International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Mayur S. Deore1 , K. K. Tolani2

1PG Student, Civil Department, L.G.N.S.C.O.E. Nashik 2Assistant Professor, Civil Department, L.G.N.S.C.O.E. Nashik ***

Abstract – The Solid waste management is big problem with quantities of waste material that is being generated in cities and in industrial areas. The major contributors are of industrial solid waste disposal are Thermal Power plant, Iron and steel mills which produces blast furnace slag etc. And Disposal of this by products produced from this industries is major problem Also landfill operating cost is high and availability of land for landfill is also problem. Recently research showed that, it is possible to utilize industrial by products as sand replacement of normal concrete.

Key Words: PondAsh,SEManalysis,compressivestrength, C S Hgel,Microstructural

Disposingtheindustrialby productsismajorproblemofbig industriesasduetolargequantitygenerationofwasteby productgeneratedrequiresincreasedcostsformaintaining the landfills and also there is problem scarcity of landfill grounds.Duetothepotentialhazardouseffectsofindustrial by products, it’s consumption for the various purposes is becoming trend instead of dumping it, in view of grown environmental awareness relating. Some of these waste materialscouldpossiblybeusedinconstructionalmaterials for the production of concrete. So in this research I have triedoneoftheby productPondashwhichislocatednear EklahareThermalpowerplant.AndPondashisavailablein tons outside the power plant. So I have used pond ash as partial sand replacement on concrete. And find out how strengthisaffected.

TheObjectiveofpaperis,

a. To study the feasibility of Industrial By Product PondashasSandReplacementinconcrete

b. To check Compression strength and durability of concrete with Industrial By Product Pond ash as sandreplacement

c. To find out Microstructural Analysis of Concrete specimenwhicharecasted.Andtocheckstrengthof specimenishowincreasedanddecreased

Thisresearchfollowsastep by stepmethodologywhich startedwithfindingtheprojecttopicidentifyingthefactors affectingtoachieveobjective,aspertheguidelinesprovided and standard IS code specification the casting of cubes by applyingvarioustechnicsisdone.Thecastedcubesfurther mergeforcuringandthentestingshouldbedone.Also,SEM analysisisdoneonspecimens.

a. Cement: ACCOrdinaryPortlandCement53Grade wasusedasperBIS:269 19789R1998

b. CoarseandFineAggregate: Coarseaggregate10,20 mm were collected from Vilholi Nashik region, Maharashtra. And Fine aggregate natural sand of riverbed from Tapi river, Nandurbar, Maharashtra IndiaAccordingtogradingzone1andasperBIS:383 1970R 1997.

c. Industrial By Product (Pond Ash): Industrial By productPondAshisobtainedfromEklahareThermal powerplant.Nashik,Maharashtra,India.

Fig 1:IndustrialBy ProductPondAsh

d. Plasticizer: EmceplastBVPlasticizerswereusedas directed by the manufacture to improve the workability of the fresh concrete mix according to BIS:2645 2003.

e. Water: Potable (drinking) Water was used for castingandcuringprocessofconcretespecimens.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

The specific gravity of coarse aggregate (20mm &10mm),sandandpondashisdeterminedbyusing Pycnometerandarefoundtobe2.81,2.68,2.59& 1.68 respectively. It is observed that the specific gravityofpondashislessascomparedtosand

C.A.(20mm) C.A.(10mm) sand PondAsh 2.81 2.68 2.59 1.684

Todeterminethefinenessmodulusofsand,pondashand coarseaggregatesof10mm&20mmdetailedsieveanalysisis performed. The fineness modulus of coarse aggregate (10mmand20mm),sandandpondashare7.0,7.29,3.5and 2.04respectively.

Table

C.A. (20mm) C.A. (10mm) Sand PondAsh 7.0 7.29 3.5 2.04

The water absorption of coarse aggregate (10mm &20mm),sand&pondasharedeterminedbyconventional method.

Particulates (gm) Aggregate (10 mm) Aggregate (20 mm) Sand Pond Ash

Wet wt. of aggregate(W1) 167 155 144 92

Dry wt. of aggregate(W2) 171 157 160 116 Water absorption= [(W1 W2) /W2]x100

1.02% 1.01% 1.11% 26.08%

Water absorption of pond ash found more so we used plasticizertoincreaseworkability.

For laboratory testing program, the M 40 Grade mix design was selected and Concrete mixture with different proportionsofIndustrialBy ProductPondAshwasselected forw/cratio0.40.Forthiswork36Cubesspecimenswere castedandtestedfor7,28days.

Cube: Cubeofsize150mm×150mm×150mmwereused. Thecubeswerecleanedthoroughlywithawasteclothand thenoilwasproperlyappliedalongitsfaces.Concretewas thenfilledinmouldinthreelayers,whilefillingthemould concreteiscompactedusingtampingroadof600mmhaving acrosssectionalareaof25mm2thenthemouldiskepton the vibrating table for 60 seconds to achieve proper compactionandthenthemouldarekeptonplaneandlevel surface in the laboratory for 24 hours and then cubes are removedfromthemouldandkeptforcuring.Forthisreport 36cubespecimenarecastedandtested.

Fig 3:CubecastingtestingandFailurepatternofcube

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table

Type Description

M0 ControlledConcrete

M1 10%sandreplacedwithbyproductpondash

M2 20%sandreplacedwithbyproductpondash

M3 30%sandreplacedwithbyproductpondash

M4 40%sandreplacedwithbyproductpondash

M5 50%sandreplacedwithbyproductpondash

Table

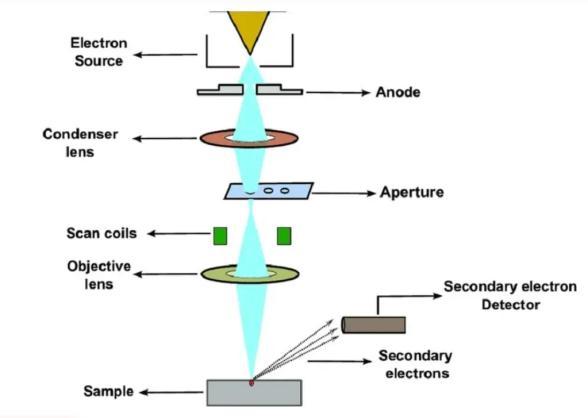

Mix 7 Days in N/mm2 28 Days in N/mm2

M0 32.40 47.50

M1 32.60 48.24

M2 33.20 49.10

M3 24.68 43.84 M4 22.71 43.16

M5 21.58 41.84

Itwasobservedthatfor10%and20%sandreplacement thecompressivestrengthwasincreasedandfor30%,40%, 50% sand replacement is was decreased, when compared withcontrolconcrete.

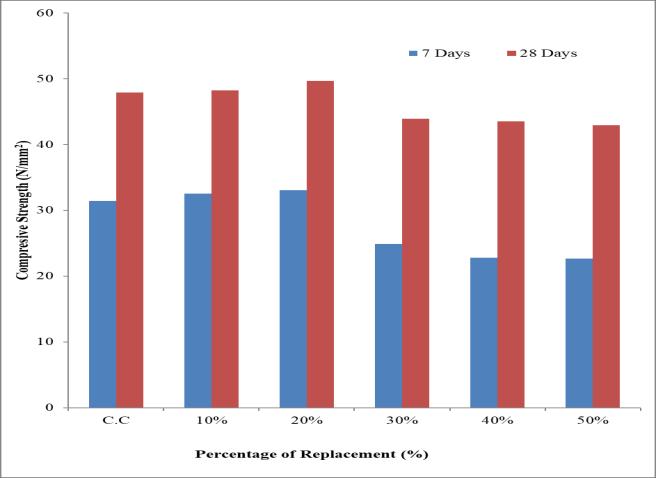

electronmicroscope(SEM)scansafocusedelectronbeam overasurfacetocreateanimage.Theelectronsinthebeam interactwiththesample,producingvarioussignalsthatcan beusedtoobtaininformationaboutthesurfacetopography andcomposition [7]

TheSEMuseselectronsinsteadoflighttoforman image.

A beam of electrons is produced at the top of the microscopebyheatingofametallicfilament.

Theelectronbeamfollowsavertical paththrough the column of the microscope. It makes its way through electromagnetic lenses which focus and directthebeamdowntowardsthesample.

Onceithitsthesample,otherelectronsareexpelled fromthesample.

Detectors collect the secondary or backscattered electronsandconvertthemtoasignalthatissentto a viewingscreensimilartotheoneinanordinary television,producinganimage.[7]

Chart 1:CompressiveStrengthVsVariationinpondash

A scanning electron microscopeis that kind of electron microscopewhichpreparesimagesofasamplebyscanning thetopsurfacewithafocusedbeamofelectrons.Ascanning

Factor

(Source: www.informationpalace.com)

Fig -4:SchematicRepresentationofSEM[7]

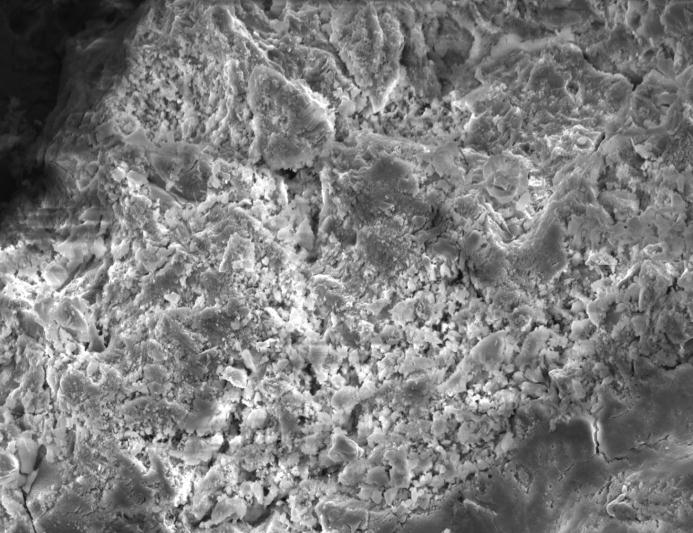

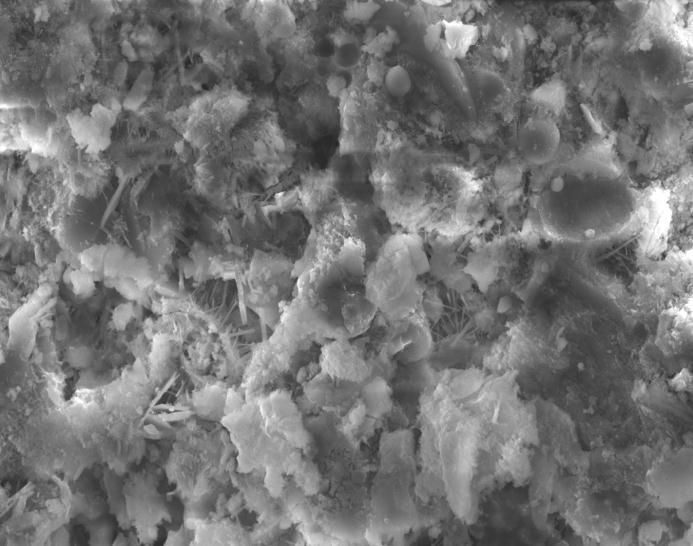

Theformationanddistributionofhydrationproductsof hydratedcementpasteofSixdifferentmixproportionsare picturedbelow.Themicrostructureofthesevenmixeswere examined and compared with the nominal mix. The microstructure and strength properties of all the seven mixes were correlated based on the hydration products formedafter28days.Thereasonbehindthestrengthofthe concretewasanalysedandexplainedbasedonthegrowthof hydrationproductsinthemicrostructureofconcretemixes.

Fig 5:SamplepreparationforSEM

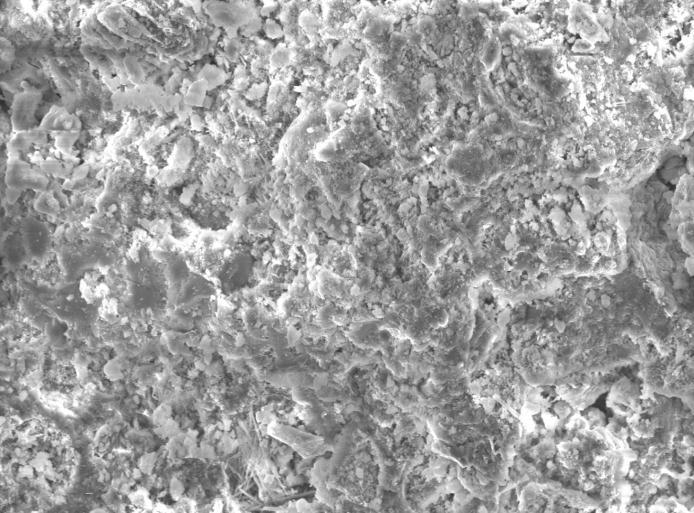

Mix -0 Normal Concrete

FromMicrographFigure,itshowstheformationofproper andclearC S Hgelinvariousstages.Theimportantpointto be noted in the micrograph is that the C S H gel i.e., the bright masses with nodules and big chalky gel parts are spread over the entire micro graph, as it is evident from various literatures, the C S H gel gets spread over the aggregatesthusactingasbindersforthepaste.

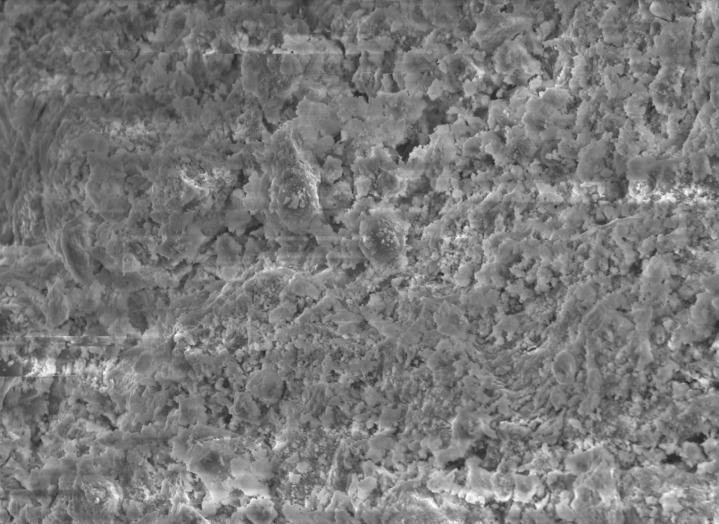

Mix 1 10 % sand replaced with by product

From Micrograph Figure, it shows two major features. Firstly, the number of voids in the mix has significantly reducedandsecondly,theC S Hgelpasteiswidelyspread as it was in the reference mix, secondly showing some aversiontothebinderpastebutmoreimportantly,theeffect ofbyproductaddsstrengthtoconcretemix.

Mix 2 20 % sand replaced with by product

From Micrograph Figure, it shows again two major features. Firstly, the number of voids in the mix has significantlyreducedthanabovefigureandsecondly,theC S Hgelformationisbetter,andwhichaddsstrength.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

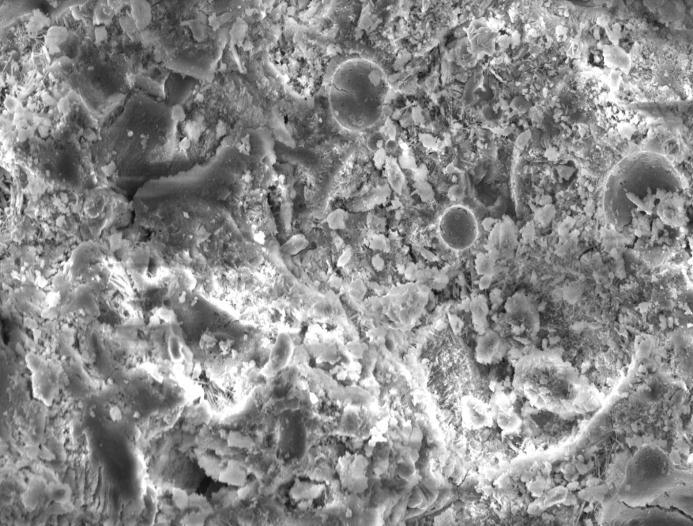

Mix 3 30 % sand replaced with by product

Mix 5 50 % sand replaced with by product

From Micrograph Figure, it shows again two major features. Firstly, the number of voids in the mix has significantlyreducedthanabovefigureandsecondly,theC S Hgelformationisbetter,andwhichaddsstrength.Some voidsaredeveloped.

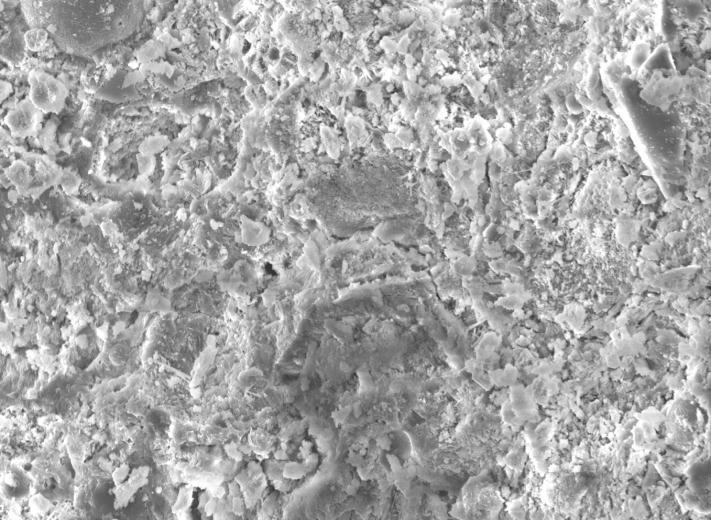

Mix -4 40 % sand replaced with by product

From Micrograph Figure, shows that voids in mix are clearlyvisibleinthemicrograph.TheC S Hgelcouldnotbe seenatmanyplacesinthemicrograph.Themostimportant inferencefromtheimageisthatthepasteiscrumbling,as theamountofreplacementgoessohighinthissamplethat theequilibriumfallsandleadstolowerstrength.

Itwasobservedthatfor10%and20%sandreplacement the compressive strength was increased when compared withcontrolconcrete.Also,themicrostructuralobservation shows how strength is increased and decreased. From overall study, we can use this industrial by product in concreteaspartialreplacementtosand.

[1] A. Sofi ,B.R. Phanikumar(2015),“An experimental investigationonflexuralbehaviouroffibre reinforcedpond ash modified concrete”,Ain Shams Engineering Journal, Vol.6,pp.1133 1142.

From Micrograph Figure , shows that voids in mix are morethanabovefigure.alsosecondlyC S Hgelformationis lowcomparatively.alsothemixhascrumbledandstrength goesdown.

[2] M. P. Kadam& Y. D. Patil (2015), “Effect of sieved coal pondashasasandreplacementonthepropertiesofcement concrete”,MagazineofConcreteResearch,Vol.67,pp.227 234.

[3] R. Siddique, Y. Aggarwal, P. Aggarwal, E. Kadri, and R. Bennacer, “Strength , durability , and micro structural propertiesofconcretemadewith,”Constr.Build.Mater.25, vol.25,pp.1916 1925,2011.

[4]V.Vasugi, K.Ramamurthy(2014),“Identificationofdesign parametersinfluencingmanufactureandpropertiesofcold bondedpondashaggregate”MaterialsandDesignVol.54pp. 264 278

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[5] Y. Aggarwal and R. Siddique, “Microstructure and propertiesofconcreteusingbottomashandwastefoundry sand as partial replacement of fine aggregates,” Constr. Build.Mater.,vol.54,no.(2014),pp.210 223,Mar.2014.

[6]RafatSiddique,MalkitSingh(2014)“Strengthproperties andmicro structuralpropertiesofconcretecontainingcoal bottom ash as partial replacement of fine aggregate”, ConstructionandBuildingMaterialsVol.50 pp.246 256

[7] Sushant Waghmare, " Microstructural Analysis of M30 GradeConcreteUsingScanning ElectronMicroscopy(SEM)MethodInternationalJournalof Engineering Research and Applications, Vol. 10, Issue 5, (Series I)May2020,pp.65 71.

[8]A.S.AdithyaSaran,P.Magudeswaran,"SEMAnalysison Sustainable High Performance Concrete", International JournalofInnovativeResearchinScience,Engineeringand TechnologyVol.6,Issue6,June2017.

[9] Rafat Siddique,”Utilization of industrial by products in concrete”,2ndInternationalConferenceonSustainable Civil Engineering Structures and Construction Materials 2014 (SCESCM2014)ProcediaEngineering95(2014)335 347

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal