseinthevolumefractionof SiC,garnetandZrSiO4(particlesizeofabout105μm)addedtoLM25alloy.SiCshowedthehighestwearresistancewhichwas foundtoincreasewithincreasingparticlesizeduetotheincreasedagglomerationofthereinforcementsatreducedsize[11] HybridcompositespreparedbydispersingflyashandSiCintoAl7075alloyshowedreducedexperimentaldensitycompared

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

tothoseobtainedbyusingthedensitycalculationsviaruleofmixturesduetoporosity.Theultimatetensilestrengthofthe compositeswascomparablewhilethemodulusofelasticityofthe10%Si 10%flyashwasthehighest(80GPa)andshowedthe highestwearresistance[12].

Themorphologyofthereinforcements,theiramount,distributionandstabilityinthematrixaffectsthewearresistance. Smallerthereinforcementsizewithincreasedconcentrationanduniformdistributioninthematrixhasreducedtheextentof wear.Conventionalmicroandmillimetersizedreinforcementsenhancewearresistanceuptoacertainlimitbeyondwhichdue to their size limitation they do not markedly increase wear resistance performance. This shortfall due to the size of the reinforcementsisdealtwith byutilizing nanomaterialsinsteadof the microand millimetersized reinforcements andthe compositesthusformedaretermednanocomposites.

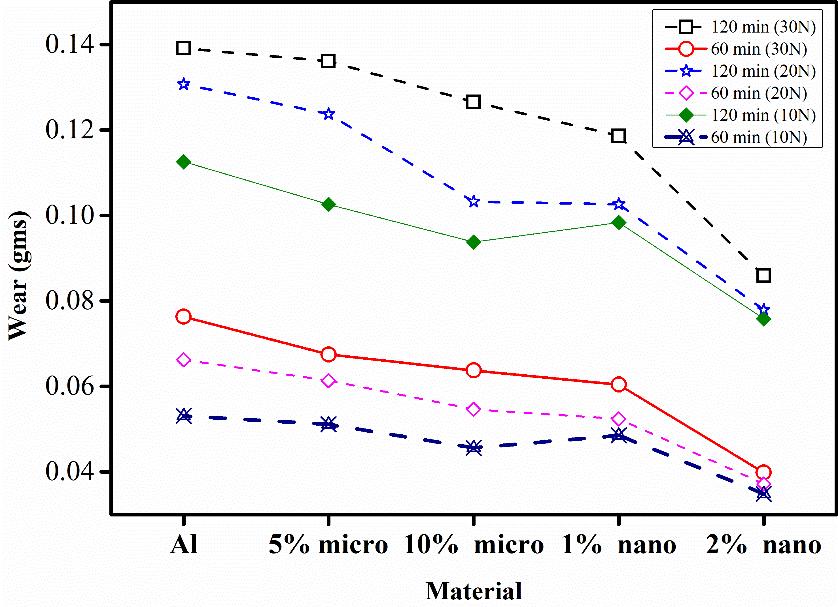

Pin on diskweartestofSiCnanoparticles(SiCn)usedinA356alloyshowedafour foldreductioninmateriallosscompared tothebasealloyatthehighestloadof9kgusedduringexperimentsconductedat2.5m/s.Thebehavioroffrictioncoefficient withincreaseddistanceandloadshowedanearconstantandreducedvaluewithincreasedfractionofSiCn[13].Comparisonof wearbehaviorbetweenmicroandnanocompositeofSiCreinforcementsaddedtoanAlmatrixcomprisingofhighmagnesium content and low concentration of Fe Zn Si showed no significant effect of applied load on wear behavior of 2% SiCn nanocomposite(Fig.1).Significantreductionofover38%isseenfromthedataonmateriallossforthe2%SiCncomparedto thebasealloy. Animprovementofover36%inwearresistancewasobtainedat120min,30Nforthe2%SiCncomparedtothe 5%microSiCundersimilartestconditions,Chart 1[14].

[14].

TheexaminedmechanicalpropertiesofAl0.1wt.%GrOnanocompositebyhotisotacticpressingandextrusionshowed reducedtensileandhardnessvalues. ThiswasattributedtotheformationofAlC4intermetallicduetoincreaseddefectdensity ingrapheneoxide[15].Wearresultsunderdryandwetconditionsfor1%and1.5%Grapheneinpurealuminiummatrix showedremarkablycontrastingbehavior.Thewetsliding(SAE20W50oil)conditionsincreasedwearrateforthe1%overthe dryslidingconditionwhilewearratewasreducedforthe1.5%compositeunderwetconditioncomparedtothatofthedry conditionwhentheappliedloadwasincreasedfrom15to60N.Acombinationofoxidation,hardness,agglomeration,and adhesionandabrasionphenomenoncouldbethereasonforsuchananomaly[16].HardnessmeasurementsofAA2024 2% SiC 1.5%h boronnitridehybridnanocompositeswas38%higherthan2024basealloyandwasthehighestamongstthe hybridcompositesused.Further,the wearresistanceof thismaterial wassuperior comparedtothebasealloyandother nanocompositesattemperaturesrangingfrom30°Cto300°C.Moreover,upto100°Ctheappliedloadhadinsignificanteffect onthewearrate.However,thereisathreetimeincreaseinthewearrateforthiscompositewhentestedat300°Ccomparedto thatobservedat30°C[17].OpticalprofilometermeasurementsfortheAl/10vol.%Al2O3/0.25wt.%GrOhybridnanoparticles showednarrowestwidthofdeepweartrackregioncomparedtothebaseand0.5and1wt.%GrOhybridcomposite.The superiorityofthiscompositewasfurthervalidatedbythespecificweardatathatshowedtheleastvalueforthe0.25wt. % GrO Highestoxygencontentof46%wasdetectedonthesurfaceofAl/10vol.%Al2O3/0.25wt.%GrOsubjectedtowear[18]. Addition of flat faced irregular shaped ZrO2 of 26 nm size to Al reduced wear by 44% due to the presence of oxides that providedahardsurfaceandpinnedthegrainsofAl[19].Thewearresistanceandfrictioncoefficientresultswereinagreement forthecompressedandsinteredaggregatemixtureofAl SiandSiC(10wt.%)particleswithdepositedreducedgraphiteoxide Nano sheets (0.3, 0.5 and 0.7 wt. %). Highest hardness of 73 HVN was reported for the 0.3% Nano sheets. The hardness

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

measurementsfortheother2concentrationswereabout60HVN.Thesereadingswereapproximately5HVNhigherthanthat forthe0%Nanosheethybridcomposite.Highestwearresistancewasexhibitedbythe0.5%Nanosheethybridatloads rangingfrom1to3.5N[20].Equalconcentrations(2.5wt.%)ofTiO2 andCuOeachaddedtoAlmatrixshowedcomparative hardnesstothatofthe0.3%Nanosheetcompositementionedabove.TheresearchshowedthattheTiO2particlesweremore effectiveinmitigatingtheextentofwearcomparedtothatofCuO[21].

Low cost,light weightmaterialswithgreatstrengtharerequiredinmodernproducts.Thispaperdiscussestherelevanceof aluminiumalloys,aswellastheresultsofweartestsandthevariablesthatinfluencetheexperimentalevaluationofwear characteristics.Itisclaimedthatincludingtwodifferentreinforcementsinsmallamountsinhybridcompositesispreferable than increasing the single reinforcementand improving the materials' wear resistance. Addition of hard reinforcement particlesinthemetalmatrixhasenhancedthetribologicalperformanceofthecomposites.Withanincreaseinthevolume percentageofreinforcingelements,thecoefficientoffrictionandweightlossofmetalmatrixcompositesreduced.Byaddition ofnanocompositestotheAMMC’sthewearresistancecanbesignificantlyimprovedascomparedtothattomicroandsub microparticulateasreinforcement.ThisisduetothebetterdispersioncausedwhilefusingitwithAluminium. Further,useof grapheneasnanocompositeshasshownanomalousbehaviorundervarioustestconditions.Nanocompositeshadlowerwear ratesthanunreinforcedaluminium,demonstratingthatnanocompositesshowmajorimprovementinmechanicalproperties comparedtothatofMMC.Therefore,reinforcedaluminiummatrixnanocompositeshavestrongpotentialtobeasubstituteto aluminiumalloycounterpartsintermsofhardness,strength,frictionalandwearbehavior.

[1] C.Subramanian,Wearpropertiesofaluminium basedalloys,Surfaceengineeringoflightalloys,Elsevier,2010, (pp.40 57).

[2] RoopLal,R.C.Singh,RanganathMSingari,AnkitKumarSaxena,InvestigationofWearBehaviourofAluminium AlloyandComparisonwithPureAluminium,MaterialsScience, ICARI 2015.

[3] AjithArulDaniel,SakthivelMurugesan,Manojkumar,S.Sudhagar,DrySlidingWearBehaviourofAluminium 5059/SiC/MoS2HybridMetalMatrixComposites,MaterialsResearch,2017.

[4] RinkiYadav,JaiprakashSharma,GianenderKajal,RekhaYadav,PredictionofMechanicalandWearProperties ofAl 6061/MoS2(MolybdenumDisulphide)Composites,IJIRSET,2017.

[5] N. Radhika, R. Subramanian, S. Venkat Prasat, B. Anandavel, Dry sliding wear behaviour of aluminium/ alumina/graphitemetalmatrixcomposites,IndustrialLubricationandTribology,Vol.64,2012

[6] JJoyMathavan,AmarPatnaik,Analysisofwearpropertiesofaluminiumbasedjournalbearingalloyswithand withoutlubrication,IOPConferenceSeriesMaterialsScienceandEngineering,2016.

[7] BarrieS.Shabel,DouglasA.Granger,andWilliamG.Truckner,FrictionandwearofAluminium Siliconalloys, ASMHandbook,Volume18:Friction,Lubrication,andWearTechnology,1992.

[8] MadhanPrabhuDeva,A.Parthiban,B.RadhaKrishnan,AdisuHaile,WubishetDegife, Investigationofwear behaviourandmechanicalpropertiesoftitaniumdiboridereinforcedAMMCcomposites,AdvancesinMaterials ScienceandEngineering,2022.

[9] RajuK,BalakrishnanM, Dry Sliding WearBehavior of AluminumMetal MatrixComposite Reinforced with LithiumandSiliconNitride,Silicon14,2022.

[10] Abdul Aabid, Mohammed Ali Murtuza, Sher Afghan Khan, Muneer Baig, Optimization of dry sliding wear behavior of aluminium based hybrid MMC's using experimental and DOE methods, Journal of Materials ResearchandTechnology,Volume16,2022.

[11] Vijayakumar.S,Karunamoorthy.L,Wearcharacterizationofaluminiummetalmatrixcomposites, Advanced CompositesLetters,Volume:22,,2013.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[12] RaviKumarMandava,VajramVenkataReddy,VeeravalliRamaKoteswaraRao,Wearandfrictionalbehaviourof Al7075/FA/SiChybridMMC’susingresponsesurfacemethodology,2021.

[13] MTAlam,SArif,AHAnsari, Wearbehaviourandmorphologyofstircastaluminium/SiCnanocomposites, MaterialsResearchExpress,2018

[14] Amir Hussain Idrisi, Abdel Hamid Ismail Mourad, Fabrication and Wear Analysis of Aluminium Matrix CompositeReinforcedbySiCMicroandNanoParticles,ASME,PressureVesselsandPipingConference,2017.

[15] SF Bartolucci,J Paras, MA Rafiee, J Rafiee, Graphene, Aluminum nanocomposites, Materials Science and Engineering:A,Volume528,Elsevier,2011

[16] AJayapragash,GGSolamannan,IGuganeswaran,Comparisonstudyondryandwetslidingwearbehaviourof aluminium/nanocomposites,IOPConferenceSeriesMaterialsScienceandEngineering,,2020.

[17] P Paulraj,R Harichandran, The tribological behaviour of hybrid aluminum alloy nanocomposites at High temperature:Roleofnanoparticles,JournalofMaterialsResearchandTechnology,Elsevier,2020

[18] AS Mohammed, OS Aljebreen, AS Hakeem,Tribological Behavior of Aluminum Hybrid Nanocomposites ReinforcedwithAluminaandGrapheneOxide,Materials,2022

[19] M.Ramachandra,A.Abhishek,P.Siddeshwar,V.Bharathi,HardnessandWearResistanceofZrO2NanoParticle ReinforcedAlNanocompositesProducedbyPowderMetallurgy,ProcediaMaterialsScience,2015.

[20] XiangZeng,Jin GangYu,DingfaFu,Wearcharacteristicsofhybridaluminum matrixcompositesreinforcedwith well dispersedreducedgrapheneoxidenanosheetsandsiliconcarbideparticulates,Vacuum155,2018.

[21] M.Ahmadi,M.HosseinSiadati,Synthesis,mechanicalpropertiesandwearbehaviorofhybridAl(TiO2+CuO) nanocomposites,JournalofAlloysandCompounds769,2018.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal