International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1 Student, Department of Civil Engineering, SND College of Engineering & Research Center Babhulgaon Tal. yeola Dist. Nashik

2Professor, Department of Civil Engineering, SND College of Engineering & Research Center Babhulgaon Tal.yeola Dist. Nashik ***

Abstract:-

HighPerformanceConcreteisalogicalprogressionofcementconcreteinwhichtheelementsareproportionedandchosento contribute effectively to the various qualities of cement concrete in both the fresh and hardened phases. One of the characteristicsofHighPerformanceConcretethatgivesconsiderablestructuralbenefitsisitsincreasedstrength.Concrete, steelreinforcement,andformworkarethethreekeycomponentsthatcontributetothecostofastructuralpart.Thisresearch comparestheseprimarycomponentswhenhigher gradeconcreteisutilisedinthedesignandconcludesthathigh strength concreteisthemostcost effectivewaytoconstructload bearingpartsandtransportaverticalloadtothebuildingfoundation throughcolumns.

Key Words:HighStrengthConcrete,Scope,Methodology,ETABS.TopofForm

INTRODUCTION :

VariousstudieshavedescribedtheadvantagesofutilisingHighPerformanceConcrete,specificallythestructuraladvantagesof employinghighstrengthconcrete.Theseincludeareductioninmembersize,areductioninself weightandsuperimposedDead Loadwithaccompanyingsavingsduetosmallerfoundations,areductioninform workareaandcostconstructionofhigh rise buildings with accompanying savings in real estate costs in congested areas, longer spans and fewer beams for the same magnitudeofloading,reducedaxialshorteningofcompressionsupportingmembers,andareductioninthenumberofsupports andthesupportingmembersthemselves.Lowcreepandshrinkage,improvedlong termserviceperformanceunderstatic, dynamic,andfatiguestress,andlowweightandcostofthemajorityofstructuresTheuseofvariouschemicalandmineral admixturestoachievehighstrengthconcreteisalsoastudytopic,andseveraldesignmixmethodsandtrialmixprocedures havebeenofferedforthecreationofhighstrengthconcrete.Thevariousparametersthatgovernthestrengthofconcrete,such as the various constituent materials required, their properties, the proportions in which they are to be used, and the specificationsfortheproductionandcuringtechniquetobeusedforthedevelopment ofhighstrengthconcrete,arealsoa subjectofcontinuousresearchforthedevelopmentofhighstrengthconcrete,whichisnowbeingseen.

Objective of Study: Tocomparethecostofbuildingastructurewithhighperformanceconcretetothecostof buildinga structurewithnormalconcretegrades.

SCOPE: ThepurposeofthisstudyistodeterminethecostefficacyofdevelopingstructureswithHighPerformanceConcreteby comparingthecostsofconcreteM20andM40usingalaboratory createdconcretemix.Thedifferencesinthequantityof concreteandsteelrequiredfordifferentbeamsandcolumnshavebeencomputed,examined,andcomparedwithrespectto theircostinthedesignofamulti storyreinforcedbuildingutilisingbothM20andM40inStaadPro2018.

TheconceptofpackingdensityisintroducedbyHenryH.C.WongandAlbertK.H.Kwan(DepartmentofCivilEngineering,The UniversityofHongKong,HongKong)(5)asafundamentalpremiseforbuildingHPCmixes.Theconceptisfoundedonthebelief thatmaximisingthepackingdensitiesofaggregateparticlesandcement materialscanimprovetheperformanceofaconcrete mix,anditproposesapreliminaryHPCdesignapproachcalledthree tiersystemdesign.

Papayianni*,G.Tsohos,N.Oikonomou,andP.Mavria(DepartmentofCivilEngineering,AristotleUniversityofThessaloniki,54 124Thessaloniki,Greece)(6)investigatedtheeffectofsuperplasticizertypeandmixdesignparametersonsuperplasticizer performanceinconcretemixturesforhigherstrengthconcrete.

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page836 `

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

4 Details of concrete mix design for grade M20

PPCcementisthetypeofcementused.

Aggregatenominalsize:20mm 75mmslumpisworkable.

Cementcontentmaximum:450kgpercum

1 Cementspecificgravity2.86

2 Specificgravityofcoarseaggregate(underSSDconditions):2.68

3 FineaggregateSpecificGravity(SSDConditions):2.63

4 Waterabsorptionrateofcoarseaggreagate:0.68%

5 Fineaggregatewaterabsorption:1.12percent

6 Moisturecontentofcoarseandfineaggregatesisnil.1.08

SpecificgravityofchemicaladmixtureformixproportioningaccordingtoISCode10262:2019

AccordingtoIS10262:2019Pageno.3tableno.1and2

fck+1.65xstandarddeviation

Fck=fck+1.65xstandarddeviation

Fck=fck+1.65xstandarddeviationF

Fck=20+1.65x4=26.60N/mm2

Fck=20+5.5=25.50N/mm2 Fck=20+5.5=25.50N/mm2

As perIs 10262:2019,free w/c ratio requiredfor targetstrength of 26.60 N/mm2 is 0.58(curve2) which is higher than maximumvalueof0.55(AsperIS456), Asaresult,thew/cratiois0.55.

Hence192/0.55=349Kg/Cumulus (minimumnecessary=340Kg/Cumulus)

Water=349*0.55=192Kg/cum

Volumeofcement=349/(2.86*1000)=0.122cum

Watervolume=192/(1*1000)=0.192cum

Entrappedairvolume=0.005cum

Cumulativevolumeofcoarseandfineaggregate=1 (0.122+0.192+0.005)=0.681 cumulativevolumeofcoarseandfineaggregate coarseaggregatevolume=0.66perunitvolume

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page837 `

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Fineaggregatevolume=0.34perunitvolume

Cumulativevolumeofcoarseaggregate=0.681*0.66=0.449

Coarseaggregateweight=0.449*2.68*1000=1203.00Kg/cum

Fineaggregatevolume=0.681*0.34=0.232sum

Fineaggregateweight=0.232*2.63*1000=610.00Kg/cum

M20Cement(PPC)rateanalysis:349kg*450per50kgbag=3150/

Cumulativefineaggregate=0.232*2700=626

0.449*2700percum=1212coarseaggregate

RateofM20gradeconcrete=Rs.4988percum

Grade of concrete Rate (Rs.per cum)

M20 4988 M25 5245 M30 5752

1) M35 5300

2) M40 5640

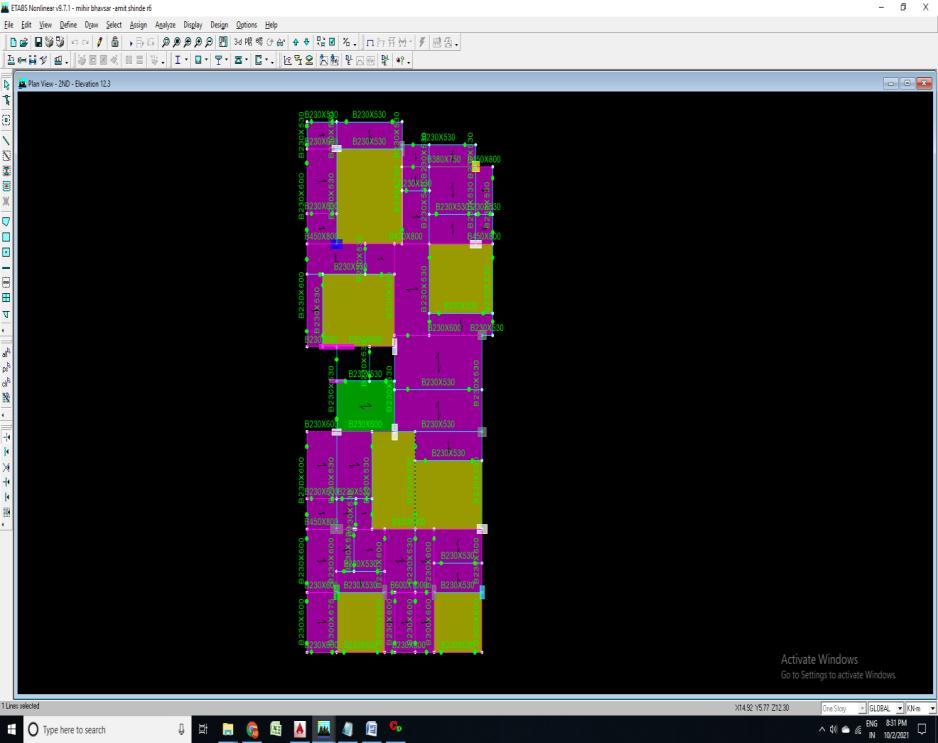

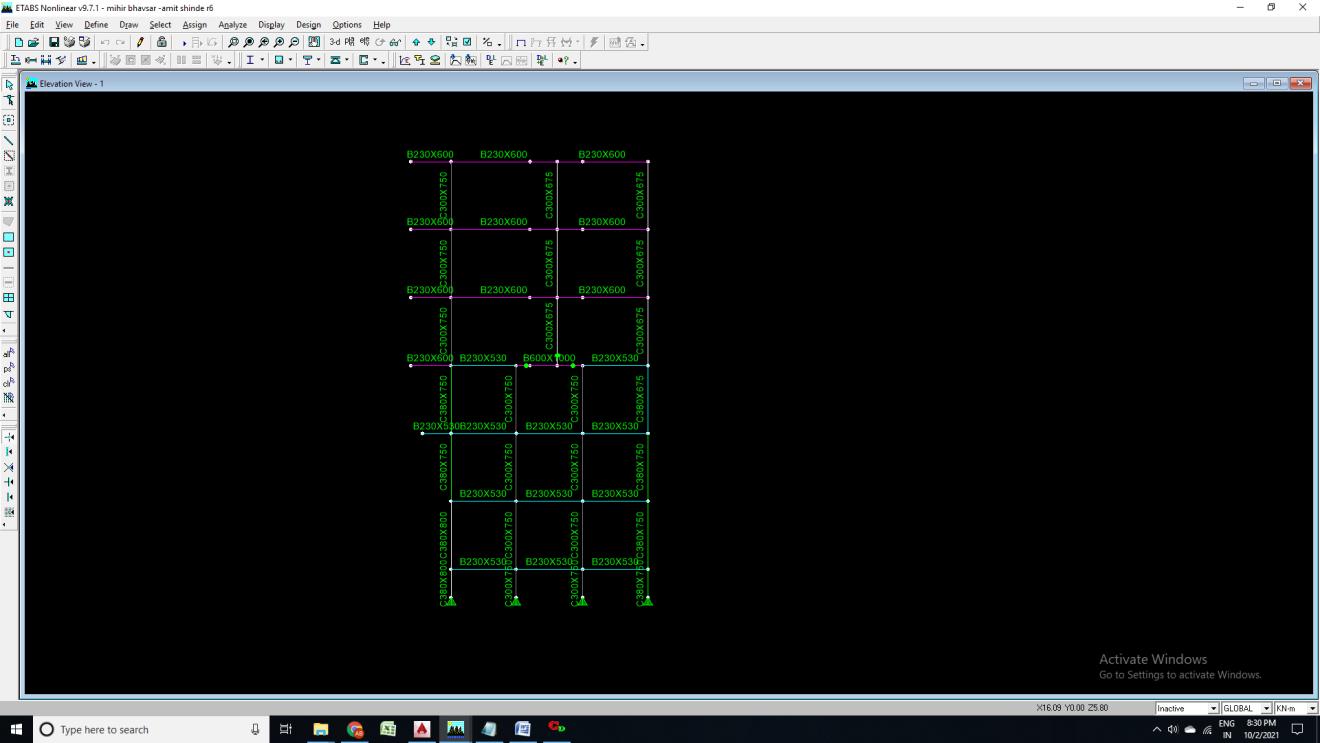

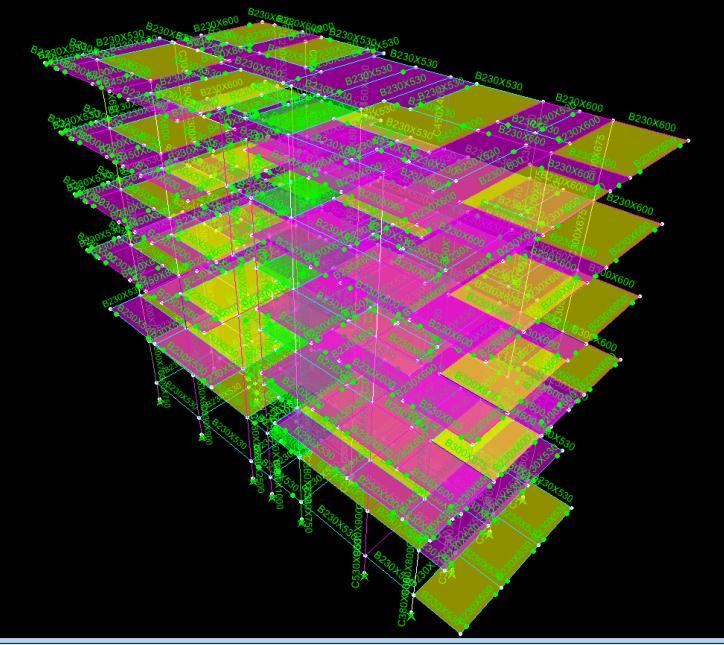

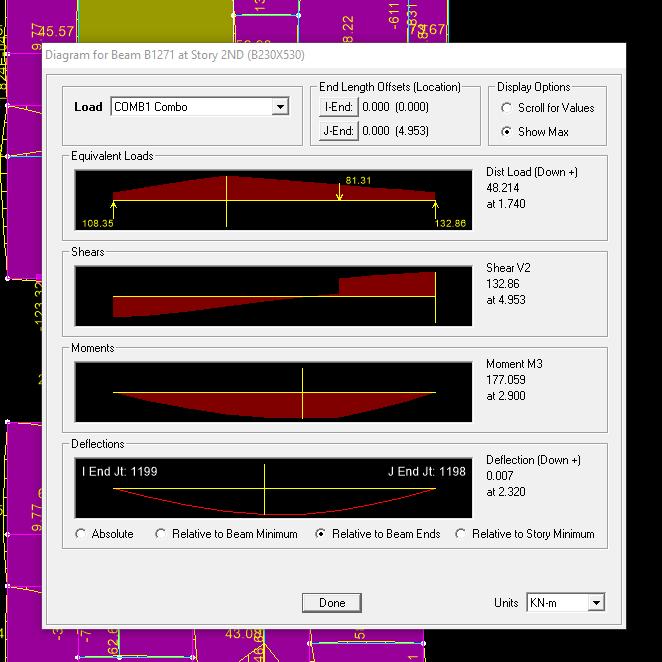

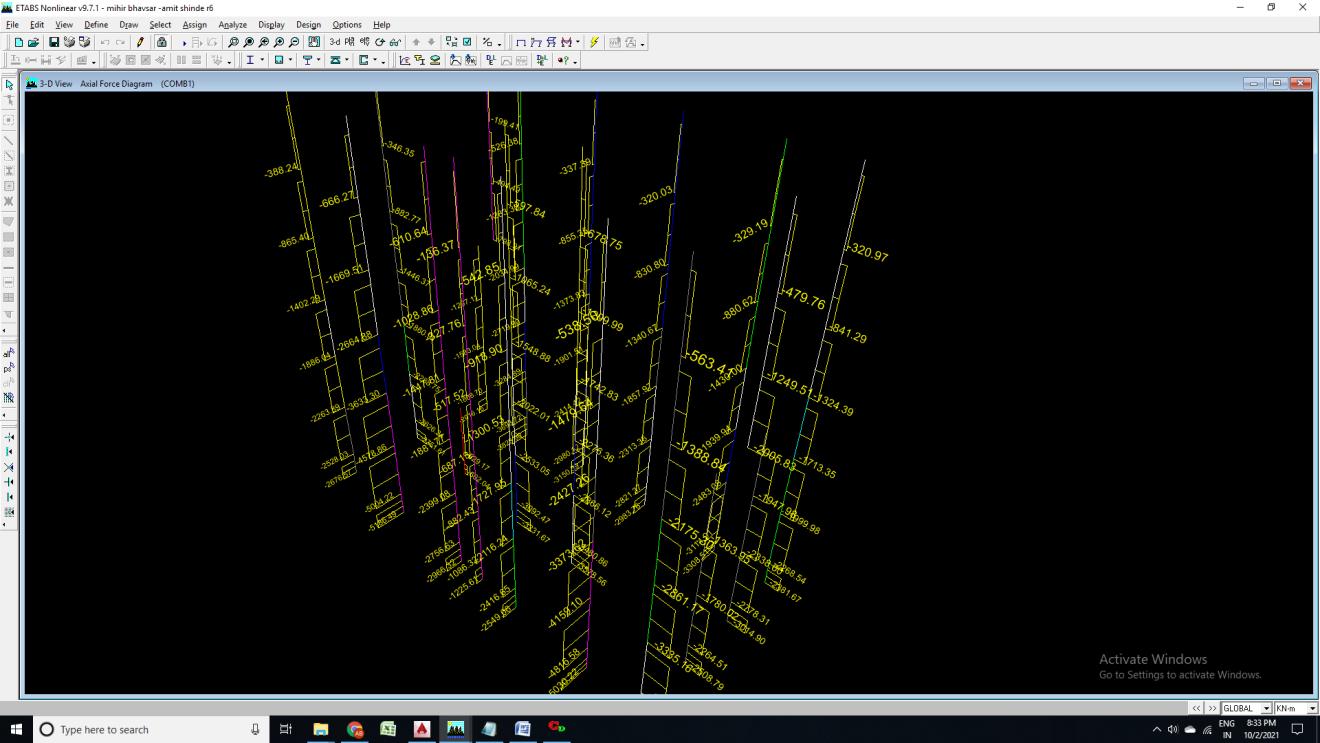

Areinforcedconcretebuildingframe,whichwasassumedtobeacommercialbuilding(locatedinDhule),wasanalysedand designedusingETABSusingconcretegradesrangingfromM20toM40,andthebeamandcolumnconcreteconsumption,steel reinforcementrequired,andcostaspectsforconcreteconsumptionandsteelreinforcementrequiredwerecompared.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

Figure 3 Generation of member properties

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | June 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 31 | May 2022 www.irjet.net p ISSN:2395 0072

AcubicmetreofHighPerformanceConcretecostsmorethanacubicmetreofregularconcreteatthemoment.Toensurethat the concrete reaches the stipulated strength and performance, High Performance Concrete requires greater quantities of componentssuchascementandhigh rangewater reducers,whichraisesthecostofHighPerformanceConcrete.However, usingconcretewithhighercompressivestrengthsincolumnsandotherload bearingelementsisaneconomicallyviableoption. Furthermore,theuseofHighPerformanceConcrete,whichhasahigherconcretecompressivestrengththanconventional concrete,hasbeenfoundtoprovidestructuralbenefits,suchasmoreefficientfloorplansduetosmallerverticalmembers (columns),andalsoprovestobethemostcost effectiveoptionbyreducingboththetotalvolumeofconcreteandthetotalcost ofconstruction.

1. Aflexuralmembermadeofhighperformanceconcrete(M40)cansaveupto2.23percentofitsweightwhencomparedto thesamecrosssectionmadeofnormalgrade(M20)concrete.

2. Comparedtosteelandconcrete,thedesignofaflexuralmemberwithalowercrosssectionwillcostnearly15%more.

3.Tosavemoney,it'sbesttocastaflexuralelementwithhigh strengthconcreteonlywhenthecrosssectionsaren'tchanged (i.e.thesameasforregulargrade).

4.Whenitcomestoaxialmembers,utilisinghighstrengthconcretecansaveyouupto16.21%.(ascomparedtothesame sectionwithnormalgrade).

"ReinforcedConcreteDesign,"byUnnikrishnaPillaiandDevdasMenon,Tata+McGraw Hillpublishingbusinesslimited.

N.KrishnaRaju,CBSPublishers&Distributors,Delhi,"AdvancedReinforcedConcreteDesign."

. N.KrisnnaRaju,CBSPublishers&Distributors,Delhi,"DesignofReinforcedConcreteStructures."

. Bureau of Indian Standards, New Delhi, IS:456 2000 "Indian Standard code of practise for plain and reinforced Cement Concrete."

. SP:16 1980,BureauofIndianStandards,NewDelhi,"DesignAidsReinforcedConcrete"toIS:456 1978.

IS:875 1987 (parts 1 5), Bureau of Indian Standards, New Delhi, "Code of practise for Design Loads in Buildings and Structures."

. "AnalysisanddesignproposedfemalesHostelsinJITCAMPUS",InternationalResearchJournalofEngineeringandTechnology (IRJET),BharathH.M,SachinPD(2017).

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page841