International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Khandelwal1 , Sourabh Ajit Varagiri2, Tribhuvan Singh Rathore3 , Suraj Prashad Sharma4

1 4SMEC, Vellore Institute of Technology, Vellore, Tamil Nadu, India. ***

Abstract The welding input parameters of any welding have a major role on the quality, productivity and expenses of the assembly formed. In this experimental study, the spot welding parameters were optimized and by conducting the T S strength test of the IF steel weld the parameter was validated. Also, the effects of parameters on the weld were studied. The experimental study is conducted by using the Taguchi design method by considering three different levels of process parameters. The RSW input parameters chosen were welding current, welding time and pressure with 3 different levels of each one of them. An L9 orthogonal array was designed for Taguchi analysis. The S/N ratio was determined after conducting the T S strength test of the weld material. The importance level of each welding parameter for tensile test is done by the Analysis of Variance (ANOVA) technique. Hence, it can be concluded that Taguchi method helps in increasing the welding quality by optimizing the weld parameters in the RSW process. Finally, it can be validated that we can increase the tensile shear strength or in broader terms, the quality of the weld by using the optimum RSW parameters.

Index terms Resistance Spot Welding (RSW), Tensile Shear Strength, Taguchi Method, S/N Ratio.

ResistanceSpotWelding(RSW)isregularlyusedasasuccessfuljoiningmethodforavarietyofjobsintheautomotiveand manufacturingfields[1][9]. Inthispaper,atrialhasbeendonetooptimizeresistancespotweldingparametersofIFSteel sheets.Thespot weldingprocessparametershaveadirectimpactontheweldstrengthandquality[3].Thequalityofweldis determinedbyitsstrength,geometryandotherproperties.Iftheweldingparametersareoptimizedthentheweldqualitywill alsoimprove[5].

Themajormottooftheresearchistodeterminetheoptimuminputparametersofweldingsuchasweldingcurrent,pressure, weldingtimeetc.andtostudytheireffectonweldquality.Inthisstudy,wehaveperformeddifferenttestsontheweldsuchas tensileshearstrengthtest,microstructuralanalysisandfinallyfindingoutthedefectscreatedduringtheweldingprocess.We haveappliedtheTaguchiDesignMethodinordertoreducethenumberofexperimentswithoutlosingthestatisticalaccuracy.

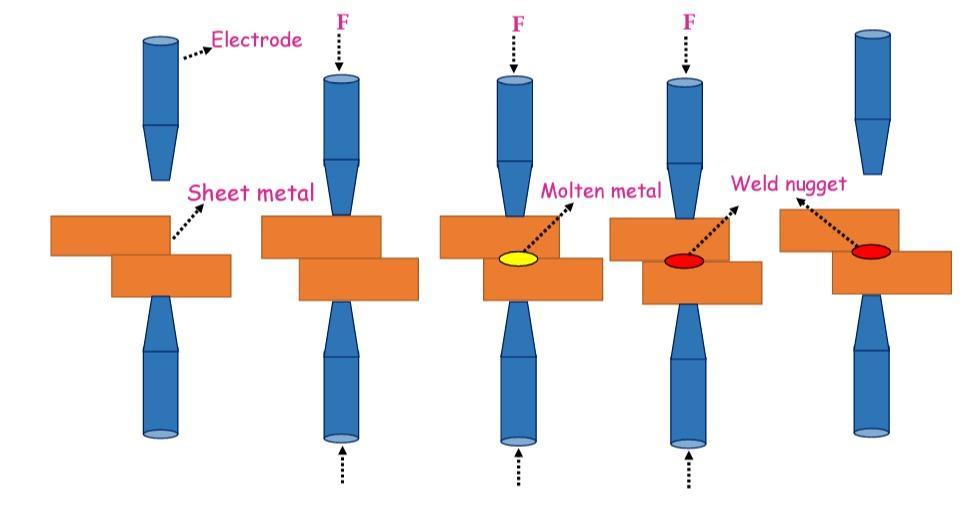

Resistanceweldingisofvarioustypes,butoneofthemaintypesisResistanceSpot Weldingwhichisbasicallyusedfor coalescenceoftwometalsheets bythehelpofpressureandheatobtainedbyelectriccurrentontheweldzone.Bythehelpof copperalloyelectrode,electriccurrentandpressureisappliedonthesteelsheets.Boththecopperalloyelectrodesareplaced oppositetoeachotherseparatedbythemetalsheets.Theheatwhichisdissipatedmeltsthemetalandthepressurewhichis appliedfromtheelectrodessqueezesmoltenmetaltoformthe“nugget”.Thisnuggetortheweldcreatedduringtheprocessisin theformofasmalldotandthatiswhyitiscalledasSpotWelding[2].Resistancespotweldingisbasicallyusedforcoalescenceof twoelectricallyconductivemetalsheetslikelowcarbonsteel,aluminium,etc.Itisusuallyusedtomanufactureautomobile components.[1].Avehiclegenerallyhasover1000spotweldsoveritsbodypanels.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Figure - 1:SpotWeldingStages

SushreeSefaliMishra[1]shedslightontheRSWofdifferentdissimilarmetalsheetsandtheiranalysis.Itdiscussesthevarious factorsthatdeterminecorrosionfatiguestrength.ThemetalsheetsanalysedwereAluminium Zinccoatedlowcarbonsteeland Stainless SteelGalvanizedsteel.Itwasconcludedthatcorrosionfatiguestrengthremainsunaffectedwhendifferentstrength levelsofthematerialswereapplied.Itwasalsofoundoutthatwiththeincreaseinsheetthicknesstheoverallfatiguestrength oftheweldedstructuregetsincreased.

ShravanSinghRaoetal.[2]intheirstudymainlydealwiththeestimationofcriticalnuggetdiameterandvariationindifferent processparametersofhighstrengthinterstitialfreesteel.Themechanicalpropertiesweredeterminedthroughtensiletesting onUniversalTestingMachine.Athicknessof1.6mmwasconsidered.Attheendoftheexperimentalanalysis,itwasfoundout thatasthecontactresistanceincreasesthenuggetdiameterisfoundtodecrease.Asmoreheatisgenerated,tensileshear strengthalsogetsincreased.

SachinKJadavetal.[3],intheirresearchmainlystudiedtheimpactofvariousRSWprocessparametersonthequalityofthe jointformedbywelding.Thestudywasperformedbychangingthevaluesofweldtime,weldcurrent,holdingtimeandsqueeze time.T SstrengthoftheweldisthemeasureoftheweldqualitywhichwasdeterminedusingtheGRAMethod.Theoptimum weldingparametersofthespot weldingprocesswasobtainedbythehelpofgreyrelationalanalysis.

ManojRautetal.[4]estimatethemaximumtensilestrengthofthespotweldafteroptimizingtheweldingparameters.The parametersrequiredforthe weldingwerefound outusingtheTaguchimethod. The variousinprocessparameterswere studiedusingtheS/Nratioanalysis.TheresultsobtainedvalidatedandupheldtheTaguchimethod.Theweldingparameter directlyaffectsthequalityoftheweldanditsstrengthinparticular.Itmaycausethestrengthoftheweldtoriseorfallbasedon theparameterschosen.

PPChoughuleetal.[5],intheirresearchcarryouttheresistancespotweldingoftwonon similarmetalsnamelymildsteeland stainlesssteelplatesand studytheeffectofparameterslikeweldingcurrent,pressure,weldingtimeontensilestrengthand further analysed by analysis of variance, the dimension of specimens is 150*25*1 mm, different parameters is used to determinegoodresultofnuggetdiameterandhightensilestrengthandothermechanicalproperties,it’sobservedthatincrease inweldingcurrentinspotweldingofdissimilarmetalincreasesnuggetdiameter.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

VijayKamble[6]performsresistancespotweldingonlowcarbonsteelandexperimentandteststheeffectofvariousinput parameterssuchasweldforce,weldcurrent,weldtimeandthediameteroftheelectrodeontheT Sstrengthofspecimens.To findsettingoftheprocessparametersTaguchi'sexperimentaldesignmethodisusedandbyusingS/N ratio,andANOVA optimumparametercombinationwasdetermined.Intheexperiment1mmand2mmsheetisusedwithdifferentparameters. Iftheweldingcurrentandweldingtimeisincreasedtoahigherlevel,thenitwilldeterioratetheweldqualityandtheelectrode willgetoverheated.Thiswillalsonegativelyaffecttheweldstrength.

ShaikSafeeetal.[7],intheirstudy,carryoutmanyexperimentswithdifferentparameterssuchasweldingforce,welding currentandweldingtimetofindoutbestoutcomeandtheirinfluenceontheRSWprocess.Taguchidesignmethod,S/Nratio andANOVAareusedforcheckingtheeffectofdifferentparametersonspotwelding.2typesofspecimensofthickness0.8mm and1mmareusedwithdifferentprocessparameterlevelsandS/Nratio,directtensilestrengthismeasured.For0.8mm, weldingcurrentandweldingtimearearethemajorparametersandfor1mmspecimen,weldingcurrentandweldingforceare themajorparameters.

PampaGhoshetal.[8]selectedtwotypesofIFHSmaterialfortheirstudywhicharebatchannealedIFHSandcontinuous annealedIFHS.Differentcompositions(C,N,P,S,Al,Mn,TiandNb)ofbothtypesofmaterialareusedtostudytheeffectof composition on IFHS. Scanning electron microscopy (SEM) is used to investigate microscopy and transmission electron microscopyisusedforstudyingprecipitationbehaviour.Boththinfoilmethodandcarbonextractionmethodisused.Inthis paperdifferentprecipitationrelationwithtextureandformabilityanditalsoeffect,strength,andremovalofCfromIFsteelis observed.

MinJou[9]observedthat itisimpossibletoexaminetheweldnuggetsizebythermalmodel,amethodtoidentifythenugget sizeistomeasuretheelectrodedisplacementcausedbythecombinedthermalexpansionandsolid to liquidvolumechangein theworkpieces,inthispaperitisdiscussedhowfactorslikedifferentpartfit upconditions,surfacecondition,basematerial canaffectdisplacementcurveandexperimentdoneinthisresearchpaperdiscussthephenomenonofhowchangesof%heat inputaffecttheelectrodedisplacementcurve.

ThematerialusedintheexperimentisInterstitialFree(IF)Steel.IFsteelisatypeofsteelwithnointerstitialsoluteatomsto strainthesolidironlatticewhichresultsinasoftsteel.IFsteelshaveinterstitialfreeBodyCentredCubic(BCC)ferritematrix. SincealloyingelementslikeMnandSiarepresentintheIFSteel,ithasverygoodmechanicalproperties[2].Sincethefraction of precipitate in IF steel is very low hence, it is also called as Clean Steel. Vacuum degassing is used to eliminate carbon monoxide and other such gases and hence IF steel has less percentage of carbon. There are very minimal changes in the mechanical propertiesofIF steel with the passage oftimesince the carbonatomsintheinterstitial sitesare replacedby TitaniumwhichformsTitaniumCarbide.IF steelshavehighformabilityandstrainratewhereasitsyieldstrengthisverylow [8]

Table 1

%)

C Si Mn P S N Al Nb TI

0.002 0.01 0.15 0.01 0.01 0.0025 0.04 0.016 0.025

Theweldinginputparametersinanyweldingareveryimportant.Ifanyoneparameterischangedthenitwillaffectallthe otherparametersandtheoverallqualityoftheweldwillalsobeaffected.Theoptimizedspot weldingparameterwillresultin highstrengthjointsandimprovedweldquality.Weldinginputparameterswhichareconsideredduringtheexperimentswere:

Welding time: Weldingtimereferstothetimeintervalduringwhichtheweldcurrentispassedthroughthemetalsheetstobe welded.Astheheatgenerationincreases,weldingtimealsoincreases.Afterpassingtheweldcurrenttheheatpassesthrough theweldareaandinthemetalsheetandalsotheheatgetsdissipatedfromtheopensurfacetothenearbysurroundings,which resultsintheformationofweldifproperweldtimeisgiven.Iftheweldtimeisstretchedthenexpulsioncanoccurandeventhe electrodemaygetdistorted.[4]

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Welding Current: Weldingcurrentisdefinedastheelectricity/currentflowingthroughtheelectrodetothemetalsheetbeing welded. With the rise in weld current, the dimensions of the weld nugget increase. But if the current is very large then expulsionsmayoccurandcancausedamagetotheelectrode.[4]

Electrode Force or Pressure per square inch: Theelectrodeforcehelpsinsqueezingthemetalsheetstobejoinedtogether. Theforceshouldbehighenoughotherwisethequalityoftheweldwillgetcompromised.Buttheelectrodeforceshouldnotbe verylargebecauseifforceisverylargethentheareaofcontactwillgetincreasedanditmayleadinlowdensityofcurrentand lesscontactresistance.This,inturn,willdecreasetheheatbeinggeneratedandwillreducethediameterofweldnugget.[4]

TheprocessparametersrangewasdeterminedbytheDesignofExperiment(DOE)approach.Apparently,manyweldingtests werefound,butafterthetrialtests,thefeasibleworkingrangewasdetermined.Differentcombinationsofweldingparameters wereusedinthetestandthenuggetwascheckedtodecidewhetherthetestingvalueiscorrect.Thegiventablerepresentsthe selectedweldingprocessparametersrangeasrestparametersresultedinweldingdefectsandincompletepenetration.

Table 2: ProcessparameterswiththeirvaluesatthreedifferentlevelsinDOE

Levels Welding time cycle (ms) (A) Welding current ka) (B) Pressure per sq. inch (C) 1 5.00 15 50.00 2 12.50 45 67.50 3 20.00 75 85.00

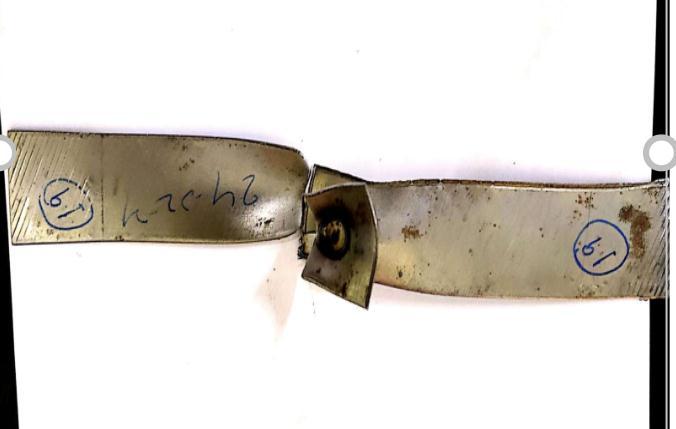

Figure 2:IFSteelSheetspostWelding

TheTensileshearstrengthtestisameasuretodeterminetheweldquality[7].Inthisexperimentalstudy,thetestswere conductedonthespecimenwhoselengthwas100mm,width25mmandthickness1.2mm,asshowninthefigure2.

Inordertogethighqualitywithoutcompromisingthecost,theTaguchiDesignMethodoptimizestheinputparameters.Itis sobecausetheoptimizedinputparametersobtainedfromtheTaguchianalysisdoesnotchangewithchangesinsurroundingsor anyotherchanges.Inthisstudy,TaguchimethodwasusedwhereinexperimentsweredonebyapplyingL9OrthogonalArray

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

with3parameters(pressure,weldingtimeandweldingcurrent)with3distinguishedlevels.Iftherearemoreinputparameters thennumberofexperimentstobedonealsobecomesmoreduetowhichthecomplexityalsoincreases.So,tosolvethisproblem, TaguchiDesignmethodisusedwhereinaspecialorthogonalmatrixisdevelopedwhichdecreasesthenumberofexperiments after optimizing the entire input parameters. This orthogonal array helps the designer to study the impact of multiple controllable factors and their variations in a rapid wayand also decreases the cost.Hence, all the workpieces used in the experiment are welded by the help of designof experiment mentioned inthebelowtable, inwhichwehaveconsidered3 WeldingParametersand3differentlevelsofeveryparameter.Hence,anineLevelArray(L9)forstudyingthelevelsofallthe3 parametersthreetimeshasbeenconstructed.TheL9orthogonalarrayismoreeffectiveascomparedtoL6arrayiftimeis availableandcostisnotanissueasinL9,thereare3levelsandallofthemaretestedbyalltheparameters.Andthiscostwillbe obviouslylessthanthecompleteanalysis,asthenumberneededforentirefactorialanalysiswillbeN=LP=33=27;whereN= numberofexperiments,L=numberofLevelsandP=numberofParameters.[4]

Table 4: L9OrthogonalArray

Experiment Welding time (ms) Welding current(ka) Pressure per sq. inch

1 5 15 50 2 5 45 67.5 3 5 75 85 4 12.5 15 67.5 5 12.5 45 85 6 12.5 75 50 7 20 15 85 8 20 45 50 9 20 75 67.5

ThetensileshearstrengthtestwasperformedusingtheUniversalTestingMachinefortheentirespecimenmentionedin theL9Orthogonalarrayandtheresultsobtainedareasfollows:

Table 5: T Sstrengthtestresults

Experiment Welding time (ms) Welding current (ka) Pressure per sq. inch T s strength

1 5 15 50 10 2 5 45 67.5 6.95 3 5 75 85 10.67 4 12.5 15 67.5 11.05 5 12.5 45 85 9.73 6 12.5 75 50 10.80 7 20 15 85 10.25 8 20 45 50 10.45 9 20 75 67.5 10.40

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Figure 4: WeldafterTensileshearstrengthtest

Alossfunctionisdefinedtocalculatethedeviationbetweentheexperimentalvalueandthedesiredvalue.Thisvalueis furthertransformedintoaSignaltoNoise(S/N)Ratio. Thelossfunctionofthe“largerthebetter”characteristicisgivenas:

µ= 10*log(1/N)*

TheS/Nratioforeachlevelofprocessparametersiscomputedbythehelpof“Minitab”softwareandisgivenbelow:

Table 6: S/Nratiovalues Experiment Welding time(ms) Welding current(ka) Pressure/in2 T s strength S/n ratio 1 5 15 50 10 20.00 2 5 45 67.5 6.95 16.84 3 5 75 85 10.67 20.56 4 12.5 15 67.5 11.05 20.86 5 12.5 45 85 9.73 19.76 6 12.5 75 50 10.80 20.69 7 20 15 85 10.25 20.21 8 20 45 50 10.45 20.38 9 20 75 67.5 10.40 20.34

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

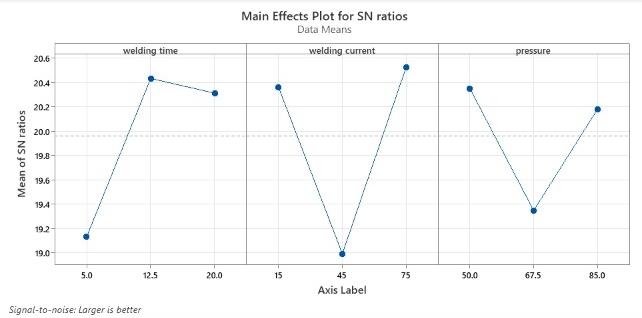

Thefigure5showstheS/NratiographwherethehorizontallineisthevalueofthetotalmeanoftheS/Nratio.Basically,the largertheS/Nratio,thebetteristhequalitycharacteristicforthetensileshearstrength.

ThemainaimofANOVAistoinvestigatethedesignparametersandtoindicatewhichparametersaresignificantlyaffectingthe outputparameters.Intheanalysis,thesumofsquaresandvariancearecalculated.F testvalueat95%confidencelevelisused todecidethesignificantfactorsaffectingtheprocessandpercentagecontributioniscalculated.[6]

Thetables7.1and7.2showstheresultsobtainedfromtheANOVA

Table 7.1:AnalysisofVarianceforSNratio

Source DF Seq SS Adj SS Adj MS F P %C Welding time 2 3.7939 1.2860 0.64299 1.13 0.553 27.97 Welding current 2 9.0392 6.6889 3.34446 5.90 0.280 66.64 Pressure 2 0.1624 0.1624 0.08120 0.14 0.14 1.19 Residual error 1 0.5673 0.5673 0.56727 Total 7 13.5673

AccordingtoANOVAanalysisasshownintheabovetable,themosteffectiveparameterswithrespecttotensileshearstrength isweldingcurrent(66.64%)followedbyweldingtime(27.97%)andthenfinallypressure(1.19%).

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Table 7.2:ResponsetableforSNratios

Level Welding time Welding current Pressure 1 19.13 20.36 20.35 2 20.43 18.99 19.35 3 20.31 20.52 20.18 Delta 1.30 1.53 1.00 Rank 2 1 3

AspertheS/Nratioanalysisfromtheabovetable,thelevelsofparameterstobesetforgettingoptimumvalueofT Sstrength areA2B3C1.

Thisexperimentwasperformedtooptimizethespot welding processparameterstofind outthemaximumtensileshear strengthofthespotweldedjointofIFsteelsheet.BasedontheANOVAmethod,thehighlyeffectiveparametersontensileshear strengthwerefoundasweldingcurrentandweldingtime,whereaspressurewasleasteffectivefactor.Forafactorwitha higher percent contribution, a small variation will have a great influence on the performance. An optimum parameter combination (A2B3C1) for the maximum tensile shear strength was obtained by using the analysis of S/N ratio. The experimentalresultsconfirmedthevalidityofTaguchimethodforenhancingtheweldingperformanceandoptimizingthe weldingparametersinresistancespotweldingoperations.

1) Mishra, Sushree Sefali. "Research on Resistance Spot Welding of Dissimilar Metal Sheets: An Overview." “Technological Advancement in Manufacturing & Processing of New Materials”(TAMPNM 2016) 9 th 10th April 2016:35.TechnologicalAdvancementinManufacturing&ProcessingofNewMaterials.319327732.

2) Rao,S.S.,Chhibber,R.,Arora,K.S.,&Shome,M.(2017).Resistancespotweldingofgalvannealedhighstrength interstitialfreesteel. Journal of Materials Processing Technology, 246,252 261.

3) Sachin K Jadhav, Jaivesh Gandhi. “Experimental Investigation of Resistance Spot Welding: A Literature Review.”“InternationalJournalofEngineeringResearchandTechnology” March,2014

4) Raut,Manoj,and Vishal Achwal."Optimization ofspot welding processparameters for maximumtensile strength." International Journal of Mechanical Engineering and Robotics Research 3,no.4(2014):507 517.

5) ChoughulePP,BiradarAK,ModiAK.ResistanceSpotWeldabilityofDissimilarMaterialsin1MmThickSheet. J.Mech.Eng.Tech.2016;4:15 21.

6) Ananda, Kamble Vijay. "Analysis of effect of process parameters on resistance spot welding shear strength”." International Journal of Scientific Research 2,no.11(2013):224 227.

7) Shafee,Shaik,B.BaluNaik,andK.Sammaiah."Resistancespotweldqualitycharacteristicsimprovementby Taguchimethod." Materials Today: Proceedings 2,no.4 5(2015):2595 2604.

8) Ghosh,P.,&Ghosh,C.(2009).Precipitationininterstitialfreehighstrengthsteels.ISIJinternational,49(7), 1080 1086.

9) Jou, Min. "Experimental investigation of resistance spot welding for sheet metals used in automotive industry."JSMEInternationalJournalSeriesCMechanicalSystems,MachineElementsandManufacturing44.2(2001): 544 552.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page949