International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Arihant Satpute1, Prasanna Patil2, Mayur Kulkarni3, Rishikesh More4

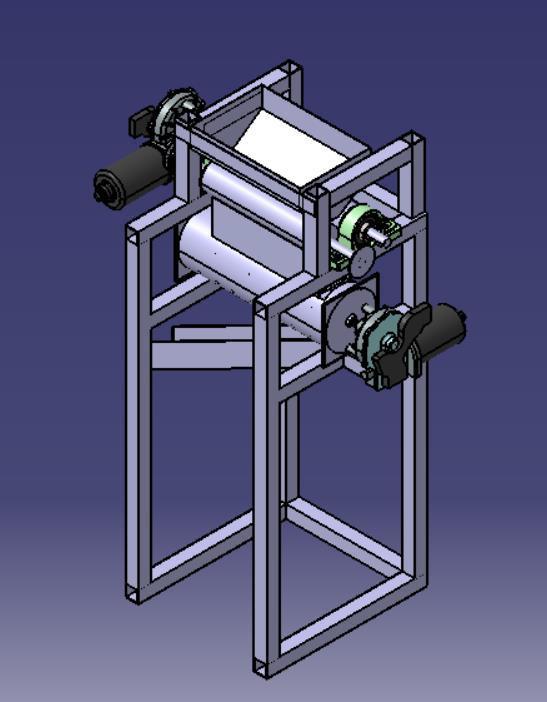

Abstract Tamarind is very helpful kitchen product. It's a very important ingredient in Ayurvedic medicines. These desires are consummated by tamarind pulp, which become obtainable once the separation of seed and cover from tamarind. The methodology of preparation of this pulp maybe a hand method that becomes a tedious and prolonged task to remove out the cover and seed from Tamarind. This operation require immense manpower needs. Tamarind seeds are separated manually which is less hygienical and grueling. All this method needs a ton of your time and hands which might be reduced by automation of the method. The machine consists of a seed separating the unit during which the fruits are subjected to shear force. Deshelled and dried tamarind is feed into tapered grooved disc one by one manually with facilitate of roller. The tapered grooved disc is driven by a motor at very low revolutions per minute. Once tamarind comes close to the cutter blade that is driven by a motor at high speed it shears the tamarind pulp. The projection in tray removes the tamarind seeds out of the oblong sieve, therefore the tamarind is deseeded. Since the machine is economical and efficient in separating tamarind seeds thus most of the farmers can afford it. The machine will scale back human labour, labour cost, and time.

Key Words: Terms Tamarind,Design,FEAStaticstructural andResults,FabricationandManufacturing.

The food industry is growing very fast because of the demand.Theneedofprocessingthefooditemshasalsotobe quick and effective. Tamarind which is one of the major integrantinthefoodandusedaseverydaykitchenproduct. Tamarind fruits will be ripened in summer. They may be harvestedafter6monthsaftermaturitysothatthemoisture contentlevelisreducedbutusually,theyareharvestedas soonastheymatureandprocessed.

Tamarind fruit is anti helminthic (expels worms), antimicrobial,antiseptic,antiviral,sunscreenandastringent and to promote wound healing, asthma, bacterial skin infections, boils, chest pain, cholesterol metabolism disorders,colds,colic,conjunctivitis,constipation(chronicor acute),diabetes, diarrhea, dry eyes, dysentery, eye inflammation,fever,gallbladderdisorders,gastrointestinal disorders, gingivitis, hemorrhoids, indigestion, jaundice,

keratitis,leprosy,liverdisorders,irondeficiency,nauseaand vomiting(pregnancyrelated generallyeatrawunripesour fruits),salivaproduction,skindisinfection/sterilization,sore throat,sores,sprains,swelling(joints)andurinarystones.

Theneedofprocessingthefooditemshasalsotobequick andeffective.Themethodologyofpreparationofthismaybe ahandmethodthatbecomesatediousandprolongedtaskto remove out the cover and seed from Tamarind. This operation require immense manpower needs. Tamarind seeds are separated manually which isless hygienical and grueling.Allthismethodneedsatonofyourtimeandhands whichmightbereducedbyautomationofthemethod.

To develop method for deseeding tamarind. Design and fabricationoftamarinddeseedingmachineforhouseholdas wellassmallscaleindustries.

Step1: Westartedtheworkofthisprojectwithliterature surveywiththehelpofresearchpapers.Wegatheredmany researchpaperswhicharerelevanttothistopic.

Step2: Afterthatwediscussedaboutcomponentswhichare requiredforourproject.

Step3: Afterdecidingthelistofcomponents,Concept2D and3DmodellingaredonebyCATIAsoftware.

Step 4: The components were manufactured and then assembledtogether.

Step5: Thetestingiscarriedoutandthentheresultand conclusionsaredrawn

Thecoverof150gmTamarindby300gmweight =weightxheight =300X10 3x9.81X300X10 3

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

=0.8829J

Hence,Energyrequiredforremovingthecoverof1000gm Tamarind=5.886J

1.Tocomputeforcesactingonshaftsfromgearspulleysor shredderblades.

2.Findbendingmomentsfromgears,pulleysandshredder blades.

3.Todeterminetorqueinshafts.

4.Determinesuitabilityofshaftdesignand/ornecessarysize ofshafting.

Diameter(in.) Diameterincrements(in.) Upto3 1/16 3to5 1/8 5to8 ¼

Torsionofcircularshaft

Angleoftwist,θ=

θ=theangleoftwist(radians)

T=theappliedtorque(in lb.)

L=shaftlength(in.)

J=polarmomentoninertiaoftheshaftcrosssection(in4)

G=shearmodulusofelasticityoftheshaftmaterial(lb/in2) IandJrelationshipsforcircularcrosssectionareas

Forsolidcircle,

I= and J= ForHollowcircle,

I= and J=

Aswehaveachievedthebendstressanddeformationvalues by considering the weight applied on the shaft on Ansys workbenchandproceededforfurthercalculations.

For simplified calculations and to obtain an approximate valueofthebearinglife,theso called“handbookmethod”is usedtocalculatethebasicratinglife.Thebasicratinglifeofa bearingaccordingtoISO281is

= Where,

= basic rating life (at 90% reliability), millions of revolutions

C=basicdynamicloadrating,kN P=equivalentdynamicbearingload,kN p=exponentforthelifeequation = 3forballbearings

= 10/3 for roller bearings, as used typically in axle box applications

The basic rating life for a specific bearing is based on the basic dynamic load rating according to ISO 281. The equivalent bearing load has to be calculated based on the bearingloadsactingonthebearingviathewheelsetjournal and the axlebox housing. For railway applications, it is preferable to calculate the life expressed in operating mileage,inmillionkm

= [(PixDw)/1000)]x Where,

= basicratinglife(at90%reliability),millionkmDw =meanwheeldiameter,m

Torquerequiredbythemotortocrushtamarind=? Forceexertedbyasingleseed=weightofseedx9.81m/s =10gx9.81m/s =0.001kgx9.81m/s =0.0098N

Consideringweightatatime=10x0.0098N=0.09N

Hencetotalweight=weightofsystem+weightofseed

TotalLoad=40N+0.09N=40.09N

Hencetorqueexerted=40.09Nxradiusofroller=x50mm =2004.5Nmm(approx)=2Nm

ThereforewehaveselectedaWipermotorwhichhas50rpm ,12vrating.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1161

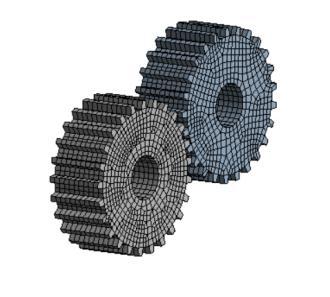

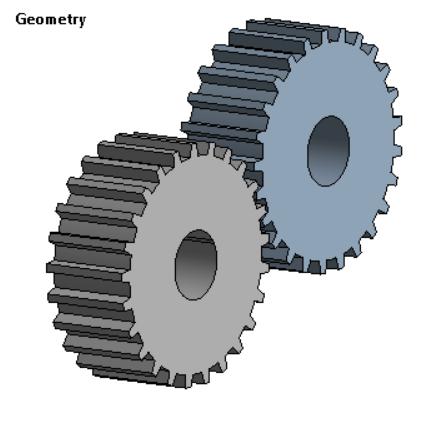

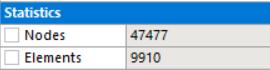

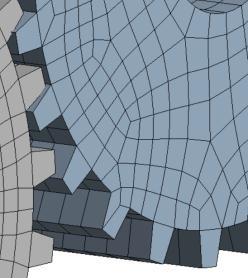

ANSYSMeshingisageneral purpose,intelligent,automated high performanceproduct.Itproducesthemostappropriate meshforaccurate,efficientMultiphysicssolutions.Amesh well suited for a specific analysis can be generated with a singlemouseclickforallpartsinamodel.Fullcontrolsover theoptionsusedtogeneratethemeshareavailableforthe expertuserwhowantstofine tuneit.Thepowerofparallel processingisautomaticallyusedtoreducethetimeyouhave towaitformeshgeneration.Creatingthemostappropriate meshisthefoundationof engineeringsimulations.ANSYS Meshingisawareofthetypeofsolutionsthatwillbeusedin theprojectandhastheappropriatecriteriatocreatethebest suited mesh. ANSYS Meshing is automatically integrated witheachsolverwithintheANSYSWorkbenchenvironment. For a quick analysis or for the new and infrequent user, a usable mesh can be created with one click of the mouse. ANSYSMeshingchoosesthemostappropriateoptionsbased on the analysis type and the geometry of the model. Especially convenient is the ability of ANSYS Meshing to automatically take advantage of the available cores in the computertouse parallel processingandthussignificantly reduce the time to create a mesh. Parallel meshing is available without any additional cost or license requirements.

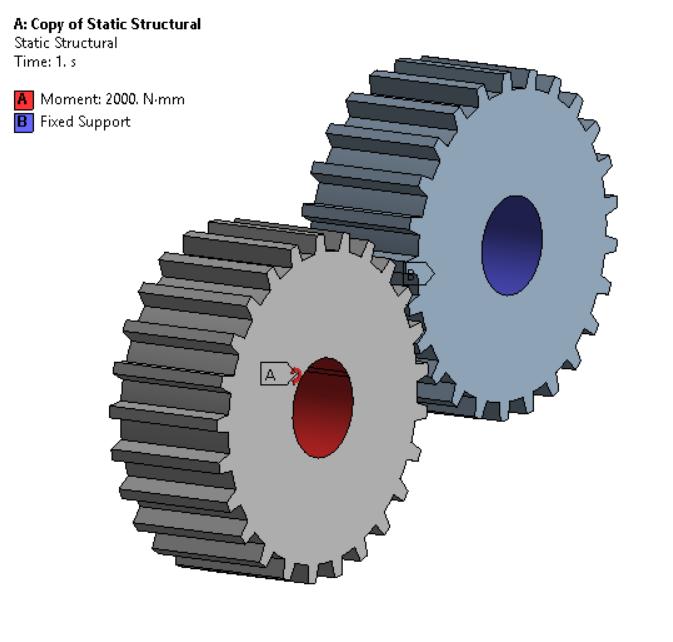

Aboundaryconditionforthemodelisthatthesettingofa well knownvalueforadisplacementoranassociatedload. Foraspecificnodeyou'llbeabletoseteithertheloadorthe displacement but not each. The main kinds of loading obtainableinFEAincludeforce,pressureandtemperature. Thesemaybeappliedtopoints,surfaces,edges,nodesand componentsorremotelyoffsetfromafeature.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume:

Issue:

www.irjet.net

ISSN: 2395 0072

Figno.4:boundaryconditions

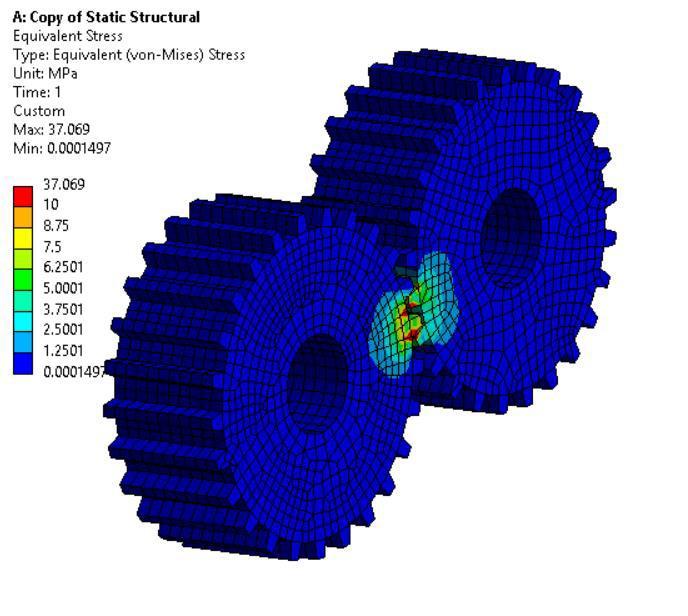

RESULTS :

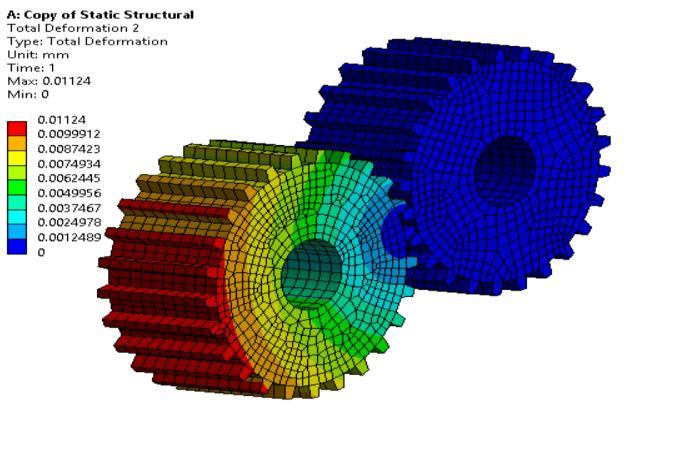

TOTAL DEFORMATION

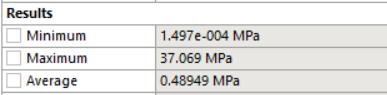

Figno.6:stressonthegears

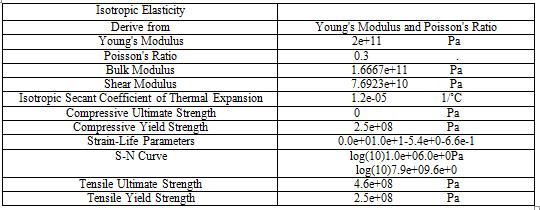

Table stressesongear

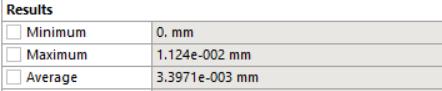

Figno.5:totaldeformationdiagram

Table Totaldeformation

Followingcomponents were manufactured and fabricated fortheproject:

8.1.1 Frame:

Aframedstructureinanymaterialisonethatismadestable byaskeletonthatisabletostandbyitselfasarigidstructure withoutdependingonfloorsorwallstoresistdeformation.

8.1.2

The capacity of a cylindrical box is basically equal to the volumeofthecylinderinvolved.Thus,thevolumeofathree dimensionalshapeisequaltotheamountofspaceoccupied bythatshape.

8.1.3

The rolling mechanism is used to apply pressure on the tamarind seed here so that it would pop out from the tamarindfruitcovereasily.

8.1.4 Motors:

An electric motor is an electrical machine that converts electrical energy into mechanical energy. A pair of viper

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

motorsareusedinourmachineforefficientworkingofthe rollingmechanism

8.1.5 Bearings:

Rollingbearingsprovidehighprecisionandlowfrictionand therefore enable high rotational speeds while reducing noise,heat,energyconsumptionandwear.

8.1.6 Hopper:

Hoppers are used for the temporary storage of materials. Theyaredesignedsothatstoredmaterialcanbedumpedor fedtoaprocesseasily.

8.2

Followingoperationswerewhilefabricatetheproject

8.2.1 Cutting:

Cuttingistheseparationoropeningofaphysicalobject,into twoormoreportions,throughtheapplicationofanacutely directedforce.Implementscommonlyusedforcuttingare theknifeandsaw,orinmedicineandsciencethescalpeland microtome.

8.2.2

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool causingfusion.Weldingisdistinctfromlowertemperature metal joining techniques such as brazing and soldering, whichdonotmeltthebasemetal.

8.2.3

Drillingisacuttingprocessthatusesadrillbittocutahole ofcircularcross sectioninsolidmaterials. Thedrillbitisusuallyarotarycuttingtool,oftenmulti point.

Finishingisabroadrangeofindustrialprocessesthatalter the surface of a manufactured item to achieve a certain property.

Polishing is the process of creating a smooth and shiny surface by rubbing it or using a chemical action, leaving a surfacewithasignificantspecularreflection(stilllimitedby the index of refraction of the material according to the Fresnel equations.) In some materials (such as metals, glasses,blackortransparentstones),polishingisalsoableto reducediffusereflectiontominimalvalues.

The following points should be considered for the safe operationofmachineAndtoavoidaccidents:

Allthepartsofthemachineshouldbecheckedtobe inperfectalignment.

Allthenutsandboltsshouldbeperfectlytightened.

The operating switch should be located at convenient distance from the operator so as to controlthemachineeasily.

The inspection and maintenance of the machine shouldbedonefromtimetotime.

Allthenutsandboltsshouldbeperfectlytightened.

Thefabricatedmachineisdesignedforremovingthe10kg Tamarindpodscoverandseedperhour.Theresultsofthe trialsaresatisfactoryforcoverremovalprocess.Butthereis further scope in development of same model for seed removalprocess.Themodificationssuggestedabovecanbe made so that the machine would show the result for tamarindseedseparationveryefficiently.

1. The design of the project was made according to calculations.

2. Static structural analysis was performed on most crucial part of the system ie. gear on which the wholecrushingmechanismwasbased.

3. Hence, as a result we got maximum total deformation=<<0andmaximumequivalentstress obtained was 37.069 MPa which falls under the yieldpointofthegear.

4. Hence,thedesignwasconsideredtobesafeandthe manufacturingwasdonesuccessfully.

5. The machine was tested and the purpose was successfullyexecuted.

I take this opportunity to express my sincere gratitude towards the Department of Mechanical Engineering, PES ModernCollegeofEngineeringShivajinagarPune,thatgave meanopportunityforpresentationofmyProjectStage Iin their esteemed organization. I would like to express my sincere thanks to my Project guide Prof. C. K. Gosavi and Head of the Department Prof S. Y. Bhosale without whose guidanceandadequatefacilities.Iwouldnothavecompleted

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1164

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

myProjectStage II,hisvaluableadvicemadeiteasyforme to proceed for this Project Stage II. I express my sincere thanks to Project Co Ordinator Prof. S. S. Darewar for his constant support and experienced guidance andproviding meprecioushelpandadvicewithoutwhichthesuccessful completion of this Project Stage I would not have been possible.IamalsothankfultoProf.Dr.Mrs.K.R.Joshi,PES ModernCollegeofEngineeringShivajinagarPune,forgiving menecessaryresourcesandsupporttocompletemyProject Stage II. Last but not the least, I thank all others, and especially my classmates and my family members who in onewayoranotherhelpedmeinthesuccessfulcompletion ofthiswork.

References:

[1] Design and Fabrication of Tamarind Cover and Seed Separation Machine A.R.Lende, P.A.Chandak, tanuja.chandak@yahoo.com,pukharaj@rediffmail.com

[2]IdentificationofAMechanismForMechanicalDeseeding Of Tamarind by Anagha Balan*, Arathy Krishnan, Josna.K, Libina Stephen, Er. Shivaji. K. P.** *Department of Farm Power Machinery and Energy, K.C.A.E.T, Tavanur, Malappuram, Kerala 679573 **Assistant Professor, DepartmentofFarmPowerMachineryandEnergy,K.C.A.E.T, Tavanur,Malappuram,Kerala 679573

[3] Tamarind seed processing and by products Arudra SrinivasaRao1*,ArudraAshokKumar2,MapakshiVenkata Ramana3 (1. Assistant Professor & Head, Dept. of Agro Energy, College of Agricultural Engineering, Madakasira, AndhraPraseh,India;2.AssistantProfessor,Dept.ofFarm Machinery & Power, College of Agricultural Engineering, Madakasira,AndhraPraseh,India;3.AssociateDean,College of Agricultural Engineering, Madakasira, Andhra Pradesh, India.)

[4]DEVELOPMENTANDEVALUATIONOFACONTINUOUS TYPETAMARINDDESEEDERParamasivanKarthickumar1, Narasingam Karpoora Sundara Pandian*1, Perumal Rajkumar1, Allimuthu Surendrakumar2, Murugesan Balakrishnan1 1Tamil Nadu Agricultural University, DepartmentofFoodandAgriculturalProcessEngineering, Coimbatore, India 2Tamil Nadu Agricultural University, AgriculturalMachineryResearchCentre,Coimbatore,India

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page1165