International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1,2,3,4B Tech Student, Department of Mechanical Engineering, Mangalam College of Engineering, Kerala, India 686631

5 Assistant Professor, Dept. of Mechanical Engineering, Mangalam College of Engineering, Kerala, India 686631 ***

Abstract - In the modern world, everybody is looking for comfort and comfort mainly is associated with the perfect ambient temperature and perfect humidity which helps to reducethestresstoacertainextent.Today,thetemperatureis risingdaybydayandthesameinthecaseofvehicles.Vehicles are primarily meant for a space that provides comfort to the occupants. Considering the comfort factor vehicles are installed with air conditioning systems. But these air conditioning systems act as a parasite on the vehicle consuming a part of the energy produced by the engine. This paperpresentsanumericalanalysisandmodellingresults for aninnovativesystemwhichhelpsinreducingthetemperature inside the vehicle on sunny days. A PCM named Calcium Chloride Hexahydrate is used for the numerical and experimental analysis

Key Words: Phasechangematerials(PCM),computational Fluid Dynamics, Automobile cabin, thermal management, automobiles,heattransfer,HVAC

The temperature during the summer days is increasing gradually.Whenvehiclesareparkedfacingthesunalarge amountofheatenergyemittedbythesunentersthecabin throughthegreenhouseofcars.Theheatgetsaccumulated inside the cabin. The dashboard and other parts of most automobilesaremadeofplastic,whichwheninthepresence ofheatfromthesunemits harmfulgaseswhichcancause harmfuleffectstotheoccupants.Thisincreasedheatinthe carcabincanalsoresultindamagetothedashboardplastics. To reduce the temperature inside the vehicle cabin air conditioning systems are used but to reduce this high temperatureinsidethecabintolowlevelstheworkdoneby theairconditioningsystem ofthevehicleisveryhighand also the power required for the working of the air conditioning systems are from the work produced by the engine. Air conditioning systems are a parasite to the automobileengine.Theuserhastowaitforalongtimefor theinteriortemperatureofthecartocooldownbyeither rollingdownthewindoworswitchingonthea/c.Therisein the temperature inside the cabin may make the users

uncomfortable. Moreover, the vehicle cabin may face an agingproblemandmaydamagethedashboardplasticsand materialskeptinthevehicle.Variousfindingssaythatevery yearhasrecordedmanychildrendieduetoheatstrokedue tobeingleftinsidethevehicles.Whenthevehicleisparked in direct heat and sun the temperature rise in the parked vehicleismainlyduetothesolarradiationthatentersthe carthroughtheglassesandispartiallytrappedwithinthe car.Thetemperatureinsidethecaronasummerdaycould reachupto110ºCwhereastheoutsidetemperatureranges from 35ºC to 45ºC. so, to reduce thermal heat inside a vehiclewehaveproposedaninnovativemethodtostopthe heat entering the cabin by arresting the heat on the roof itself.ForthatPCMhasbeenusedwhichhastheabilityto absorbtheheatandstoreitwithinthematerialitself.Phase changematerialshavetheabilitytochangetheirphasefrom solidtoliquidandviceversa.Phase changingmaterialshave the ability to absorb heat and convert it into liquids. And when it releases heat, it changes into a solid state. In this paper, a numerical analysis is performed on a two conditioned roof system with PCM and a Roof other than PCM. The PCM analysed in the present study is Calcium ChlorideHexahydrate(CaCl2.6H2O).Atestmodel wasalso developedtoshowhowthesystemworks.Theroofismade of5086seriesaluminium.Thephaseswitchesareinserted betweentheinsulatorlayersandthetopsheetmetallayers TheinsertedroofcontainsPCMinit.PhaseChangeMaterial (PCM)isacompositematerialthatmeltsandhardensata certaintemperatureandisabletostoreandreleasealarge amountofheatenergy.PCMisinasolid stateatfirst.Asthe naturaltemperaturerises,itabsorbsenergyintheformof heat. When the ambient temperature reaches the melting point, PCM absorbs most of the heat energy at an almost constanttemperature.Thiscontinuesuntilallthematerialis convertedintoaliquidphase.Inthisway,theheatisstored inthePCMandthetemperatureismaintainedataverygood level.Whenthetemperaturearoundanobjectdecreases,it hardensasitreleasestheheatbackintospace.Thepurpose istodesignandbuildavehicleroofthatisresistanttoheat enteringthecarcabintomaintainacentraltemperaturein the car park where the car is parked in a shady area. The mainfeatureofthedesignistomakethecabintemperature

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page756

Nirmal P Sabu1 , Mithun Cheriyan2 , Nevin Philip Joji3 , Sanju Jacob Varghese4, Asst. Prof. Tony Mathew5International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

morecomfortableforpassengersastheyentertheparked car.Installationofthisroofdesignwillreducetheinternal temperatureofthecarhouse.Duetothisroofstructure,the deteriorationofplasticpartscanbereduced.Thedriverdoes nothavetokeepthecarwindowslowtovent.Whenchildren andpetsareleftinthecarcabin,theywillnotbeaffectedby theincreaseincarroomtemperature.

VarietiesofPCMshavebeenshowntohaveawiderangeof melting points. However, for their involvement as subtropical heat retaining materials, a certain desirable thermodynamic(high temperaturelowtemperature,good heat transfer), kinetic and chemical properties (non toxic, long termstability,heat)isrequired.Additionally,economic considerationsandtheavailabilityofPCM alsoneedtobe explored. As PCMs are defined by their melting points, specific to a specific application, i.e., each application may require a specific PCM or PCM set based on operating temperature.Therefore,thethermalconditionofthevehicle andtheavailabilityofappropriatePCMisveryimportant.

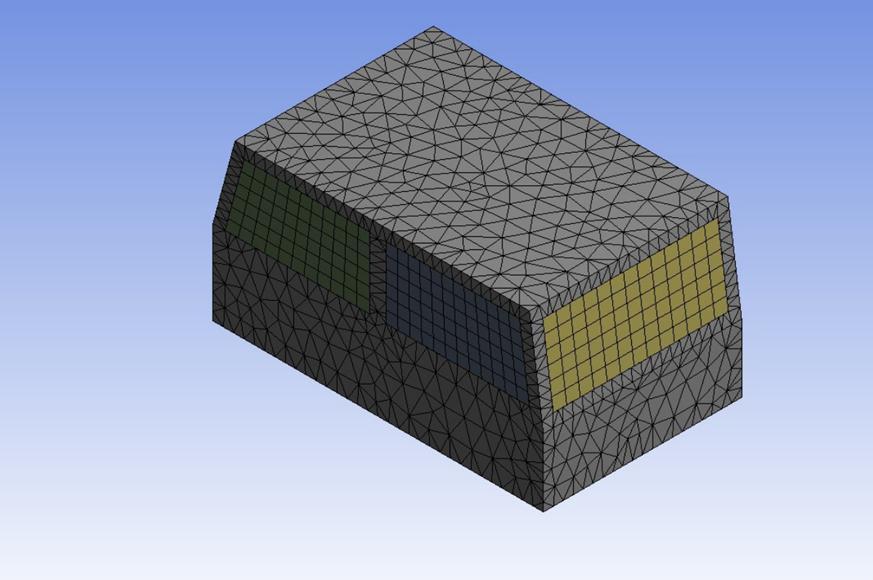

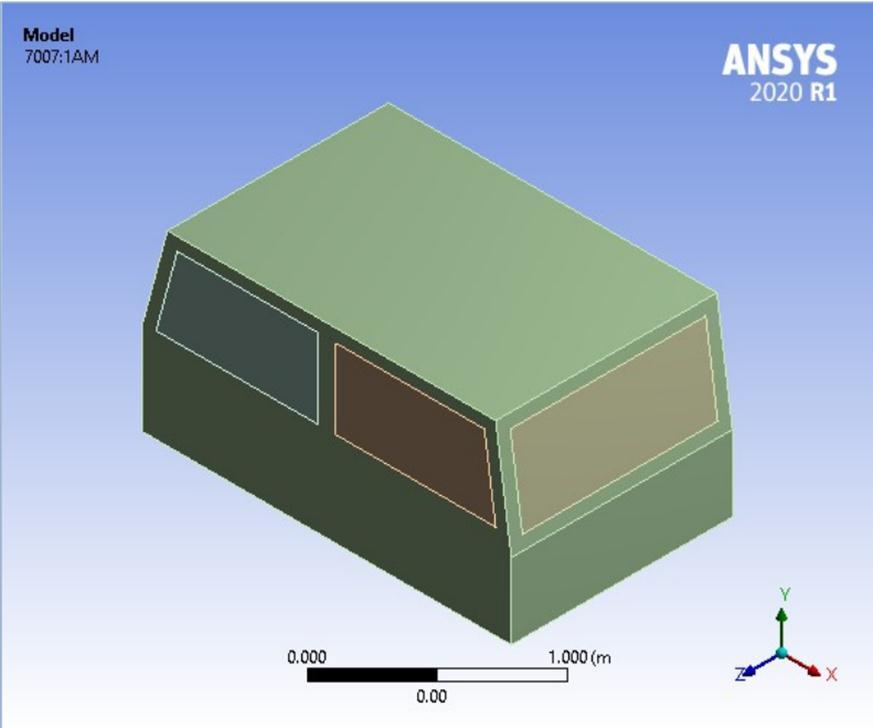

The 3D model of the car has been designed in Solidworks, ThePCMlayerisincorporatedintotheroofofthecar.PCM helpsinmaintainingthedesiredtemperaturebyabsorbing theexcessheat.Whentheengineisturnedoff,say,atatraffic signal, PCM restricts the increase in cabin temperature by absorbingtheexcessheattosomeextentdependinguponits thermophysicalproperties.TheheatabsorbedbythePCMis releasedeitherduringthevehiclemovementoratnightwhen the outside temperature is lower than the melting temperatureofthePCM.ThePCMaddedtothevehiclebody should notconsiderablyaffect the weight of the body. The analysisisdoneusingANSYSFluent Bothsteady stateand transientstatethermalanalyseswereperformed

The inside surfaces of the vehicle are provided with a temperature similar to room temperature i.e., 26°c simulations. The external free stream temperature is consideredtobe309K,i.e.,36°C,andthepropertiesofair are taken into consideration. The conditions inside the vehiclecabinareconsideredastheidealroomtemperature conditionof299Ki.e.,26°CForsolvingtheaboveproblem,a pressure basedsolverandbothsteady stateandatransient time basedapproachisbeingused.InthecaseofPCM,the melting and solidification model along with the energy modelisused.Thethermalmixedmodelisusedtosolvethe problem.Doubleprecisionmodewithdualprocessorusage ispreferredforsmoothworkingandlowerCPUdemand.The modelhasbeenanalysedforthelocationofKeralaforthe month of June. The latitude and longitude of Kerala are 10.8505°N,76.2711°E.

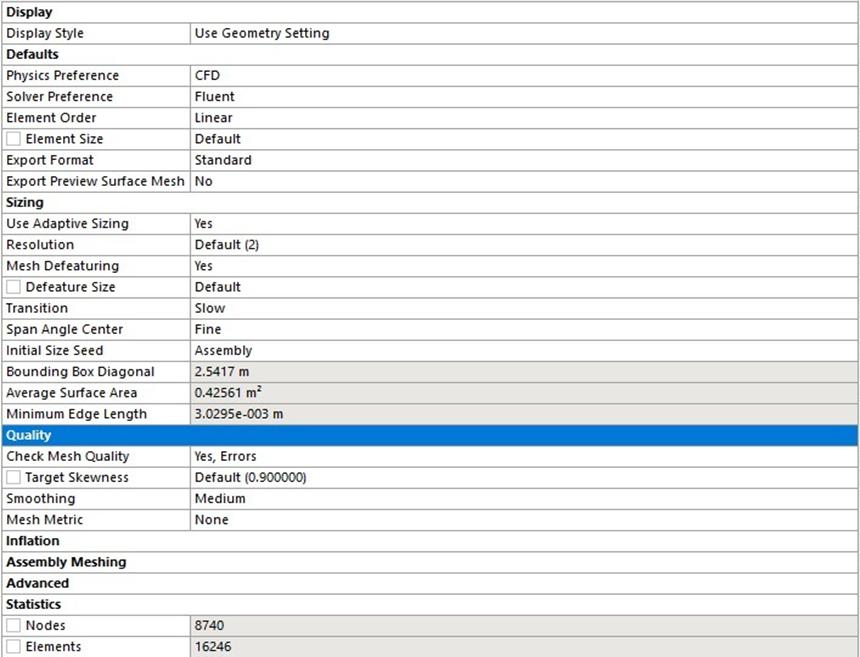

Fig 3

Fig

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

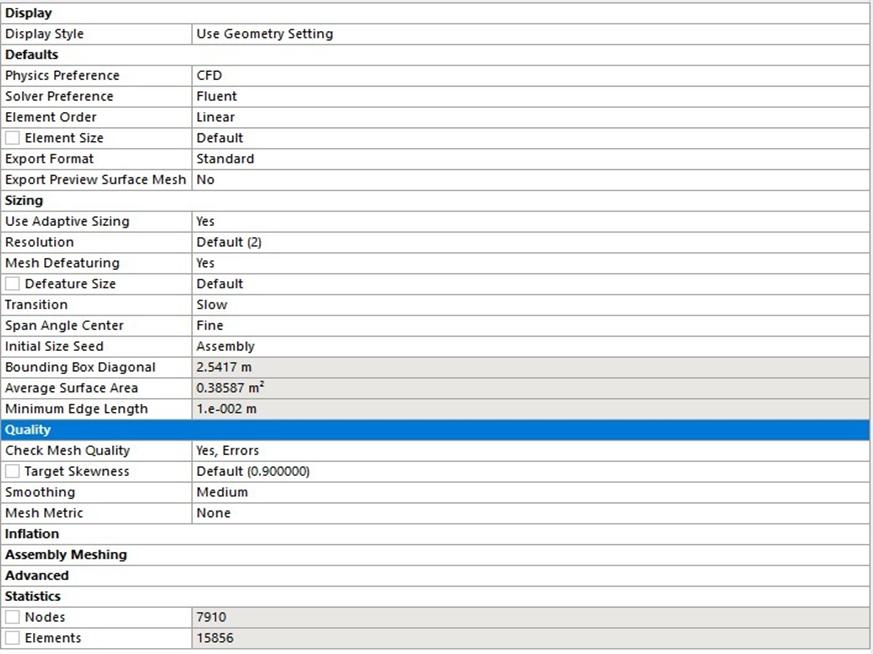

Fig 4:Meshsetupfor3DmodelwithoutPCM

PCM CalciumChlorideHexahydrate

Roof 5086seriesAluminium

Sideglass Windowglasswith4mmthickness

Temperaturesensor TPM 10DigitalThermometer

Base Wood

Side panel Aluminium Composite Panel (ACP) Sheet

Calcium chloride hexahydrate is a low inorganic hydrated salt, non toxic at 29 ° C, compliant with the optimal operatingtemperatureofsolarphotovoltaicpanelsandhas anambienttemperatureofphasechange(190kJ/kg).

Strongodorless,colourless.Theformationhasthestability of a high switching phase, passing 3,000 cold and hot rotationtests,andcanmaintainthesamedistributionofthe nucleatingagentinashorttime.SomeofthefeaturesofPCM areshowninTable 1

MeltingTemperature(°C) 24 27

LatentHeat(kJkg 1) 190 SpecificHeat(Jkg 1K 1) 1800 ThermalConductivity(Wm 1 K 1 0.81 Density(kgm 3) 1805 Non toxic Yes

Flammability No

Table 1: PropertiesofCaCl2.6H2O

Thetestsetisbuiltontheitemslistedabove.Planeglassis sealedtogetherwiththehelpofaliquidsealantsothatthe heat of the cab does not come out of the setup. Roofs are madefrom5086seriesofaluminumonesheetmetalsheetis cutandmadeintheformofaroofandthePCMmaterialis filledintothecavityprovidedbetweenthealuminumroof. similarly,aroofisconstructedwithoutplacingthePCM.so that the difference is reflected in the temperature. The automotivecabinetisrepresentedbyasetoftestsperformed onexactlythesamecomponentspresentinthecar.Initially,a squarepipeframeisconstructed.Thesidepanelsaremadeof ACP sheet. The ACP sheets are considered because it resemblesthestructureofavehicledoor.Itconsistsofglass, ametalroof,andawoodenbase.Theglassisgluedontothe frameprovidedfortheglasstofitintheglassisthenfixed intothealuminumchannelareabyusingsilicongluethetop ofthecarismadeofAluminum.Insulationmaterialusedby PCM.PCMisatransitionphasecapableofabsorbingheatand transformingaphasefromitssolidstatetoaliquidstate.And whenthematerialreleasestheheat,itconvertsitsphaseback

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

intosolid state.PCMisstoredinametalbottomplatemade ofthesamematerialastheroof.

Theanalysiswasperformedinthecaseofavehicleparked underthesuninthemonthofJune2022,whentheambient temperaturewas309K.Thestudywasperformedat1000s; a situation where the car is outside the traffic where the vehiclehasoccurredindirectsunlight.Bothconditionsare considered (i) roof without PCM and (ii) Roof where PCM materialisinstalled.

Whenthecarisstandingfor1000sunderthesuntheengine is turned off, with an ambient temperature of 309 K and direct sunlight, heat transfer occurs from the surrounding areatothecarroom.Consideringthesurroundingconditions andthetotalthermalloadonthevehicle,simulationswere performedshowingthatthepassengerswereexposedtohigh temperaturesof301K,actingasthebasisforanalysis,i.e.,the case where PCM was not incorporated to the roof of the vehicle.

Length 2.00ft

Breadth 2.00ft

Height 2.00ft

Glassarea 4.65sq.ft

Table -2: Dimensionsoftheexperimentmodel

Fig 6:FabricatedsetupofPCM

Fig 7:RoofwithoutPCM

Fig 8:RoofwithPCM

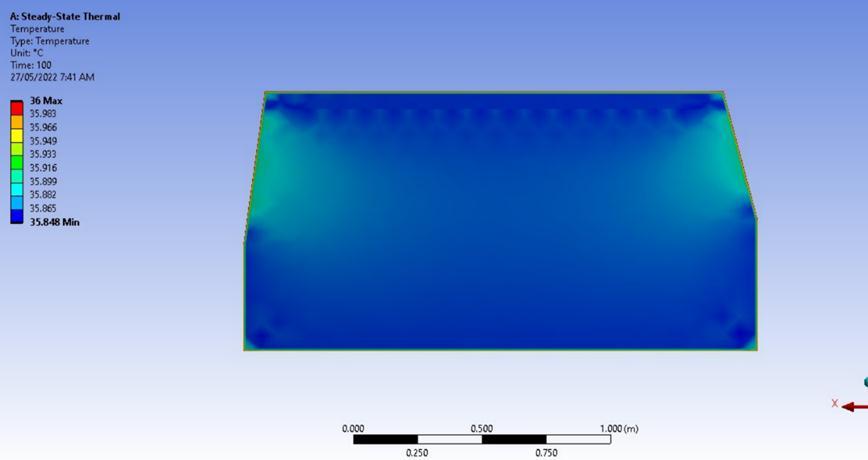

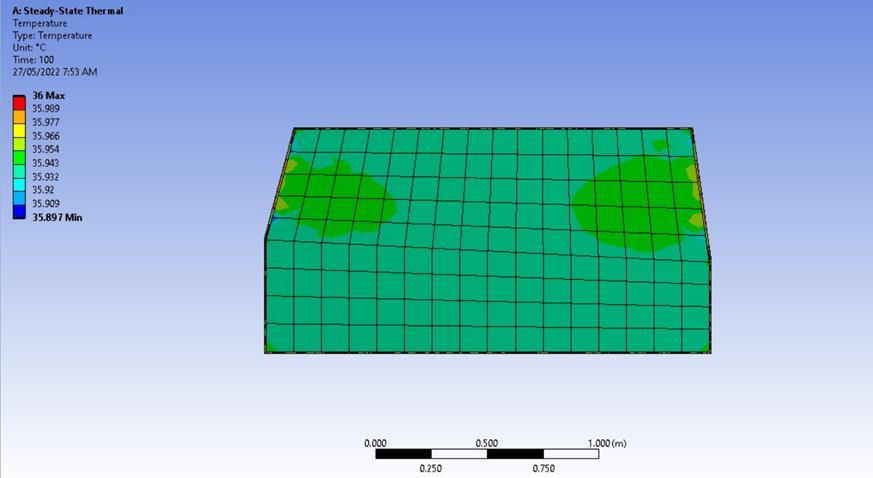

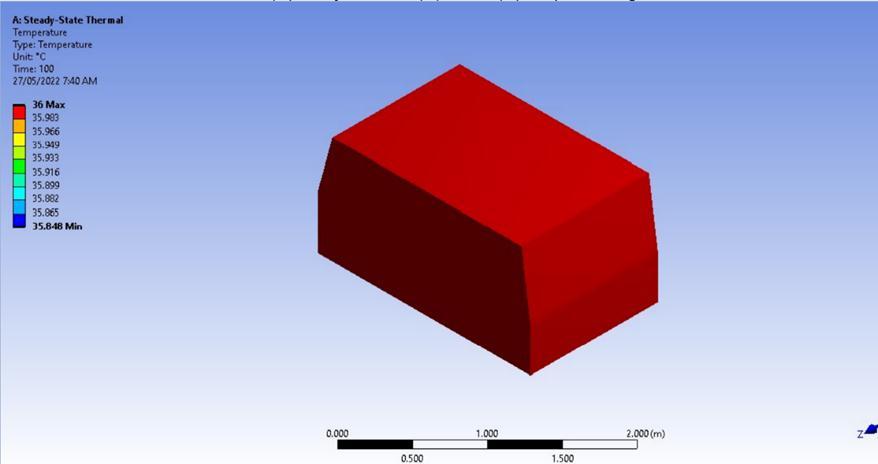

Thesteadystatethermalanalysisisconductedtodetermine whether there is any difference in temperature when the PCMisincorporatedintothecavityprovidedintheroof.For the analysis, the roof which is not insulated with PCM is consideredandthenthePCMinsulatedroofisconsidered. The surrounding temperature is assumed to be 36° C i.e. 309K. from the results obtained from the steady state thermalanalysis,aslightvariationinthetemperaturecanbe seenwhencomparingboththecondition.Theresultsofthe analysisaregiven

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

TEMPERATURE WITH PCM [°C] WITHOUTPCM[°C]

MAXIMUM 36 36. MINIMUM 35.915 35.962 AVERAGE 35.848 35.897

Table -3: ResultsofSteadystatethermalanalysison differentconditions

Fig 9:Boundarycondition

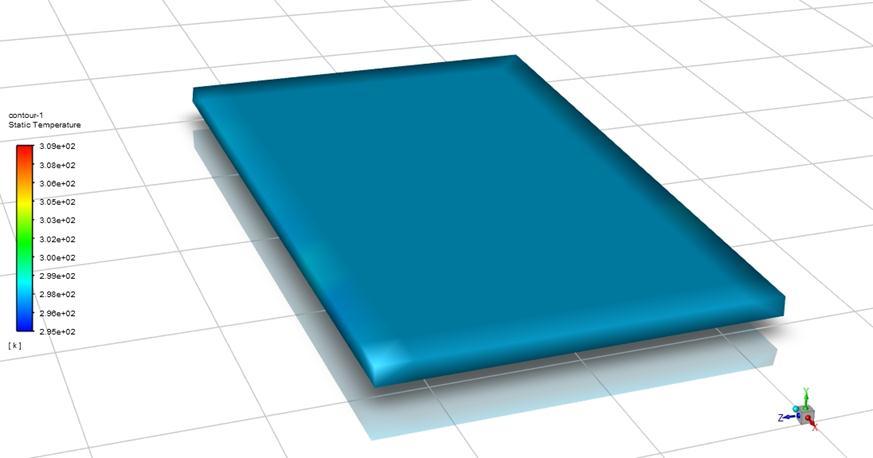

Theinitialtemperatureinsidethecabinetisestimatedat295 K as maintained by the air conditioner. This increase in temperature is caused by excessive sunlight emitting through the wind window and side glass windows due to highcrackingandlowglassabsorptionandduetothecar's hotroof.

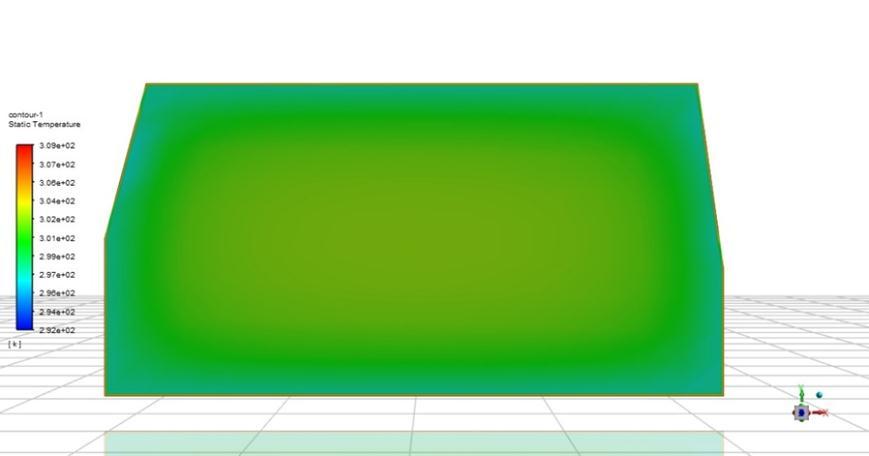

Fig 10:ResultsofSteadystatethermalanalysisoncabin withoutPCMonroof

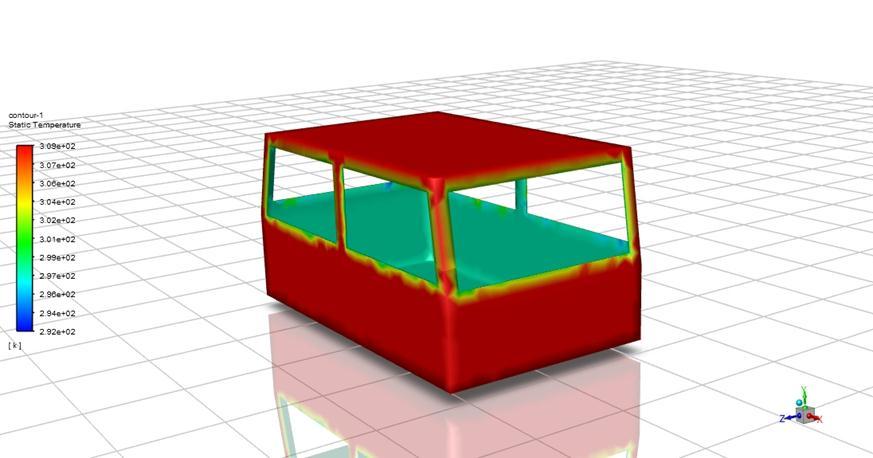

Fig -12: Temperaturedistributiononthevehiclesurface

Fig 11:ResultsofSteadystatethermalanalysisoncabin withPCMonroof

Fig -13: Temperaturecontoursinsidethecabinwithout PCMonrooffor1000sec

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

passengerstoturnontheengineandturnontheACtogeta comfortabletemperaturenearthesetpoint.Toanalyzethe effectofPCMoncabinetheating,fourselectedPCMsareused individuallyandareinvestigatedfortheeffectoftemperature reduction due tovarious sizes. In this case, a 50 mm thick CaCl2.6H2Oisinstalledinsidethecarroof

The simulation results showed that there is a decrease in temperatureatwhichridersareexposed,from303Kto298 K,i.e.,about5K.InPCMapplications,thereisaslightincrease intemperature.comparedtothebasecasebecausetheheat isabsorbedbythePCM.Itcanbenotedthatthetemperature insidetheroomdoesnotexceed298Kafter1000seconds. Thissubtletemperaturemaintainsacontinuoustemperature in the PCM during the phase conversion process, thus, helping to reduce the heat accumulation inside the car compartment.

Theinitialtemperatureinsidethecabinetisestimatedat295 K as maintained by the air conditioner. This increase in temperatureiscausedbyexcessivesunlightemittingthrough the wind window and side glass windows due to high crackingandlowglassabsorptionandduetothecar'shot roof. The effect of the greenhouse also plays a role in increasing the temperatureas the incoming sunlight has a relativelyshortheight,whichiseasilypenetratedthroughthe glasswindows.Whenitenters,itlosesenergyandconverts into long wavelength rays, which have difficulty passing throughtheglass,thus,beingtrappedinside,leadingtoarise in temperature. This unfavorable situation will cause

ToassesstheimpactoftheinstallationofPCMinsidetheroof on car thermo regulation, further studies have been performedcomparingthebasecase(roofwithoutPCM)with acasewithPCMinstallationandcomforttemperature.The Bureau of Energy Efficiency (BEE) guidelines suggest that based on the comfort chart, the ideal temperature can be maintained at about 24 ° C 25 ° C According to the new guidelinesforCOVID 19also,thetemperatureofcomfortis measuredbetween24°C 30°C.Therefore,keepinginmind these two factors, taking into account the comfort level of residentsas25°C,furtheranalysiswasdonebystudyingthe differenceincomforttemperatureandbasecaseandthecase ofPCMinstallation.PCMsretainheatbychangingtheirphase, thus, maintaining a continuous temperature in the PCM during the process and preventing an increase in temperatureinsidethecabinet.CaCl2.6H2Ohasahighmelting pointof24°C.Thus,basedontheconsideredambientstate, CaCl2.6H2Owilltakelongertomeltandthus,willretainheat longer,andtherefore,maintainalowertemperatureinside thecabin.TheresultsmeanthatCaCl2.6H2Ohasshownbetter resultswithalowermeltingpoint.BasedonPCM'sanalysisof thetemperaturesreached,thedifferencebetweenthenormal comforttemperatureandtheambienttemperaturesreached, itcanbeconcludedthatPCMCalciumChlorideHexahydrate hasanexcellentthermalstoragecapacityandcanholdlow temperaturesforalongtime.

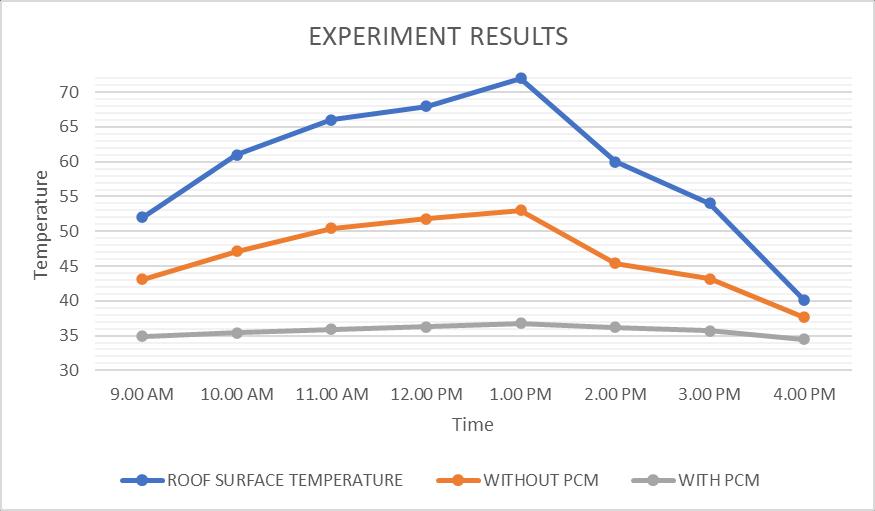

WhentherooffilledwiththePCMmaterialwasinstalledin the setup, the range of temperature inside the cabin was noted much low than in the experiment with the roof, in whichthePCMmaterialwasnotfilledandtheresultswere much better than it could decrease the temperature by at least 10ºC. The temperature sensors were kept at two differentlocationsoneatthebottomcornerandoneatthe top corner. The temperature range of the complete cabin setupcanbemeasured with thehelpof thisarrangement. Thetemperatureatdifferentlocationsisnoted.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

TEMPERATURE(°C)

TIME WITHOUTPCM WITHPCM

9.00 AM 43.1 34.9 10.00 AM 47.1 35.4 11.00 AM 50.4 35.9 12.00 PM 51.8 36.3 1.00 PM 53 36.8 2.00 PM 45.4 36.2

Table 5: Temperatureatdifferenttime

Whenacarengineisturnedoffandparkedindirect sunlight,itisthoughtthat,foramaximumof1000 seconds,thetemperatureinsidethechamberrises from297Kto303K,thatis,thetemperaturerises by6Kin1000.s.Themainreasonsfortheincrease in temperature inside the car cabinet is the occurrenceofsolarradiation,aswellasmetabolic loadduetopassengerssittinginsidethecar.

Toreducethistemperature,PCMCalciumChloride Hexahydrate (CaCl2.6H2O) was selected based on their melting point and individual comfortable temperaturesadoptedbyASHRAE.AfterPCMuse, the reduction in temperature found inside the cabinetisapproximately6K.ThisisbecausePCM beginstoabsorbexcessheatthatreachestheinside ofthecabinetaftertheengineisturnedoff.

After simulation was performed on the ANSYS Fluent, it was noted that the PCM, CaCl2.6H2O provedtobethebestadvantageinitsapplication. Thus,itisusedontheroofofacar.

This project presents a new design for a car roof structure,madebyaddingalayerofPCMtothecar roof. The result shows a decent decrease in the temperatureofthecarhousewhenthePCMroofis installedonthecarroof.

Fig -16:Temperaturevariationwithtime

Table3.2showsthedifferenttypesofreadingofthevehicle cabinontwoparticulardaysandoftwodifferentrooftypes. The readings were taken for a day with the two roof conditions i.e., the insulated and non insulated roof the amount of heat and temperature present inside the cabin wasnotedandrecorded.Itwasnotedthatthetemperature wascomparativelylowduringtheearlyhoursofthedayand itincreasesasthetimeincreases.Thecabintemperatureis veryhighduringpeakhoursanddecreasesgraduallyasthe outside is reduced. And the next day the study noted the temperature of the cabin with the insulated roof. Temperature is noted in two different areas of the car cabinet.Temperaturesensorswerekeptintheuppercorner on one side and the lower corner on the other end to determinethefulltemperaturesettingofthecarcabinettest. It was observed that the temperature variation gradually increased and decreased, but the temperature inside the cabinetwasmuchlowerthanbefore.Theefficiencyofthe roof was shown in high hours PCM can hold high temperatures during peak hours. This demonstrates the abilityoftheselectedPCMtobindexcessheatinmostcases withoutallowingheattoenterthevehiclecompartment.

Thetestfullyfulfilledthepurposeofloweringthe car'scabinettemperaturewhenthecarisparkedin asunnyorshadyplace.Theresultsobtainedfavor thetest.

Whenthetemperaturewasmeasuredinbothnon insulatedandinsulatedcabin,theinsulatedcabin had a much lower internal temperature than the non insulatedcabins

Test results have shown that the new design has betterthermalperformancethanthestandardroof designofavailablecars.

Thenewdesigncanhelpreducebyupto30%ofthe amountofenergyneededtocooltheheatentering thecabinetfromtheroof.Thelevelofsavingscan beveryhighifthereisnaturalairandmovementin thevehicleused.

PCM insulated roof test cabin had a much lower cabintemperaturecomparedto theconventional cabin, PCM had resolved the purpose of binding externalheattotheentryofthecaraddingtothe cabintemperatureincreasewhenallvehicleswere

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page762

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

insulated. PCM cabinet temperature will be very lowandcanreducethedeteriorationoftheplastic partsofthecar.Thisisapromisingdesignthatcan beveryproductiveduetoitssimplestructureand reasonableprice.

[1] D. Sood, D. Das, S. Fatima Ali, D. Rakshit, Numerical analysis of an automobile cabin thermal management usingpassivephasechangematerial,ThermalScience and Engineering Progress (2021), doi: https://doi.org/10.1016/j.tsep.2021.100870R.

[2] A. Jamekhorshid and S. M. Sadrameli, “Application of PhaseChangeMaterials(PCMs)inMaintainingComfort TemperatureinsideanAutomobile,”Int. J.Chem.Mol. Nucl.Mater.Metall.Eng.,vol.6,no.1,pp.33 35,2012, doi:doi.org/10.5281/zenodo.1057511.

[3] R. Rangappa, S. Rajoo, P. M. Samin, and S. Rajesha, “Compactness analysis of PCM based cooling systems for lithium battery operated vehicles,” Int. J. Energy Environ.Eng.,vol.11,no.2,pp.247 264,Jun.2020,doi: 10.1007/s40095 020 00339 z.

[4] M.Purusothaman,S.Kota,C.SamCornilius,andR.Siva, “ExperimentalInvestigationofThermalPerformancein a VehicleCabinTestSetup withPcmintheRoof,”IOP Conf. Ser. Mater. Sci. Eng., vol. 197, no. 1, 2017, doi: 10.1088/1757 899X/197/1/012073.

[5] A.Sharma,V.V.Tyagi,C.R.Chen,andD.Buddhi,“Review onthermalenergystoragewithphasechangematerials and applications,” Renewable and Sustainable Energy Reviews,vol.13,no.2.Pergamon,pp.318 345,Feb.01, 2009,doi:10.1016/j.rser.2007.10.005.

[6] Vikas, Ankit Yadav, S.K. Soni “Simulation of Melting ProcessofaPhaseChangeMaterial(PCM)usingANSYS (Fluent)InternationalResearchJournalofEngineering and Technology (IRJET) Volume: 04 Issue: 05 | May 2017

[7] Bureau of Energy Efficiency, “Frequently Asked Questions on BEE recommendations on temperature settingofAirConditioners,”PressInformationBureau, 2018.https://pib.gov.in/PressReleaseIframePage.aspx?P RID=1537124

[8] FarahSouayfane,FaroukFardoun,Pascal HenryBiwole, PhaseChangeMaterials(PCM)forcoolingapplications in buildings: A review, Energy and Buildings http://dx.doi.org/10.1016/j.enbuild.2016.04.006

[9] Ting Zou , Wanwan Fu , Xianghui Liang , Shuangfeng Wang,XuenongGao,ZhengguoZhang,YutangFang, Preparation and performance of modified calcium

chloridehexahydratecompositephasechangematerial forair conditioningcoldstorage,InternationalJournal of Refrigeration (2018), doi: https://doi.org/10.1016/j.ijrefrig.2018.08.001

[10] SumanKumarJha,Dr.S,N.ManikandaPrabu.“Study andanalysisofthermalenergystoragesystemusing phasechangematerials(PCM)”InternationalJournal ofAppliedEngineeringResearch,ISSN0973 4562Vol. 10No.62(2015)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal