International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1SMEC,VelloreInstitute ofTechnology,Vellore,TamilNadu,India ***

Abstract- The vehicle's braking system is a critical component that ensures safety and stability in a variety of situations. To increase control, the braking unit is connected with the Anti Lock Braking System (ABS) and Traction Control System (TCS) and provides a variety of control strategies. The current review presents the core architecture of the braking control unit, as well as a performance comparison of several ABS and TCS control strategies, such as PID control and fuzzy logic control.

Index terms- Brake Control Unit, ABS, TCS, Vehicle Control System.

Automobiles,motorcycles,trains,andplanesallhavebrakesystems.Frictionisakeyperformancecomponentinbrakesystems aswellasapossiblesourceofunwantednoiseandvibration.Differenttypesofautomobiles'brakesystemshaverelatedand similararchitecturesandprinciples.

Whenitcomestovehiclebrakingsystemscategorization,therearediscanddrumbrakesintwoandfour wheelerpassenger vehicles,aswellaspneumatic,hydraulic,andelectromagneticbrakingsystemsinbigcommercialvehicles.

Toimproveperformance,safety,andstability,moderncarbarkingsystemsareintegratedwithABSandTCS.ABSshortensthe stoppingdistanceandmaintainsvehiclecontrolwhilebraking,ensuringsafetyandperformance.TCSofferstractionduring acceleration,allowingforstabilityandperformancetobemaintained.

Asuitablebrakingsystemforalandvehicleisonethatcanswiftlyhaltorreducethevehicle'sspeedwhilemaintainingthe vehicle'sdirectionandrecoveringasmuchkineticenergyaspossible.Generally,thebrakingcontrolsystemisusedforsafety,but itcanalsobeusedforstabilityandperformancemaintenanceincertainsituations.

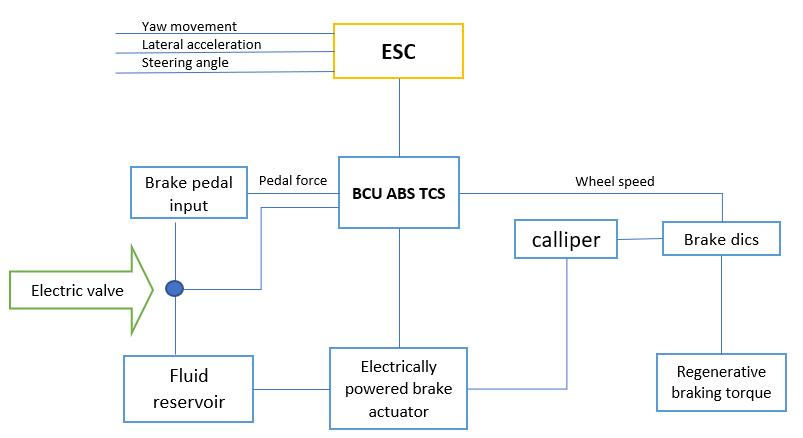

ThedesignofasinglewheelbrakestructureisshowninFigure1.Eachwheelhasadifferentconnectionbecauseeachwheel demandsadifferentamountofbrakingforce.Thepressuresensorfirstmeasuresthepressure.Thefluidissubsequentlyemptied intotheaccumulator,afterwhichthecontrolunitestimatestherequiredbrakingforceandthemotorproducesit.Intheevent thatthecontrolunitfails,theelectricvalveopens,andthesystemoperatesasastandardmechanical/conventionalbraking system.[1][2]

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Figure 1:Architectoftypicalbrakingsystem

Itismeanttokeepavehiclesteerableandstableduringhardbrakingmomentsbypreventingwheellock,HenceABSiswidely consideredasavitaladditiontoroadsafety.

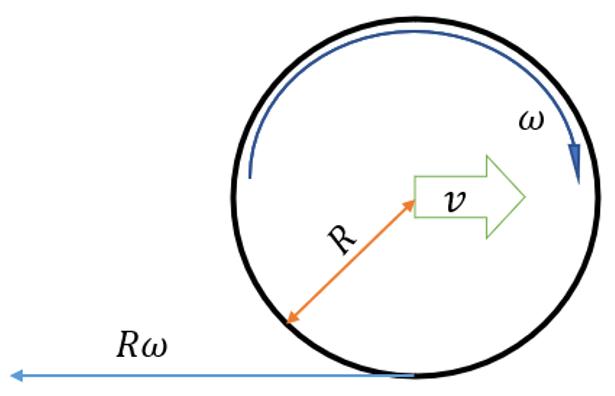

ABSkeepsthewheelsfromlockingup,ensuringdirectionalstability.Whileworking,ABSconsidersavarietyofelementssuchas vehiclespeed,acceleration/deceleration,friction,andsoon.Theanti lockbrakes(ABS)playacrucialfunctioninmaintaining traction.Thetractionforce(F)isproportionaltothenormalload(N)onthetyre,withtheequationF=µN.µisknownasadhesive coefficientanditdependsontyreconditionaswellasroadconditions.Generallyadhesivecoefficientisconsideredasfunctionof slipratio(s).[2]

Acceleration

Braking

Table 1 Slipratioequationsindifferentscenario Case Equation Were, s=Longitudinalslipratio V=vehiclevelocity R=Wheelradius

=angularvelocityofwheel

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Table1providesprincipalequationfortheconstructionofABSalgorithm.Whilebraking,wheelspeedchangesfirstandthen vehiclespeedduetolargemomentumdifference,atacertainstagethewheelvelocityreacheszerobutvehiclestillmoveswitha certainvelocity.Atthissituationslipvaluebecome1andwecallitwheellock up.ABStakeinputformthespeedsensor,which arepresentinallthefourwheelorapairinfrontandrear,ifsensordeductsslipratioisinuncontrolledregion,ABSimmediately changesthebrakepatterntomaintainthecontrolandthusavoidingthesituationofwheellock up.Comparedwithconventional antilocksystem,theelectronicallycontrolledbrakesystemeliminatesthemechanicalmovementinthesolenoidvalve,which switchesbetweenhighfluidpressureandlowfluidpressure.Thus,itscontrolismuchfasterandmoreaccurate.[2][3]

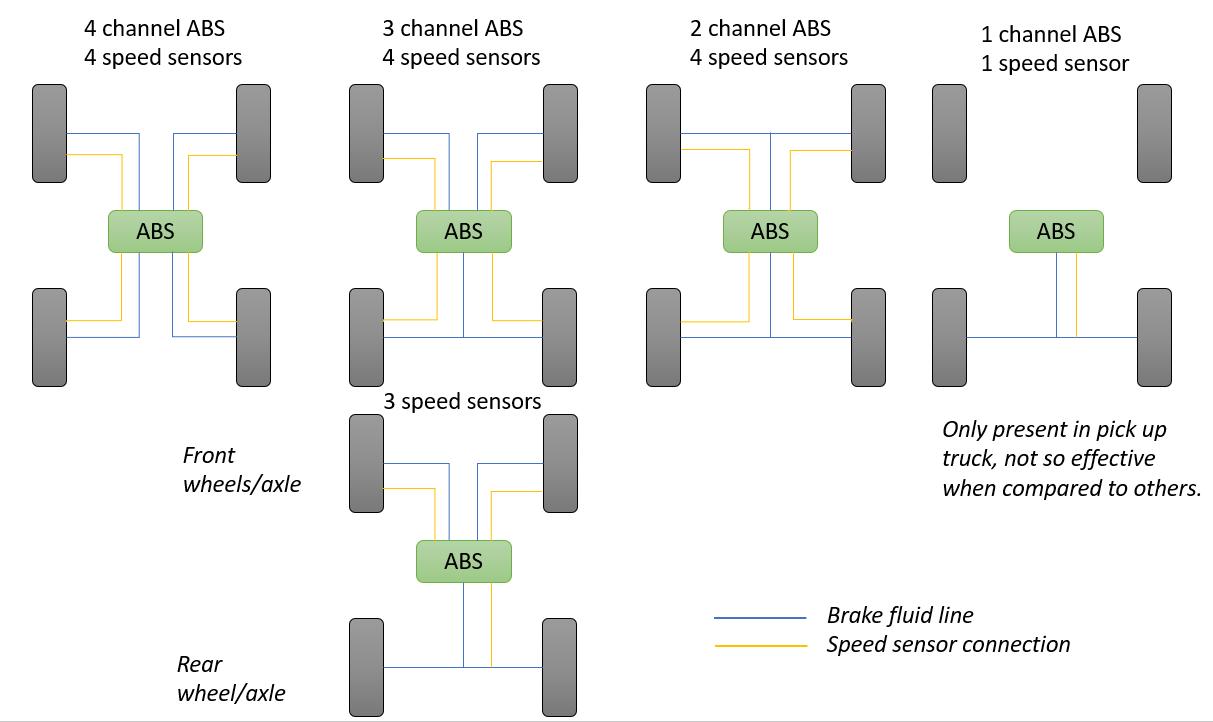

If we focus on its categorizations based on number of valves and speed sensor input, we have 4 categories with the sub categorizationstoo.Herewewilltake4 wheelerintotheconsideration.Itissimplydividingthestudybasedonindependent brakeforcecontrolovereachwheelandcommonbrakeforcecontroli.e.,havingdifferentvalveforallwheelsandsinglevalvefor rearwheels/frontwheelsrespectively.

Figure 3:TypesofABS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

TherearedifferentcontrolapproachesforthedesignofABSeachhasitsownadvantagesandnumberofchallengestoclear,such as:

(a) Optimumperformancewithmaintainingpassengercomfort.

(b) Maintainingstabilitywithdifferentbrakingforce/Torqueindifferentwheel.

(c) Workingwithvaryingbrakepadandroadcoefficientoffriction.

(d) Dependingontheroadcondition,highvariationinbrakingforcecanberequired,systemmustbequicktominimize thetimedelay.

Table 2: AnalysisofdifferentcontrolstrategiforABS

ModellingandPIDcontrolof antilockbrakingsystemwith wheel slip reduction to improve braking performance[4]

considered

5 DOF vehicle longitudinal dynamic model is utilized for the designing the ABScontrol.

Closed loop is generated and PID controller are used in inner and outer loop system to regulate the wheel longitudinalslipandmaintainingbrake torqueforreducingstoppingdistance.

Forsimulationseveralparametershave beenadoptedfromthemodernvehicle, Mercedes Benz, which is using a V8 engine.

Frontwheelbase:1.5m

Rearwheelbase:1.5m

HeightofVehicle:0.6m

Vehiclemass:1626Kg

Tyreradius:0.3m

AerodynamicdragCo.:0.29 Rollingresistance:0.01

ViscousFrictionco.:0.1Nm/radS 1

Singleequivalentlagforthrottle:0.2s

Singleequivalentlagforbrake:0.3s

Frontbrakeconstant:13.33Nm/Bar

Rearbrakeconstant:6.666Nm/Bar

Inertiaofwheel:4.5Kgm2

Finaldriveratio:2.82:1

Firstgearratio:3.56:1

Secondgearratio:2.19:1

Thirdgearratio:1.41:1

Forthgearratio:1:1

Fifthgearratio:0.83:1

A combining sliding mode controlapproachforelectric motor anti lock braking system of battery electric vehicle[5]

The model proposed is verified under TruckSim environment. It consists of vehicledynamic,suspension,powertrain modelandtiremagicformula.

ParametersofVehicle:

Grossvehicleweight:2200Kg

Radiusoftire:364mm

Wheelbase:3360mm

Inertiaofwheel:1Kg/m2

UnsprungFrontmass:450Kg UnsprungRearmass:550Kg

Brakesareappliedaftervehiclereachesthespeed of60m/s.

PDIcontrolmaintainedtheslipbetween0.1to0.3 untilthevehiclestops.

ComparedtoP,PIandPD,betterperformanceis obtainedinPIDwithlessovershootandsettling time.

Case1.Lowadhesionroad

Initialspeedis50km/hr,desireddeacceleration is1.4m/s2,optimumslipis0.06.

RLandRRwheelareinstablestatevariationof slipisobservedin0.06

Case2.Highadhesionroad

Initialspeedis100km/hr,desireddeacceleration is4m/s2,optimumslipis0.16. Minimumoscillationinslipisobserved,stability ofRLandRRwheelalsocoincides.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

AfuzzylogiccontrolledAnti lock Braking System (ABS) for improved braking performanceanddirectional stability[6]

Thefuzzycontroldevelopedconsistof2 parts,longitudinalandside slipcontrol.

Vehicledata:

Massofvehicle:1300Kg

Inertiaofvehicle:1620Kgm2

Radiusofwheel:0.33m

Inertiaofwheel:2.03Kgm2

Trackwidthfront:1.45m

Trackwidthrear:1.45m

Simulationwasdonefor3kindsofroadsurface i.e., dry, wet and ice with 0.85, 0.5, 0.15 respectivelyascoefficientoffriction.

Fordryandwetroadsurfaceinitialvelocityis100 km/hr, and for icy road initial velocity is 50 km/hr.

Brakingtorqueis3000Nm,takenwithstepinput. Pre specifiedslipis0.075inlongitudinalmember. Lessstoppingdistanceisobserved(45.3mindry road), vehicle deaccelerated with stability and possibletosteerwithsmallsideslip.

Eachcontrolapproachisprovidingthecontroleffectively,PIDprovideslesssettlementtimeandreducedsteadystateerror. Focusingonlongitudinalslip,PIDandcombineslidingmodelshowslessamplitudeinvariationofslip(maxvariationis0.12to 0.22ofslip valuein slidingmodel and0.08to0.15in PID control)anditsreductionappearsina constantmanner. In the presenceofsteeringinputPIDisobtainingthecontrolledslipregionwithpropervariationinindividualwheelspeedandslip.

TheworkingofTCSissimilartoABS,itsjobistomaintaintractionduringacceleration.Peoplegenerallygetconfusedbetween ABSandTCSoperation,ABSactsduringbrakingwhileTCSactswhenvehicleaccelerates[7].Themaximumtorqueneedstobe transmittedtowheelisdeterminedbythecoefficientoffrictiongeneratedbetweentyreandroadsurface.Iftoqueexceedsthe level,thenwheelwilllosegripresultsinlosingthecontrolofdriveronvehicle[8].

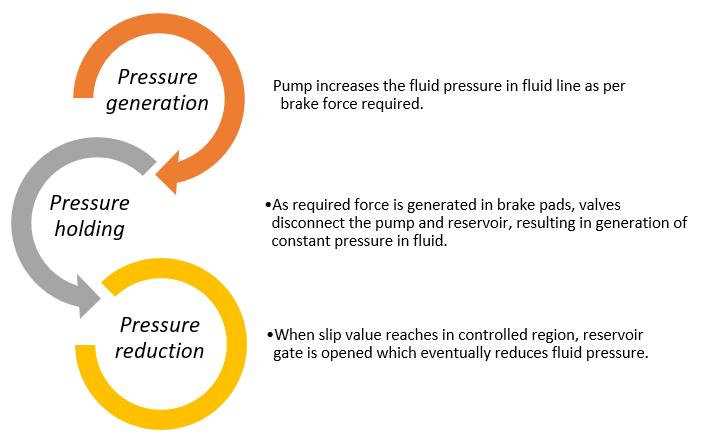

Generally,ABS,TCSandECMworkstogetherinordertomaintaintraction.Wheneverslipisdeterminedinuncontrolledregion whileacceleration,TCSsendscommandtoECU,whichactuatesthehydraulicpressurebrakestoapplybrakes,eventherequired brakepressureisalsocalculatedbytheprocesser,alternatelyTCSsendssignaltoECMwhichreducestheenginetorqueby reducingthrottle,thisalsosavethefuel,heretheactuatorisfuelinjector.InageneraEVsandhybridvehicle,separateTCSswitch isprovided.WhenitisOFF,alltheactuatorvalvesoffandvice versa[9].

Figure 4: ProcessofBrakesunderTCS.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

TCShasseveralcontrolmethods,majoroneareanalysedandcompaedinTable3.

Table 3: ComparisonsofTCSControlSystems

Reference Title Description & Parameters considered

Development of Integrated Brakes and Engine Traction ControlSystem.[10]

FuzzyandPIDcontrolisutilizedfor controlling brakes and engine actuatorsrespectively.

Vehicelparamets:

Vehiclemass:1200kg

Numberofdrivingwheels:2 Wheelradius:0.3307m Wheelinertia:2.656kg.m2 Aerodynamicdragcoefficient:0.29 Rollingcoefficient:0.01

Threecaseswerestudied,excessiveaccelerationon dry road, wet road and transition from dry to wet road.

Initialvelocityistakenas5m/sandrequiredslipis keptas0.18.

Atinitialstageforshortdurationoftimeslipexceeds targetvalue,brakecontroltakestheslipregulation roleinitiallyandafter3secenginecontrolcomesinto playforsmoothaction,laterafter7.6secbrakesget deactivatedindryroadand6.7seconwetroad.

In road transition condtion, it occurs after 15 sec hence longer action of TCS is present, at transition brakeplayfor0.35secroleandthrottlereductionis more.

Coordinatedvehicletraction control based on engine torque and brake pressure under complicated road conditions[11]

Sliding mode control approach is present to achieve max driving accelerationandassistanceofbrake forslipregulation.

Vehicleparameter:

Vehiclemass:1660kg

DistancefromfrontaxlestoCG:1130 mmDistancefromrearaxlestoCG: 1660mmHeightoftheCG:500mm Wheelbase:2790mm Wheelradius:307mm Brakediscfrictioncoefficient:0.38 Brakediscradius:122mm

Simulationwasdonein3caseswithTCS

Case 1: SplitRoadcondition: Roadfrictionforleftandrightwheelare0.2and0.8 respectively.

Highvariationandslipoccilationcanbeobservedin leftwheelbecauseoflesstraction.

Onoverallviewvehiclespeedremainstable.

Case 2:SlipperyRoadcondition: Roadfrictionis0.2andtargetslipis0.11.

Slip occilation is observed with a gap holding constant slip for short duration of time and then occilationagain.

Nobrakeactionisobserved.

Case 3:TransitionRoadconditions: Heretorqueisthetargetvalue.

Firstly road friction changes from 0.2 to 0.8, here engine torque increases to desire value, no brake action is present, increament in vehicle speed is in stablemanner.

Secondlyroadfrictionchangesfrom0.8to0.2.Here high slip is dedcuted so brakes come into play for short duration to bring wheel in stable state. Decrement in acceleration can be observed at the pointofaction.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

DevelopmentandValidation oftheControllerofVehicular ASR System via Braking Intervention[12]

Control system is developed with modern methodology V cycle, and slip control is obtained by braking actiononly.

Severalkindsoftesthavedoneonit,focusingmainly ontheroadtestwithASRECU,itsfinishedinshort durationoftimehenceappearswithhighefficiency formaintaingslip.

Tough nocontrol is presenton engine,couldeffect fueleconomy.

Integrationofthrottlemechanismshowsthegoodresultwithoutmuchvariationinlongitudinalslip,maintainingconstantslip valuewithintegratedthrottleandbrakeactuations,alsoreducingexcessivefuelconsumptioncomparingtoonlybrakeactuated ASRmechanism.WiththeintegrationofbraketorquewithcoordinatecontrolImethodfortractionmaintenance,highamountof slipvariationisobserved andit’sinunevenmanner,henceinthiscasesintegrationofthrottlemechanismwithbrakeviaPID andfuzzycontrollershowgoodresultwithapproximately 50%reductioninthrottleinputinallcasesandslipvariationfrom optimumvalueof0.18is+ 0.02whichisveryminimumvariationwithobservationofconstantreductionmannerinbrakes, providingstableaccelerationinend.

Numberofexperimentswereperformedinbrakingsystemimprovementandishotresearchtopicforengineers.Lotofnew controlstrategiesweredeveloped.ProvidedpaperdeltwithfewofthepopularonesinABSandTCSastheyarethemajor controlunitsinBrakingsystemincludingPID,SlidingmodeandvariousintegrationwithFuzzylogiccontrol.

[1]WilliamHCrouse,DonaldLAnglin,“AutomotiveMechanics”,10thedition,theMcGrawHillcompanies.

[2]Aly,Ayman&Zeidan,El Shafei&Hamed,Ahmed&A.Salem,Farhan.(2011).AnAntilock BrakingSystems(ABS)Control:A TechnicalReview.IntelligentControlandAutomation.02.10.4236/ica.2011.23023.

[3]Gao,Y.andEhsani,M.,"ElectronicBrakingSystemofEVAndHEV IntegrationofRegenerativeBraking,AutomaticBraking ForceControlandABS,"SAETechnicalPaper2001 01 2478,2001,https://doi.org/10.4271/2001 01 2478

[4]Aparow,Vimal&Ahmad,Fauzi&Hudha,Khisbullah&Jamaluddin,Hishamuddin.(2013).ModellingandPIDcontrolof antilock braking system with wheel slip reduction to improve braking performance. Int. J. of Vehicle Safety. 6. 265 296. 10.1504/IJVS.2013.055025.

[5]LinHe,WeiYe,ZejiaHe,KeSong,QinShi,Acombiningslidingmodecontrolapproachforelectricmotoranti lockbraking system of battery electric vehicle, Control Engineering Practice, Volume 102, 2020, 104520, ISSN 0967 0661, https://doi.org/10.1016/j.conengprac.2020.104520.

[6]Yazicioglu,Yigit&Unlusoy,Y.Samim.(2008).AfuzzylogiccontrolledAnti lockBrakingSystem(ABS)forimprovedbraking performanceanddirectionalstability.InternationalJournalofVehicleDesign INTJVEHDES.48.10.1504/IJVD.2008.022581.

[7]Hori,Y,Toyoda,Y&Tsuruoka,Y1998,'TractionControlofElectricVehicle:BasicExperimentalResultsUsingtheTestEV UOT Electric March', IEEE Transactions on Industry Applications, vol. 34, no. 5, pp. 1131 1138.https://doi.org/10.1109/28.720454.

[8]Yin,Dejun&Hori,Y..(2008).AnewapproachtotractioncontrolofEVbasedonmaximumeffectivetorqueestimation.2764 2769.10.1109/IECON.2008.4758396.

[9]JinL Q,LingM,YueW(2017)Tire roadfrictionestimationandtractioncontrolstrategyformotorizedelectricvehicle.PLoS ONE12(6):e0179526.https://doi.org/10.1371/journal.pone.0179526.

[10]M.M.Abdelhameed,M.Abdelaziz,N.E.ElHadyandA.M.Hussein,"Developmentofintegratedbrakesandenginetraction controlsystem," 15th International Workshop on Research and Education in Mechatronics (REM),2014,pp.1 5,doi: 10.1109/REM.2014.6920246.

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

[11]MingxinKang,LiangLi,HongzhiLi,JianSong&ZongqiHan(2012)Coordinatedvehicletractioncontrolbasedonengine torque and brake pressure under complicated road conditions, Vehicle System Dynamics: International Journal of Vehicle MechanicsandMobility,50:9,1473 1494,DOI:10.1080/00423114.2012.67274.

[12]WeidaWang,LijuanYuan,WeiZhangandHongmingZou,"DevelopmentandvalidationofthecontrollerofvehicularASR system via braking intervention," 2010 International Conference on Computer, Mechatronics, Control and Electronic Engineering,2010,pp.277 282,doi:10.1109/CMCE.2010.5609757.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |