International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

2

1Student, Mechanical Engineering Department, Walchand College of Engineering, Sangli, Maharashtra, India

2Asst. Prof. Mechanical Engineering Department, Walchand College of Engineering, Sangli, Maharashtra, India ***

Abstract Thecastingindustryemploysavarietyofwaysto address casting fault issues. A large number of casting rejections results in a waste of both money and effort. Single flaws incasting might havea singleorseveralcauses, thus it's critical to figure out what's causing the problem. This industry's productivity has risen to an all time high. Modern technology has reduced resource use while simultaneously reducing faults. Adopting a more controlled approach to describing, recognizing, and regulating the underlying cause of an issue will be advantageous. The primary goal of this research is to identify solidification defect and minimize it by optimizing new design with help of casting simulation software. This research will aid in improving strength of material and hence quality.

Key Words: Sand casting, Solidification defect, ProCAST, L type Sealing casting, shrinkage porosity, Misrun

Castingisoneofthemaineconomicalproductionprocesses used in industry and is a complex process that involves importantmetallurgicalandmechanicalaspects.Therateof solidificationlargelydeterminesthemicrostructure,which inturndeterminesmechanicalpropertiessuchasstrength, hardness,machinability,etc.Thelocation,size,andshapeof risers in a casting depend on the shape, mold design, and heatofthecasting,propertiesofthemetalandotherfactors, process parameters. Improperly designed riser and gate systemswillalwaysresultindefectivemoldswithshrinkage cavities or poor experimental results, which are always better for mold design and development and to achieve optimalprocessparameters.

However, this can be expensive, time consuming, and in some cases impossible. Therefore, the casting simulation process is a convenient way to properly design a riser system and analyze the effect of various parameters. The number of foundry simulation programs in India is also increasingdaybyday,asitessentiallyreplacesorminimizes shopfloortestingtoachievethedesiredinternalqualityin themaximumpossibletime.Itcangreatlyreduceiterations ontheshopfloorand ismainlyusedforproof of concept. Simulation programs generally increase the confidence of

foundrieswhencreatingmorecomplexcastings(complex, large)withhighermargins.Italsoprovidesascientificand documentedbasisforqualityassuranceandcertification.

Ravi(2008)havestudiedatthebenefitsofcastingsimulation, bottlenecks and best practices for overcoming bottlenecks without burial testing, they provide quality assurance and significantly minimize lead times to cast the first good sample.

Naveen(2014)hasdiscussedthestepswhichisincludedin simulationthepossiblesourceoferrorandcaretobehasto be taken during the time of casting simulation process. According to him the designer should have confidence in casting simulation tool which are going to be used. The confidencelevelwillcomeonlybyexperienceandusageof thetooltomimiceffectofvariousprocessparameters.

Prabhakara etal.(2006)havestudiedonthesolidification mold filling simulation of green sand casting, ductile iron castingsand,andusingcastingsimulationsoftwaresuchas PROCAST,itwasconcludedthatdefectssuchasshrinkage, porosity,etc.couldbeeliminated.Itcanalsoimproveyieldof thecasting,optimizethegatingsystemdesign&moldfilling.

Karl B. Rundman explained metal casting procedure, sand castingprocedureandothercastingprocedure.Hediscusses the defects in casting. He also studies the solidification phenomenaincastingprocedure.

C. W. Ammen [1979] He discussed the different elements required in sand castings. He also discussed the defects in sandcasting.

Inordertoremaincompetitiveintoday’smarket,amodern foundryhastotakefulladvantageofthebenefitsofferedby castingsimulation.Theseallowthefoundrymantoanalyses problemsindetail,faster,andatanearlystageinthedesign cycle,thusenablingdecisionstobemadetowardsimproving design and quality. Therefore, the costs and the risk associated with the trial and error procedure of

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1247

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

experimental castings are minimized. In the present dissertation we use the casting simulation software to identifythesolidifyingdefectspresentinthesealingcasting andanattemptwasmadetooptimizethesealingcasting.

Themainobjectiveofpresentinvestigationisoptimization ofsealingcastingbycastingsimulationprocess.

1.Tostudythecastingprocedure,application,problemsand defectsinsealingcasting.

2.TodosolidificationAnalysisoftheexistingsealingcasting.

3.Togivesolutionforthedefectslikeshrinkage,Misrunand improve strength of sealing casting by using casting simulationprocess.

4.Tocarryouttheresultsofanalysis.

Inthischapter,theapproachemployedinthepresentwork isbrieflydiscussed.Inthisresearch,asealingcastingmodel constructedofgreycastironisexamined.Forsandcasting, differentcircumstancesaresimulatednumericallyusingthe commercial software pro CAST. Various solidification performancemetrics,includingtemperature,hotspot,total shrinkageporosity,voidscontour,andsolidificationcontour, etc. The existing technology utilized for simulation of solidificationisinvestigatedasthefoundationofthiswork. Attheconclusionofthechapter,thefindingsobtainedusing theexistinggatingsystemforthemouldsarediscussed.

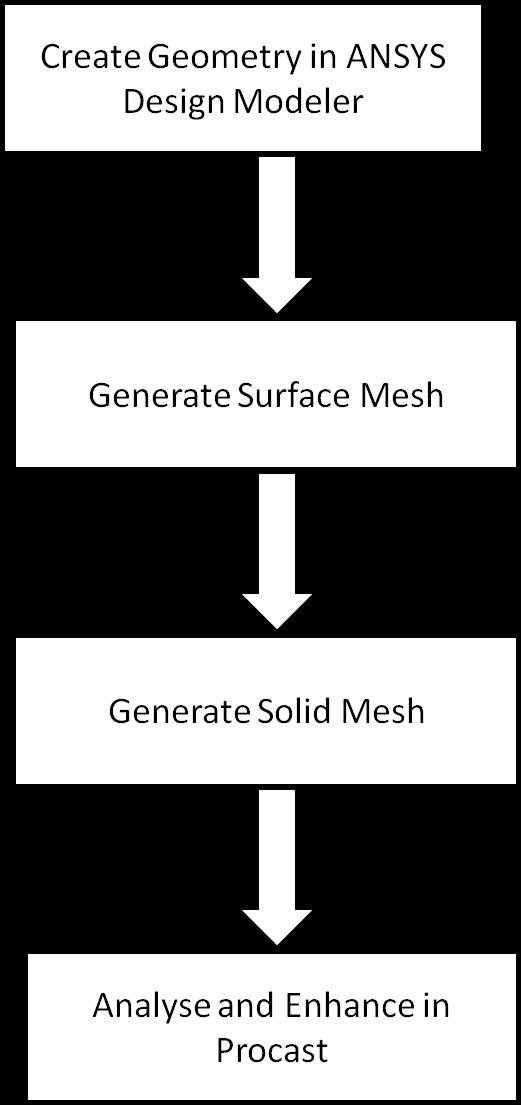

Typically, simulation software consists of three primary components:(1)Pre processing(theprogrammereadsthe CADgeometryandgeneratesthemesh),(2)Mainprocessing (additionofboundaryconditionsandmaterialdata,filling, and temperature calculations), and (3) Post processing (presentation and evaluation). Based on Finite Element technology, ProCAST offers a comprehensive simulation solution for a wide variety of applications. proCAST's objectiveistoconstructafiniteelementmodel,configurethe calculation,executetheanalysis,andevaluatethefindings. The following actions (procedures) were carried out in ProCAST'ssimulationofthesealcastingprocess.

Computer aided design (3D) of a seal casting featuringagatingsystemutilizingtheANSYSDesign Modelerprogramme.

Meshthemouldandcastusinga2Dand3Dsurface meshandvolumemesh.

Inputdataincludingvolumemanager,interfaceHTC manager, process condition manager, and simulation parameters, and initiate simulation by selectingProCASTwithasolvercountoffour.

Analyzetheresultswiththeviewcast,suchastemperature, solidificationtime,andfractionofsolidandtotalshrinkage porosity.ThestepsrelatedtosimulationareshowninFigure 1. Fig

SavetheCADfileinIGESformatandimportitinto the proCAST software using the geometry transformationtool.

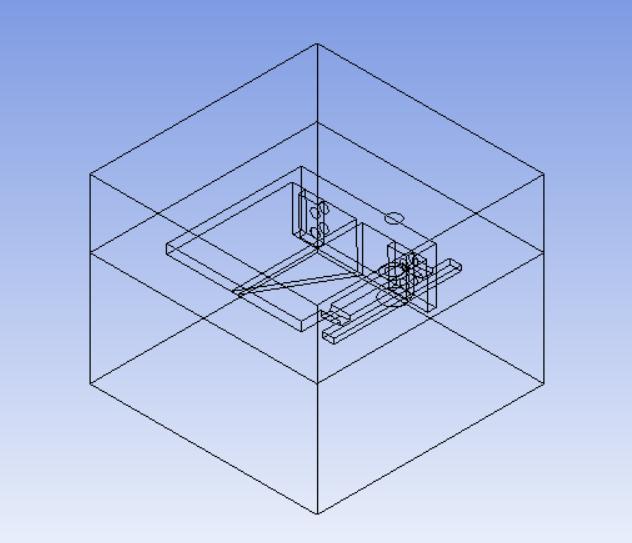

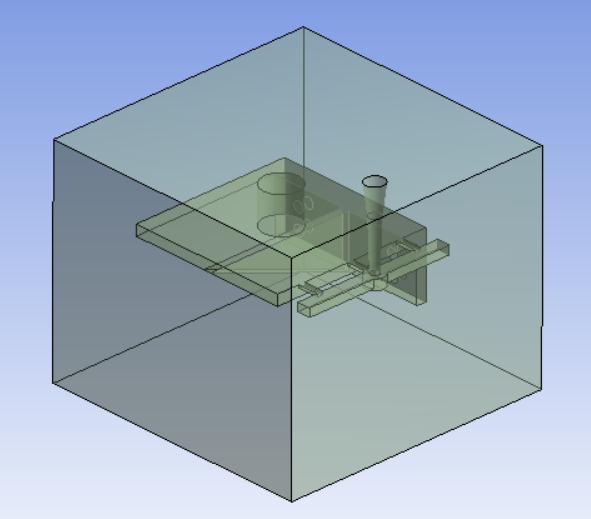

Figure2showstheisometricwireframeviewofthecasting mold used for the study. The dimensions of the same are givenasbelow,

Length=300mm,Width=300mm,Height=120mm.

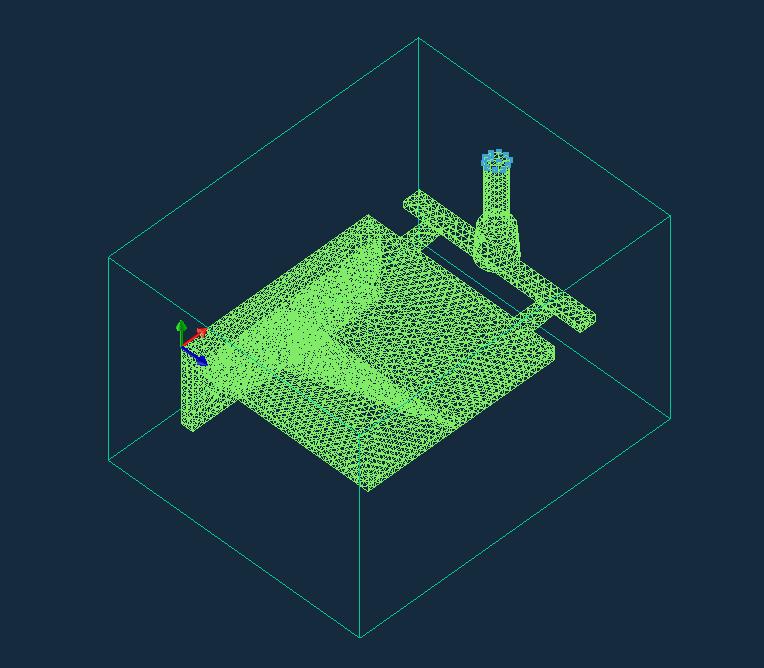

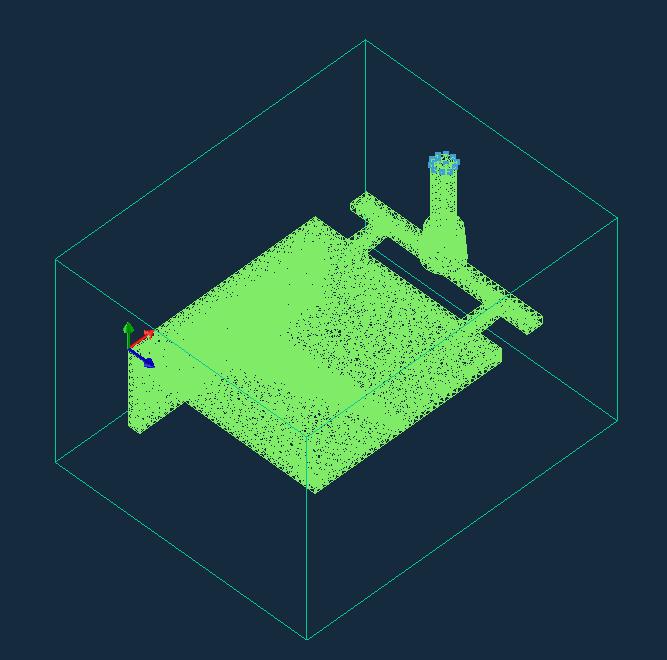

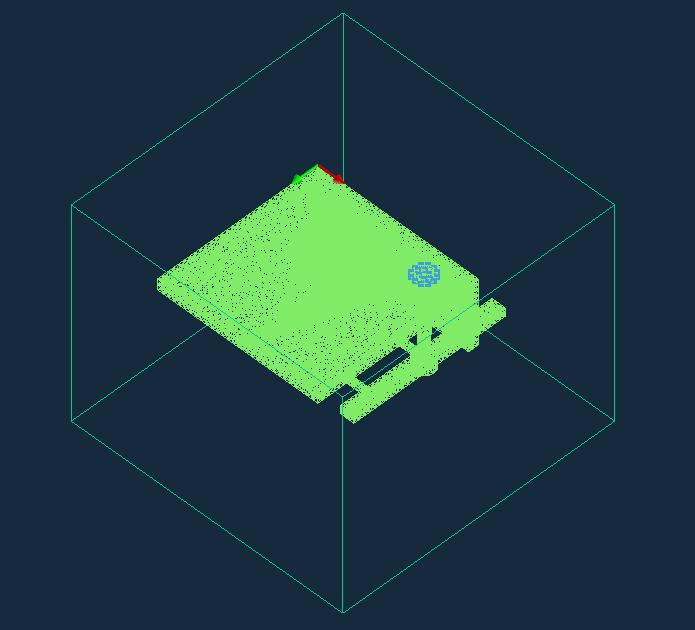

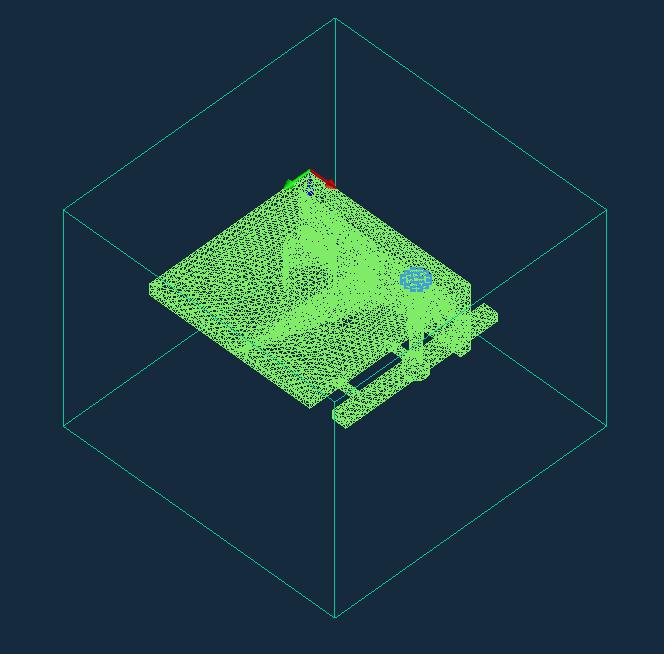

The model is drawn and developed in the Ansys Design Modelerssoftware.Thedevelopedmodelisthenimported for the meshing purpose. The meshing of the model is carriedoutintwosteps,firstthesurfacemeshingiscarried outfollowedbythevolumemeshingofthemodel.Boththe

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1248

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

surface meshing and volume meshing of the model are showninFigure3andFigure4respectively.

2.2 Main processing (addition of boundary conditions and material data, filling, and temperaturecalculations)

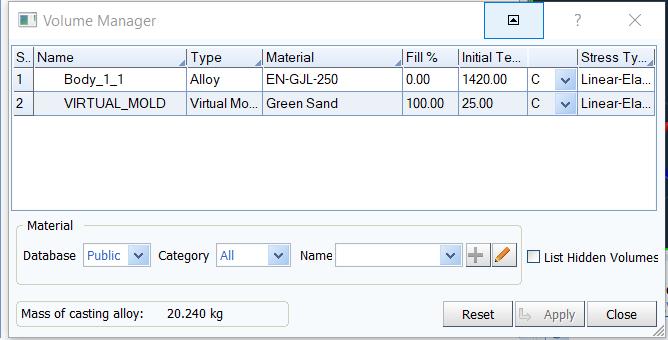

Aftermeshingthemainprocessingstagecomesinpicture.In mainprocessingmaterialassignment,boundarycondition andheattransferconditionsfrombodytomold shouldbe given. Material assignment is done in volume manager as showninfigure5.

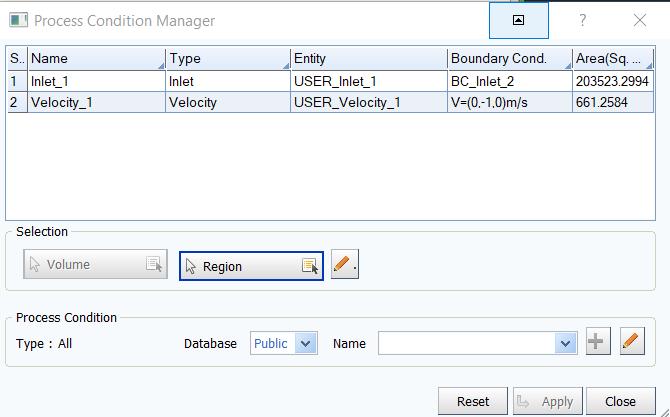

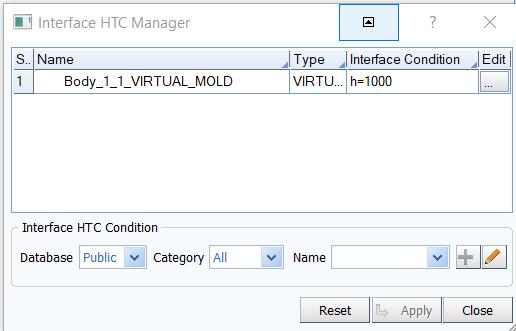

Boundaryconditionsaregiveninprocessconditionmanager asshowninfigure6,inwhichwegeneratedinletboundary conditionasBC_inlet_2.InBC_inlet_2weaddedmassflow rateandpouringtemperatureandalsovelocitycomponent. Heat transfer condition from body to mold is given in interfaceHTCmanagerasshowninfigure7.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

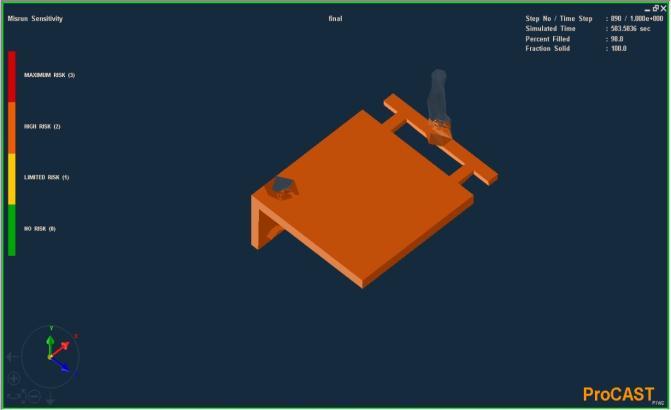

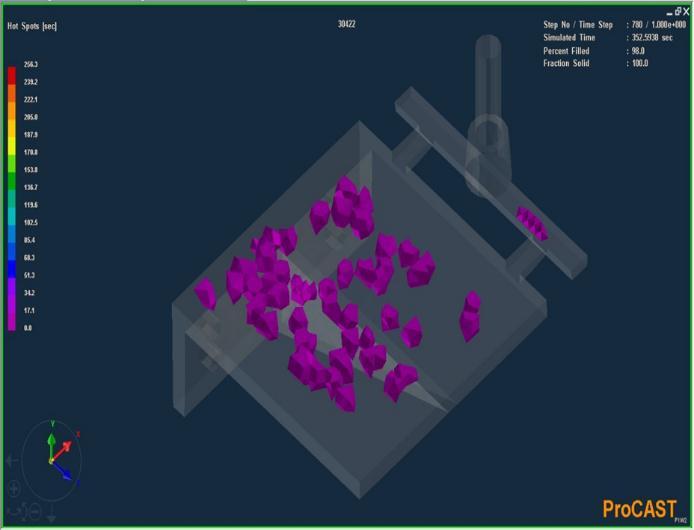

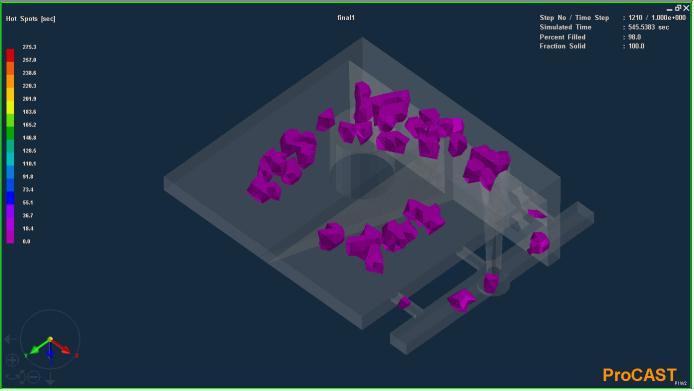

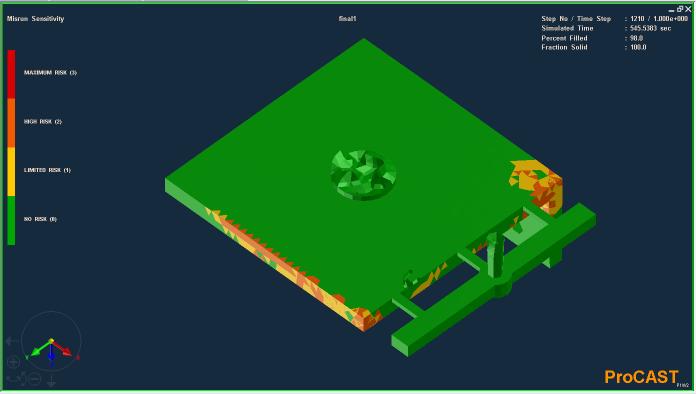

Figure9showsthecontourofhotspotontheexistingmodel, fromthefigurewemaysaythatexistingmodelhas several hotspots on its top surface. Misrun sensitivity of existing model is shown in figure 10, from the figure we may concludethatexistingmodelhashighriskmisrunsensitivity.

Fig 6: ProcessConditionManager

Fig -7: InterfaceHTCManager

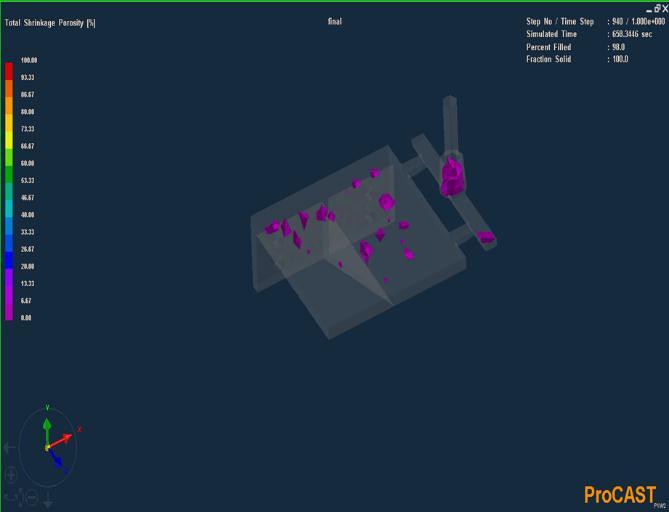

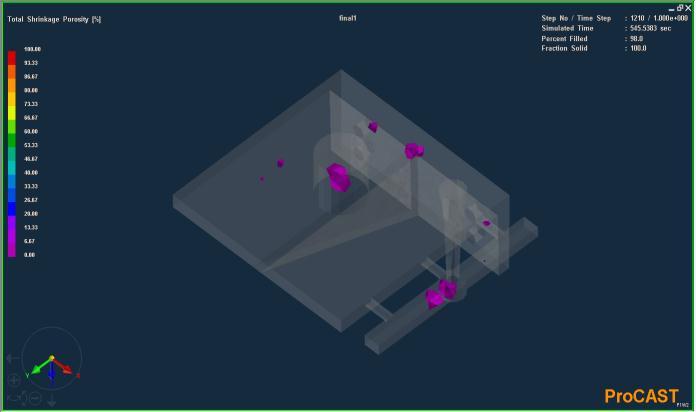

Post processing is the last and important step in the simulation process. In post processing we got various contours, graphs charts, etc. our focus in this research is mainly on the shrinkage porosity, hotspot and misrun sensitivity. Figure 8 shows total shrinkage porosity of the existingmodelwhichisabout6.67%atdifferentlocations.

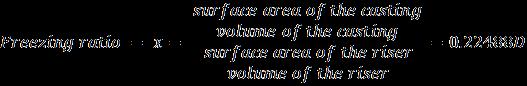

InthepreviouschaptertheexistingmodelofLtypesealing castingissimulatedinProCASTsoftware.Theexistingmodel hasseveralcastingdefectswhichneededtoberectified.In presentchapter,amodifieddesignisdevelopedbasedonthe severaldesigncalculationandthesameissimulatedinthe ProCASTsoftwareundervariableconditions.Attheendof this chapter the results obtained from the numerical simulation of the modified L type sealing casting are discussed.

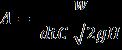

Pouringtime,

Forlessthan40Kg Where,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

T =Averagesectionthicknessinmm W =Massofcasting So, 3.2Chokearea

Chokearea: Where, W=castingmassinkg d=massdensityofmoltenmetal t=pouringtime C=efficiencyfactor g=accelerationduetogravitymm/ H=effectivemetalheadinmm So,

mm2 mm

[Note:ConstantCaniesequationforGreyCastIrona=0.3,b =0.03,c=1.00]

SubstitutingabovevaluesintoCaniesequationforgreycast iron

Gatingratio=1:2:1(sprue:runner:gate) ChokeareaA=201mm2

Runnerareafromgatingratio(1:2): mm2 Ingateareafromgatingratio(1:1)=201mm2

Spruewellarea:

Bytrialanderrormethod,

Heightoftheriser=diameteroftheriser=7cm.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1251

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Figure 11 shows the isometric wireframe view of the modifiedcastingmoldused.Thedimensionsofthesameare givenasbelow,

Length=300mm,Width=300mm,Height=120mm.

The model is drawn and developed in the Ansys Design Modelerssoftware.Themodifiedmodelisthenimportedfor themeshingpurpose.Themeshingofthemodeliscarried out in two steps, first the surface meshing is carried out followed by the volume meshing of the model. Both the surface meshing and volume meshing of the model are showninFigure12andFigure13respectively.

3.6 Main processing (addition of boundary conditions and material data, filling, and temperaturecalculations)

Aftermeshingthemainprocessingstagecomesinpicture.In mainprocessingmaterialassignment,boundarycondition andheattransferconditionsfrombodytomoldweregiven aspertheexistingmodelshownonfigure5,6and7.

3.7Postprocessing(presentationandevaluation).

At post processing we got the contours of total shrinkage porosity,hotspotandmisrunsensitivity.Infigure14wecan clearlyseethattotalshrinkageporosityreducedandpresent atonlyfewpoints.

Figure 15 shows the contour of hotspot on the modified model,fromthefigurewemaysaythatmodifiedmodelhas fewer hotspots on its top surface. Misrun sensitivity of

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

modified model is shown in figure 16, from the figure we mayconcludethatmodifiedmodelnoriskmisrunsensitivity.

Alsobymodifyinggeometryasperthesizesofthe gating system defects like hotspot, misrun and shrinkage porosity decreased. After all it reduces thecastingrejectionrate.

[1] Dr. Ravi, “casting simulation & optimization, benefits, bottlenecks & best practices”, India Foundry Journal, 2008

[2] Naveen Hebsur, and Sunil Mangsheety, “Casting SimulationforSandCastingofFlywheel”,ALUCAST,pp. 62 67,2014

[3] P. Prabhakara Rao, G. Chakaraverthi, “Application of casting simulation”, International journal of thermal technologies,Vol.12011.

[4] Karl B. Rundman, Metal Casting, Michigan Tech. University,Michiga

[5] C.W.Ammen,TheCompleteHandbookofSandCasting, TabBooks,UnitedStatesofAmerica,1979.

[6] A.Bermudez,M.V.O.(2006)."Anexistenceresultfora two phase Stefan problem arising in metal casting in metal casting." Mathematical methods in applied sciences29:325 350.

[7] A.V.Arasu,A.S.M.(2012)."Numericalstudyonmelting of paraffin wax with Al2O3 in a square enclosure." International Communications in Heat and Mass Transfer39:8 16.

Inthisresearch,itisproposedtoexamineasealingcasting model produced from grey cast iron. For sand casting, differentcircumstancesaresimulatednumericallyusingthe commercial software pro CAST. Various solidification performancemetrics,includingtemperature,hotspot,total shrinkageporosity,andsolidificationcontour,etc

1. Casting simulation technology has sufficiently matured and has become an essential tool for casting defect troubleshooting and method optimization.Itenablesqualityassuranceandhigh yield without shop floor trials, and considerably reducesthelead timeforthefirstgoodsamplecast.

2. By moving the trial and error process into the virtual world and determine the cost of different design and process options. By minimizing real world trial and error (and surprises) making castingsrightthefirsttime.

3. Fromabovethesiswork,wefoundthatwhenriser is introduced the shrinkage porosity decreased.

[8] B.Rubinsky,E.G.C.(1981)."Afiniteelementmethodfor the solution of one dimensional phase change problems."InternationaljournalofHeatMassTransfer 24:1987 1989

[9] BabakKamkaria,H.J.A.(2017)."Numericalsimulation andexperimentalverificationofconstrainedmeltingof phase change material in inclined rectangular enclosures."InternationalCommunicationsinHeatand MassTransfer88:211 219.

[10] FengLiu,“OptimizedDesignofGating/RiserSystemin Casting Based on CAD and Simulation Technology” Worcesterpolytechnicinstitute,December2008

[11] Hwang, K. Y. (1997). "Effects of density change and naturalconvectiononthesolidificationprocessofapure metal."JournalofMaterialsProcessingTechnology71: 466 476.

[12] Slota,D.(2011)."Restoringboundaryconditionsinthe solidificationofpuremetals."ComputersandStructures 89:48 54.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1253

Fig 15: HotspotonExistingModel Fig -16: MisrunSensitivityofExistingModel