International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

1,2,3,4

Abstract - Agriculture has been the key driver of Indian Economy over past many decades. It has empowered the alignedfields like Chemical Industry, MechanicalIndustryand Research sector along with its consistent growth. The advancements in all the sectors of today’s world at the peak reducing human efforts and providing more comfort to humans and increasing the per capita income of the farmers. The advancements in the agriculture sector have made it possible to lower the cost of various stages of cultivation of farm products. We have looked this journey very closely as we are backed up agricultural background in and around our surrounding. The advanced technologies available today is high cost andnot affordable for small scale farmertoinvestin and to maintain it. Hence, considering it, we thought of making a low cost planter which would be versatile in nature of all types of single row seedling plantations. The materialized planter is completely manually operated and does not need any procuring external power source for its working. This planter works upon human push and force for its plantation and propelling. It requires two persons for its operation hence reducing manpower required, labor cost. As this planter finds replacement for conventional method using Suspensions, Gear and Chain Drives, Planter and operating levers; it reduces back pain (Spinal Cord Issues) of workers. It is low cost, low maintenance, less time consuming machine meant for small scale farmers

Key Words: Agriculture, Push Force, Planter, Manually operated, Suspensions, Gear and Chain Drives, Back pain, Low cost.

Being from agricultural background, we were known to variousproblemsneedtobefacedwhilepracticingfarming. Henceafterthoroughdiscussion,wedecidedtoworkupon the project which would help to reduce plantation cost of vegetables cultivated in our locality. Plantation of Tomato seedlingswasobservedwhichusedconventionalmethodof plantation. The side effects and shortcomings of conventional practice was understood and decided to develop a solution for this. We decided to keep the mechanism simple and open to get modified according to user’schoice.Forpowertransmissionwehaveusedchain drive and gear drive which consist of major part of the mechanism of plantation. The machine was developed consideringthegroundsurface,varioustypesofsoil,applied forcebytheoperatorandwasdeclaredsafeforwork.

Asmallholeisdiggedinsoilforplantationoftheseedling, the seedling is planted in the hole and hole and roots are againcoveredwithsoil.Thedistancebetweentwoseedlings is calculated by eye seeing and rough predictions which resultsin irregularplantationdistance. Thismayresult in impropergrowthoftheplantandcanaffecttheproductivity oftheplant.

Theconventionalmethodusedtodayistimeconsumingand requirehugemanpowerforitsworking.Henceincreasesthe plantation cost and reducing profits of the farmer. Consideringhealthoftheworkers,itcausesmajorissuesto backboneofourbodyanddamagesthespinalcordofthe body.

There was need to develop a productive and low cost machinetoresolvetheproblem.Toworkuponthesame,we fabricatedmanualseedlingtransplanterwhichisoperated manuallyandisaffordableforsmallfarmers.Themachine consistsof4wheels,outofwhichfront2wheelsareofsmall diameter.Suspensionisprovidedtobothfrontwheelswhere thetransplanterisattachedinordertoobtainverticallinear movementoftheplanter.Thebottomofplanterisattached withadroppingconetodropseedlings.Theconeisprovided with opening/closing arrangement and its control is provided to the handle from where the operator will be operatingthemachinefunctioning.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Figure 2 Single Row Manual Seedling Planter

Theserodswereusedformakingoftheframe.Therestof theassemblyisconnectedwiththeserods.Thesquarerods usedarein2dimensions:4&2inches.

4inchessquarerodisusedfortheprincipalframewhile2 inches square rod is used for supporting planter and the hollowshaftoftheconveyors.

side(ClosertoHandle)comprisesofsmalldiameterwheels andwhilerearwheelsarecomparativelylargerindiameter.

Themachinedisplaceswiththehelpof4wheelswhichareof samediameterinthefrontandrearsiderespectively.Front

Figure 4 Front Small Diameter Tyres (STANDARD)

3. Suspensions:

These are introduced between the frame and the front wheelsmountedvertically.

Figure 5 Suspensions connected to Frame and Wheels.

4.

The hollow shafts are used for mounting gears and the conveyor.3HollowShaftsareusedinthemachine.Hollow shaftsareusedtoreduceoverallweightofthemachine.

5.

Theseareusedtoprovidesupporttoarotatingshaft.Ithas been used in the machine to provide free rotation of the hollow shaft. It is also known as Pillow Block Bearing or PlummerBlock.Intotal,6PedestalBearingswereused

6.

Sprocketsareusedtotransmitrotarymotionbetweenrear axleofwheelandgeardriveshaft.Thechainismountedon thesprocketsofdifferentdiameter.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

7. Chain Drive:

Itisusedforpowertransmissionbetweenrearwheeltothe geardriveshaft,mountedonthesprockets.

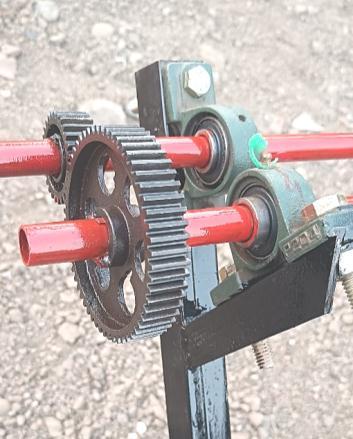

8. Gear Drive:

Gearsaremountedonhollowshaftsintherearendwhich receivemotionthroughthechaindrive.

11. Spring:

Itismountedontheconetocontroltheopening/closing.The clutchwireoperatesitwiththehelpofbrakelever.

Figure 7 Gear Drive for Reverse Power Transmission

9. Conveyor:

Itisabeltrotatingbetweentwohollowshafts,outofwhich oneshafthasgearmountedonit.(GearDriveAssembly)

It is a railing pipe fitted with cone shaped orifice at its bottom(SeedlingDropper).Planterisfittedtosmallsized (2inches)squarerodwiththehelpoflockingpin.

Figure 9 Tension Spring for Opening/Closing

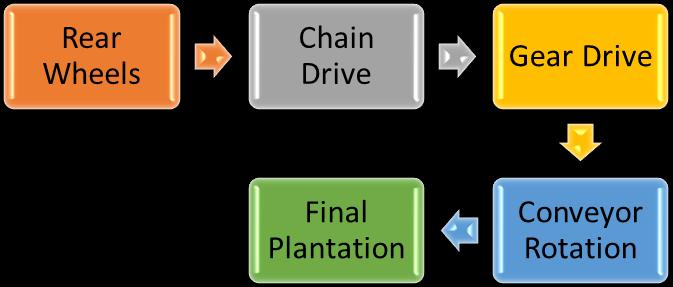

1. The machine is powered manually using human handeffortstodriveinforward(working)motion.

2. When the machine is in forward motion or when pushed forward, the chain drive connected to the rearlargewheeltransmitspowerfromthewheelto inputshaftsofsmallersprocket.

3. The machine comprises of gear drive unit having two gears, one half of the diameter of other’s meshingwitheachother.

4. Theinputshafthavingsmallsprocketandgear(Dia 52mm)mountedtogethertransmitspowertogear (Dia.106mm).

5. Due to the gear drive mounted parallel, opposite powertransmissionispossibletoachieveconveyor rotation.

6. This gear (Dia. 106 mm) is mounted on the shat having the conveyor rear side mounted for movement.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

7. As the operator will apply efforts, the power transmission will be done in above mentioned manner.

8. Theshaftsaremountedonanglecuttingswiththe helpofPedestalBearingsusedforfreerotationof theshafts.

9. Further, the conveyor is provided with seedling compartments at uniform distance to achieve uniformplantationofseedlinginthefield.

10. This distance is calculated in proportionate of distance between two seedlings and speed of the machine.

11. As the planting compartment comes towards the frontendoftheconveyor,thereisplantermounted close to the conveyor end to getting accurate droppingoftheseedlingintheplanter.

12. Asseedlingdropsintheplanter,theoperatorwill apply push (downward force) on the handle for plantation.

13. The machine has front wheels of small diameter. Suspensionsystemisintroducedbetweenthefront wheelsandtheprincipalframe.

14. Whentheoperatorwillapplydownwardpushforce, therewillbechangeinstrokedistance(length)of thesuspensions.

15. This will enable the machine to get inclined, reducing height of handle (front side) from the plantationrow bed.

16. Hence, the planter cone will get inserted into the soilforfinalprocessofplantation.

17. Foropening/closingoftheplantercone,thereare twoclutchleversprovidedatthehandle.

18. Nowastheconeneedstogetopenedforplantation, theoperatorwilloperateclutchlever.

19. As the cone is attached with spring and tension wiring arrangement, it gets opened and drops seedling:Plantation.

20. Aftertheplantation,theoperatorreleasestheclutch lever and due to spring tension, the spring gets compressedandtheconegetsclosed.

21. The second operator helping from rear side will position the seedlings in correct manner in compartmentsfromseedlingtrays.

22. The operator then releases force applied on the handle and the suspension hence get to its full lengthoriginalposition.

23. Theoperatorwillthenrepeatthesameprocedure for further plantation reducing cost and time requiredforplantation.

Figure 10 Power Transmission Flow Diagram

5. ADVANTAGES:

Reducedhumaneffortsrequired.

Eliminatesproblemsofbackpainofoperator.

Reducesplantationcostofseedlings.

Properhandlingofseedlings.

Speedyplantationthanconventionalmethods.

Lowmaintenanceandcosteffective.

6. APPLICATIONS:

TomatoPlantation

CabbagePlantation

Cauli flowerPlantation

ChilliPlantation

AllkindsofRow Plantations.

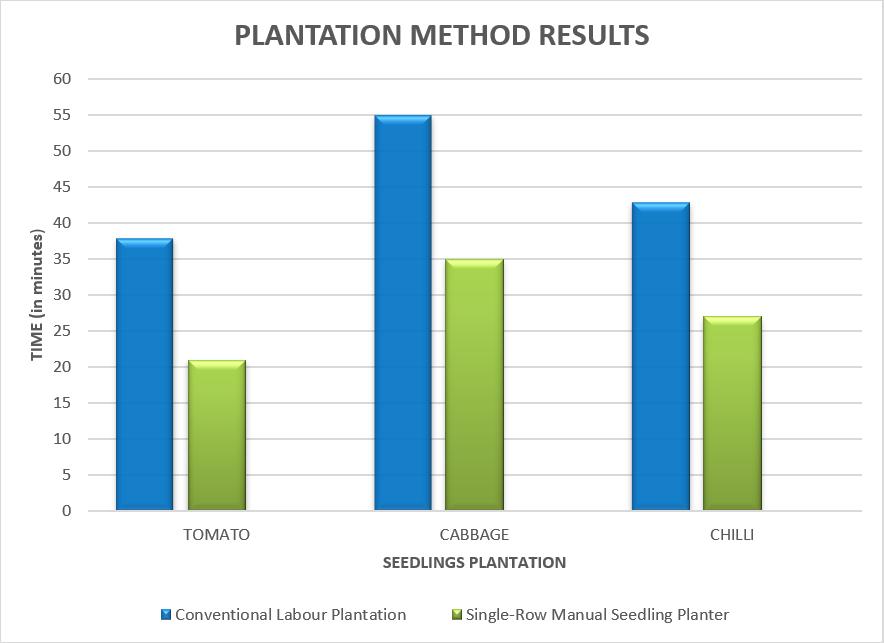

Thefollowingresultswereobtainedafterthetrailonasingle rowof650feetinlength.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

This fabricated project has wide scope of improvement considering the daily increasing advancements in technology:

1. Inclusionofelectricpoweredpropellingsystem.

2. We also look forward to automate the plantation process by application of image sensors for scanning holeandcommandedplantation.

3. This project can also be modified for variable length between the two front and rear wheels for increasing extentofrowscovered.

Chart 1 Time Vs Seedling Plantation by both methods for various seedlings.

Theaboveobservationshenceprovetheeffectivemethodof plantationandverifiesitslesstime consumingability.

Themainaimfordevelopmentofthisprojectwastoreduce thehumaneffortsandthetimerequiredforplantationsof variousseedlings.Afterthecollecteddataafterthetrails,the set aim was successfully achieved. The health issues occurring due to conventional plantations were also eliminated to great extent. The developed project was manufactured considering the farm ground surface conditions and nature of the soil. This machine was fabricatedusingthedatacollectedfromfarmersandMORYA AGROINDUSTRIES,CHANDWAD.Allthecomponentswere designed considering the stresses and possible failures. Hence,weconcludethatthedesignisSafe.

We express our sincere gratitude towards our Guide and HeadofDepartment,Prof.D.V.Lohar. Hehasbeenatorch bearerforusthroughouttheplanningandexecutionofthis project. We admire his expertise in this subject and consistentsupportduringvariousstagesofproject.Weare grateful to all the faculties of our department for their continuous guidanceandsuggestionstomakethisproject better than it can be. Lastly, we thank all the workshop instructorsandnon teachingstaffofthecollegewhohelped in all possible ways. We are forever grateful to every individualwhohascontributedtothisprojectinanymanner tomakeitwhatitistoday.

[1] Vinay Kumar and Jagvir Dixit. 2018. Design, Development and Fabrication of a Single Row Manual VegetableTransplanter.IndianJournalofHillFarming 31(1):177 182.

[2] Molin,J.P.,Bashford,L.L.,Von Bargen,K.AndLeviticus, L.I.(1996).Designandevaluationofapunchplanterfor no tillsystems.JAmericanSocAgricEng41:307 314.

[3] MechanismsandMechanicalLinkages:IAChironis

[4] MachineDesign:R.S.Khurmi

[5] Amruta,S.,Patil,Sushil,S.,Davane,S.andMalunjkar,V. 2014. Design, Development and Testing of Hand Held Vegetable Transplanter. International Journal of AdvancedResearch(2015),Vol.3.Issue1.PP:247 253

[6] PSGDesignDataBook

[7] Anuj Kumar Rai., Ashok Tripathi., Akash Agarwal., RanjanKumarNirla.,HimanshuRaj.andRohit Kumar Pandey.2018.Evaluationandperformanceoftworow semi automatic vegetable transplanter. International JournalofChemicalStudies4:125 127.

[8] Raheman,H.G.andPrasanna,V.K.(2011).Development ofawalk behindtypehandtractorpoweredvegetable transplanter for paper pot seedling. Science Direct, BiosystemsEngineering110:189 197.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

MehulManojKotwal

Pursuing Diploma in Mechanical EngineeringatSNJB’sShriH.H.J.B. Polytechnic,Chandwad,MH,India.

MayurAnilChavan

Pursuing Diploma in Mechanical EngineeringatSNJB’sShriH.H.J.B. Polytechnic,Chandwad,MH,India.

PremMadhavGangurde

Pursuing Diploma in Mechanical EngineeringatSNJB’sShriH.H.J.B. Polytechnic,Chandwad,MH,India.

KiranChhaganGhuge

Pursuing Diploma in Mechanical EngineeringatSNJB’sShriH.H.J.B. Polytechnic,Chandwad,MH,India.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal