International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

1B.Tech. Student, Department of Mechanical Engineering, Vishwakarma Institute of Technology (VIT), Pune, Maharashtra, India

2Assistant Professor, Department of Mechanical Engineering, Vishwakarma Institute of Technology (VIT), Pune, Maharashtra, India ***

Abstract Advancement in the field of robotics has led to the development of soft robots that use innovative techniques to replicate desired motion. Compared to traditional robots, soft robots are made from deformable and conformable materials that withstand harsh conditions.Theuseofsuchsoft robots has found several applications, a notable one being prostheses. Pneumatically actuated soft robots have been developed to mimic human limb motion. However, existing designs were not often effective enough to capture the complexity of the kinematics involved.Additionally,veryfewof these devices have reached the final product stage. In this work, a pneumatically actuated soft robotic finger was developed to mimic human finger motion, capable of offering higher freedom over kinematic control while maintaining the benefits of easy andquickmanufacturing.Theproposeddesign was studied analytically through simulations to optimize the geometry and explore suitable materials. Further,aprototype was developed to validate simulation results. Good conformance was observed in the analytical and empirical findings. The efforts made in thisresearchwereaimednotonly towards improving prosthetics but also towards better implementation of soft robotics in product design.

Key Words: soft robots, pneumatically, finger, prosthetics

Injuries to the hand and fingers are a common phenomenonthatmightleadtoamputationofthelimbs.It can affect people of all ages and can happen while doing many day to day activities like operating doors, knives, powersaws,andlawnmowers,beinga fewcommonones, according to a study conducted [1]. Apart from trauma, medical conditions like Buerger’s disease that leads to gangrenecausethousandsoflimbamputationsworldwide. Given the importance of fingers in daily activities and a variety of vocations, the impact of an amputation can be traumatic.Lossofapplicationhasasignificantimpactonthe daily well being and, in extreme cases, can even cause depressionandanxietyamongamputees.Detailedstatistics of finger loss and its impact on people’s daily life are described here [1, 2]. Such patients need advanced prostheticdevices,andthroughthiswork,possiblesolutions

to restore lost limb function using soft actuators were studied.

Soft robots have shown great potential in prostheses applications due to their lightweight, chemically passive materials and compliant and compact designs. They have beenusedtodevelopwearabledevicesthatprovideanon invasivealternativetoinvasivesolutionsthatarestillvery experimental.Moreover,themanufacturingprocess’sease and adaptability to suit each patient make soft robotics a compelling solution for prosthetic devices. Pneumatically Actuatedsoftrobots,whilemaintainingtheaforementioned advantages,alsoprovidesimpleractuationwithouttheneed forcomplexelectroniccircuitry.ThesePneumaticNetworks (Pneu Nets),originallydeveloped byWhitesidesResearch Group at Harvard, were chosen as a basis for our device’s development.

Whilesoftmatterandthepossibilitytocreatecomplex shapesopenupmanypossibilitiesinthefiledofprosthetics, theseadvanceddesignsalongwiththehighamountofDOFs alsobringchallengestocontrolthekinematics.

This study aimed to harness the highly beneficial properties of soft robots and develop a prototype for a prosthetic finger. Our design was developed to provide improvedkinematiccontroloverthebendingmotionwhile maintaining simplicity in actuation, an improvement over previous works that did not offer kinematic freedom to mimictheexactbendingmotionofthreejointedfingers.To improvethekinematicflexibilitywhilemaintainingsimple actuation methods, the geometry itself was optimized to eliminate unwanted motions. Moreover, the rapid prototypingmethodisusedtocreatemoldparts,allowing for quick alteration to the design according to the individual’srequirements.

Followingisadetailedreviewoftheresearchliterature related to the function and anatomy of the human finger, kinematicsofbendingmotion,andthedevelopmentofsoft robots.Thesectionpresentsinitialconsiderationsnecessary fordesigningoftheactuator.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

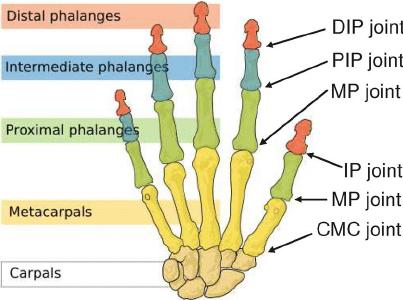

Whendesigningthemechanismfortheprostheticdevice, itiscrucialtoevaluatethemotionanalysisoffingers,mainly thebendingmotionofjoints.Fingerkinematicdataisvitalin enablingthisdevicetoperformhuman likemovement.The human hand iscomposed ofa thumb,index finger, middle finger,ringfinger,littlefinger,andpalm,whichincludesthe thenareminence,thehypothenareminence,andcreases.The fingers contain 19 distal phalanges, middle phalanges, proximalphalanges,andmetacarpalbones.Thus,thefingers havemetacarpophalangeal(MP),proximal interphalangeal (PIP), and distal interphalangeal (DIP) joints, whereas the thumbhascarpometacarpal(CMC),MP,andinterphalangeal (IP)joints.

The nature of this motion is controlled by modifying the geometry of the embedded chambers and the material properties of their walls. When a Pneu Nets actuator is pressurized,expansionoccursinthemostcompliant(least stiff)regions.Forexample,ifthePneu Netiscomposedofa single,homogenouselastomer,mostexpansionoccursatthe thinnest structures. Hence, by controlling the wall thicknesses,designerscanpre programthedesiredmotion.

In addition, different materials can be used in combinationtoenablefurthercontroloveractuatorbehavior. If a Pneu Nets actuator contains layers of materials with differentelasticbehavior,asshowninfig.3,themoreelastic materialexpandsmorewhentheactuatorispressurized.In thisconfiguration,themorerigidmaterialiscalledthe“strain limitinglayer”,as itrestricts theamount ofstrain thatcan occur.The“differentialstrain”effectcanbeusedtoachieve valuablemotionssuchasbendingandtwisting.

Fig 1:Jointsandbonesinhumanhand.Thispictureis adaptedfrom[3]

Fig - 3:Differentialstraineffect[5]

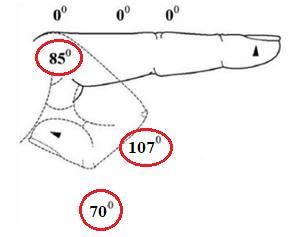

Fig 2:MeanflexionROMforthemiddlefinger

Therangeofmotion(ROM)isthemostcommonlyused functionalmeasurementvariable.Anatomicalmeasurements andtheROMareusuallyusedtodesignhandproductsand rehabilitation. Several studies have measured the flexion rangeofmotion(ROM)ofeachfingerjoint.Themeanflexion ROMoftheDIP,PIP,andMPwas68°,104°,and80°forthe index finger; 70°, 107°, and 85° for the middle finger, 66°, 107°,and87°fortheringfinger;and69°,104°,and86°for thelittlefinger,respectively[4].

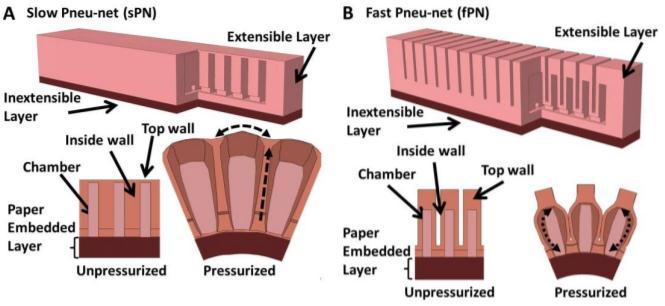

Pneu Nets (Pneumatic Networks) are a class of soft actuators. They are made of small channels inside elastomeric materials. When pressurized, these channels inflate,producingsophisticatedmotionwithsimplecontrol.

AlthoughearlydesignsofPneu Netscouldachievemotion withlargeamplitudes,theydidsoslowly(overseconds).A study[6]conducteddescribesanewdesignforfastactuating Pneu Nets(FPN)thatreducestheamountofgasthatmustbe transportedforinflationofthePneu Net,thusincreasingits

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page190

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

actuation speed. The design achieved an improvement in overall performance showing improvements in 1) speed achievedforagivenrateofinflation,2)forceexertedfora givenpressure,3)changeinthevolumerequiredforagiven degreeofbending,4)thenumberofactuationcyclesbefore failing,and5)correlationbetweenthepressureinthePneu Netanditsdegreeofbendingwithoutaload.

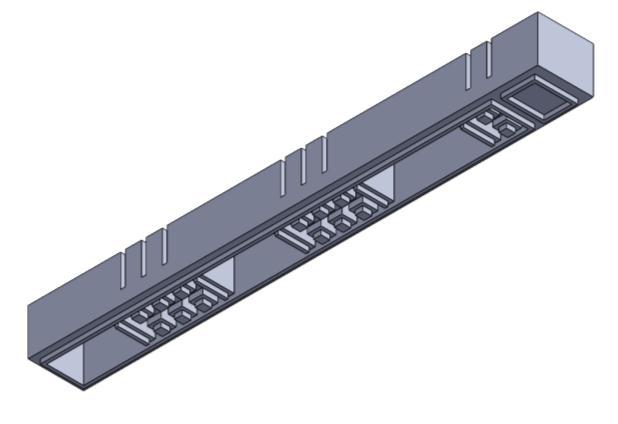

Duetoitsadvantages,thisnewdesignofFastactuatingPneu Netswasusedasabasisforourprostheticdevice,adopting the improved geometry. Refer fig. 4 to understand new geometry. Similar to the FPN actuator, our device has topographicalfeaturesalongtheinsideandoutsidesurfaceof the actuator for high speed actuation and performance improvement.

The actuator is designed for middle finger, taking appropriatedimensionsforphalanges(Distal,Intermediate, Proximal). Geometry of wall thicknesses and internal chamber dimensions were adjusted according to optimizationmethodsmentionedhere[7].

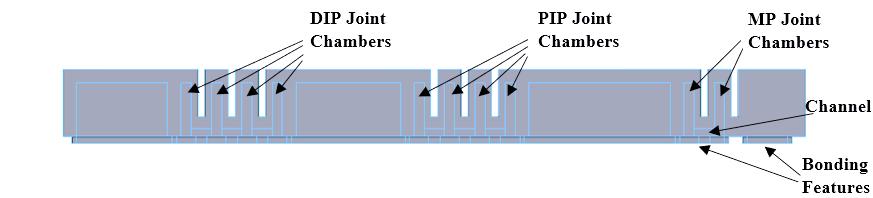

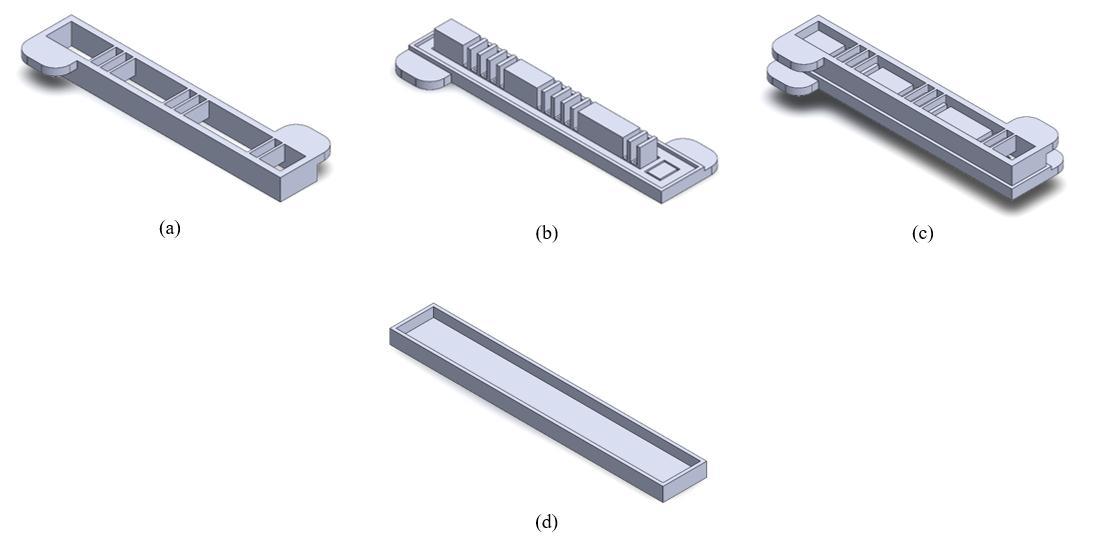

The design consists of three layers: top, middle and bottomlayers.Themiddle(enclosinginextensiblelayer)and bottomlayerstogetherformthebaseoftheactuator.TheTop layer primarily consists of topographical features on the

inside and outside surface. It is provided with internal chambersatthreelocationsalongitslengthtomimicDIP,PIP andMPjoints.Thebendingangleofactuatordependsupon the pressure applied at these joint locations. Figs. 5 and 6 showtheCADmodeloftheextensibletoplayer.Fig.6shows the geometric features such as chambers provided for bendingandthechambersmadetoreduceunwantedweight betweenadjacentjointssothatbendingduetogravityload can be minimized. The actuator also consists of bonding featuresaddedtoaidadhesionoftoplayerwithbasepart.

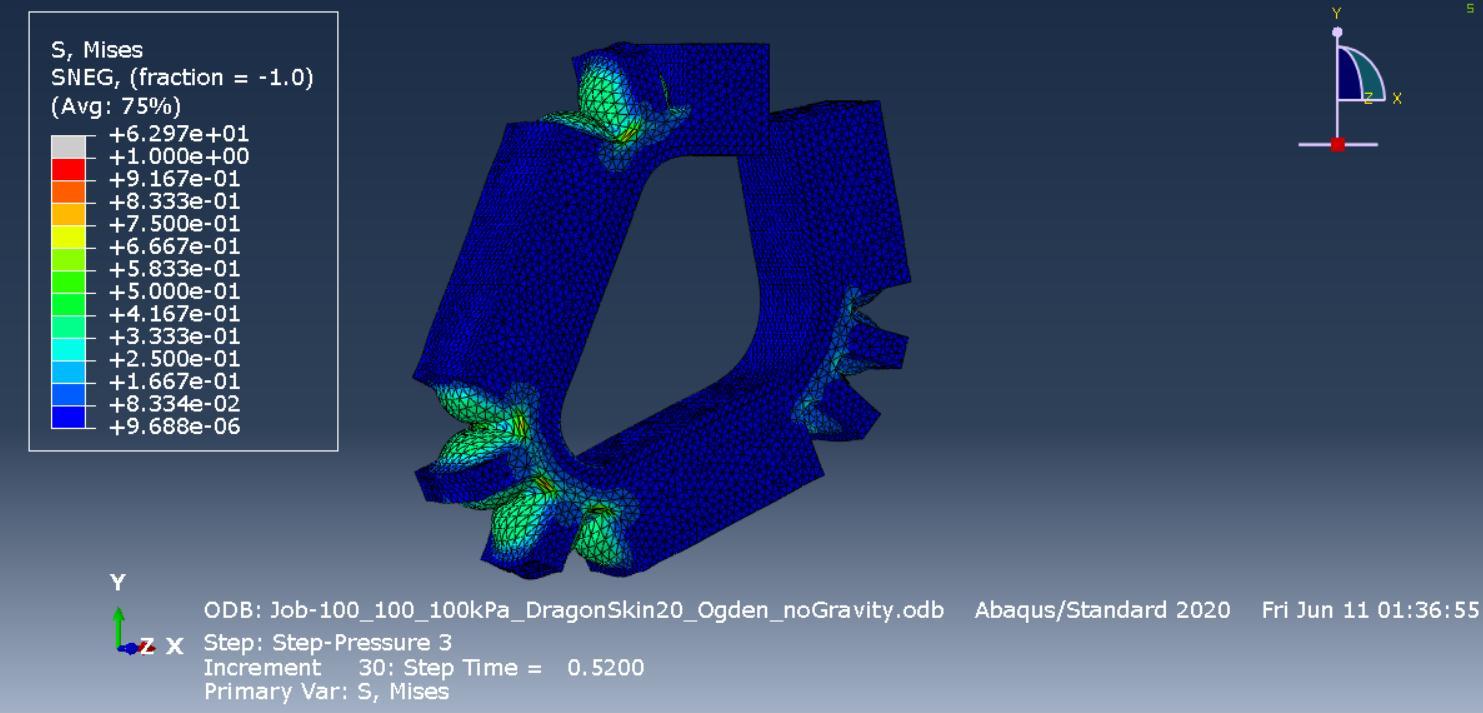

SimulationofactuatorshasbeencarriedoutusingAbaqus software.Twotypesofloadingcaseshavebeensimulated, thefirstisbendingofactuatorduetogravity,andthesecond is actuator bending due to application of pressures inside hollow cavities. Gravitational loading indicated unwanted bending that was minimized by adjusting the geometry. Pressure loading inside the internal cavities indicated the pressure vs bending relation upon pneumatic actuation. Simulationparameterswereasfollows:

DragonSkin 20 silicone rubber (assigned to extensible parts): Ogden strain energy potential definedbythecoefficients

=1.3077, = 2.3497, =1.2075MPa, =1.1087, = 0.0317, = 1.6291, =0.4900, =0, =0MPa 1 ,obtainedfrom[8] Densityof1080Kg/m³,assumedisotropic

Paper (assigned to inextensible layer): density of 750 Kg/m³, Young’s Modulus of 6.5 GPa, and Poisson’sratioof0.2

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

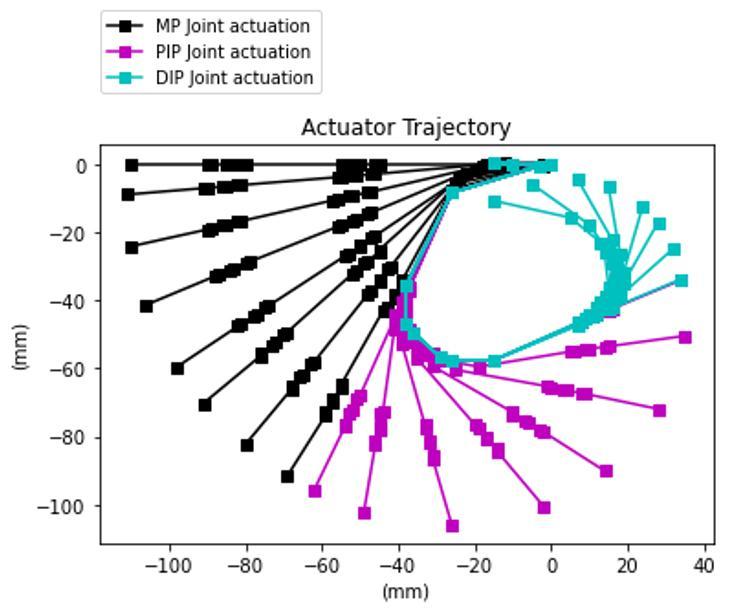

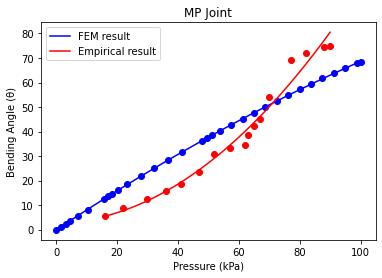

TheresultantstressandbendingareillustratedinFigs.7 and 8. Fig. 8 shows the bending trajectory on sequential actuation of MP, PIP, and DIP joints in that order. The maximumstressintheextensiblesiliconematerialisbelow itstensilestrengthof3.8MPa,ensuringsafeoperation.The bendingangles ateachjointwerecalculatedusingspecific node coordinatesfor everypressure step.From this data

bending angle against pressure graph plotted to further compare with empirical data. Also, pressures required to attaindesiredbendinganglesineachjointwereinterpolated from the plots. Details are discussed in the results section below.

Fig 7:FEMresults

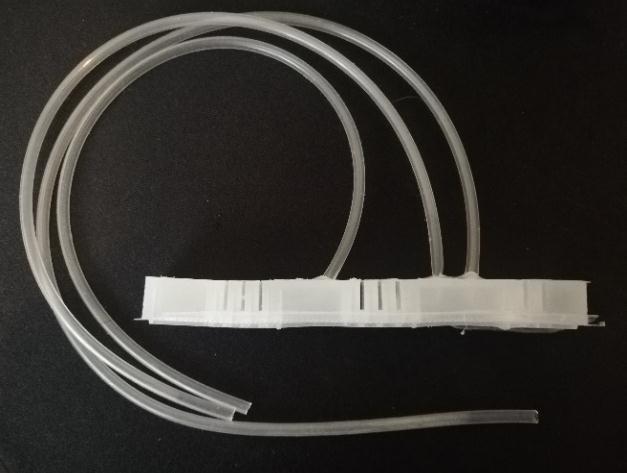

Casting process used to manufacture the actuator is explainedhere.Initially,amoldisdesignedfromtheactuator geometry, and 3D printed using affordable Polylactic Acid (PLA)filament.Fig.9showsthemoldpartstobeprinted;the top part and bottom parts for main body (or top layer of actuator) mold and a base mold for casting the base (consistingofthemiddleandbottomlayerofactuator).

Fig - 8:Actuatortrajectory

The chamber are fabricated with bio compatible DragonSkin20silicone,inordertoguaranteeasafecontact withtheskin.Therubbercomesintwoparts:A andBare mixed in the required quantities, and the mixture is deaerated. Removing air bubbles ensures homogenous properties throughout the geometry after hardening and reducesthechancesoffailure.Themixtureisthenpoured intorespectivemoldsandlefttoharden.Thetimerequired forformationwasobservedtobe1.5hoursfortheproposed design.Afterforming,theactuatorpartsareseparatedfrom the mold parts and combined together with a paper layer embeddedbetweenthetopandbottomlayers.Thispieceof paper acts as the inextensible layer. Air tubing is inserted

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

betweenthelayerstoserveastheinlettopneumaticpower. Finally, a Pneumatic circuit consisting of an air pump, pressure gauge, and tubing is connected for experimental testing.

Fig - 9:(a)mainbodymold toppart,(b)mainbodymold bottompart,(c)mainbodymold assembly,(c)basemold

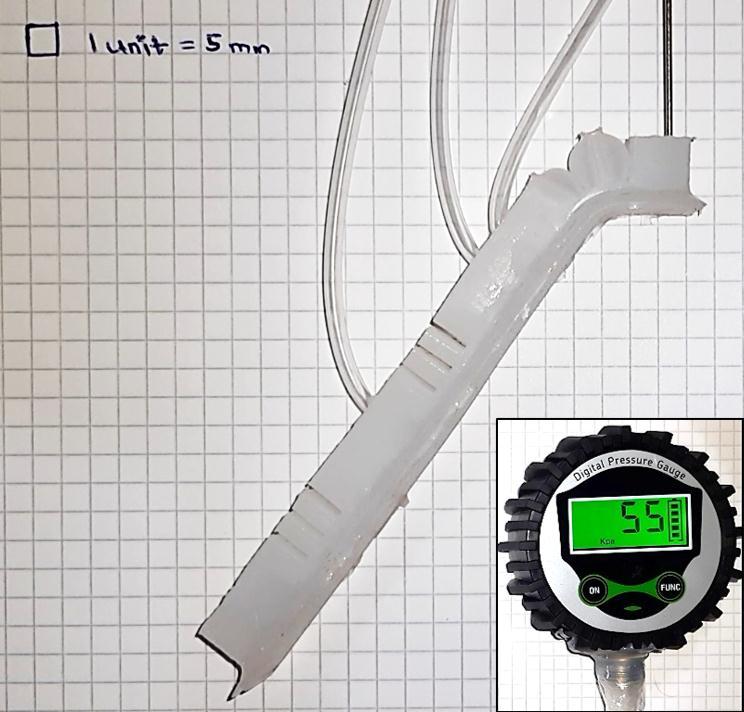

Fig 12:Prototypeactuation(MPjointpressurized); pressuregaugevalueinkPa

The simulation and empirical results obtained are discussedandcomparedinthefollowingsection.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

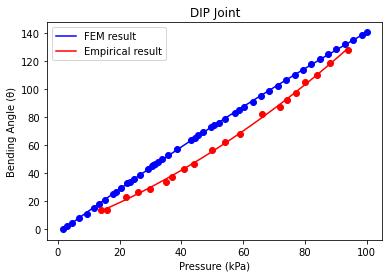

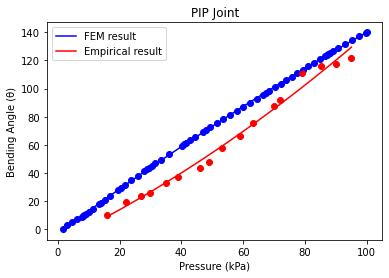

Graphsinfigs.13,14,and15comparetheBendingAngles vs. Actuation Pressure trends for simulation and experimentalresults.

experimentallyobservedPIPandDIPjointsvaluesweremore thantheFEMresultsby10.9%and25.5%,respectively.This dissimilaritycouldbeduetoadditionalpressurerequiredto overcomeunaccountedfactorsinthesimulation,likefriction andminorimperfectionsinthemoldingprocess.Asforthe MP joint, the practical value is less than the FEM value, possibly due to the effect of weight of cantilever mounted actuatorthatcausesittobendmoreattheMPjoint.These results could be improved upon with more accurate manufacturing,electronicallycontrolledpneumaticcircuitry, andpreciseanglemeasurement.

Table 1:Actuationpressurevalues

Joint Desired Bending Angle (deg)

Graph 1: MPjoint BendinganglevsPressure

Graph - 2: PIPjoint BendinganglevsPressure

Graph 3: DIPjoint BendinganglevsPressure

Table1presentspressurevaluesinkParequiredineach jointtoobtaincorrespondingmaximumbendingangles.The

FEM Result (kPa) Empirical Result (kPa)

MP 85° 132.38 92.60

PIP 107° 74.45 82.59

DIP 70° 47.74 59.90

A soft robotic actuator for mimicking human finger movement was studied and developed. The finger kinematics, based on DIP, PIP, MP joints in the finger mimicked, achieving complete flexion range of motion (ROM). The pressure required to actuate was studied through FEM analysis, and based on the data obtained, a prototype was developed to demonstrate the designed modelempirically.Theimportantfactorsconsideredwere material properties, actuator geometry, and manufacturability.Theprostheticdevicewasdevelopedwith scalabilityandaffordabilityinmind.Theresultingactuatoris cheap,easytomanufacture,andhighlycompatiblewithan individual’sphysique,makingitsuitableforaffordableand novelprostheticapplicationsofthefuture.

[1] D. Reid, K. Shah, A. Eltorai, C. Got and A. Daniels, "Epidemiology of Finger Amputations in the United States From 1997 to 2016," Journal of Hand Surgery GlobalOnline,vol.1,no.2,pp.45 51,2019.

[2] J.Marty,B.PorcherandR.Autissier,"Handinjuriesand occupationalaccidents.Statisticsandprevention,"Ann ChirMain,vol.2,no.4,pp.368 370,1983.

[3] Z. H. Mao, H. N. Lee, R. J. Sclabassi and M. Sun, "Information Capacity of the Thumb and the Index Finger in Communication," IEEE Transactions on

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

BiomedicalEngineering,vol.56,no.5,pp.1535 1545, 2009.

[4] S.Shimawaki,T.Murai,M.NakabayashiandH.Sugimoto, "Measurement of Flexion Angle of the Finger Joint during Cylinder Gripping Using a Three Dimensional Bone Model Built by X Ray Computed Tomography," AppliedBionicsandBiomechanics,2019.

[5] P.Polygerinos,B.MosadeghandA.Campo,"softrobotics toolkit," [Online]. Available: https://softroboticstoolkit.com/book/pneunets bending actuator.[Accessed1May.2021].

[6] Mosadegh, Bobak, P. Polygerinos, C. Keplinger, S. Wennstedt,R.F.Shepherd,U.Gupta,J.Shim,K.Bertoldi, C.J.WalshandG.M.Whitesides,"PneumaticNetworks for Soft Robotics That Actuate Rapidly," Advanced Functional Materials, vol. 24, no. 15, p. 2163 2170, 2014.

[7] Y. Sun, Q. Zhang, X. Chen and H. Chen, "An Optimum Design Method of Pneu Net Actuators for Trajectory Matching Utilizing a Bending Model and GA," MathematicalProblemsinEngineering,2019.

[8] M. Xavier, A. Fleming and Y. Yong, "Finite Element ModelingofSoftFluidicActuators:OverviewandRecent Developments,"AdvancedIntelligentSystems,vol.3,no. 2,2020.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal