International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

1Mayukshi Devi, 2Manash Jyoti Das

1,2 Student, NITRA TECHNICAL CAMPUS, GHAZIABAD, India ***

Uses of different natural fibers have gained importance in the recent years due to ecofriendly nature. Moreover, by 2020 the world total fiber demand will be 102.4 million metric tons. Use of the wastage of food crops as alternative source of raw materials for clothing is a good solution to meet up this demand. Pine needle fiber could be a good source of natural fiber. The main objectives of this project are extraction of fiber from the pine leaves and characterization of collected fiber, produce yarn from the fiber and then characterization of yarn. The properties of pine cotton blend yarn and 100% cotton yarn were studied in terms of cvm %, total imperfection index, tenacity, CSP, and elongation %. The overall results showed that the pine cotton blend yarn was good denier value which was found to be higher than that of cotton. Unevenness (U) % of pine cotton blend yarn was higher as compare to 100% cotton yarn. It was happened because drawing and doubling was carried out in same machine and doubling was done by only four plied of drawn sliver. Pine cotton blend yarn having lower strength because of higher unevenness percentage as compare to 100% cotton yarn. Breaking strength in both yarns i.e., pine cotton blend and 100 % cotton were good. Pine cotton blend yarn tenacity could be increased by changing the TPI or other parameters like fiber fineness, fiber strength, twist level, evenness level and fiber length variation and distribution. By blending uniformity with high quality cotton fiber & use of synthetic fiber in blending desired strength of yarn could be obtained. Elongation % of pine cotton blends yarn was found to be higher i.e. 6.76 as compare to 100% cotton i.e. 5.55. So that pine cotton blend yarn could be possible to use in heavy fabric, decorative purpose, non woven and composites also.

There are various measures taken to revolutionize the Textile Industry by using various natural wastes occurring in the environment like waste leaves, barks etc extracted from various trees. Because of biodegradable in nature.

By this project it is concluded that a pine needle yarn made of pine needle fiber by extraction of pine fiber either mechanically or chemically from the dry pine leaves. Because waste can be recycling or reused.

Key words: pine fibers, TPI, CSP, elongation, waste product

For thousands of years, natural fibers have been at the core of the textile industry. From cloth, to paper and building materials, natural fibers were always the base material.Natural fibers originate from either plant fibers, such ascoir,cotton andflax, or animal fibers such ascamel hair,alpaca wool, andcashmere. As a completely renewable resource, natural fibers provide many benefits both to the environment and to those involved in the market that they create.Naturalfibersnotonlycomefromtheenvironment,butalsobenefitit.Thesefibersarerenewable,carbonneutral, biodegradable and also produce waste that is either organic or can be used to generate electricity or make ecological housing material. Natural fibers provide a multitude of human and environmental health as well as economic benefits. Eachfiberhasitsownpurposeinmanufacturing,andprovidesbetterqualityandmoresustainabletextilesthansynthetic materials [1].

Naturalfibersinclothingallowfabrictobreathe,reducingtheriskofskinrashesandallergicreactions,andalsoinsulate theweareragainsthotandcoldtemperatures.Thesefiberscanalsoreplacesyntheticsinindustrialmaterials,forexample, inhomeinsulationpanels.Insulationmadefromwoolorhempratherthanfiberglassdrawmoistureawayfromwallsand timber,andaresaferbecausewoolisnaturallyfireresistant.Syntheticmaterials,whileinexpensivetoproduce,cancause moreharmtotheenvironmentandeconomythanthey dogood [1]. Inordertoimprovefoodsecurity,thelivelihoodsof impoverishedpeople,andthehealthoftheglobalcommunity,theshiftbacktonaturalfibersmustbe made.Theonsetof syntheticmaterialshasnotonlybeendestructivetowardstheenvironment,ithasalsohadanegativeeconomicimpacton thosewhoselivelihoodsdependontheproductionandprocessingofnaturalfibers.Inanefforttoraiseglobalawareness oftheimportanceofnaturalfibersnotonlytoproducersandindustry,butalsotoconsumersandtheenvironment.There are different natural fibers are available such as cotton, flax, hemp, wool, silk, ramie, sisal, jute etc. These natural fibers having some disadvantages like cotton fibers are not wrinkle resistant, it has poor elasticity, and long time to dry, color

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

fadesinsunlightveryeasily.Flaxfibersarealsowrinklesveryeasily,expensive, shrinks,burnseasily,affectedbymildew andperspiration,ravelsnature,difficulttoremovecreases,shinesifiron [1,2]. Hempfibersareusedtoproduceorganic clothing;theyarenotusuallytreatedwiththesameanti wrinklechemicalsascottonorsyntheticclothing.Thisgiveshemp clothing a tendency to bunch up and crease in certain areas it is worn. A fine wool sweater may cost two to three times more than one constructed of synthetic fibers. Some varieties of wool can be very itchy to sensitive skin. Lower quality woolensarecomposedofshorter,coarserfiberswith manymore endstostick outandcauseirritation.Silk isoneofthe most expensive fabrics on the market. Compared to cotton or nylon, silk is pricey. Silk is considered a luxury product; expect to pay more for it. Silk cannot be bleached or soaked in prewash products. All silk items must be air dried and steamironedona lowsetting. Wringingor twistingsilk garmentscanruinand permanentlydamagetheclothing.Ramie fibers elastic properties are low, lack of resiliency, hardy than other fibers, low abrasion resistance, wrinkles easily, stiff andbrittle [2]. Jutefibersarelowercreaseresistance, baddrapeproperty,createshadeeffectsandbecomes yellowish if sunlightisused,itlosesstrengthwhenitiswetted.

To overcome all the difficulties one of the new natural fibers i.e., pine needle fibers. Leaves of pine, is a very new raw materialitdoesnotaffecttheenvironmentbecauseitisbiodegradableinnature,noextracostofrawmaterial,becauseit isobtainedfromwastematerialsi.e.,drypineleaves,nothavinganyskinirritations,notcolorfadeinsunlighteasily,low density,lowweight.So,thisprojectwastakeni.e.,“Developmentofyarnfrompineneedlefibers”.

1)Developmentofyarnfrompineneedlefiber.

2)ToassessthepropertiesofPineneedleyarnobtainedfrompineneedlefiber.

Usesofdifferentnaturalfibershavegainedimportanceintherecentyearsduetoeco friendlynature.Moreover,by2020 the world total fiber demand will be 102.4 million metric tons. Use of the wastage of food crops as alternative source of rawmaterialsforclothingisagoodsolutiontomeetupthisdemand.Environmentalawareness,newrules,andlegislation are forcing to seek new materials that are eco friendly and do not have any harmful effect on environment. For the past severalyears,publicattentionhasgoneonnaturalfibersasaresourceduetothefastgrowth.Now a days,naturalfibers arewidelyusedasreinforcementsbothinpartiallyandtotallybiodegradablenaturalfiberComposites.Naturalfiberslike, cotton, coir, sisal jute etc. have attracted the attention of scientists and technologists [1,2]. The promotion of the use of natural fibers as CO2 neutral resource is believed to contribute to a greener planet. The transition towards a bio based economy and sustainable developments as a consequence of the Kyoto protocols on greenhouse gas reduction and CO2 neutral production offers high perspectives for natural fiber markets. Plant fibers from agricultural crops are renewable materials which have potential for creating green products and replacing synthetic materials which are currently being used such as glass fiber, carbon fiber and plastic fibers. Among others, natural fibers (e.g., flax, jute or sisal) reinforced materials have important significance for reduction of density in automobile construction components due to its higher specificstiffnessandspecifictensilestrength [3]. Manyattemptsweremadebythescientistsandtechnologists toutilize naturalfibersinthefabricationofcomposites.

The low cost, less weight and density make the natural fibers an attractive alternative. In recent years, due to increased awareness,extensivestudieshavebeendoneonvariousnewnaturalfiberssuchaspineapple,banana,oilpalm,arecanut orbetelnuthuskfiber,grassfiber,bamboofiber,coirfiber,woodfibersetc.aremorewidelyusedintheworld.

1)Piña is a fiber made from the leaves of apineappleplant and is commonly used in thePhilippines.It is sometimes combined withsilkorpolyesterto create atextilefabric. Piña name comes from the Spanish word Piña which literally means pineapple. Its fabric is hand loomed by only a few weavers, it is very precious and scarce, which also makes it expensive.Pineappleleaffiberismulticellularwithanaverageultimatecelllengthof5mm.Thefiberislignocelluloses in nature. Pine fiber consist of alpha cellulose 78.11%, hollow cellulose 87.56%, hemicelluloses 9.45%, lignin 4.78%. Its length is 3 9mm, breadth 4 8mm, gravimetric fineness 1.54 tex, tenacity 50 g/tex, extension at break 2 6%, flexural rigidity(dynecm 2)3.8,density(gm/c)1.48 [3].

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

2)Banana fiber is a natural bast fiber. It has its own physical and chemical characteristics and many other properties that make it a fine quality fiber. Appearance of banana fiber is similar to that ofbamboo fiberand ramie fiber, but its finenessandspinabilityisbetterthanthetwo.Thechemical compositionofbanana fiberiscellulose,hemicellulose,and lignin. It is highly strong fiber, smaller elongation, and shiny appearance depending upon the extraction & spinning process. Light weight, strong moisture absorption quality. It absorbs as well as releases moisture very fast. It is bio degradable and has no negative effect on environment and thus can be categorized as eco friendly fiber. Its average finenessis2400Nm. [4].

3)Oil palm fiber isproducedfromemptyfruitbunchthatareconsideredaswasteaftertheextractionoilpalmfruits.The similar quality of oil palm fiber with normal wood had made it very versatile in its use. Inherent characteristics such as highmoisturecontentwillhaveadetrimentaleffectontheoilpalmresidues.ISclean,biodegradableandcompatiblethan manyotherfibersfromotherwoodspecies.Suitableforthemanufactureofmattress,carseat,insulation,compositepanel productandparticleboard [5].

4)The husk of the Areca isahardfibrousportioncoveringtheendosperm.Itconstitutes30 45%ofthetotalvolumeof thefruit.Arecahuskfibersarepredominantlycomposedofhemicellulosesandnotof cellulose.Arecafiberscontain13to 24.6% of lignin, 35 to 64.8% of hemicelluloses, 4.4% of ash content and remaining 8 to 25% of water content.The fibers adjoining the inner layer are irregularly lignified group of cells called hard fibers and the portions of the middle layer containsoftfibers.Arecafiberishighlyhemicellulosicandismuchgreaterthanthatofanyotherfiber [6].

5) Bamboo fiber isa regeneratedcellulosic fiber producedfrom bamboo. Starchypulpisproduced from bamboostems and leaves through a process of alkaline hydrolysis and multi phase bleaching. Further chemical processes produce bamboo fiber.Repeated technological analysis has proved that this kind of fiber has a thinness degree and whiteness degree close to normal finely bleached viscose and has a strong durability, stability and tenacity.Bamboo fiber fabric is madeof100%bamboopulpfiber.Itischaracterizedbyitsgoodhygroscopicity,excellentpermeability,softfeel,easiness tostraightenanddyeandsplendidcoloreffectofpigmentation. Bambooissofterthancotton,withatexturesimilartoa blend of cashmere and silk. It has incomparably wide foreground on application in sanitary material such as sanitary towel,gauzemask,absorbentpads,andfoodpacking [7].

6)Coconut fiber isextractedfromtheoutershellofacoconut.Itisthenaturalfiberofthecoconuthuskwhereitisathick andcoarsebutdurablefiber.Thecommonname,scientific nameandplantfamily ofcoconut fiberis Coir,Cocos nucifera andArecaceae(Palm), respectively.Therearetwo types ofcoconut fibers, brown fiber extracted from matured coconuts and white fibers extracted from immature coconuts. Brown fibers are thick, strong and have high abrasion resistance. White fibers are smoother and finer, but also weaker [8]. Both brown and white coir consist of fibers ranging in length from 4 12 in (10 30 cm). Those that are at least 8 in (20 cm) long are called bristle fiber. Shorter fibers, which are also finer in texture, are called mattress fiber. Coir fiber consist of lignin 45.84%, cellulose 43.44%, hemi cellulose 00.25%, Pectin’sandrelatedCompound03.00%,Watersoluble05.25%,Ash02.22%.Coirfiberlengthis6 8inches,Density(g/cc) 1.40 Tenacity (g/Tex) 10.0, Breaking elongation 30%, Diameter in mm 0.1 to 1.5, Rigidity of Modulus 1.8924 dyne/cm2, swellinginwater(diameter)5%,Moistureat65%RH10.50%.[9].

7)Wood fibers areusuallycellulosicelementsthatareextractedfromtreesandusedtomakematerialsincludingpaper. Theendpaperproduct(paper,paperboard,tissue,cardboard,etc.)dictatesthespecies,orspeciesblendthatisbestsuited to provide the desirable sheet characteristics, and also dictates the required fiber processing (chemical treatment, heat treatment, mechanical "brushing" or refining, etc.).In North America, virgin (non recycled) wood fiber is primarily extractedfromhardwood(deciduous)treesandsoftwood(coniferous)trees.Thewoodfibercanbeextractedasaprimary product,orcollectedduringthemillingoflumber.Woodfiberscanalsoberecycledfromusedpapermaterials [10].

Pineneedlefiberisalsoincludingamongthosenewnaturalfibers. Sooneofthefiberwastakeni.e.``Pine needle fiber` `Leavesofpine,isalsoaverynewrawmaterialanditispossibletodevelopedofyarnfrompineneedlefiber.

7)Pine Trees are generally found in hilly areas like Himachal Pradesh (2) etc. Fibers are extracted from the dry pine leaves.Theyareprocessedmechanicallyandchemicallytoobtainpineneedlefiber.Pineneedlefiberisacellulosicfiber. It consistsof43%lignin,52%hollowcellulose,and5.8%extractivescontent.Pineneedleshavemanyuses,whethertheyare cutfromthetree,freshlyfallen,ordried [11]. Dimensionofpineneedlefiberis200 microns. Pineneedlesfiberisbrittle innature.Thereisalittlescatterintheaxialmodulus&theultimatetensilestrength.Itsaveragelengthisabout20 29.5 mm & width is 16.81 micro meter and its denier is 2.6. Pine needle can be used as a composite for low and medium strength application. Pine needle is 68.5% holocellulose, 4.56% extractives and 31.0% lignin, Pine needles (pine leaves)

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

wereanalyzedfortheirchemicalconstituents,andthedimensionsoftheextractedfibersweredeterminedtoassesstheir utilizationforpulpmakingaccordingtotheirstudiesCellulosecontentofpineneedles(41%)wascomparabletosoftwood (42%), whereas the lignin content (35.1%) was high as compared to both softwood (28%) and hardwood (20%). Ash content of pine needles (3.2%) was less than wheat straw (4 9%) and comparable to biogases (1.5 5 %). The average lengthofthepineneedlefiber(13mm)wasgreaterthanfibersofsugarcane(1.7mm),wheatstraw(1.4mm)andesparto (1.2mm),butlessthancotton(30mm).

The average diameter of pine needle fiber (32 mm) was greater than all the common fibers used for papermaking. The composition of pine needle as per study carried out by Ghosh and Ghosh has reported 64.12 % holocellulose, 3.24% extractivesand27.79%lignin.

Pineneedlesaretheadultleaves,whicharegreenbundledinclustersof1 6,commonly2 5,needlestogether.Pineneedles havemanyuses,whethertheyarecutfromthetree,freshlyfallen,ordried.Pineneedlesarecommonlyusedingardening and landscaping, can be made into decorative yet practical crafts and even have nutritional. The fine, inner fibers in the pineneedles,withoutthedryexteriorleaves,areofinterestforthetextileindustry.Theindustrialprocessbywhichthese canbeaccessedandharvested,andthenveryfineyarnsmadefromthem [11, 12].Theyarnscanbecoloredwithnatural dyes. Moreover, different types of pine produce different natural shades of dye, which can be used to print on textiles. Turning this raw material into a useful for the textile industry harbors huge potential. Pine is the second most common type of tree in Germany, after the spruce, so there is no shortage of pine needles. Tapping into this organic, biologically degradable resource is, moreover, a simple matter,involving cooperation with branches of industry that use the wood fromthepines,butnottheirneedles ThepinetreeisthemostcommontreeinEuropeandAsia.About20to30percentof itsmassconsistsofpineneedles,whichamountstoabout70to100kilograms(154to220pounds) [12, 13]. Bytreating the needles, they can be turned into paper, textile, and composite material, making them a good (local) alternative for otherfiberslikecottonandcoiretc.

This research paper is because raw material for making pine yarn is easily available in nature, it is eco friendly, non hazardous,costeffectiveaswellaslowenergyconsumption.

Materials ¦

Pine trees are found in hilly areas. From which dry pine leaves as a waste are collected. These dry pine leaves were processedthroughchemicalandmechanicalaction.

Specifications of pine fiber

1) Length=25mm 2)Fiberstrength=1.26g/d 3)Extension%=6.06% 4)Denier=1.2

Specifications of S 6 cotton fiber

1) Length=30mm 2)Fiberstrength=2.55g/d 3)Extension%=7.84%4)Denier=1.64

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Extraction process (Raw material to fiber)

Pineneedlefiberwasextractedbyfollowingmethods

1)Bymechanicalprocess

2)Bychemicalprocess

1)Thepineneedlefibersconsistofsilicaandresin,whicharetheprincipalobstructionsintheconvertingoftheseneedles intofiberfitforuseinspinning.

2)Thereisanouterlayerofparticularlythick glazingofsiliceous material whichitisnecessarytoremovebytheuseof alkalis.

3) The first step was breaking the needles. This was done, preferably, between tightly pressed rollers, either smooth or corrugated, and was for the purpose of loosening the silica which surrounds the fibers in order to more thoroughly impregnatetheneedleswiththealkaliatthepropertimeandtoallowalkalitoreachunderthissiliceouslayerandattack thesilicaatallsurfacesatonce.

4)Andthenpinedryleaveswereboiledinalkalinebath,andthentowashedoutthesolutionanddisintegratedthefiber mechanically.Bymeansofmechanicalactionpineleaveswerebrokenupandshortened [13].

1)Aftermechanicalactionchemicalactiontookplacebyplacedthe pineneedleinasuitablevatortank,maybemadeof castiron. Thistank waseachprovided witha coilofperforatedsteampipe. Thetank wasfirstprovided with a chargeof theneedles.Asolutionofcausticsodainwaterwasthenallowedtoflowintothetankthrough waterinletvalve.

2)Thestrengthofthesolutionwaspreferablyabout3to4%ofsodatotheweightofthechargeoftheneedle.

3)Nowvatwasboiledat212 degreeFahrenheitfortentofifteenminutes,oruntiltheebullitionofthewatercausesahead offoamtoriseupabovethelevelofthegrating.

4)Thisstepconstitutedtheactivetreatmentnecessarytoremovetheoutersiliceouscoatingoftheneedles.Andthefoam wastheresultoftheglutinousmassofsolubleglassformedbytheunionofthesodawiththesilicaformingsilicateofsoda.

5) Then vat or tank was filled with clean water. And the steam turned gradually heat it to a temperature was about 150 degreesto180 degreeFahrenheitthenwashedout [13].

Aftermechanicalandchemicalprocess,thepineneedlefiberswereextractedandsenttothespinningdepartment. Firstly,variousblendratiowasdecidedaccordingtothespinningprocedurewhichwereasfollows

Pine(30%)+Cotton(70%)

Pine(50%)+Cotton(50%)

First of all, fiber was opened by means of metallic comb. Thenthefiberwasblendedwithcottonataratioof70:30of which70%wascottonand30%waspineneedlefiber.AndanotherblendRatiowas50:50ofwhich50%wasthecotton fiberwhereother50%wasthepineneedlefiber.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

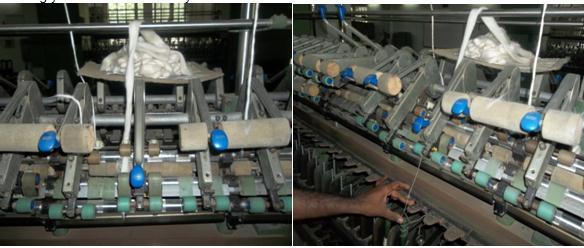

Thecardwebwasplacedintoprototypedrawframeformakingsliver.Afterobtainedthesliveritwaspliedinto four plies. The plied sliver was again fed into same draw frame for doubling then sliver was delivered on to the drawframecane.

specifications 1)Suitablefiberlength=21 64mm 2) Totaldrawratio=2 10times 3)Rollerpressuremode=spring weighted 4)Workingwidth(mm)=240 5)Draftingsystem=3over3,twozone 6)Deliverylaphank=0.0100to0.0140 7)Draft/delivery/doubling=upto13/single/6 10fold 8)Deliveryrate(m/min)(max)=150 [15].

After doubling some amount of sliver was directly input into ring spinning machine due to unavailability of minisimplex.Theringyarnwasobtaineddirectlyfromthesliver.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

1)Spindlegauge(mm)=70 2)Lift/Brokenendcollection=152/bypneumaticsuction 3)Draftingsystem=superhighdraft,springloaded 4)Ringdiameter(mm)=30/42

5)Spindlespeed/draft/TPI=10,000 15000rpm/Upto300/18 50[16]

Thetestingofsampleswascarriedoutatdifferentstages

Testingatprocessstage

Yarntesting

Whiletheprocessofyarnformationiscarriedout,whenasmallamountofthematerialispreparedtestingiscarriedout todeterminewhetherthepreparedmaterialisaccordinglytotherequiredqualityornot.Thisiscarriedoutateachstage. Thesearefewimportantparameterstobetestedaftereachstage

Countofsliver Countofyarnbeforepreparationofcompletepackage

Twistintheyarnbeforepreparationofcompletepackage

Thewrapblockisusedtomeasurethecountofsliver.Thecircumferenceofwrapdrumisoneyardandformeasurement ofcountofsliver6 yardlengthismeasuredandthenweighedonweighingbalance.

Thehankofslivercanbethen,calculatedas Hank=3.24/Sliverweight

A wrap reel or skein winder is a device for measuring yarn and making it into hanks of a standard size. The reel is of a standardsizeanditsrevolutionsarecountedastheyarniswrappedaroundit.Typically,asetnumberofrevolutionswill beusedsothatthehankisofastandardsize.,askeinorlea.Forexample,askeinofcottonwouldbe80turnsonareelof 54 inches circumference, making 120 yards, while the standard length for wool worsted would be 80 yards.Count of yarn=64.8/yarnweight

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Yarn testing-

Different yarn samples which are developed are taken for quality assessment. Following quality parameters are to be testedforthedevelopedsamples

Evenness

Imperfections Thinplaces,thickplaces,Neps

Singleyarnstrength

Theinstrumentsusedforthetestingoffollowingqualityparametersare

Twisttester

Ustertester5(forevennessandyarnimperfections)

CSPtester

Singleyarnstrengthtester

Determining of TPI of pine cotton blend yarn and 100% cotton yarn

Gaugelength=10 inch,Nosofreadings=5

Fig 7 single yarn twist tester

Sample TPI Pinecottonblendyarn 10.12 100%cottonyarn 11.02

USTER TENSORAPID 4 Duringroutinetesting,boththebreakingloadandextensionofyarnatbreakareusually recordedforassessinginyarnquality.Mostoftheinstrumentsrecordtheload elongationdiagramalso.Various parameterssuchasinitialmodulus,theyieldpoint,thetenacityorelongationatanystressandstrain,breakingload, breakingextensionetc.,canbeobtainedfromtheload extensiondiagram.

Specifications of TENSORAPID4 TEST

1. AmeasurementmustbeperformedaccordingtheCREprinciple

2. Testingspeedmustbeexactly5m/min.

3. Thegaugelengthortheclamp to clampdistanceshouldbe50mm.

4. Thepretensionshouldbe0.5cn/Tex.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

• Capacitivemeasurementofmassvariationsandimperfectionsinyarn,rovingandsliver ofstaplefibers.

• Measurementofforeignmatters.

• Collection,evaluationandstorageofmeasurementvalues.

• Automaticcheckofallmeasuredvalues,diagramsandspectrograms.

• YarnclassificationbasedontheUSTER®STATISTICS.

• Editorforcustomizingreportlayouts.

• Filterfunctionsforquickdataretrievalandforthepreparationoflong termreports.

• Simulationofyarnboards,wovenandknittedfabrics.

• QualiProfile,graphicpresentationoftheoverallquality.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Table 2

Warp Count Weft count and blend

2/20Ne 8ne (p+c) blend

Thread density/ GSM

EPI=44 PPI=32/224. 2 gm

Reed count Ends per dent

No. of beat ups

Warp tension No. of heald frames Draft/drawing order/weave/weft colorscheme

44 2 1 1st beam=1.8 2nd beam=8

PROCESSING (grey fabric to dyed fabric)

Desizing process (Desized sample)

SampleAfabricweight/NaoHweight=16.861gm/5.372gm, Fabricweight/NaoHweight=25.50gm/5.185gm

4

1234/1234/plain weave/single (Greycotton)

Gripper speed/reed speed

7/7

1)Desizingagent=5gpl 2)Water=1litre

3)Temperature=70degreecentigrade.

Scouring process (Scoured sample)

1)Na2co3=5gpl 2)Water=1litre

3)NaoH=2.5gpl 4)Time=1hr Bleaching process (Bleached sample)

1)H2O2=5ml 2)NaoH=3gpl 3)Time=1hr 4)Water=1litre

RESULT AND DISCUSSIONS

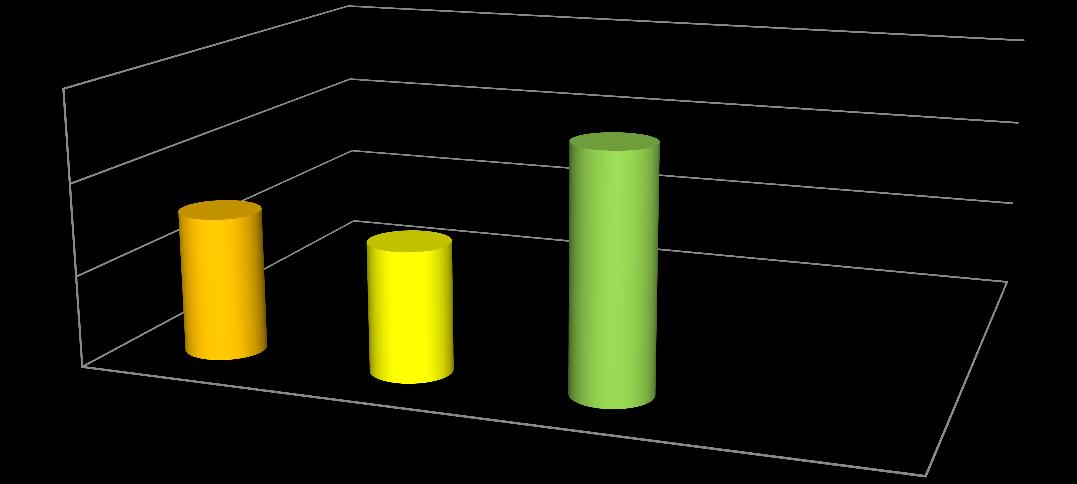

Result-- Comparison of CSP value between pine cotton blends and 100% cotton yarn Table 3 Specification of lea strength of Pine cotton blend & 100% cotton yarn

Sample Lea length Lea Weight Lea strength Count (Ne) CSP of the given sample

SAMPLEA (Pinecottonblend Yarn)

SAMPLEB (Pinecottonblend Yarn)

120yds 9.98gm 120 lb 6.492Ne 779.04

120yds 8.075gm 88 lb 8.024Ne 706.11

SAMPLEC (100%Cottonyarn) 120yds 6.95gm 164.5lb 8.00Ne 1316

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

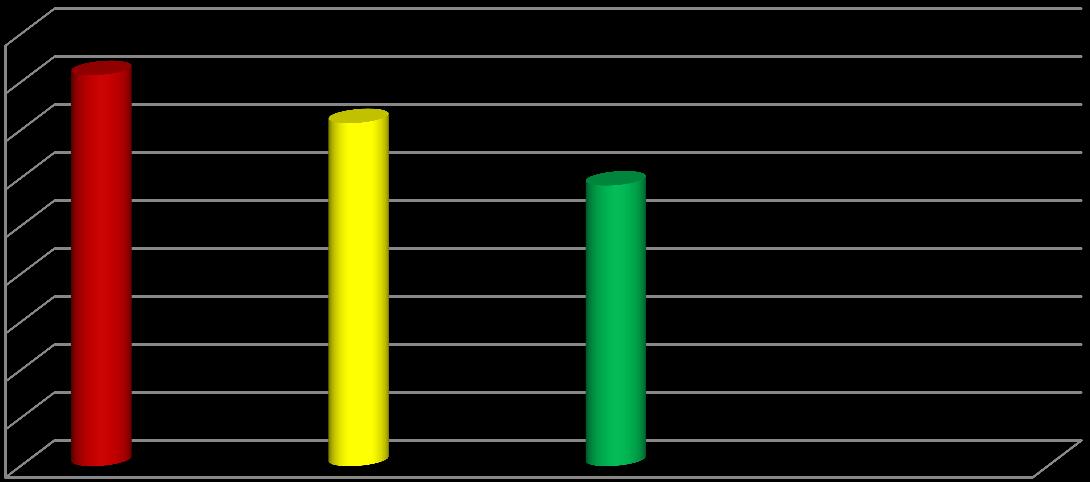

Fig no 12 InsampleAandSampleBCSPvaluewasfound779.04withleastrength120lbfor6Ne(pine+cotton)and706.11withlea strength88lbfor8Ne. SampleCi.e100%CottonyarnCSPvaluewas1316andstrength164.5lbfor 8NeWhichstronger thanpinecottonblendyarn.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

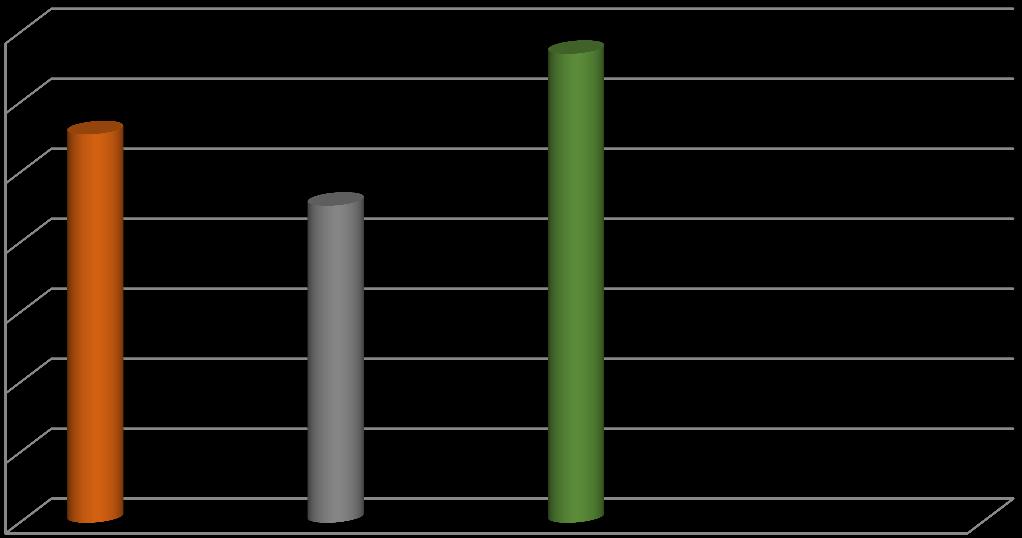

Elongation comparison

Fig no -13 Elongationinbothyarnisgood.Elongation%ofSampleAi.epinecottonblendyarnwas5.55%for8NeandSampleBie., pinecottonblendyarnelongation%was4.53%for6Ne. AndSampleCi.e.100%cottonyarnelongationwasfound6.70% for8Ne. Results comparison IPI value of 100% cotton and pine cotton blend yarn Specification of yarn IPI V=100m/min,T=1min Table 5-Single values and mass diagram, Material- Pine cotton blend yarn and 100%cotton Sample Count

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Fig no 14

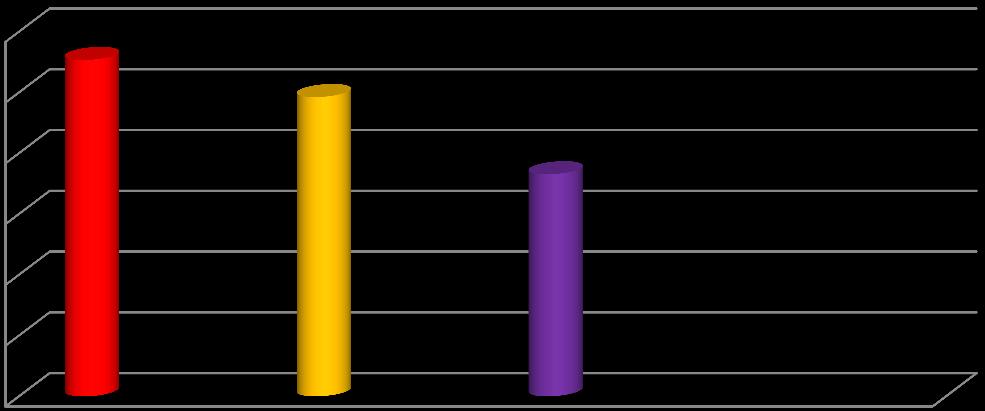

RKM value of Sample A was found (P+C blend) 6 g/d for 8 Ne and Sample B (P+C blend yarn) was 4.3 g/d for 6Ne. And SampleC(100%cottonyarn)RKMvaluewas8.75for8Ne.Pinecottonblendyarntenacitycouldbeincreasedbychanging the TPI or other parameters like fiber fineness, fiber strength, twist level, evenness level and fiber length variation and distribution.Byblendinguniformitywithhighqualitycottonfiber&useofsyntheticfiberinblendingdesiredstrengthof yarncouldbeobtained. Unevenness (u%) comparison

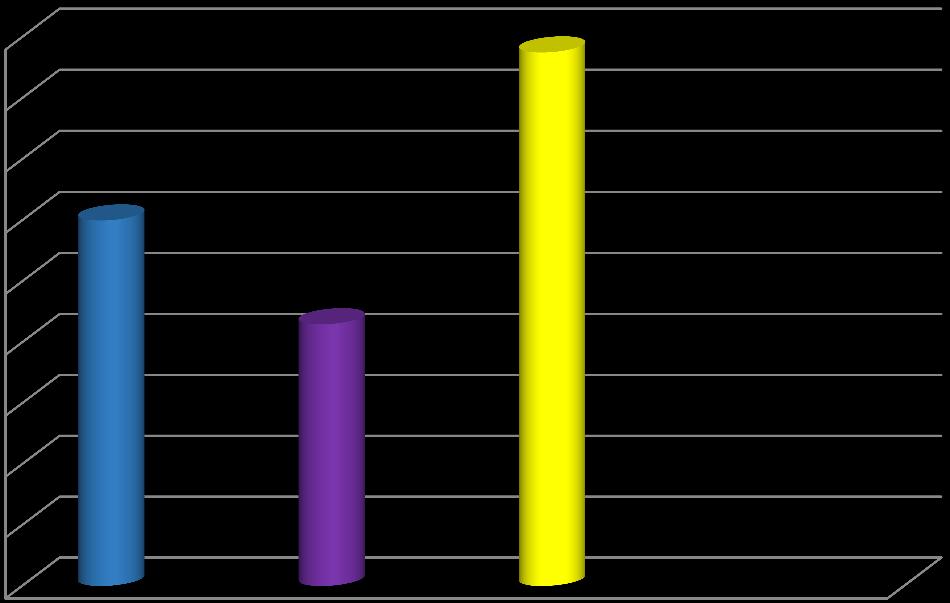

Fig no-15

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

U% of Sample A (p+c blend yarn) was found 16.3% for 8Ne and 14.3% for 6Ne. Sample C (100% cotton blend yarn) hairiness value was 11.7% for 8Ne. U% of pine cotton blend yarn is higher as compare to 100% cotton yarn. It was happenedbecausedrawinganddoublingwascarriedoutinsamemachineanddoublingwasdonebyusingonlyfourply of drawn sliver. Pine cotton blend yarn having lower strength because of higher unevenness percentage as compare to 100%cottonyarn.

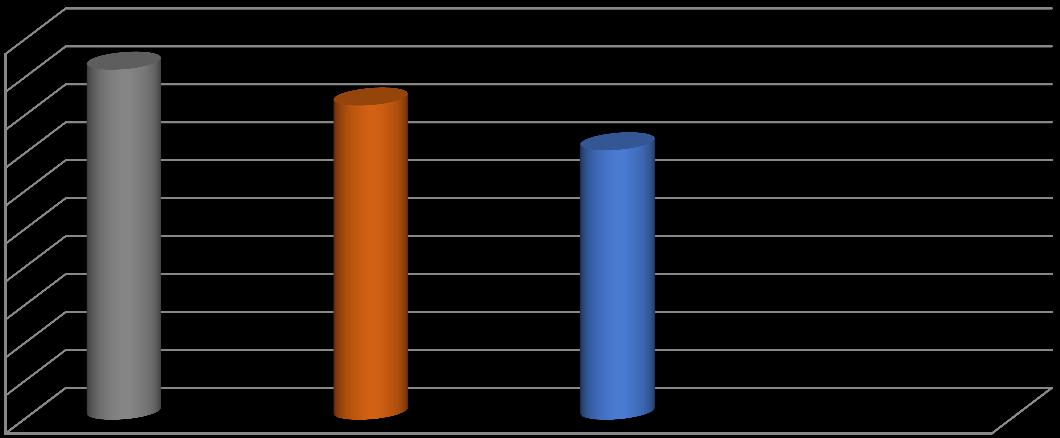

IPI (Imperfection index) comparison

Fig no 17

Irregularity or cvm % of Sample A(p+c) was found 18.45% for 8Ne and Sample B was16.56% for 6Ne. Sample C (100% cotton yarn) cvm% for 8Ne was 14.2 which is lower than pine cotton blend yarn. Because of lower uniformity level and havingbadsurfacepropertiespinecottonblendyarnhavinghigherimperfectionvaluethancotton.

The properties of pine cotton blend yarn and 100% cotton yarn were studied in terms of cvm %, total imperfection index, tenacity, CSP, and elongation %. The overall results showed that the 100% cotton blend

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

having good denier value, yarn extensibility, Tenacity, CVM%, U%, which having higher than that of pine cotton blendyarn.

Unevenness(U) %ofpinecotton blendwasfoundhigherascompareto100%cottonyarn.Ithappenedbecause drawinganddoublingwascarriedoutinsamemachineanddoublingwasdonebyusingonlyfour pliesofdrawn sliver.

Pine cotton blend yarn having lower strength because of higher unevenness percentage as compare to 100% cotton yarn. Pine cotton blend yarn tenacity could be increased by changing the TPI or other parameters like fiberfineness,fiberstrength,twistlevel,evennesslevelandfiberlengthvariationanddistribution.

Byblendinguniformitywithhighqualitycottonfiber&useofsyntheticfiberinblendingdesiredstrengthofyarn couldbeobtained.

Pine cotton blend yarn could be possible to use in heavy fabric, decorative purpose, non woven and composites also.Bysurfacemodificationthefibercanbeusedalonewithoutblendingandcouldbepossibletomakeapparel also.Thefabricthatwasproducedgavekhadieffect.

1) “Environmental Benefits of Natural Fiber Production and Use”Jan E.G. van Dam Wageningen University, The Netherlands

2) ``Structure and properties of some vegetable fibers`` 2 pineapple fibers (A nannus comosus), Mukherjee PS and satyanarayanaKGJ.materSci.,25,51,1986

3) ``Structure&propertiesofsomevegetablesfibers``.SatyanarayanaKG.,RaviKumarK.KsukumaranK.,Mukherjee PS.,pillaiSGK.&kulkarni.AK. J.materSci,21,57,1986

4) ``Resources structure, properties & uses of natural fiber of Madhya Pradesh``, Chand N, Sood S, Rohatgi PK and satyanarayanaKG,J.ofscientific&industrialResearch,43,487 499,1984.

5) ``An Empirical evaluation of structure property relationships in natural fibers and their fracture behavior``, MukherjeePSandsatyanarayanaKGJ.MasterSci.,21,4162,1986.

6) ``Structure property studies of fibers from various parts of the Coconut tree``, Satyanarayana KG, pillai CKS, SukumaranK,pillaiSGS,RohatgiPKandVijayanK, J.mater.Sci.17,2453,1982.

7) ``Structure & properties of some vegetable fibers part 1`` , Mukherji PS and satyanarayana KG,`` J.Mat.Sci.,London,19,3825 3934.,1984

8) ``Bioinoculant treatment of unretted coir fiber for quality improvement coir`` Ravindranath, A.D.and U.S. Sarma.a (1995).Bioinoculantsforcoirretting,CORD11,34 38.,b.(1993)37. 9) https://www.coirkerala.com

10) Mechanical performance of wood fiber waste plastic composite materials, Resources, Conservation & Recycling``, KrishnanJayaraman,DebesBhattacharya(2004),41307 319

11) Eco friendly utilization of hazardous Pine needle waste for the pollution of paper, conference proceedings of AmericanInstituteofChemicalEngineers’’,ARay,A.andDas,M,2010,chE,USA

12) InvestingofpineneedlesforPulp/PaperIndustry``,Asadullah,Jan2006,PakJ.ofSci.Ind. Res.,49(6)407 409

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

13)W.LATIMER,processofmakingfiberfromPineneedles,no.397,240.Patented Feb.5,1889.

14)https://embossing.machine.en.made in china.com

15)www.cicr.org.in/pdf/circot 18

16)https://dir.indiamart.com