International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

1,2,3,4 Btech students, Department of Mechanical Engineering, Mangalam College Of Engineering ,Kerala, India 686631

5,6 Faculty, Department of Mechanical Engineering, Mangalam College Of Engineering ,Kerala, India 686631 ***

Abstract - The natural fibers have attracted substantial importance as potential structural material. Natural fibers are replacing the traditional man made fibers as reinforcements. They have many advantages over man made fibers . Natural Fibers are low in cost and have high mechanical properties. Natural fiber is a good renewable and biodegradable . Availability of natural fibers and ease of manufacturing have tempted many researchers to try locally available fibers and to study their feasibility of reinforcement purposes. Geopolymer composites were prepared from neat and alkali treated sugarcane bagasse fibers. The results proved that alkali treatment leads to an increase in stiffness and strength of composites . In this study, epoxy based composites has been reinforced with sugarcane bagasse fiber and are fabricated. Bagasse is a by product of the milling process after production of sugar. Bagasse is mainly used as a burning raw material in the sugarcane millfurnaces.

Keywords: Natural Fibres, Miliing Process, Geopolymer composite,Biodegradable,BagasseFibre.

Composites are also known as Fiber Reinforced Polymer composites, are made from a polymer matrix that is reinforced with man made or natural fiber or other reinforcing material. The matrix protects the fibers from environmental and external damage. Matrix transfers the load between the fibers. The fibers provide strength and stiffness to reinforce the matrix and also help to resist cracksandfractures. Compositematerialsarealsocalled composition materials or shortened to composites. Compositematerialsarematerialsmadefromtwoormore constituent materials with significantly different physical or chemical properties. When we combined these materials, produce a material with different characteristics from the individual components. Composites are materials that comprise strong load carrying material is known as reinforcement. Reinforcement provides stiffness and strength, helping to support structural load . Bio based composites possess a widerangeofend of lifepossibilitiessuchasincineration, recovery/recycling and composting . The interactions,

betweenfillerandtheepoxymatrix,resultsintheincrease of mechanical strength. NaOH treatment results in improvementofstrengthofthefibre.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

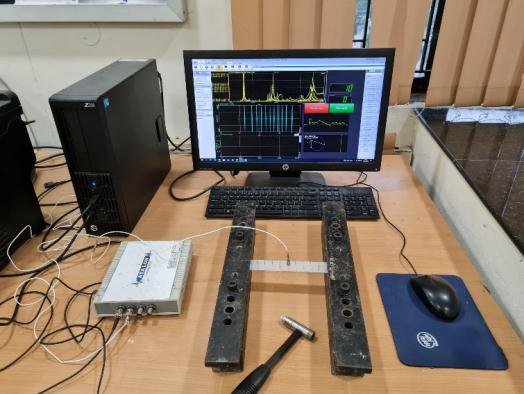

Sugarcane stalk is composed of an outer rind and inner pith.Theouterlayersofbagasseishardfibroussubstance and inside is soft material. The experiment was initiated fromthepreparationofthesugarcanebagasse.Achemical treatmentwasperformedonthebagassefibers.Thefibers were submerged in 30 ml NaOH for 4 hours at temperature of 80 deg C . Then they were rinsed with distilled water to remove excess NaOH from the surface then and then dried up in an oven at temperature of 20° for3seconds.

Fig.22EpoxyResinLY556andHardnerHY951

Fig.2.1(a)Chemicaltreatmentofbagasse

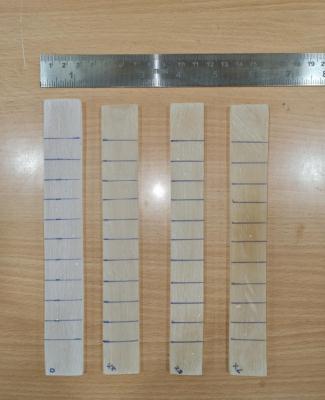

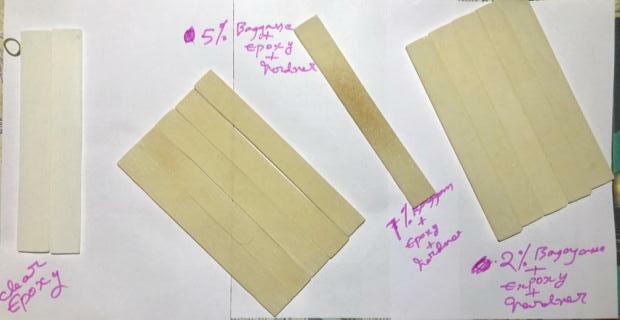

Four wooden molds of dimension 250x250x10 mm were use for casting the composites. The samples were casted with 0, 2, 5 and 7 % volume fraction of fibers. For different volume fraction of fibers, a calculatedamount of epoxy resin and hardener in the ratio of 10:1 weight was thoroughly mixed in a jar and stirred well. Here shear mixingisdoneinthisexperiment.Itisthenplacedinahot watertoremoveairbubblesthatgotintroduced.Afterthat mixture was poured in the mould and allowed to cure at room temperature for 24 hrs. After 24 hrs the samples were taken out of the mold and it is then cut into desired shapesforthecorrespondingtest.Thesamplesfortensile test and Vibration test were prepared in the following volumefractions:

The Epoxy Resin used in this experiment is Epoxy Resin LY556 and Hardner is HY951. The viscosity of conventional epoxy resins is higher and they are more expensive compared to polyester resins. The cured resins havegoodmechanicalandthermalproperties.

Fig.23(a)EpoxyandHardnermixing

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

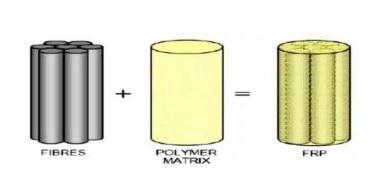

Modal analysis of epoxy/bagase Nanocomposite

Fig.2.3(b)Shearmixing Fig.23(c)CastingofSample Fig 23(d)SampleComposites

Fig3.1(a)variousbagassesamplespreparedfordynamic analysis

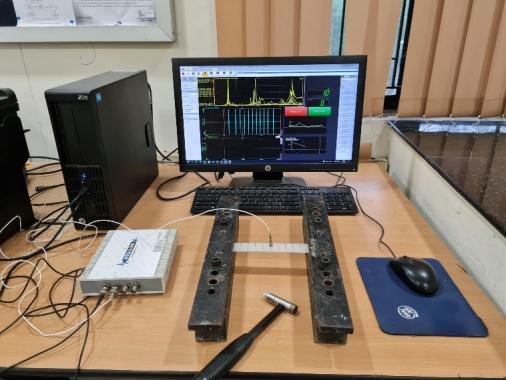

The modal analysis of the polymer composite is demonstrated by performing an experiment on a miniaturemodelofbagassereinforcedpolymercomposite beamwith200mminlength,25mminwidth,and4mmin thickness under cantilever end condition as shown in figure . The polymer composite beam is fabricated using DGEBA epoxy resin and hardener to carry out the experimental test. First, the bagasse reinforced polymer composite beam is fixed on the CFCF end condition followed byCFFF,thenthe data acquisitionsystem(DAQ) wasconnected to the computer system and the other end of the DAQ was connected to the accelerometer and the impact hammer. The impact hammer was employed to excite the bagasse reinforced polymer composite beam, and the sensor was mounted at the top layer of the compositebeam,whichcouldgettheresponsesignalsdue to the excitation. The DAQ was used to convert the responsesignaltofrequencyresponsefunctionandcanbe seeninthedisplayunitofDewesoftsoftware.

(b)

International Research Journal of Engineering and Technology (IRJET)

e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

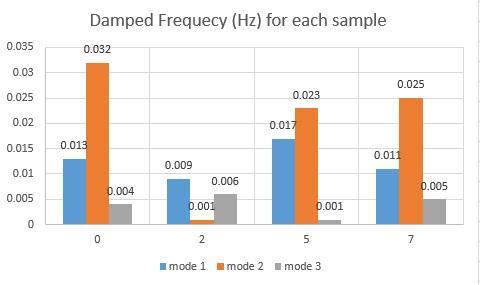

Graph 3.1 (b) Damping factors of the various bagasse reinforced composites in CFCF boundary condition.

Fig3.1 Modalanalysistestsetup(b)Epoxycomposite(c) bagassereinforcedcomposite.

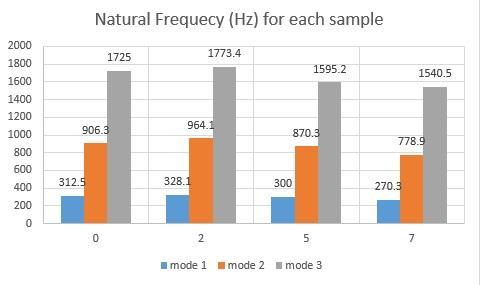

Table 3.1 (a) Natural Frequencies of the various bagasse reinforced composites in CFCF boundary condition.

Wt% Natural Frequencies (Hz)

Mode 1 Mode 2 Mode 3 0 312.5 906.3 1725.0 2 328.1 964.1 1773.4 5 300.0 870.3 1595.2 7 270.3 778.9 1540.5

Graph 3.1 (a) Natural Frequencies of the various bagasse reinforced composites in CFCF boundary condition.

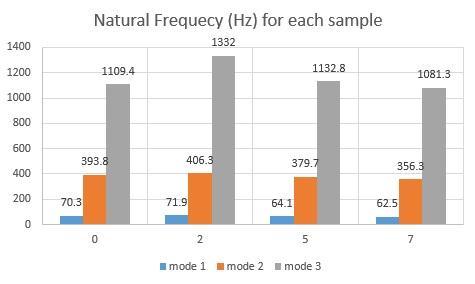

Table 3.1 (c) Natural Frequencies of the various bagasse reinforced composites in CFFF boundary condition.

Wt% Natural Frequencies (Hz)

Mode 1 Mode 2 Mode 3 0 70.3 393.8 1109.4 2 71.9 406.3 1332.0 5 64.1 379.7 1132.8 7 62.5 356.3 1081.3

Graph 3.1 (c) Natural Frequencies of the various bagasse reinforced composites in CFFF boundary condition.

Table 3.1 (b) Damping factors of the various bagasse reinforced composites in CFCF boundary condition.

Wt%

Damping Factors

Mode 1 Mode 2 Mode 3 0 0.013 0.032 0.004 2 0.009 0.001 0.006 5 0.017 0.023 0.001 7 0.011 0.025 0.005

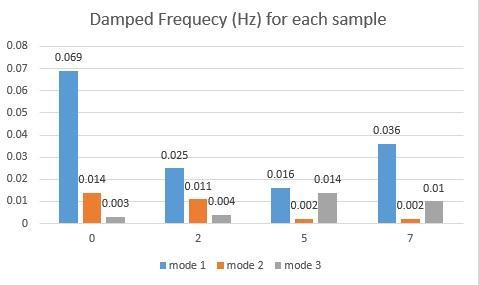

Table 3.1 (d) Damping factors of the various bagasse

reinforced composites in CFFF boundary condition.

Wt% Damping Factors

Mode 1 Mode 2 Mode 3 0 0.069 0.014 0.003 2 0.025 0.011 0.004 5 0.016 0.002 0.014 7 0.036 0.002 0.01

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

Graph 3.1 (d) Damping factors of the various bagasse reinforced composites in CFFF boundary condition.

CFFF ClampedFreeFreeFree CFCF ClampedFreeClampedFree

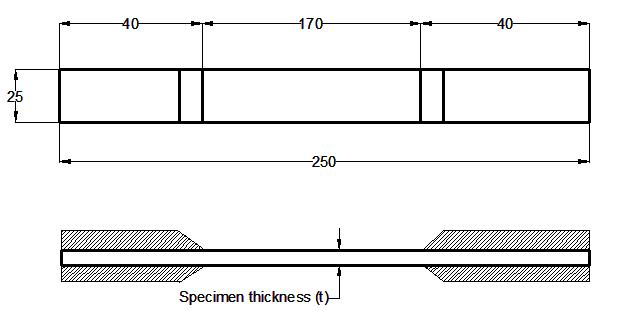

The common specimen for tensile test is based on ASTM D3039. It is constant rectangular cross section of 4mm thick, 25 mm wide and 250 mm long. Specimens are placed in the grips of a Universal Test Machine at a specified grip separation and pulled until failure. For ASTM D3039 the test speed can be determined by the material specification . A typical test speed for standard testspecimensis2mm/min.

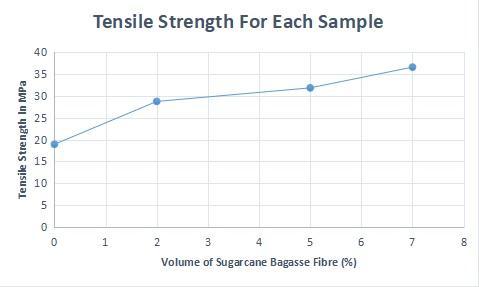

Graph3.2(a)Variationoftensilestrengthwithdifferentof sugarcanebagassefiber

The experimental results of composite testing of different fibercontent inTable3.2

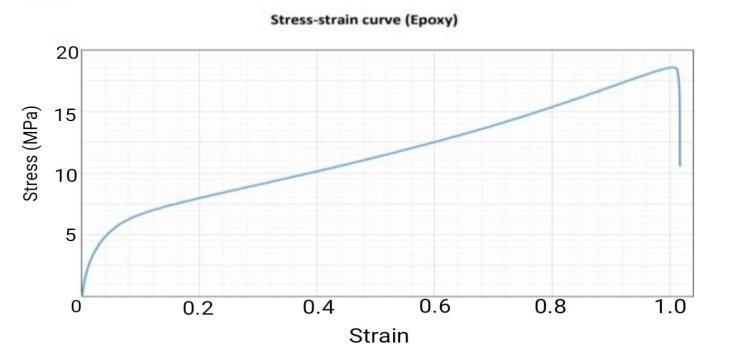

Graph 3.2(b) Stress Strain Curve for 0% Sugarcane BagasseFibre.

SlNo FibreContent(%) TensileStrength(MPa) 1. 0 18.92 2. 2 28.70 3. 5 31.80 4. 7 36.53

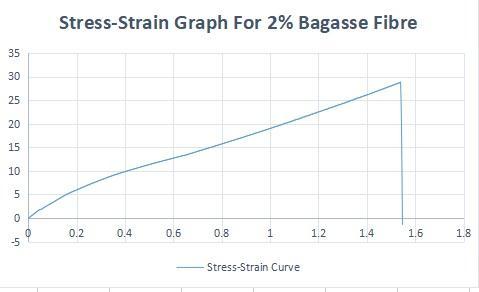

Graph3.2(c)Stress StrainCurvefor2%Sugarcane BagasseFibre.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN:2395 0072

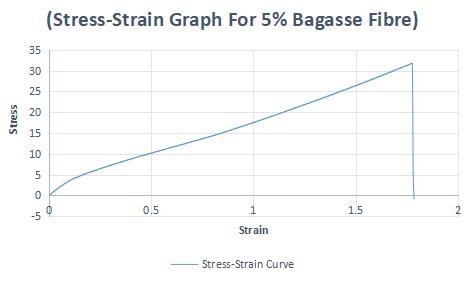

increaseswithincreaseintheconcentrationofthebagasse fibre.Compositecontaining7%ofbagassefibrehashigher ultimate strength or higher breaking point than 5% and the composite containing 5% of bagasse fibre has higher ultimate strength than 2% and so on . Therefore we can conclude from the result that the tensile strength of a composite increases with increase in the concentration of thefibrepresentinthecomposite.

Graph3.2(d)Stress StrainCurvefor5%Sugarcane BagasseFibre.

Thenaturalfrequenciesofthevariousweightpercentages (0, 2, 5, 7%) of bagasse reinforced polymer composite beams under CFCF and CFFF boundary conditions are tabulated in Table 31(a), 3.1(b),3.1 (c) and 3.1(d). From the experimental results it can be seen that the polymer compositebeamswith2wt%ofbagassereinforcementhas higher natural frequency than those of the other composite beams. This might be because the significant interaction between the bagasse and epoxy composite's intermolecular polymer chain increases the natural frequencies of the composite beam. The increase in naturalfrequencyofthecompositebeamaccordingtothe increaseintheweightconcentrationofthebagassefibreis shown in graph 31 (a) and 31(c). The fluctuation in the damping factors of the composite beam under various weight percentages of bagasse fibre is under CFCF and CFFF is shown in table 31(b) and 31(d). By plotting the graph under various conditions it is seen that composite beamshaving0wt%ishavinghigherdamping factorthan othercompositebeamsundervariouswt%.

Fromgraph 3.1(a),(b), (c)and(d)itis observedthat the composite beams having higher weight concentration of bagasse fibre is not having the highest value of natural frequencyordampingfactor.Thisisbecausethestructure gotstifferorthedistributionofthefillergotconcentrated indifferentareasofthecompositewhichisthereasonfor the decreased damping and natural frequencies. The amplitude of the resonance peak decreases at a lower frequency. From this experiment we can conclude that when natural frequency of the composite increases, correspondingdampingfactordecreases.

The sugarcane bagasse fiber composite material has a much higher tensile strength and modulus of elasticity thantheothermaterialshaving0%concentrationoffibre. From graph 32 (b), (c) and (d) we can see that the ultimate strength or the breaking point of the material

Factor value:

[1] Korniejenko,K.,Frączek,E.,Pytlak,E.andAdamski,M., 2016. Mechanical properties of geopolymer composites reinforced with natural fibers. Procedia Engineering,151,pp.388 393.

[2] G. Silva, S. Kim, R. Aguilar, et al., Natural fibers as reinforcementadditivesforgeopolymers Areviewof potential eco friendlyapplicationstotheconstruction industry, Sustainable Materials and Technologies (2018)

[3] A Review on Composition and Properties of Bagasse Fibers, SachinYadav, Gourav Gupta, Ravi Bhatnagar ISSN2229 5518

[4] Shen, L., 2014. Synthetic Fibers from Renewable Resources.InLightweightMaterialsfromBiopolymers andBiofibers(pp.37 52).AmericanChemicalSociety

[5] SachinYadav, G.G. and Bhatnagar, R., 2015. A review on composition and properties of bagasse fibers. Cellulose,45,p.55.

[6] Silva, G., Kim, S., Aguilar, R. and Nakamatsu, J., 2020. Natural fibers as reinforcement additives for geopolymers A review of potential eco friendly applications to the construction industry. Sustainable MaterialsandTechnologies,23,p.e00132.

[7] International Journal of Composite Materials 2017, 7(5):150 154DOI:10.5923/j.cmaterials.20170705.04 A Study on the Vibration Characteristics of Bagasse Banana Fibre Hybrid Composite Pavana Kumara B. * , JohnPaulVas,ShreerangaBhat,KarthikMadhyasthaN