International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Abhilash Koli1, Prof. Dr. B. S. Gawali2

1M. Tech, Mechanical Heat Power Engineering, Walchand College of Engineering, Sangli, Maharashtra, India

2Professor, Mechanical Engineering Department of, Walchand College of Engineering, Sangli, Maharashtra, India ***

Abstract: High pressuresteamisusedtogenerateelectricityinmostindustrialindustries.Steamisgeneratedinboilersand transferredtotheindustrialfacilitiesviapipelines.Losscanoccuralongtheirjourneyduetopressureloss,pipelineinsulation failure, and temperature loss. Steam network losses are what they're called. This lowers steam efficiency and, as a result, lowers steam quality at the receiving end. Steam traps are automatic valves that catch steam and remove condensate from steampipes, preventingsteamloss. Becauseitisa steamconnection utilization Thesteamtrap isthe most importantlink in thecondensateloopwhenitcomestocondensatereturn.Thepurposeofasteamtrapistoallowcondensatetoescapewhile keepinglivesteamfromescaping. TheThermodynamicTrapFMTD64isfullstainlesssteelwithinbuiltstrainer construction, anditisverybestusefulforheaderandmainlinedrainsforsteamsystems ItisavailablewithFlangedendswithModelhaving FMTD64 & with 25 Socket and also Weld Ends Model FMTD64SW.in this dissertation the applications of steam traps are studied and the set up for testing of steam trap is made. The functional study of the steam test is done. The project is sponsoredbyTheForbesMarshallundertheguidanceofMr.MangeshAashtekar.

Keywords: steam trap, tests up, Thermodynamic Trap, header, mainline drains.

Introduction:

Whereverheatingisrequired,steamhasproventobeaflexibleandversatiletoolfortheindustry.Evaporationofwater,which isacheapandabundantcommodityinmostregionsoftheworld,producesit.Itstemperaturemaybepreciselycontrolledby employing simple valves to alter its pressure. The dryness fraction, or the amount of fully dry steam present in the steam under consideration, is used to describe the quality of the steam. Steam cannot be described as dry saturated steam since it frequentlycarriesmicroscopicdropletsofwaterwithit.Steamtrapsareusedtokeepthesteamutilizedforprocessorheating asdryasfeasible.Asteamtrapisavalvethatallowscondensateandairtoescapefromalineorpieceofequipmentwithout releasingsteam.

Thethreeimportantfunctionsofsteamtrapsare:

•Assoonascondensateiscreated,itshouldbedischarged.

•Nosteamshouldbeallowedtoescape.

•Theabilitytodischargeairandothernon condensablegases.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

a)

Have a float that rises and falls in response to the amount of condensate in the system, and this is usually connected to a mechanical linkage that opens and closes the valve. The amount of condensate in the steam trap's body determines how effectivemechanicaltrapsare.Invertedbucketsandfloattrapsareexamplesofmechanicaltraps.

Thermostatic Steam Traps are controlled by the temperature difference between steam and condensate. The condensate's temperature is lower than that of the steam. A thermostatic steam trap has a port that opens or closes depending on the temperature of the intake fluid. The port is closed if the temperature exceeds the stated range. When the fluid temperature falls below the previously determined value, the port opens. Bi Thermostatic traps include liquid expansion and balance pressuretraps,amongothers.

are based on the dynamic response of compressible and incompressible fluids to changes in velocity. When steam enters, static pressure above the disc presses the disc against the valve seat. The static pressure over a large area overcomes the steam'shighinputpressure. Asthesteamcondensesandthetrapcycles,thepressureagainstthedisc reduces.Asa result,a TDtrapfunctionsasa"timecycle"device.

Visual inspectionisa crucial initial stepinestablishing whetherornota trapisworkingeffectively.Certainvisiblesignals, If there is no condensate discharge or abnormally large amounts of steam oozing out of a trap, it may need to be repaired. Externalinspectionoftrapsforpinhole,connectionjoint,andgasketleaksisalsopossible

Most traps' opening and shutting valve mechanisms, as well as the condensate pouring through them, cause sound and vibration. When a trap isn't working properly, these sounds regularly vary (due to wear, blockage, or other factors). Recognizingthisgapisonemethodofassessingtheconditionofasteamtrap.Soundtestingcanbedonewithultrasonicleak detectors,mechanicalstethoscopes,screwdrivers,orametalrodwithahumanearagainstit.

Amongtheequipmentprovidedareinfraredguns,surfacepyrometers,temperaturetapes,andtemperaturecrayons. They're usuallyutilizedtocheckthedischargetemperatureonthetrap'soutletside.Lowreadingsusuallysuggestanundersizedtrap, an improper trap pressure orifice, or a blocked trap/strainer discharge failure. Infrared guns and surface pyrometers may quicklydetectblockedorturned offtrapssincetheywillexhibitloworcoldtemperatures.Theycouldalsodetectundersized trapsorhugeamountsofcondensatebackingupbysensinglow temperaturereadings.

Thermodynamic steam trap benefits include:

1) Thermodynamic traps can operate across their whole working range without requiring any tweaks or changes on the inside.

2)Incomparisontothevolumeofcondensatetheymaydischarge,thermodynamictrapsaresmallandcompact.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

3) Thermodynamic traps, which can be used on high pressure and superheated steam, are unaffected by water hammers or vibration.

4) Thermodynamic traps are unaffected by freezing, and they are unlikely to freeze if placed vertically with the disc dischargingfreelytotheatmosphere.However,functioninginthismannermayresultinthediscedgewearingoff.

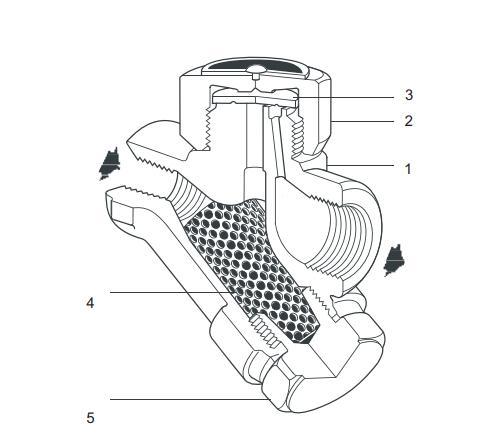

Material: Table 1 material [2]

Sr.No. Part Material Standard

1 MainBody StainlessSteel ASTMA743Gr. CA40

2 Cap StainlessSteel ASTMA743,CA40

3 Disc StainlessSteel ASTMA743,CA40

4 Strainer StainlessSteel Type304ASTMA240

5 StrainerCap StainlessSteel ASTMA743,CA40

1.Withstainlesssteel,thisdesignoffershighermechanicalandcorrosion resistantqualities.

2. During the induction hardening process, the disc and seat were hardened to around 45RC, allowing them to endure continuouswaterpounding.

3.Seatbecomesanextensionofthebody,eliminatingleakyjointsandgaskets.

4.Condensateentersconcentrictothediscorseatbelowthedisc,ensuringparallelandacleanreferencetotheseatwithalift tothedisc,aswellaseliminatinganylocalizedripandwear.

5.Anincorporatedstrainerfilterwithasufficientlybigareaassureslongandtrouble freeoperation.

The thermodynamic trap has the following advantages:

•Thermodynamictrapscanbealteredortweakedwithoutdamagingtheparts'internals.

•Theyareexceptionallycompact,simple,andlightweighttrapsduetotheirlargecondensatecapacity.

•Thermodynamictrapsareunaffectedbywaterhammersor vibrationandcanbeutilisedonhigh pressureandsuperheated steam.Theall stainlesssteeldesignprovidesahighlevelofresistancetocorrosivecondensate.

•Whenfittedwiththediscinaverticalplaneanddischargingfreelytotheatmosphere,thermodynamictrapsarenotdamaged byfreezingandareunlikelytofreeze.However,thiscausesthediscedgetowearoutinthisposition.

•Theonlymovingportionisthedisc,whichmayberemovedwithoutremovingthetrap.

There are a few disadvantages also,

•Atverylowdifferentialpressures,thethermodynamictrapwillnotworkbecausetheflowvelocityoverthedisc'sunderside isinsufficienttoallowforlowerpressure.Theyaresubjectedtoaminimuminletpressure(usually0.25barg)butcantolerate upto80%oftheinletpressureinbackpressure.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1580

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

•Thermodynamictrapscanreleaseasignificantamountofaironstartupiftheinletpressurerisesupslowly.'Air bindoccurs when a high velocity cause builds up enough air to shut off the trap in the same manner that steam does. In addition, a separate air vent thermostatics was fitted in conjunction with the trap. In modern thermodynamic steam traps, an anti air bindingdisccanbeemployedtopreventairpressurefrombuildingupontopofthediscandallowingairtoescape.

•Thethermodynamictrap's emissioncan beloud, whichmayexcludeitsuseincertainsituations,suchasoutsidea hospital wardoroperatingtheatre.Ifthisisaconcern,adiffusercanreadilybefittedtominimizedischargenoisesignificantly.

•It'scrucialnottooversizeathermodynamictrap,asthiswillcausecyclelengthstolengthenandwear.Aslongasthedrain pocketsareproperlypositioned,low capacityvariationsareusuallysuitableformainsdrainageapplications.

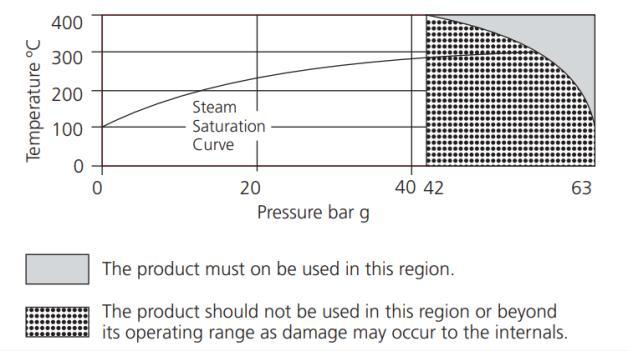

Limiting conditions of FMTD64 :

Table 2 Limitingconditionoftrap64model[2]

Bodydesignconditions PN63

Maximumallowablepressure 63barg@100:c

Maximumallowabletemperature 400:c@42barg

Minimumallowabletemperature 0:c

Recommended maximum operatingpressureforPMO 42barg

Minimum operating temperatures 0:c for satisfactory operations, a minimum operating differential pressurerequired

0.25barg

The maximumcoldhydraulic test pressureof 95barg

Testing steam traps:

Thefollowingprocedurescanbeusedtoverifyatrap'soperatingstateandwhetheritisfunctioningproperly:

1.Visualinspectionoftrapsisthefirststepinthetestingprocess.

2.Usingatemperaturegun/equipmenttotesttraps

3.Sound/ultrasoundtestingoftraps

4.Onlinemonitoringisusedtotesttraps.

Working: The steam Trap FMTD64 is designed for header and mainline drains and is made of stainless steel with an incorporatedstrainer.Itis availablewithFlangedendsandhencewithModelFMTD64&withthisparameterin SocketWeld ModelFMTD64

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

•Failuredetectionissimpleifasteamtrapfailsopenanddischargesintotheopen.Ifasteamtrapfailsto closeorasteamtrap from which condensateis collected failstoopen, detection becomesmoredifficult. Asa result, it's always a goodidea to use theappropriate equipment tomonitorthesteamtrap's operation ona regular basis.Thefollowingarethe various problems thatcanoccurwhenasteamtrapfailstoclose.

• In this section, we discovered the failed steam traps, verified that there is no more steam wastage, and improved the productivityandperformanceofthesteamsystemaswellastestingparameters.It'salsoworthconsideringtheconsequences ofsteamtrapfailuresinthesteamsystemonthetestingsystem'sperformance.

•Steamtrapscanfailintwoways:openorclosed.

•Whenasteamtrapfailsopen,itisreferredtoasanopenvalvesinceitleaksbothcondensateandsteam.Whenasteamtrap does not close properly, it behaves as a closed valve, preventing steam and condensate from passing through. Regardless of whether a steam trap fails open or closed, it does the same amount of damage to the steam system and should be fixed or replaced.

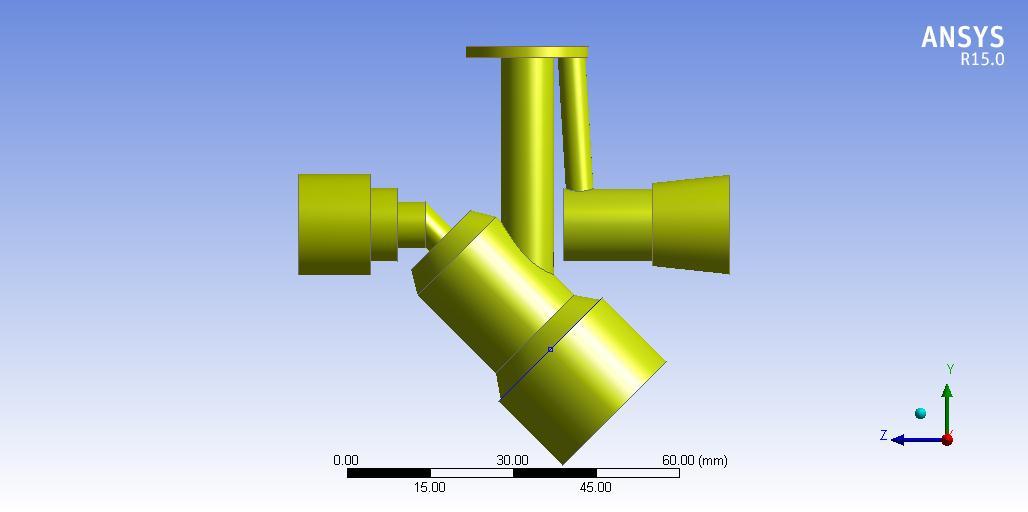

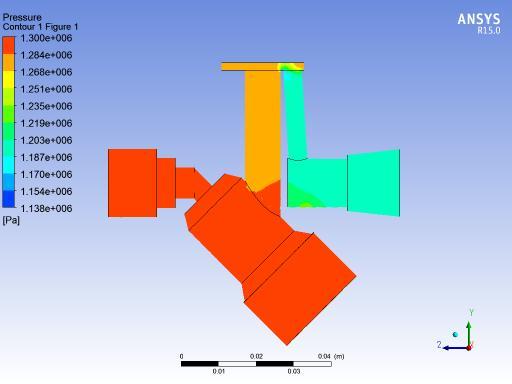

Inthischapter,ananalysisofsteamtrapaspressuredistribution,andvelocityvariationisdiscussed.

Geometry :

Fig. 2 Steamtrapgeometryoffmtd64

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

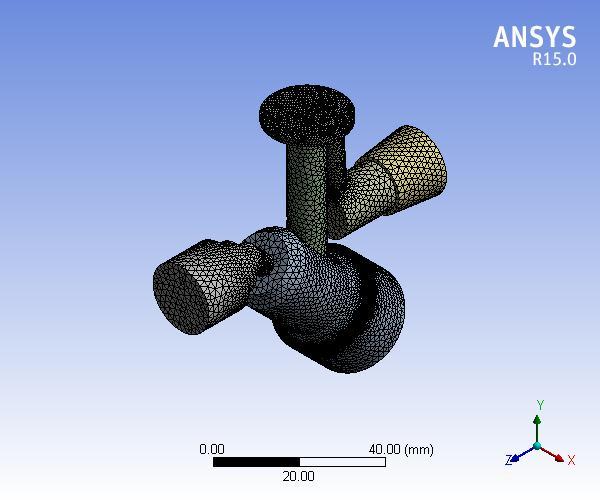

Meshing: themeshingofthemodelisdoneintheAnsysworkbench.

1]NumberofNodes=481393 2]NumberofElements=243624

Table 3 Cellzonecondition

Zone Type Inletsection Fluid(vapor+water) Pressuresection Fluid(vapor+water) Outletsection Fluid Porussection Fluid 2] Boundary condition :

Table 4 Boundarycondition

Zone Type Inlet Pressure Inlet Outlet Pressure outlet Porussection Pressure

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Fig. 5 operatingconditionfromForbesMarshallmanual

Operatingpressurerangeofthisproduct:

MaximumoperatingpressurePMO=14.0barg@at197:c MaximumoperatingtemperatureTMO=400:c@5.5barg • Hydraulictestpressureinthecold=21.0barg(ANSI#150)

PMO(PotentialOperatingPressure)=41.5barg 253:c

TMO(TemperatureMaximumOperating)=400:cat28.0barg

testpressureofhydraulic =62.0barg

Conclusion:

It is concluded from the above study and data, that study and testing of thermodynamic steam trap can be done manually. Thesteamtrapsarecheckedunderthelimitingconditionsandwithintheoperatingconditions. ThepressureparameterofCFDanalysisisalsotheexperimentalresult.At12.84bar.

Future Scope:

Iftheresultsofmanualtestingareacceptable,automatictestingalsocanbeimplemented. Similarproductscanbetestedbythesamemethod.

References:

[1]https://www.spiraxsarco.com/learn about steam/steam traps and steam trapping/thermodynamic steam traps [2]ForbesMarshallThermodynamicTrap.FMTD64InstallationandMaintenanceManual [3]Himanshu1,AkhilArora2,PratikS.Ghatake3,2018|Volume6,Issue2|ISSN:2321 9939,Design,Fabrication,andTesting OfCostEfficientThermodynamicSteamTrap,©IJEDR2018

[4]OverviewofSteamStrapsCourseNo:D04 001Credit:4PDHA.Bhatia, [5]Volume:07Issue:03| Mar2020,RaghvendraPratapSingh1,MBSorte2,MadanMJagtap3, STEAMLOSSMINIMIZATION THROUGH STEAM DISTRIBUTION A CASE STUDY OF A CRUDE OIL REFINERY NETWORK USING AN INTEGRATED METHODOLOGY,Volume:07Issue:03|Mar2020,InternationalResearchJournalofEngineeringandTechnology(IRJET).

[6]July2015,SreedeviK.P, ANALYSISOFSTEAMTRAPSINPROCESSPLANTS,InternationalResearchJournalofEngineering andTechnology(IRJET),July2015

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

[7]CourseNo.D04 001:OverviewofSteamStrapsContinuingEducationandDevelopment,Inc.22StonewallCourtWoodcliff Lake,NJ07677

[8] Aug 2013, SELECTION AND ANALYSIS OF STEAM TRAP PERFORMANCE IN THE PROCESS INDUSTRY, Binoy P* et al. [IJESAT][InternationalJournalofEngineeringScience&AdvancedTechnology],Aug2013

[9]STEAMTRAPS:AREVIEWBASEDONASTUDYATBPCL KR,1CHINNUMOLFRANCIS,2JEENAJOHN,3AMRUTHATHOMAS, 24thMay2015,Proceedingsof13thIRFInternationalConference,Bengaluru,India

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1586