International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1Nikita Jadhav, 2Mohite Snehal, 3Kasar Chaitali, 4Patil Suraj, 5Yadav Tejas, 6Tikudve Tejashri

12345Student ,SSIET’s B.Tech College Ghogaon, karad, Maharashtra, India. 6Faculty, SSIET’s B.Tech College Ghogaon, Karad, Maharashtra, india. ***

ABSTRACT:

Weallbeawareofthatmortarisnothinghoweverthemixtureofcement,sandandwater Whenconcreteisusedinpresence ofreinforcementthenitisreferredtoasRCC(ReinforcementCementConcrete).ifwedoawaywithcoarseaggregatesthenitis called as no aggregate concrete. In this study no aggregate(course) concrete has been made by means of thinking about polypropylenefiber20%ofweightofcementandincludingextraordinaryadmixture(aluminiumsulphate,sodiumhydroxide, sodium metasilicate),havinghightensilestrengthandcompressiveelectricityrespectively.additionallyimprovesomehousesof concreteUsing25%,30%,35%aggregatebyaddingpolypropylenefibersandexclusiveadmixtures(aluminiumsulphate, sodiumhydroxide,sodiummetasilicate)inconcreteenhancecompressivestrength,durabilityandadditionallyimprovesome propertiesofconcrete.

1) INTRODUCTION:

Thistypeofconcreteisanadvancedtypeofconcreteinwhichtheuseofcoarseaggregatesistotallyeliminated.Thisleadsto preservation of natural resources of rocks hills and mountain. This concrete which have low density as compared to conventional concrete and gives high order of strength. It proves economical as it does not contain coarse aggregate. Compactionisnotrequiredforthisparticulartypeofconcreteforcastinginsitusituation.Itisalsoeasytopumpthisconcrete athighlevelswithouttakingadditionalefforts.Theworkabilityofthisconcreteismorethanconventionalconcretewithout usingextraamountofwater.

Necessity:

Coarsecombinationnownotsolelyincreaseswaterdemandhoweveralsowillincreasethetendencyofsegregation.Thiskind ofconcretehelpsustoenhancesegregationpropertyasnicelyasrequiredlessquantityofwater.Stonequarryingleadsto depletionofnaturalresourcesaswellasitreasonsquiteanumberkindsofpollutionsuchasairpollution,noisepollution Usingthistypeofconcrete

Objectives:

Tofindoutabouttheresidencesofadmixture.

Tocompaircompressivepowerofconventionalconcreteblockandadmixtureconcreteblock.

Tosupplycompressiveenergycheckonblocksfor7daysand28days.

Tomakeconcreteeconomical.

METHODOLOGY:

Tolearnaboutthepropertiesoffabricforchemicaladmixture.

Making24widevarietyofconcreteblocksofanumberofpercentagesuchas25%,30%,35%theuseofdifferent admixtureswithsubstituteofhigh qualityaggregate.

Takeacompressivepowertestonconcreteblockafter7daysand28days.

Toevaluateendresultbytheuseof25%,30%,35%concreteblocksandtraditionalblocks.

“To study the properties of concrete by using polypropylene fibers and different admixture”

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

EXPERIMENTATION: Experimentalapplicationsforacquiringsuitablematerialwhichincludesanumbertests,whicharein thischapterCementmortarreinforcedwithPolypropylenefiberswithanadditionofexceptionaladmixturesareusedasa material.(Foroverallexperimentalwork1:1.5:3percentageisused)

Material:

Cement : Thecementusedinthisexperimentalworkis“ACC”fiftythreegradeOrdinaryPortlandCementconformingtoIS 12269:1987.

Fine Aggregate : ForexperimentalworkweusedsyntheticbeatensandofV.S.I.ofdimensionmuchlessthan4.75mm. Polypropylene Fibers :Weused1.5%thatis20gmforsingleblockofpolypropylenefiberwiththeaidofthemassoftotal cementitiousmaterial.

Fly Ash : TheflyashisusedinexperimentationsatisfiesofIS:3812(30)andcementisreplacedthrough20%byflyashforall mixproportion

Aluminium sulphate : Addpowderedshapeofaluminiumsulphate36.4Gm/100mlofwaterandsaveditfor1day(24hr).

Sodium Silicate : Addpowderedstructureofsodiumsilicate170.52Gm/100mlofwaterandsaveditfor2days(48hr).

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Sodium hydroxide : Addpalletsofsodiumhydroxide48Gm/100mlofwaterandstoreditfor2days(48hr).

(Theseallsolutionsmixedwithmagneticstirrerforappropriatemixing)

MIX PROPORTION:

For this we taken comparative study to get better and nice effects by using specific cloth for variable mixture like sand, admixtures,PPfibre,etc.

(Theseallsolutionsmixedwithmagneticstirrerforpropermixing)

MIX PROPORTION:

Forthiswetakencomparativestudytogetbetterandsatisfactoryresultsbyusingdifferentmaterialforvariablemixturelike sand,admixtures,PPfibre,etc Material quantity:

Case Cement Fly Ash Crush Sand Water Aggregate (%) PP Fiber NaOH Al2SO4 Na2SiO3

Block No.1 (conventional) 1.5kg 250kg 675ml 100% (4.11kg)

Block No.2 ( 2% Agg.) 1.5kg 0.5kg (35%) 3kg 550ml 25% (0.8kg) 20gm 67.05ml 40.5ml 25.31ml

Block No.3 ( 30%Agg) 1.5kg 0.5kg (35%) 2.8kg 550ml 30% (1.06kg) 20gm 67.05ml 40.5ml 25.31ml

Block No.4 (35%Agg) 1.5kg 0.5kg (35%) 2.5kg 550ml 35% (1.24kg) 20gm 67.05ml 40.5ml 25.31ml

Block No.5 (No Agg)

1.5kg 0.5kg (35%) 0.5kg (35%) 550ml 20gm 67.05ml 40.5ml 25.31mlss

Table NO.1

RESULT AND DISCUSSION:

Afterapplyingtrialanderrortechniqueforfinalizingmaterial.Havingsuitableworkingpropertiesforexperimentationproject. Wereceivedexceptionaleffectsforexceptional%ofaggregate comparingfabricforputtingtimeproperty,wefoundthatby addingaluminiumsulphateanswerincementitiousmaterialpreliminaryputtingtimeofmaterialgetdecreasedbymeansof12 min.Byaddingsodiumsilicatemakebiggercompressiveenergyofconcreteaswellasreduceporosity.Effectofaddingsodium hydroxidepreventssegregationanddecrease amountofwaterrequired.Polypropylenefiberincreasestensilestrengthof concreteandreducesweightofconcrete.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

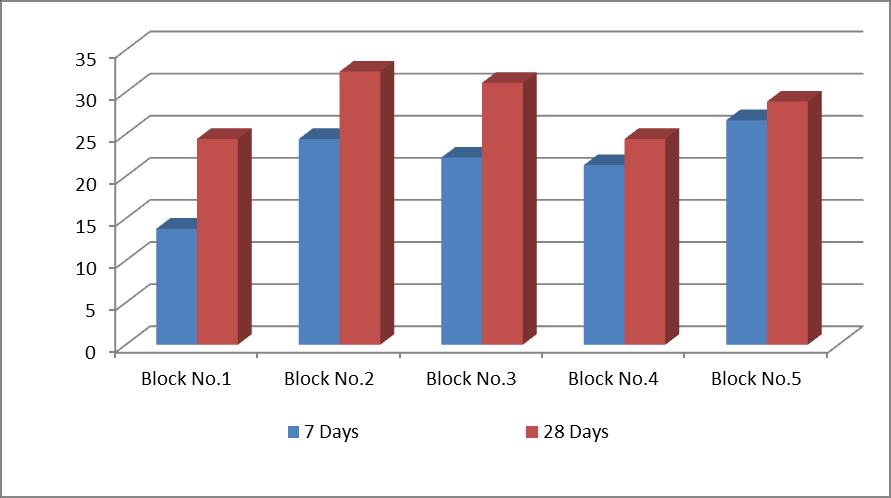

Table 4. Compressive Strength For 7 days And 28 days

Afterobservingthetestresultsforcompressivestrengthofmaterial,weobservedthatcompressivestrengthofmaterialin creaseswiththeadditionofsodiumsilicate.Whereasusing25% aggregate having more compressive strength thanconcrete using30% andthan concreteusing35%aggregate respectively.

CONCLUSION

:

Initialplacingtimeofcementminimizewiththeuseofaccelerationsuchasaluminumsulphate.

Toreducetimeoftherepressionofmetallicofwiththeaidofincreasingwatermanipulateforachievingworkability sodiumhydroxideandsodiummetasilicateareused.

Forgrowingcompressiveelectricityofcementmortar,componentslikepolypropylenefiber(ppfiber).

REFERANCES

:

EffectOfAluminiumSulfateOnCementPropertiesChangyuKan,MingzhangLan,LameiKongAndJingboYangCollegeOf Material ScienceAndEngineering,BeijingUniversityOfTechnology, Beijing100124,EffectOfAluminiumSulfateOn CementPropertiesChangyuKan.

CollegeOfMaterialScienceAndEngineering,BeijingUniversityOf Technology, Beijing100124,China.AnInvestigation OnTheEffectsOfAl2o3Nano ParticlesOnDurabilityAndMechanicalPropertiesOfHighPerformanceConcrete.

May2013conference:4thInternationalConferenceOnConcreteAndDevelopmentat:Tehran,Iran,StudyingTheEffectOf AddingSodiumSilicateAndRockWoolToConcreteMixOnThePropertiesOfConcreteRamiJosephAghajaDuriadFawzi Mahdi DepartmentOfAppliedScience UniversityOfTechnologyReceived29January2015 ;Accepted29November 2015.

Prof.RamMeghe,AssistantProfessor,DepartmentofCivilEngineering,InstituteofTechnologyAndResearch,Badnera, Amravati,PerformanceOfPolypropyleneFibreReinforcedConcrete

Dr.T.Ch.Madhavi1, L . Swamy Raju2, Deepak Mathur 1Professor and Head, Department of Civil Engineering, SRM University,Ramapuram2AdditionalChiefEngineer(Civil),BHAVINI,DAE,Kalpakkam3ScientificOfficer(Civil),BHAVINI, DAE,Kalpakkam,PolypropyleneFiberReinforcedConcrete.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

1PGStructuralEngineering,JCET, Dharmapuri,Tamilnadu,India2AssistantProfessor,StructuralEngineeringJCET, Dharmapuri, Tamilnadu, Experimental Study On Polypropylene Fiber Reinforced Concrete

ArchanaP1,AshwiniNNayak2,SanjanaRNayak3,HarshitaVaddar4,1,2,3,4StudentsCivilEngineeringDepartment,Stj InstituteofTechnology,RanebennurDineshSMagnur5,StudyOfStrengthOfPolyprop YleneFiberReinforcedConcrete