International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

EXPERIMENTAL

Abstract:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Abstract:

1, 2, 3 Department of Civil Engineering

SND College of Engineering & Research Center, Babhulgaon , Tal Yeola, Dist. Nasik, India ***

Super absorbing polymer (SAP) aninsert infreshconcrete is to prove that to have lots of many positively effects on the properties of its fresh concrete & harden concrete stages. Sodium polyacrylite is present in SAP, this absorbs the water converting it into the gel hence when addition of dry/wet polymer in fresh concrete it tends to releases the water after final setting of concrete. This release of water by SAP makes internal curing of concrete, namely known “self curing concrete”(SCC).Dueselfcuringofconcretetheexternalcuring required is minimum or nothing, other way if required for better heat of hydration. The dosage of self curing gels added in essential quantity will increase the strength and serviceability of concrete. In this investigation 0.1%, 0.2%, 0.3% by total weight of cement were used in M25 grade of concrete and then the results were compared with Standard M25 grade of concrete. And also different content of dosage is added in concrete in a different form such as gel (wet stage) and powder (dry stage). Present investigation involves various strength aspect experiment (only compression strength) on a concrete with curing, without curing and gunny bag curing. Here also studied that what strengthis achievedbyconcrete in an actual site condition if less/ no external curing is applied.

Key Words: Curing, Compression strength, Gel, Powder, Super Absorbing polymer.

Concreteisacompositionofcement,coarseaggregate,Fine aggregates,water withorwithoutanysuitableadmixture. Forattainingdesirablestrengthandserviceabilitycuringis necessary,ThusCuringistheprocedurewhichmaintainthe proper moisture content for completion of cement hydration.ThestrengthConcreteisbasicallyderivedbythe hydration reaction of cement particles, and thus process continuesforlongtime.Theprocessofhydrationinitiatesby themixtureofmoleculesofthecementwithwater.Dueto Losingofmassatmolecularleveltheenergygetsreleased, this forms bonds of molecules giving rise to thermo chemicalreactionwhichisheatofhydration.Infieldwork higherwatercementratioisused,sincetheconcreteisopen toatmosphereandevaporationtakesplacewhichlossesthe waterandtheavailableinconcretebecomesinsufficientfor completionhydrationreactiontotakeplaceparticularlyin

the upper layer. For the continuation of hydration, extra watermustbeaddedtoovercomethelossofwaterdueto absorptionandevaporation,Assoonasthecementismixed withwaterthehydrationstartsresultinginincreaseingain strength and serviceability with time. SAP gives some amount of internal curing to concrete. The absorption of water takes place in SAP thus converting it into gel, then releasesitslowlywithtime.

From a strength point of view, the addition of SAP to concretehastoopposite :whiletheSAPsgeneratevoidsin theconcreteandthusreducesstrength,theinternalwater curing provided by SAP enhances the degree of hydration andincreasesthestrength[1].Inparticular,athighwater cement ratio(>0.45)SAPaddition hasverylittleeffecton hydration and therefore generally reduces compression strength. At low water cement ratio (<0.45), SAP addition may increases compressive strength [1]. The concept of superabsorbingpolymers(SAPs)are Sodiumpolyacrylite materialsthathavetheabilitytoabsorbaliquidin170 200 times(aspermanufacturercompany)oftheirownweight. After the dried periphery it spread water that time SAP providesinternallycuring.Onepointnotedthisisadmixture notacementreplacement.Formaintaintheslump,amount of SAP may require in gel form. Gel form means sufficient wateraddedinaSAPpowder.Asperstudiedandliterature there are main focus is to SAP dosage should be added in powder formor gel form?Alsothereare main question is createshowmanyquantityshouldbeaddedinSAPpowder. Waterquantityisshowninmixdesign.Herealsostudying thatwhatastrengthachieveinaactualsiteconditionwhich isproventhehelpofwet/drygunnybag.

● Thedifficultiesofexternalcuringcanbecounteredby this.

● Itdecreasesevaporation,soappearanceofcracksare lessaswellaseliminatedshrinkage.

● Feeds continuously moisture contain for heat of hydrationofcement.

● Increase or maintain the strength of concrete if the optimumdosageofInternalcuringisusedandthisis polymeralsouseforhighstrengthconcrete.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page804

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

● As the SAP gets accumulated on small quantity on surface, this helps to reflect sunrays which making concretesurfacecoolthusresistingthermalcrackings.

● Waterquantityrequiredless

● Enhancing resistance to abrasion and compression applicationsofsaltsandchemicalatSeashoreplaces.

Materials:

2.1.1 Cement : OPC grade 53 are used in this investigation.

2.1.2 Fineaggregate : PartialNatural+Artificial.

2.1.3 Coarseaggregate : CrushedstoneLocallyavailable.

2.1.4 Water: Potablewaterisuse.

2.1.5 Super plasticizer: Locally plasticizer is used to increaseworkabilityorreducefrictionalpropertyof concrete.

2.1.6 Super absorbing polymer: SAPs are sodium polyacrylatematerialwhenitiscontactwithwater then thus polymer chain will be expand and water heldwithinastructure.HereSAPabsorbing200 250 times of their own weight. It is seen that it totally swellwithina15minasshownin(fig 2.1and2.2). SAP is sodium basis but their no any chemical reactiontoconcreteandsteel.

Chemicalformula [ CH2 CH(CO2Na) ]n

Form dry Crystalline white powder/granular

Form wet Transparentgel Particlesize 125micron

Water absorbing withdistilledwater 200 250

pHofabsorbing Neutral Density 1.08(g/cm3)

Bulkdensity 0.85(g/cm3)

Hydration/Dehydration Reversible

Thequantityofingredientsusedinconcretedepends upon therequiredperformanceoftwostates;theplasticstateand the hardened state. The concrete in plastic state must be workable if this do not happen it cannot be placed and compactedproperly,thuspropertyofworkabilitybecomes important

The Mix design for concrete was carried out with the guidelinesfromIS:10262:2009forM25gradeconcretewith thewatercementratioof0.45

LocallyavailableSuperplasticizer,watercanbereduce15% andabove,

● Super plasticizer = 5.50 kg/m3 (1.5% by wt. of cement)

2.2.

Waterquantity forconvertSAPpowderintogel= 28.83kg/m3(constant) M

Mix proportion: 0.45:1:1:2

● FactorofSafety=1.2

As per IS 7320 (1974) a light coat of oil is applied on the internalsurfaceofthemouldandiscleanedthoroughly. A cone measuring 30cm in height is filled in 4 layers, each being1/4th ofheightofthecone.Tampingisdone25times overcrosssection.Theupperlayerconcreteisstruckusing trowel.Removeconeinaverticaldirection after20secof tampingandmeasuringaslumpinmm[3].

Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table 2.1:SlumpvalueforSAPinpowderform

MIXPROPORTION SLUMP(MM)

Normalconcrete 110

SAP0.1% 125 SAP0.2% 130 SAP0.3% 140

Table 2.2:SlumpvalueforSAPingelform

MIXPROPORTION SLUMP(MM)

Normalconcrete 110

SAP0.1% 70 SAP0.2% 65 SAP0.3% 50

Compression Test:

Thetestiscarriedouton150X150X150mmsizecubes asperIS516 1954

Methodadoptedforcuring:

1) Pond curing= The Cubes of concrete are immersed in tankfilledofwater.

2) Withoutcuring=Cubesarepackindrylocallyavailable gunny bag and keep in room temperature. (Shown in fig.2.2)

3) ByGunnybag=Cubesarepackedinwettedgunnybag which is also locally available and securely place in atmospheric/ East West sun direction place such as daily routine project temperature and as per site conditionallowwaterdaily3 4timesonagunnybag.

Fig.2.2 Wet/DryGunnyBagcuring

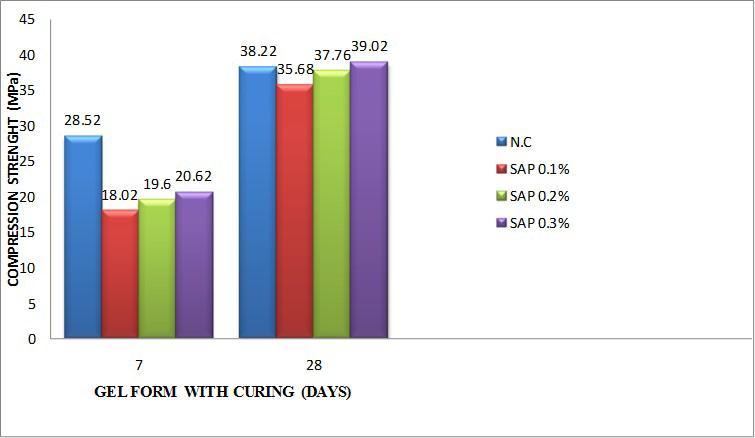

Event 3.1: The strength parameters of concrete which wereInternallycuredweredistinguishedwithexternally curedconcreteat7daysand28daysshowninfigno.3.1

1) Bycalculation/Visualinfection350mlwaterfor3cubes shouldbeaddedfordrySAPpowderintoconvertinto gel.

2) We took equal quantity of total water i.e. 350 ml for 3 cubes and applied it in process and thus checked variation of different SAP dosage which changed the propertyofconcrete.

Fig2.1 UniversalTestingMachine

Fig3.1 CompressionStrengthforGelFormPondCuring.

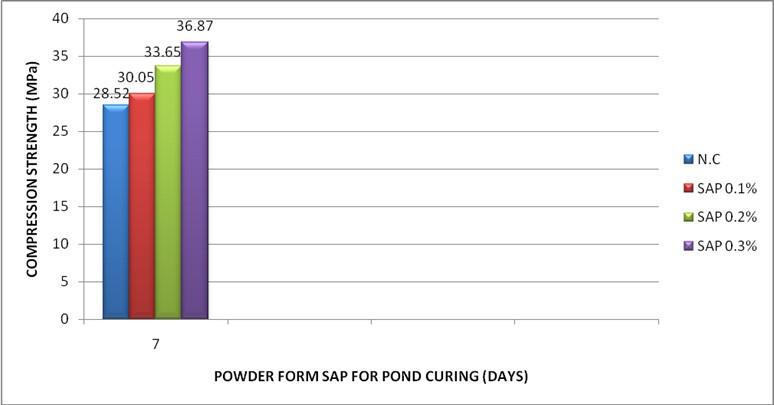

EVENT 3.2:

1) Below graph result shows (fig no.3.2), when SAP powderaddsasform(noadditionalwaterrequirement) and applying to pond/ Water tank curing enhancing higherstrengthascomparetogelformpondcuring.

2) Weobservedalso0.3%givesbestresult.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

3) WhenSAPpowderaddedinaconcretethentheslump testwilldecreaseascomparetonormalconcretedueto loweringwatercontent.ButSAPabsorbedwatertouses forinternallycuring.

3) Herealsoseenthatpolymeradded0.3%asgelform,the strength of concrete is increases and it’s gradually increaseinhydrationandachievingnormalstrengthin 28day.

4) If polymer added in concrete as powder form, SAP absorbs water and due to lowering of water content strengthof concretewillenhance.

5) Whenpolymeraddaspowderformitwillgaintheir7 daysto28daysstrengthnormal/conventionconcrete.

6) Gunnybagcuringstrengthisalmostreachestopowder formpondcuring.Anactualpracticallyfield/sitework locallygunnybag curingmostlypreferred,sothusideal conditiontherearesuitable.

Fig3.2 CompressionStrengthforpowderFormCuring.

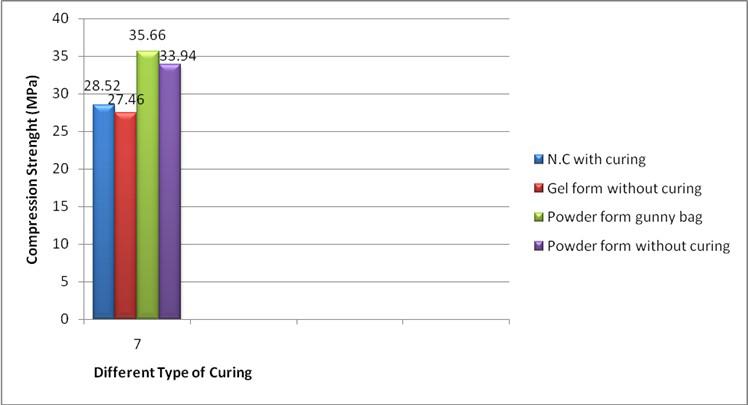

EVENT 3.3:

1) Belowgraphresultshows(figno.3.3)differentcuring strengthandapplyingSAPformationi.e.gelorpowder.

2) Above result shows SAP 0.3% by wt. of cement gives best result as compare to other SAP dosage, so best experience all below event/casting applying to only for SAP0.3%.

[1] O.MejlhedeJensen,“UseofSuperabsorbentPolymers inConcrete”ConcreteInternationalJournal,January 2013.

[2] M. Manoj Kumar and D. Maruthachalam , “Experimental Investigation on Self curing Concrete”,InternationalJournalofAdvancedScientific andTechnicalResearchIssue3volume2,March April 2013.

[3] Ravindra D. Warkhade, Mahesh S Varpe, Vikas S. Dhangar, “USE OF SAP IN CONCRETE” 23rd March 2016.

[4] MoayyadAl Nasra,MohammadDaoud,“Investigating the Use of Super Absorbent Polymer in Plain Concrete”, International Journal of Emerging Technology and Advanced Engineering, Volume 3, Issue8,August 2013.

[5] S.M.Dumne,“EffectofSuperplasticizeronFreshand Hardened Properties of Self Compacting Concrete ContainingFlyAsh”,AmericanJournalofEngineering Research(AJER),Volume 03,Issue 03,June 2014.

Fig3.3:CompressionStrengthforpowder FormCuring.

1) The dosage of polymer which gave best result for internalcuringwasfoundouttobe0.3%byweightof cement.

2) If SAP is added as gel form in concrete,the gel used increasesthewatercontentandobviouslystrengthof concretewillreducesascomparetopowderform.

[6] KennethSequeira,RaghuH.Naik,B.H.V.Pai,“UseOf Superabsorbent Polymers In Internally Cured Concrete” International Research Journal of Engineering and Technology (IRJET), Volume: 02 Issue:03,June 2015.

[7] K.BalaSubramanian,A.Siva,S.Swaminathan,Arul.M. G. Ajin, “Development of High Strength Self Curing Concrete Using Super Absorbing Polymer”, International Journal of Civil, Environmental, Structural,ConstructionandArchitecturalEngineering Vol:9,No:12,Dec 2015.

[8] VivekHareendran, V. Poornima And G. Velrajkumar, “Experimental investigation on strength aspects of

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page807

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

internal curing concrete using super absorbent polymer”, International Journal of Advanced StructuresandGeotechnicalEngineeringISSN2319 5347,Vol.03,No.02,April2014.

[9] AbhishekSinghDeshmukh&Dr.RajivChandak,“Split Tensile Strength Study of Self Curing Concrete and Conventional Concrete” International Journal for Scientific Research & Development Vol. 3, Issue 07, 2015.

[10]Abhishek Singh Deshmukh and Dr. Rajiv Chandak, “COMPRESSIVESTRENGTHSTUDYOFSELF CURING CONCRETE AND CONVENTIONAL CONCRETE” International Journal for Scientific Research & Development,Sep2015.

[11]Alexanderassmann, hanswolf Reinhardt,” some aspects of SAP in Concrete technology,” 8th fib phD symposium in Kgs. Lyngby, Denmark June 20 23, 2010.

[12] H.Beushapusen, M. Gillmer “As The use of SAP to reduce cracking of bonded mortar overlays’’ University of cape town, Department of civil Engineering, concrete Materials And Structural Integrity Research Unit, South Africa, Cement & ConcreteComposites52(2014),1 8.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page808