International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Rachit Kunder1, Bharat Sonagara2

1,2 VIVA Institute of Technology Mechanical Department, Mumbai, India ***

Theobjectiveofthestudyistofabricatesafestvehiclefora driver.Therollcagehasbeenfabricatedinaccordancewith SAEBAJArulebook.3DAssemblyofwholevehicle&Line model of the roll cage is modeled in SOLIDWORKS 2018. Different processes are used to manufacture different componentswithaviewtocutbackcostandachieveproper tolerancesatsametime.

AnOff roadcarorAll Terrainvehicle(ATV)isessentially aLandbasedvehiclecapableofreachingremoteareaswhere normalcars/bikescannotreach.ATVhasasignificantlygood range of applications nowadays like in Military, Forest departments,Farming,etc.Theprojectistomanufacturean ATVwithdifferentmachiningprocess,andmakingtheentire assemblyofanAll terrainvehicle.

Thematerial usedforthevehicleroll cageisAISI4130 (chrome molysteel)i.e.chromiummolybdenumalloysteel, on the basis of comparative study on parameters like materialavailability,Cost,WeightandPhysicalparameters. Aftercomparingthesefollowingparameterswithothersteel grades like AISI 1018 and AISI 1020, AISI 4130 is comparatively best among them with the structure, maintainingtheIntegrityoftheSpecifications

Inaviewofgainingsignificantresultsinweightreduction, some changes were incorporated in pipe sizing. For the currentcarthediameterofthepipewasselectedconsidering theequivalencycalculationsasperrules.

TABLEI

Pipe Sizing (OD mm x thickness mm)

Primary 29.2 x 1.65

Secondary 25.4 x 1

ThemanufacturingofRollcageincludesthreeprocesses thatispipebending,pipenotchingandwelding.

Pipeisbentforeasymanufacturingofrollcageandavoid unnecessaryweldingofpipewhereverstrongstructureisn’t necessary.

To avoid unnecessary movement of pipe structure and accurateassemblingofeachmemberflexandmetalfixtures wereused.

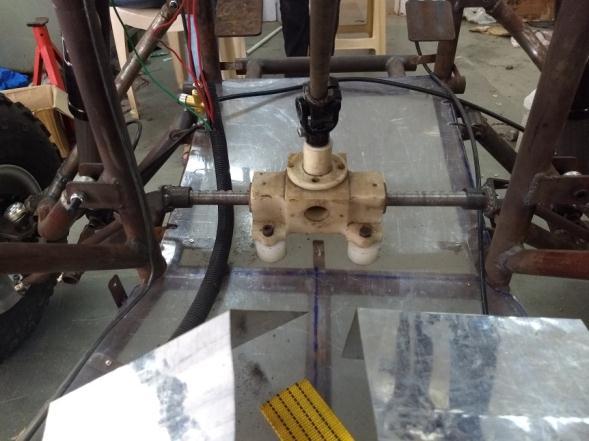

PipeNotchingisprovidedforcorrectseatingofrollcage pipesenablingaccurateassemblyandweldingofrollcage.

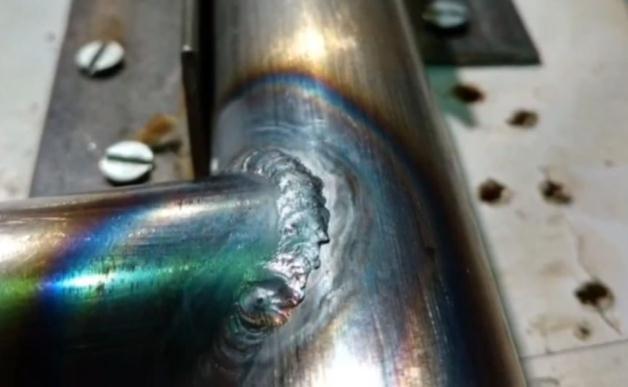

Argon welding is employed for joining of roll cage membersorpipessinceitprovidesstrengthtonodesofpipes andavoidanyfailure

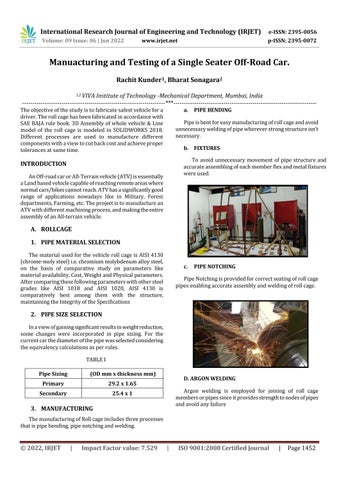

GearboxwasmanufacturedfromAluminumalloy6061 T6 block using VMC,other processes involvedare turning, gearcuttinganddrillingforGears.

Endmillingandfacemillingprocesshavebeenusedfor cuttingprocessofgearboxcasing.Around4hourswastaken tocompletetheseprocessesandasingleblockwasusedfor both sides of casing to reduce the machining as well as materialcost.

Theprimeobjectiveofthepowertrainsystemistoattaina goodvelocitywithhighefficiencypowertransmission.The powertrainsystemmustbeabletodelivermaximumtorque fromtheenginetothewheel.Hence,continuouslyvariable transmission(CVT)ischosentoattainmaximumtorque.

InadditiontoCVTitcontainstwostagereductiongearbox which is created from the Aluminum for a light weight housingofgears.

Thegearboxcasingisrequiredforoptimumoperationof the gear drives. It provides ample lubrication, protection from environmental element and proper gear orientation. ThematerialusedforgearboxcasingisAluminum6061 T6 considering its light weight, machinability and heat dissipationproperty.ItismachinedonCNCmillingmachine forproperfittingandcompactness.

Thedriveshaftiscustomizedtosuittherequirementof thevehicle.BoththeendofthehalfshaftcontainsCVjoint. One end is connected with spool and another end is connectedtowheel.Thedriveshaftdiameterisselectedafter calculationandconsideringthemaximumoperatingtorqueat spoolend.

ConventionalTurningonlathemachineofgearsandshaft wasperformedtogetrequireddiameterandfacingoperation forlengthofshaft/thicknessofgears.

Afterturninggearcuttingandsplinecuttingisdonetoget requiredgearprofile.

Drillingisdoneforremovalofunnecessaryweightform gears

Tappingisdoneforfasteningofgearboxcasingandalso forthemountingofrearbrakecaliper.

Gearshavebeencasehardenedtointherangeof30 45 HRCupto2mmthickness.

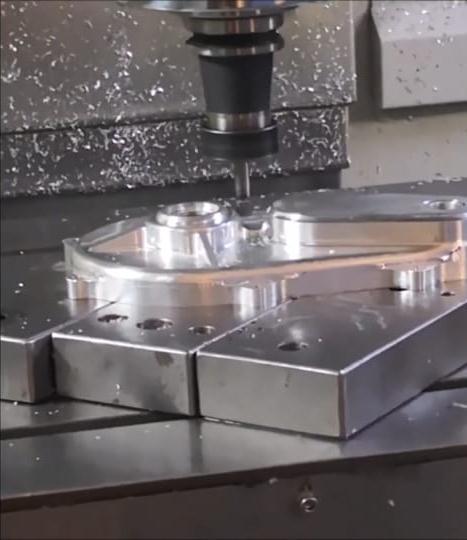

Thedesignaimofthesteeringteamwastoensuresmooth maneuveringofvehicleduringCorners.Inordertoachieve theratioofvehiclewheelbasetotrackwidthiskeptcloseto 1:1. Steering system hard points were first determined by consideringtheclearanceandergonomics.

EN 24steelwasselectedasmaterialforrackandpinion of the steering. For housing of rack and pinion, nylon 6 materialforcasingisused,asitislightinweightandeasily machinable.SteeringarmismadeofP 40steelforstrength anddurabilityofwheelassembly

Different processes were used for complete manufacturingofsteeringsystem.

a.

Togetrequireddimensionsofrack,pinion,tierodsand columnlathewasusedfortheprocessesofturningfacingetc.

b. TAPPING

Tappingwasdoneonbothsidesofrackforassemblyof Heimandballjoints.

c. GEAR CUTING

Gear cutting and spline cutting is done to get required gear.

d. CASE HARDENING

Gearshavebeencasehardenedtointherangeof30 45 HRCupto2mmthickness.

e. VMC MACHINING

Endmillingandfacemillingprocesshavebeenusedfor cuttingprocessofSteeringcasing.Around1hourwastaken tocompletetheseprocessesandasingleblockwasusedto reducethemachiningaswellasmaterialcost.

f. LASER CUTTING

Lasercuttingprocesswasusedforcuttingof4mmsteel sheetformountingbrackets.

Diameter of the pipe was considered according to the equivalencydesigncalculations.

TABLEII

Themanufacturingofsuspensionarmsincludesmajorly two processes that is pipe notching and welding after preparing appropriate fixtures for proper seating of pipe members.

To avoid unnecessary movement of pipe structure and accurateassemblingofeverymemberflexandmetalfixtures wereused.

PipeNotchingisdoneforproperseatingofsuspension armsforproperassemblyandweldingofpipes.

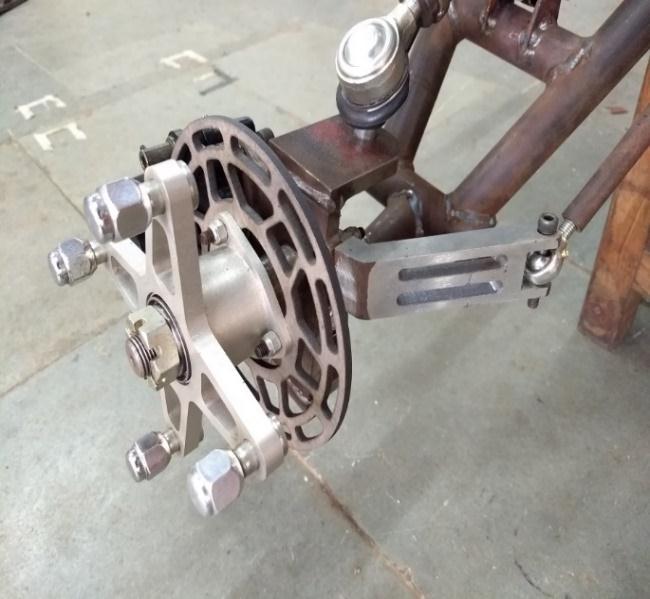

CustomdesignuprightsandhubswereusedforStrength anddurabilityofwheelassembly.P 40steelisselectedfor highimpactloadsandhighdurability.

Argonweldingisusedforjoiningofsuspensionarmsor pipessinceitprovidesstrengthtonodesofpipesandavoid anyfailure.

Different processes were used for complete manufacturingofWheelassemblycomponents.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Togetrequireddimensionsofhubandwheelaxlelathe wasusedfortheprocessesofturningfacingetc

Endmillingandfacemillingprocesshavebeenusedfor cuttingprocessofhubandknuckle.Around6hoursoverall wastakentocompletetheseprocesses.Aroundbarwasused forhubsandplatewasusedtoreducethemachiningaswell asmaterialcost.

Theobjectivebehindthebrakingsystemistolockallthe fourwheelsdynamicallysoastotoensurethesafetyofthe driverandmaneuverabilityofthevehicle.

Brake rotors are custom manufactured to achieve the required output and to achieve design requirement for reductionofweight.

Inordertoreducetheweight,slotteddesignofrotorwas selected.Accordingtothosecalculationseffectiveradiusof rotorwasdecided.

Theparametersconsideredwhileselectingmaterialfor brakerotoraremachinability,frictionalproperty,hardness and resistance against rusting and wear etc. accordingly, SS304 is selected complying with market availability and cost.

Overhangingassemblywasselectedconsideringdriver comfortandpositionofsteeringsystem.

Lasercuttingwasusedforcuttingofbrakediscandbrake pedal.

Stepbystepassemblingofsub assemblywascarriedout

AssemblingofB&Sengine,GearboxandCVT

Assemblingofbodypanelsandcovers.

AssemblingofwishbonesandFoxShocks.

Assemblingofuprights,brakerotorsandhubs

Assemblingofpedalassembly.

Assemblingofsteeringsystem.

Assemblingofseatanddriversafetyperipherals.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

VarioustracktestsincludeManeuverability,Suspension and Traction, Acceleration, Hill climb, Sled pull and Endurancetestsareperformedonvariousterrains.

a. Maneuverabilitytestisdonetocheckcar’sturning abilityatsharpcorners.

b. Suspension and traction tests are done to check abilityofcartowithstandworstofterrain.

c. Acceleration tests are done to check speed and accelerationofcar.

d. Sled pull is done to check power and torque of gearboxandtransmissionsystem.

e. Hill climb is done to test car’s ability to overcome steepslopes.

f. Endurancetestisdoneforrunningcaratleast500km to check whether the car can withstand rough terrainsinfullspeedwithoutanybreakdown.

Vinylwasprintedandpastedonbodypanelstoaddtoits aestheticview.

PaintingofCarwasdoneusingsimplespraypaintcans withDFT(Dryfilmthickness)rangefrom15 20microns.

FRP (ie. Fibre reinforced plastic) seat, Driver safety restraints, Engine Kill Switches, Fire extinguishers are alsoinstalledinthecar.

Fully functional All terrain vehicle has been manufactured, assembled and tested successfully. The basic test results prove that car is safe for driver with respecttomaterialsused.Thetracktestsprovethatcar hasspeedof52kmph,canmaneuverthroughcornersas tightas0turningradius,climbshillwithgradeabilityof 68%, stops within 4m patch when brakes applied at a speedof52kmphandcaneasilyendurefor4hoursof roughterrainatmaxspeed.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Thechosendesignwasthesafestandthemostreliable car for any long terrain. All the parameters like safety, cost, performance, aesthetics, reliability, durability, standard dimensions and material were also taken in considerationonthesametime.Thevehiclewassafeinall aspectsandconformswithsafetyrulesspecifiedinBAJA SAEINDIA2020Rulebook.

Major players in field of all terrain vehicle are Polaris, Yamaha,Hondaandmostofareusedforonlyrecreation purposesinIndia.Theall terrainvehiclescanhavewide applicationinthefieldofagriculture,constructionaland industrial applications where such type of car can be utilized up to its full potential. With minimum modificationforeachtypeofitsapplicationandwithuse oftechnologyandautomationall terrainvehiclescanbe replacedwithtractorsandmanufacturedatcheaperrates thantractors.

[1] HeelPatel,DhruvWadhwa,HarshPatel,ParthTrivedi, Jay Mandalia, “Design & Manufacturing of Reduction Box”, 2018 IJSRSET, Volume 4, Issue 4, Print ISSN: 23951990,Pageno.979 983.

[2] RishiGovindT.S,NoyalThomson,Miswaramjind,Rinto Thomas,Sreyas.k,Vysakh.V“DesignandFabricationof anAll TerrainVehicle“InternationalResearchJournalof Engineering and Technology (IRJET), e ISSN: 2395 0056, Volume: 05 Issue: 04, Apr2018 p ISSN: 2395 0072,Pageno.1215 1227.

Sujaysinh S. Patil, Poonam D. Shinde, Suraj S. Ahire, Varsha N. Nalawade, “Design, Analysis and ManufacturingofIntegratedHubandRotorforanAll Terrain Vehicle”, The International Journal of EngineeringandScience(IJES),Volume 7,Issue 5,Ver.I, Pages PP10 16,2018,ISSN(e):2319 1813ISSNpage no.23 19

[3] Sisodya S.D., Manave V.S., Giri P.M., Mali N.M,” Design and Manufacturing of Steering System in an Off Road Vehicle”,Volume7,IssueNo.6,2017,Pageno.12559 12562.

SanjayKumarMishra,ShabanaNazSiddique,“Studyof performance of milling machine for optimum surface roughness” Research Journal of Engineering Sciences Vol.6(9),October(2017),ISSN 2278 9472,pageno. 32 35.

[4] Subramanyam B, P. Bridjesh and Madhu S, “MANUFACTURING OF STEERING COMPONENTS OF

RACE CAR”, International Journal of Mechanical EngineeringandTechnology(IJMET)Volume8,Issue6, June 2017, ISSN Print: 0976 6340 and ISSN Online: 0976,pageno,207 211.

[5] Amogh Raut, Aniket Patil, “Design Analysis of Chassis usedinStudents’FormulaRacingCarusingFEATool”, International Journal of Engineering and Advanced Technology(IJEAT)ISSN:2249 8958,Volume 7,Issue 1,October2017,pageno.116 120.

[6] Kunal Vispute, Krushanu Nakade, Abhiraj Uttarwar, Rahul Deshmukh, Surendrasingh Sonaye, “Design, AnalysisandManufacturingofFrontWheelAssemblyof FormulaStudentRaceCar”,3InternationalConference on Ideas, Impact and Innovation in Mechanical Engineering(ICIIIME2017),ISSN:2321 8169,Volume: 5,Issue:6 pageno.271 275.

[7] Adarsh Adeppa,” Introduction to Metal Cutting”, InternationalJournalonEmergingTechnologies(Special IssueonICRIET 2016)7(2):Pageno.:173 176.

[8] Basavaraj Sajjan, Adithya Parthasarathy, Sai Kiran P, VarunKumarKN,“ProductDesignandDevelopmentof Wheel Hub for an All Terrain Vehicle (ATV)”, International Journal of Engineering Research & Technology (IJERT), ISSN: 22780181, Vol. 5, Issue 08, August 2016,Pageno.504 509.

[9] Saurabh Borse, Pranav Chille, Shubham Dhabade, Swapnil Deshmukh, Atul Kulkarni, “Design and Manufacturing of an effective system of ATV and performanceenhancementusingyoke nutassembly”, International journal of Research in Advent Technology(E ISSN:2321 9637)SpecialIssueNational Conference“NCMMM2016”,19March2016.

[10] Richard Kennedy, Pierre Levy, “Reinventing the (steering) wheel”,Reinventingthe (steering) wheel:a kanseidesignapproachfornoveldrivingexperience.In 6th International Kansei Engineering and Emotion ResearchConference,KEER2016,UniversityofLeeds, August31 September2,2016Leeds:JapanSocietyof KanseiEngineering.

[11] Vivek Bavisi, Deepak Nair, Hitesh Verma, “Roll Cage AnalysisandFabrication(AllTerrainVehicle)”,IJSRD International Journal for Scientific Research & Development| Vol. 3, Issue 02, 2015, ISSN (online): 2321 0613,pageno.1014 1015.

[12] K. Krishnakanth, E.R. Sivakumar, “Design and FabricationofCompositeGear”,InternationalJournalof Innovative Research in Science, Engineering and Technology(AnISO3297:2007CertifiedOrganization)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1458

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Vol.4,SpecialIssue13,December2015,Pageno.364 372.

[13] IfeanyichukwuU.Onyenanu,O.N.K.Swift,P.N.Atanmo, “DesignandAnalysisofaTubularSpaceFrameChassis forFSAEApplication”,JETIR(ISSN 2349 5162)October 2015,Volume2,Issue10,pageno.134 140.

[14] Allan Burgess, Eric Crevoiserat, Matthew Cote, Jorge Martinez, “Design and Optimization of a Baja SAE Vehicle” Worcester Polytechnic Institute, BAJA SAE 2014 2015 pageno.1 97.

[15] Shailesh S. Pachbhai, Laukik P. Raut,” A Review on DesignofFixtures”,InternationalJournalofEngineering ResearchandGeneral ScienceVolume2, Issue2,Feb Mar2014,ISSN2091 2730,Pageno.126 146.

[16] V. Senthil Kumar, “Laser cutting process A Review”, INTERNATIONAL JOURNAL OF DARSHAN INSTITUTE ON ENGINEERING RESEARCH & EMERGING TECHNOLOGIESVol.3,No.1,2014,Pageno.44 48.

[17] GregoryHyatta,MarkusPiber,NitinChaphalkara,Orrin Kleinhenza, Masahiko Moria, “A Review of New StrategiesforGearProduction”,6thCIRPInternational Conference on High Performance Cutting, HPC2014, ProcediaCIRP14(2014),pageno. 72 76.

[18] Kailashnath Manoharan, Habeeb Salman Karthik M., “Design and Development of tubular Space Frame for BAJA”Pageno.1 75.

[19] Venkatesh, Kamala, A.M.K. Prasad,” Design, Modelling andManufacturingofHelicalGear“,INTERNATIONAL JOURNALOFAPPLIEDENGINEERINGRESEARCH,DIND IGULVolume1,No1,2010.Pageno.103 114.

[20] Madhu Kumar V, Arun Kumar N, Harsha B S, Naveen KumarKN,“DesignandFabricationofPneumaticSheet Metal Cutting and Bending Machine”, International Journal of Engineering Research and Advanced Technology(IJERAT),SpecialVolume.02,Issue.01,May 2010,Pageno.564 572.

[21] O.Maluf,M.Angeloni,M.T.Milana,D.Spinelli,W.W.Bose Filho, “DEVELOPMENT OF MATERIALS FOR AUTOMOTIVE DISC BRAKES”, Automobilistic, AeronauticsandMaterialsEngineeringDepartment,São CarlosEngineeringSchool,UniversityofSãoPaulo,São Carlos,SP,Brazil

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |