International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Amjad Abbas1, Dr. Sanjay Kumar Gupta2

1Master of Technology, Production Engineering, MUIT, Lucknow, India

2Assistant Professor, Mechanical Engineering, MUIT Lucknow, India ***

Abstract - In this research paper, a numerical study of friction stir welding on the aluminum sheet, there are three Almunium sheets for friction stir welding such as Al 5086, Al 6070, and Al 7075 with different profile pins, and there are selected six types of the pin profile which are Straight Cylindrical, Threaded Cylindrical, Tapered Cylindrical, Threaded tapered cylindrical, Triangular, andpentagonal pin. Here checking that which profile pin provides maximum strength by changing the rotation speed of the profile pin and also changing pressure on the aluminum sheettoseetheeffect of strength on the materials, also checking which profile pin is more stable as compared other five profile pin. The detailed property of all these three aluminum material sheets is given in the designing section.

Key Words: Al5086,Al6070,Al7075,frictionstirwelding, numerical,pinprofile,pressure,therotationspeedofpin.

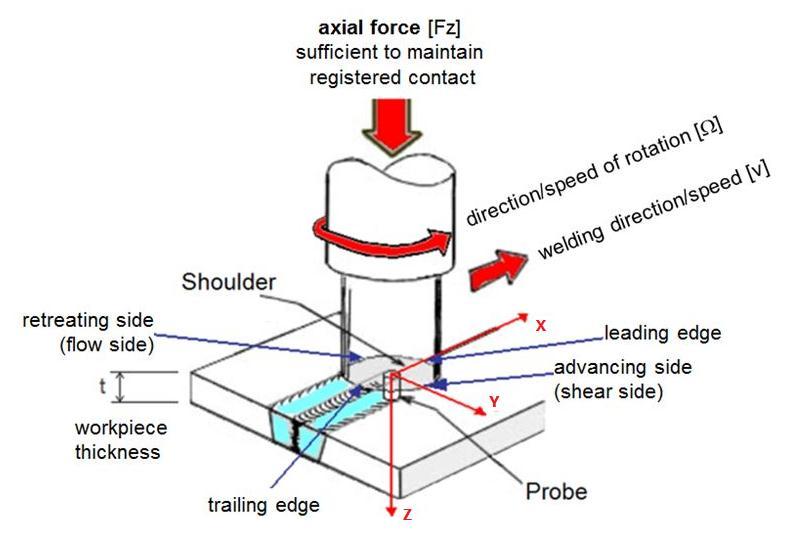

Frictionstirwelding(FSW)hasapproachalongwaysinceits improvement by Wayne Thomas, as a component of the WeldingInstitute(TWI).in1991.ThefirsttechniqueofFSW tookintoaccountadjoiningaluminumplatestobewelded commonly and, surprisingly, non wieldable compounds wereeffectivelywelded[11].Thesystemextracreatedmake itworkableforthefrictionstirweldingofdifferentmaterials like titanium, zinc, magnesium, and even steel [1]. AdvancementwasfundamentalduringFSWextension,like the utilization of an unmoving convey for titanium FSW, expectedsinceofitshighconductivity[9].Uptothispoint FSWweldinghasjustbeenfeasibleonsmoothsurface,yet newadvancementhavereasonablefortheFSWofcornersof shifting points. FSW and corner FSW (CFSW) are exceptionallyequalinteractioninvariousways[3].InFSWa non consumabledevice,commonlycomprisingofshoulder andapparatuspin(ortest),isdoveintotwoadjoiningplates inadecentposition[10].Bythecourseoffrictionalwarming fromtheturningdevice,theplannedsubstancerelaxandis thenconsequentlytwistedastheinstrumenttraversedthe weldlocale[13].WhatmakesFSWextraordinaryisthatas opposedtoliquefyingthematerial,itgoesthroughcontained unforgivingplasticstreamroughlytheborer[4].Ratherthan the welding method being a projecting strategy like other weldingstrategy,itisa hotfashioningprocessorthermo mechanical system. The divergence of being a thermo

mechanicaltechniqueratherthanaprojectinginteractionis the reason FSW accomplishes such great weld coherency, skill,andmightinfactbeestimatedtobeagreencycle[2]. The disparity among FSW and CFSW is that the convey ratherthanbeingfixed isseparatingandcreatedtoholdthe point of the bend that it is welding. Figure 01 shows the course of frictionstir welding,andtable 01addressesthe upsideoffrictionstirwelding[5].

Figure 01: ProcessofFrictionStirWelding.

Table 01: Advantage of Friction Stir Welding [3].

Metallurgical advantages Environmental Advantages Energy Advantages

Solid statejoining process. NoShieldinggas required. Improved materialsuse (i.e.joining different thicknesses) allowsa reductionin weight.

Lowdistortionof theworkpiece. Nosurface cleaningrequired. Only2.5%of theenergy neededfora laserweld.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table

Gooddimensional stabilityand repeatability.

Eliminategrinding waste. Decreasedfuel consumptionin lightweight aircraft, automotive,and ship applications.

Nolossofalloying elements.

Great metallurgical propertiesinthe jointarea.

Eliminatesolvents requiredfor degreasing[12].

Consumable materialssaving, suchasrugs,wire, oranyothergases.

Fine microstructure. Canbeperformed underwater.

Replacemultiple partsjoinedbya fastener.

Absenceof cracking.

WhileFSWispredominantlyusedonaluminumithasalso been used on multiple materials which include steel, titanium, nickel base superalloys, copper, and magnesium [5]. Besides, it has seen use in the airplane business, railroads, atomic and other electrical power plants, autos, machine instruments, metal handling, the petrochemical business [14], and electrical and mechanical areas [6]. Because of a fast take up of the innovation [4], the FS Weldingsystemhasbeenappliedtoordinarywelding[8], yet additionally further fields that include the welding of barrel shaped and three layered joints [12]. With the expansionofnowcornerFSWelding[15],therearenotmany applicationsthatFSWdoesn'thave[7].

The property of these three aluminum sheets is given in detail.

ThemechanicalpropertyandcomponentoftheAl 5085are givenintable 01andtable 02.

S.No Component

Percentage (%) 1 Al 93 96.3 2 Cr 0.05 0.25 3 Cu Max0.1 4 Fe Max0.5 5 Mg 3.5 4.5 6 Mn 0.2 0.7 7 Si Max0.4 8 Ti Max0.15 9 Zn Max0.25

Table 03: Mechanical

5086

S.No Property Metric 1 Hardness,Brinell 78 2 Hardness,Knoop 101 3 Hardness,Vickers 88 4 UltimateTensileStrength 290MPa 5 TensileYieldStrength 207MPa 6 ElongationatBreak 12% 7 ModulusofElasticity 71GPa 8 CompressiveModulus 72.4Gpa 9 UltimateBearingStrength 552MPa 10 BearingYieldStrength 331MPa 11 Poisson'sRatio 0.33 12 FatigueStrength 150MPa 13 FractureToughness 49Mpa m^0.5 14 Machinability 30% 15 ShearModulus 26.4GPa 16 ShearStrength 175MPa

ThemechanicalpropertyandcomponentsoftheAl 6070are givenintable 04andtable 05.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1603

2.3.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table 04: Component of Al 6070

S.No Component Percentage (%)

1 Aluminium/aluminum, (Al) 97 2 Silicon(Si) 1.40 3 Magnesium(Mg) 0.80 4 Manganese(Mn) 0.70 5 Copper (Cu) 0.28

Table-05: Mechanical Property of Al-6070

S.No Property Metric

1 Tensilestrength 145MPa 2 Yieldstrength 69MPa 3 Shearstrength 97MPa 4 Fatiguestrength 62MPa 5 Elasticmodulus 70 80GPa 6 Poisson'sratio 0.33 7 Elongation 20% 8 Hardness 35

ThemechanicalpropertyandcomponentsoftheAl 7075are givenintable 06andtable 07.

Table 06: Component of Al 7075

S.No Component Percentage (%)

1 Aluminium/aluminum, (Al) 94to95.1 2 Silicon(Si) 0.4 3 Magnesium(Mg) 2.1to2.9 4 Manganese(Mn) 0.30 5 Copper (Cu) 1.2to2 6 Fe 0.5 7 Zn 2.1to3.3

Table 07: Mechanical Property of Al 7075

S.No Property Metric

1 TensileYieldstrength 503MPa 2 UltimateTensilestrength 572MPa 3 Shearstrength 331MPa 4 Fatiguestrength 159MPa 5 Elasticmodulus 71.85 GPa 6 Poisson'sratio 0.33 7 Elongation 11% 8 Hardness 53.5

There are six types of pin profile used, that are Straight Cylindrical, Threaded Cylindrical, Tappered Cylindrical, Threaded tapered cylindrical, Triangular, and pentagonal pin.Thedetailsofeverypinprofilearegiven intable 08

Table-08: Mechanical Property of Al-7075

S.No Type of Pin Profile Bottom Parameter of Pin

Top Parameter of Pin

Height of Pin

1 Straight Cylindrical 5mm Diameter 5mm Diameter 8mm

2 Threaded Cylindrical 5mm Diameter with 0.5mm cuttinggap

5mm Diameter 0.5mm cuttinggap

8mm 3 Tappered Cylindrical 5mm Diameter 6.5mm Diameter 8mm 4 Threaded tapered cylindrical

5mm Diameter with 0.5mm cuttinggap

6.5mm Diameter with 0.5mm cuttinggap

8mm 5 Triangular 5.5mm width 5.5.mm width 8mm

6 pentagonal pin 3.5mm widthwith 108degree

3.5mm widthwith 108degree

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1604

8mm

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

IntheCalculationandresult,thereisresultcomeoutafter thenumericalanalysisofthedifferentpinprofilessuchas Straight Cylindrical, Threaded Cylindrical, Tappered Cylindrical, Threaded tapered cylindrical, Triangular, and pentagonalpinatthedifferentaluminumsheetssuchasAl 5086, Al 6070, and Al 7075. The dimension of every aluminumsheetis45cm*25cm*5cm.

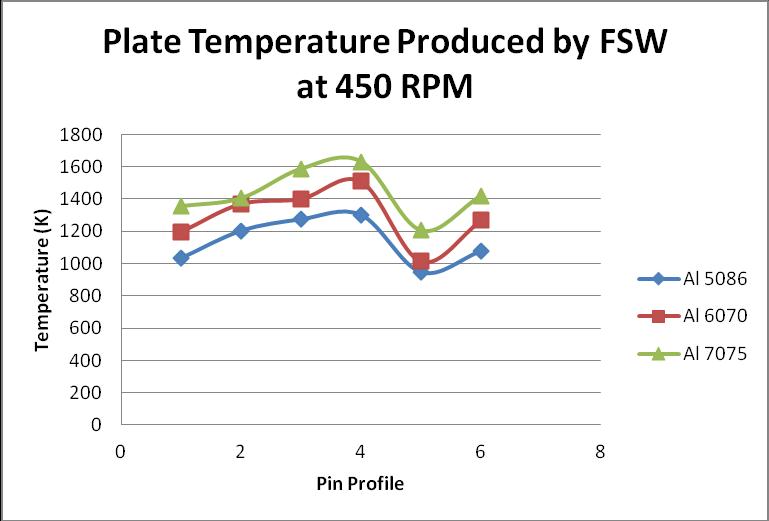

Temperatureproducedatthesurfaceofthealuminumsheet due to joining the two aluminum plates with help of the frictionstirweldingisknownasplatetemperature.When therotationalspeedofofthepinprofileiskeptat450RPM, thetemperaturegeneratedatthesurfaceofthealuminum plateisgiveninthegraph 01:

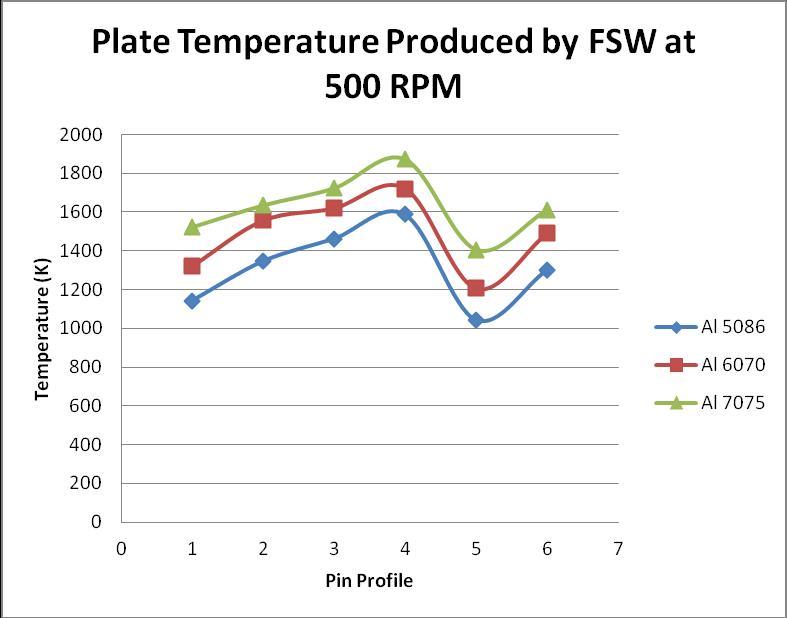

Graph 02: Plate temperature produced by FSW at 500 RPM.

From the above graph of the plate temperature, the maximumtemperaturegeneratedintheAl7075.

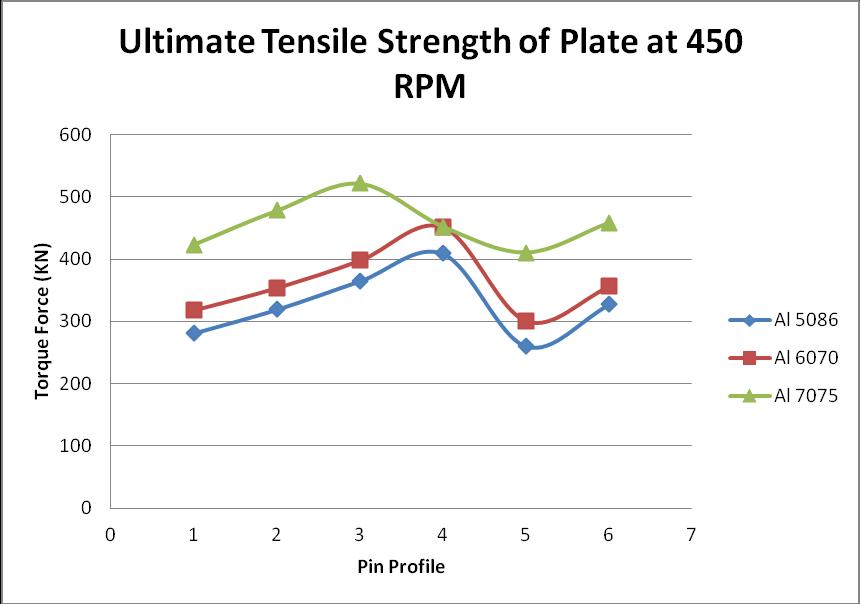

4.3. Ultimate Tensile Strength of the Plate at 450 RPM

Ultimatetensilestrength(UTS),oftenshortenedtotensile strength (TS), isthe maximum stress that a material can withstandwhilebeingstretchedorpulledbeforebreaking. Thejoiningoftwoaluminumplateswithhelpofthefriction stir welding at the rotational speed of the pin profile is 450RPM, the ultimate tensile strength of these three aluminum sheets with different pin profiles is given in graph 03:

Graph 01: Plate temperature produced by FSW at 450 RPM.

Fromtheabovegraph,theminimumtemperatureproduced in the Al 5086. Where pin profile on the X axis 1 to 6 representStraightCylindrical(1),ThreadedCylindrical(2), TapperedCylindrical(3),Threadedtaperedcylindrical(4), Triangular(5),andpentagonalpin(6)respectively.

Whentherotationalspeedofthepinprofileincreasesupto 500RPM,thetemperature generatedatthesurfaceof the aluminumplateisgiveningraph 02:

Graph 03: Ultimate tensile Strength of Plate at 450 RPM.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1605

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Fromtheabovegraphoftheultimatetensilestrengthofthe aluminumplateatthe450RPM,theultimatetensilestrength is almost the same for every aluminum sheet at the pin profile Threadedtaperedcylindrical.

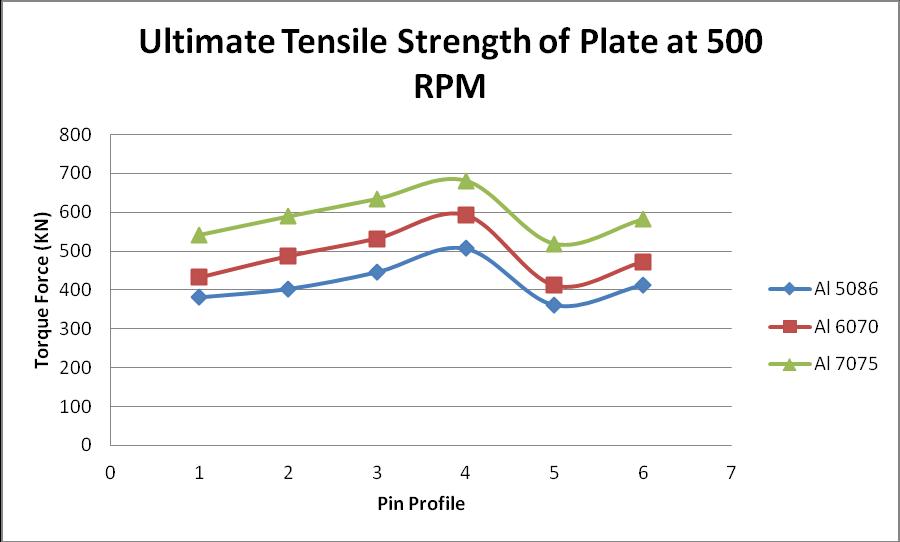

Thejoiningoftwoaluminumplateswithhelpofthefriction stir welding at the rotational speed of the pin profile is 500RPM, the ultimate tensile strength of these three aluminum sheets with different pin profiles is given in graph 04:

[1]D.Venkateswarlu,P.NageswaraRao,M.M.Mahapatra,S. P.Harsha,andN.R.Mandal,“Processingandoptimizationof dissimilar friction stir welding of AA 2219 and AA 7039 alloys,”JournalofMaterialsEngineeringandPerformance, vol.24,no.12,pp.4809 4824,2015.

[2]M.Akbari,M.Aliha,S.Keshavarz,andA.Bonyadi,“Effect oftoolparametersonmechanicalproperties,temperature, and force generation during FSW,” Proceedings of the Institution of Mechanical Engineers Part L: Journal of Materials:DesignandApplications,vol.233,no.6,pp.1033 1043,2019.

[3]T.Sathish,G.Muthu,M.D.Vijayakumar,V.Dhinakaran, and P. M. B. Ram, “Mechanical properties and microstructuralanalysisoffrictionstirprocessedAA6056 zirconium dioxide (ZrO2),” Materials Today: Proceedings, vol.37,pp.1804 1808,2021.

[4] S. T. Amancio Filho, S. Sheikhi, J. F. Dos Santos, and C. Bolfarini, “Preliminary study on the microstructure and mechanical properties of dissimilar friction stir welds in aircraftaluminumalloys2024 T351and6056 T4,”Journal of Materials Processing Technology, vol. 206, no. 1 3, pp. 132 142,2008.

Graph 04: Ultimate tensile Strength of Plate at 500 RPM.

Fromtheabovegraphoftheultimatetensilestrength,the value of the tensile strength is decreased by using the Triangularpinprofileinanytypeofaluminumsheet.

Afternumericallyanalysisofthefrictionstirweldingonthe three different aluminum sheets with six different pin profilessuchasStraight Cylindrical,ThreadedCylindrical, Tapered Cylindrical, Threaded tapered cylindrical, Triangular,andpentagonalpinbyincreasingtherotational speedof the pin profile on thealumunim sheet. Whenthe rotational speed of the pin profile kept 450RPM at every aluminum sheet, then it found that temperature getting decrease at the triangular pin profile and maximum temperature at the threaded tapered cylindrical in every profile. The ultimate tensile strength of every aluminum sheetisincreasingbyincreasingtherotationalspeedofthe pinprofile,anditalsofoundthatmaximumtensilestrength canbeachievedbyusingthethreadedtaperedcylindrical.

[5] P. Cavaliere, R. Nobile, F. W. Panella, and A. Squillace, “Mechanical and microstructural behavior of 2024 7075 aluminum alloy sheets joined by friction stir welding,” InternationalJournalofMachineToolsandManufacture,vol. 46,no.6,pp.588 594,2006.

[6] A. F. Vieda Gaona and O. F. Mora Mora, “Efecto del tratamientot´ermicodeenvejecidoartificialenlarugosidad delaluminio6061,”vol.4,pp.1 96,2018.

[7] T. Sathish, N. Sabarirajan, and S. Karthick, Materials Today Proceedings, Elsevier Publisher, Amsterdam, Netherlands,2019.

[8]M.Tamjidy,B.Baharudin,S.Paslar,K.Matori,S.Sulaiman, andF.Fadaeifard,“Multi objectiveoptimizationoffriction stirweldingprocessparametersofAA6061 T6andAA7075 T6 using a biogeography based optimization algorithm,” Materials,vol.10,no.5,p.533,2017.

[9]M.M.Hasan,M.Ishak,andM.R.M.Rejab,“Effectofpin toolfluteradiusonthematerialflowandtensileproperties of dissimilar friction stir welded aluminum alloys,” <e International Journal of Advanced Manufacturing Technology,vol.98,no.9,pp.2747 2758,2018.

[10] H. Darzi Naghibi, M. Shakeri, and M. Hosseinzadeh, “Neuralnetworkandgeneticalgorithmbasedmodelingand optimizationoftensilepropertiesinFSWofAA5052toAISI

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1606

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

304dissimilarjoints,”TransactionsoftheIndianInstituteof Metals,vol.69,no.4,pp.891 900,2016.

[11]G.GhangasandS.Singhal,“Effectoftoolpinprofileand dimensionsonmechanicalpropertiesandmicrostructureof friction stir welded armor alloy,” Materials Research Express,vol.5,no.6,ArticleID066555,2018.

[12]M.Raturi,A.Garg,andA.Bhattacharya,“Jointstrength andfailurestudiesofdissimilarAA6061 AA7075frictionstir welds: effects of tool pin, process parameters and preheating,”EngineeringFailureAnalysis,vol.96,pp.570 588,2019.

[13]T.Sathish,S.Rangarajan,A.Muthuram,andR.P.Kumar, “Analysis and modeling of dissimilar materials welding based on K nearest neighbor predictor,” Materials Today: Proceedings,vol.21,pp.108 112,2020.

[14] Z. Zhao, H. Liang, Y. Zhao, and K. Yan, “Effect of exchanging advancing and retreating side materials on mechanical properties and electrochemical corrosion resistanceofdissimilar6013 T4and7003aluminumalloys FSW joints,” Journal of Materials Engineering and Performance,vol.27,no.4,pp.1777 1783,2018.

[15]U.DasandV.Toppo,“Effectoftoolrotationalspeedon temperatureandimpactstrengthoffrictionstirweldedjoint of two dissimilar aluminum alloys,” Materials Today: Proceedings,vol.5,no.2,pp.6170 6175,2018.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1607