Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

ROBOTIC ARM CONTROL WITH WEIGHING SCALE

Abhirami Hariharan1, Salmiya S J2, Sneha PP3, Sreesanth k4, Prof. Binsa Mathew5

1,2,3,4Department of Electronicss and Communication MGMCET

5Prof. Binsa Mathew, Department of Electronicss and Communication MGMCET ***

Abstract Pick and place robot is widely used in different fields now a days. It is used in packaging, manufacturing, logistics etc. The intervention of robots have reduced the human labour tremendously. In our pick and place robot , a load cell is used to measure the weight of the object picked. Our robot consists of a robotic arm which could weigh while picking up an object, a stationary base and LCD screen to display the weight of the pick object. An electromagnet is used to pick the object up so metallic objects are picked easily. A sensor is placed in the stationary base of the robot that detects the presence of object. Position of target is fixed. Once the object is picked up the arm rotates, places the object at the target. Now the robot is free to pick up objects again. This can be used to sort the object on the basis of weight.

Key Words: Robotic arm, Load cell, Electromagnet, Pick and place roboy, Wheatstone bridge.

1. INTRODUCTION

Inthiseraofemergingtechnologies,robotshaveandwillbereplacingrolesofhumaninvariousfieldslikemanufacturing andlogistics.Robotsareofvarioustypesofwhichpickandplacerobotshavebeendiscussedhere.Fewmodelsofpickand placerobotsareRoboticarm,Cartesian,delta,fastpick ,andcollaborative based. Pick andplacerobotshave speededup theautomationprocessesinmanufacturingindustry.Also,thetimeconsumptioncanbereduced.

1. Pickandplacerobotconsistsofabasewhichisstationaryhere.

2. Rigidbodiesareconnectedusingjointswhicharemovableanddesignedaccordingtorequireddegreeoffreedom.

3. Theendeffector,hereandelectromagnetisattachedtothesecondrigidbody.

1.1 Problem definition

Usually in industries, it requires human labor to pick heavy weights and also weigh them simultaneously. Lifting heavy weightsforlongtimecanbetiringtohumanandthuswehaveamachinecontrolledfactoriesandindustries.Likewise,to tackle the major problem of labor and time, a pick and place robot is introduced here. The second problem being encountered here is the weight measurement which happens simultaneously while picking the object in the proposed system.Thus,thissystemisanintegratedapproachtowardstheproblemsinashippingandpackagingindustry.

2. LITERATURE SURVEY

Separation of degradable and non degradable waste using a robotic arm is being done in [1] This is done using android mobile connected via Bluetooth to a microcontroller which in turn controls robotic arm. AVR microcontroller is used to control the pick and place robot, there is a gripper which open according to size of object picked. It is controlled using android application via Bluetooth [2]. Using Atmega328p microcontroller, a robotic arm on a moving vehicle is built. Upward and downward movement controlled by push buttons. Soft catching arm to handle explosives. Based on microcontrollerbasedelectricalpressuresensor[3].Toperformfunctionsofalibrarybyarobot.thishasdevelopedin[4]. From fast detection of required book to picking it up and giving to user is done in here. Design and implementation of 5 DOF pick and place robot is discussed in [5]. It is designed using SOLIDWORKS18 and fabricated using 3D printing technology.ControlledusingArduinomicrocontrollerwithBluetoothmoduleconnectingovera smartphone. [6]givesan ideaonhowapickandplacerobotisconstructedusingamovingbaseandagripper.5motorsareusedformovementof thebaseandthearmstructure.

3. PROPOSED SYSTEM

Thesystemconsistsofthreemotorsforprovidinggripperandshaftmovement.Theendeffectororthegripperisattached with electromagnet to attract the object which needs to be picked up. This is ensured by controlling the arm motors throughpropercommandandusingamicrocontrollerAtmega328p.AnIRsensorisplacedinordertodetectthepresence

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

of object within its proximity, the object is picked up when the IR sensor signal goes high. The weight of the picked up object is measured using a load cell and the signal from this is amplified using an instrumental amplifier HX 711. The mainpartsofthesysteminclude.

1. Rover/manipulator:Rigidbodieslikecylinderorsphere,jointsandlinks.

2. Endeffector:Itisattachedtolastjointofroverandisusedforgrippingtheobject.It'sanalogoustohumanhand.

3. Actuators:componentslikemotors,hydrauliccylindersetc,whichconstitutedriversofrobot.

4. Sensors:Tosensetheconditionsofrobotandsurroundingsandhelpsinfunctioningofrobot.

5. Controller:Itisusedtocontroltheactuatorsbased onthefeedbackfromsensors.

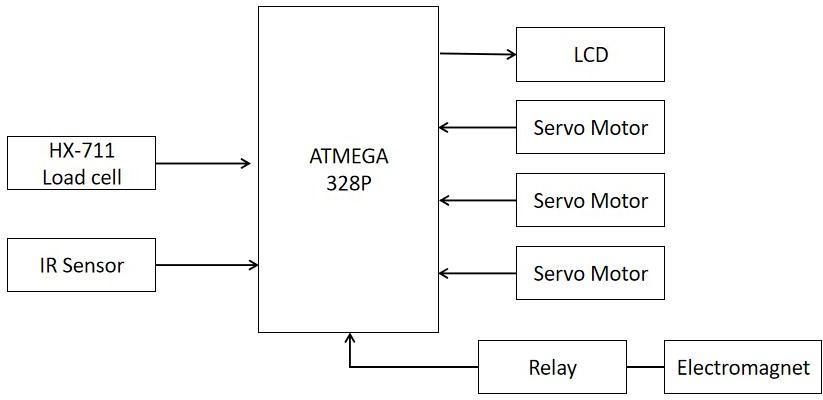

3.1 Block diagram

The position of object is sensed using IR sensor. The weight of the picked up object is calculated using load cell HX 711. Atmega328pistheusewhichcontrolsthefunctionofthepickandplacerobot.Themovementofarmiscontrolledusing servomotors.Andelectromagnetpicksuptheobject.TheweightisdisplayedinanLCD.WhenobjectissensedbytheIR sensor,signal goeshighconfirmingthepresenceofobject.Nowthearmrotateswiththehelpofservomotorandisbent down.Theelectromagneticcircuitswitchesonandpickstheobjectup.Oncetheobjectispickedupthemotorrotates,thus thebaserotatesandarmbentdowntothepositionoftarget.Simultaneouslytheweightoftheobjectismeasuredandafter planningtheobjectinthetarget,theweightisdisplayedontheLEDscreen.Nowthesensorisfreetosensethepresenceof anotherobject.

Fig -1:Blockdiagram

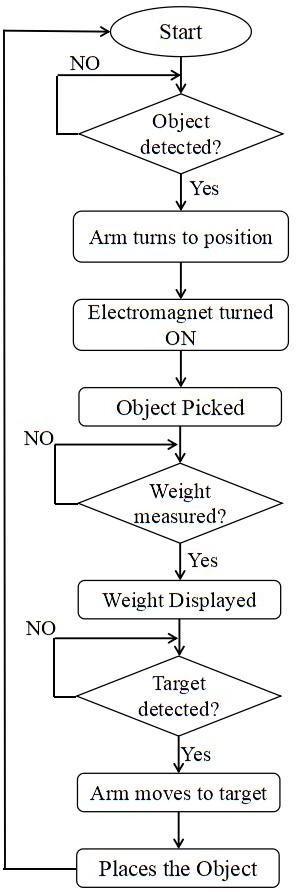

3.2 Flow Chart

Thedevice work byfirstdetectstheobject.Thesensor detectstheobjectonthearmturnstothe positionof theobject. Then the electromagnet is turned ON and the object is picked up. The weight is also measured and display on the LCD screen. Once the target is detected, arm move towards the target. Then, the electromagnet demagnetises and place the objectonthetarget.Afterplacingthetargetarmreturntonormalposition.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Fig 2:Flowchart

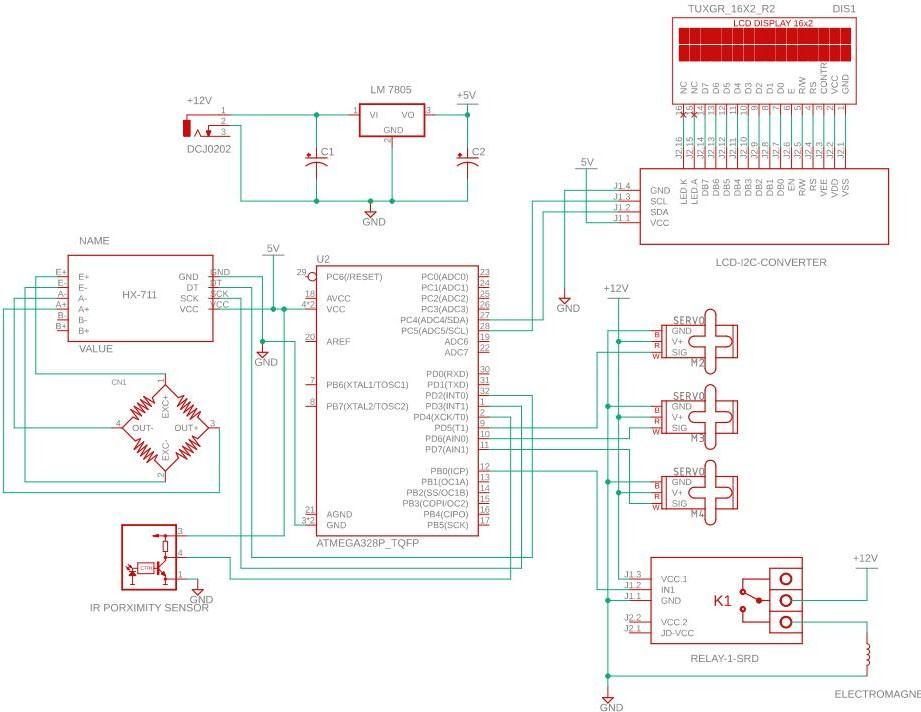

3.4 Circuit Diagram

Typically mounted on a stable stand, robotic arm is positioned to reach different areas to perform work. This type of roboticarmcan beredesignedandusedfor many useslikepackaging, itemcategorization, weight measurement etc. For example,pickandplacerobotsystemsmaybeusedtopickupitemsforanorderandplacetheminaboxforpackaging,or maybeintegratedwithbarcodescannersforcategorizingofshippingobjects.Inthepresenceofanobject,signalintheIR sensorgoeshigh,thismeanstheobjectisdetected.Thenthethreeservomotorsworktogethertorotatethearmandturns thearmtowardstheobject. Electromagneticcircuitis turned onand the object ispickedup. After thisthe arm isturned towards the target position with the help of motors and object is placed at the target, simultaneously the weight is also measured using load cell, which is wheat stone bridge configuration. the signal obtained from the load cell is amplified usingaHX 711loadcellamplifier.TheweightisdisplayedonLCDscreenwhiletheobjectisplacedinthetarget.

Fig 3:CircuitDiagram

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

5. RESULT AND DISCUSSIONS

5.1 Result

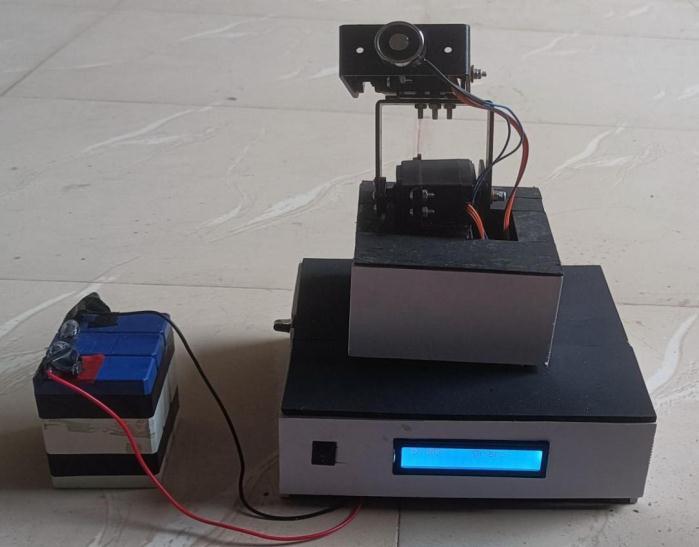

Pick and place robot with an electromagnetic arm can be used to pick metallic objects and thus sort metals from non metals.Theobjectisplacedonafixedtarget.Theuseofsensorshavehelpedtodetectthepresenceofobjectwhileplaced invicinitytothedevice.Sincethereisn’tanychangesintheinfrastructureofwarehousespaceisneededfortherobotto function.Pickandplacerobotonlyneedsminimalmaintenancedespiteofthecomplexityintechnology.

Usingthepropercleaningtechniquesandmaintenanceguidelines,thepickandplacerobotcanbemaintained.Thismakes thetotalcostforownershipofpickandplacerobotmuchlesserthanwarehouseautomationtechnologies,whichisalmost threethousandrupeesfortheproductinsmallscale.Thisprojectisverymucheconomical.

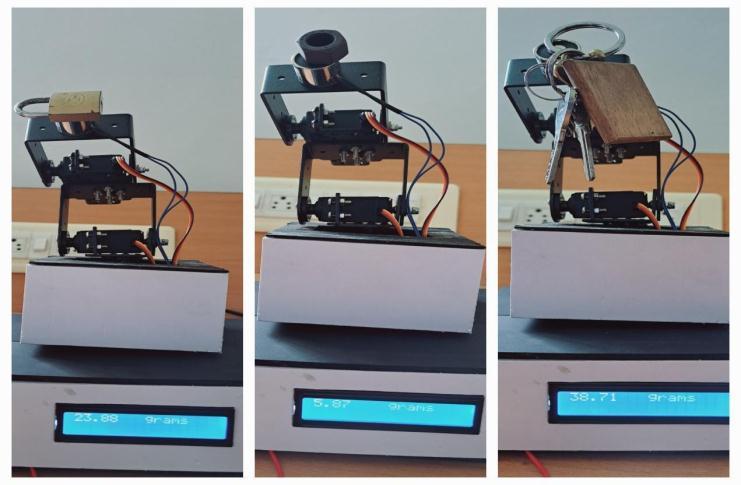

Fig

5:

(Fig

A,

FigB,FigC)Imagesofpickingdifferentobjects

A. The IR sensor senses a lock , electromagnetic circuit switches on, attracts the object moves towards the target while measuringtheweightwhichis23.88gandthenplacesinthetarget,B.AmetallicnutisdetectedattheIRsensor,picksit up and measures it's weight which is 5.87 g and positions it in the target. C. A key is detected, picked up and weight measuredanddisplayed 38.71gand placesinthetarget.

Table -1: ComparisonofWeight

Item Original weight Weight measured by Prototype Lock 36.04g 29.07g Nut 12.4g 5.87g Key 45.07g 38.71g

Weightoftheitemspickedupwhenmeasuredinbothdigitalweighingmachineandtheprototypearecomparable.

5.3 Future scope

Ithascertainlimitationswhichisthatonlymetallicobjectcanbepickedup.Whileimplementinginlargescaletheweight of the object picked up will also the varied, thus a more precise weighing scale should be used. This robot could also be mademovingbyaddedwheelsandextramotorswhichcouldbeusefulinwarehouses,tomovearoundandpickstocksand place them while measuring its weight simultaneously. But this would make it costlier. Various other sensors like QR sensorcanbeincorporatedtosortpackagesincourierserviceorsupermarkets.Variousotherapplicationslikecalculating thecostwhilepickingtheitemcanbeimplementedintheserobots.

5. CONCLUSION

We have successfully reviewed several research papers published by different authors for the better understanding of development of robotic arm. The robotic arm moves to pick and place object successfully by using sensors and simultaneously weight of the object picked is also measured. From the existing pick and place robot, we have added different features to it. The main feature added is measuring weight of the picked-up object. The secondary feature we have introduced in our prototype is electromagnet which is placed in the gripper portion of the picking arm. The measurement of picked up object is beneficial in areas lick courier services, supermarket, etc where sorting items according to the weight is required for easy functioning of the system and customer feasibility. This project aims at reducingthelabourofhuman.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

REFERENCES

[1] ArkaSain,JanardanDattaniandDharaMMehta,“DesignandImplementationofWirelessControlofPickandPlace Robot Arm”, International Journal of Advanced Research in Engineering and Technology (IJARET), p ISSN: 0976 6480ande ISSN:0976 6499,Volume9,Issue3,May June2018.

[2] M.J.Sawarkar,TruptiR.Raut,NutanP.Nemad,SonalC.Meshram,PournimaP.Tabhane,“PickandPlaceRoboticArm Using Android Device”, International Research Journal of Engineering and Technology (IRJET), e-ISSN: 2395-0056 andp-ISSN:2395-0072,Volume:04,Issue:03,Mar-2017.

[3] MuhammedJabir.N.K,NeethaJohn,MuhammedFayas,MidhunMohan,MidhunSajeev,Safwan.C.N,“WirelessControl of Pick and Place Robotic Arm Using an Android Application”, International Journel of Advanced Research in Electrical,ElectronicsandinstrumentationEngineering,p_x0002_ISSN:2320 3765,e ISSN:2278 8875,Volume4, Issue4,April2015.

[4] BabuGanesh.K,HariShankar.K,KolanchiMani.V,Thennarasu.S,Ramu.S,“AndroidControlledRoboticArmVehicle”, AdvancesinNaturalandAppliedSciences,p ISSN:1995 0772,e ISSN:1998 1090,2017February11.

[5] ElProCus Technologies Pvt Ltd, Unit # 406. “Pick N Place Robot” https://www.elprocus.com/pick n place robot/ (DatedonJune2022)

BIOGRAPHIES

AbhiramiHariharan,Btechstudent, Department ofElectronics and Communication Engineering, MGMcollegeofengineeringandtechnology,ernakulam,Kerala.

SalmiyaSJ,Btechstudent,DepartmentofElectronicsandCommunication Engineering, MGM college ofengineeringandtechnology,ernakulam,Kerala.

SnehaPP,Btechstudent,DepartmentofElectronicsandCommunication Engineering, MGM college ofengineeringandtechnology,ernakulam,Kerala.

SreesanthK,Btechstudent,DepartmentofElectronicsandCommunication Engineering, MGM college ofengineeringandtechnology,ernakulam,Kerala.

Asst.Professor,DeptofElectronicsandCommunication,MGMColleageofEngineeringandTechnology, pampakuda