International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

1,2,3 BE Mechanical Engineering, Savitribai Phule Pune University, Maharashtra, India Prof. Arpita Ekatpure, Dept. of Mechanical Engineering, SavitribaiPhulePuneUniversity,Maharashtra,India ***

Abstract -: In recent times the electrification of automotive powertrains is a major area of research and a lot of work has been carried out to improve its performance in comparison with its internal combustion counterparts. Among all ongoing research work, Battery Management System is one of the major areas, which is used to improve the transient performance and life of an electrochemical battery mainly a Li ion one. In this paper, we have focused our attention on the crucial parts of the Battery Management System which is, Cell balancing, the State of charge of the battery, etc. Based on the literature review, various control strategies are studied and a new optimal control strategy is defined to improve the battery performance according to application. The control strategy is developed using MATLAB/SIMULINK. In this paper. we developed an active and passive cell balancing model. For the active cell balancing technique, we chose switched capacitor technique. To have longer battery life, time required for the cell balancing must be as low as possible for which many control logics have been defined. So, various graphs are compared, to find the effect of these cell balancing techniques on the performance of the battery pack.

Key Words: AVL Cruise, BMS, Cell balancing, MATLAB, SIMULINK, Passive, Active, Switched Capacitor.

BecauseBMSistheconnectorbetweenthebatteryandthe car,itplaysacriticalroleinenhancingbatteryperformance andoptimizingvehicleoperationinasafeanddependable manner.Consequently,consideringtherapidgrowthofEV and HEV markets, there is an urgent need to develop a comprehensiveandmatureBMS.

Inthisstudy,first,wesimulatedthevehiclestandarddatain ordertounderstandtheAVLcruisethen,thesimilarvehicle istransformedinto anelectricvehicle. Furtheranalysis of developed model will be examined using AVL cruise and performance will be evaluated in real time environment. Furthertooptimisethebatteryperformance,weareusing different cell balancing techniques to increase the battery pack performance in MATLAB SIMULINK. Today Rechargeable batteries are most widely used for many applications such as electrical appliances, smartphone, industryetc.Theyareconsideredasbestoptionforelectrical

andhybridvehiclesduetotheiradvantageofhavingHigh energydensity,lowmaintenance,morechargecycles,Low self dischargeratecomparedtootherbatteriesavailablein the market. But the due to low cell voltage of this cell we need a high power battery pack to use them in case of electric vehicle. But considering the disadvantage of temperatureriseinthecellwecannotusesinglebatterycell inabulkratherwehavetousemultiplecellsconnectedin seriestogethigheroutputvoltage[1].

Majorfactorthatisaffectingtheuniformityofthecellsisthe non uniform temperature distribution. Due to multiple charginganddischargingcyclesthenetcellvoltagewilldrift downandwillcauseadecreaseinthenetcapacityofthecell. Forexample,considermultiplecellsconnectedinseries,now cell with the higher internal impedance will show higher voltagethanthatofothercellsconnectedinseries.Tilltime other cells reach the maximum capacity first cell be overchargedandthiswillleadtoincreaseinthetemperature andthegaseouspressurewithinthecellcausingitsfailure. Hencetoincreasetheoverallbatterycapacityandtoavoid the battery failure battery management system has to be adopted.Inthiscasewemainlyfocusonthecellbalancing techniquestoavoidoverchargingofthecellsforwhichwe havetwomainmethods:Passiveandactivebalancing.The passivebalancingtechniqueusesshuntresistorstobypass theadditionalvoltageintheformofheatduringthecharging anddischargingcycle[2,3].Incaseofactivebalancingcharge fromhighervoltagecellistransferredtothelowervoltage cellusingactiveelementslikecapacitorsandinductorsand fly back DC DC converters [4,5,6,7]. There are several embodiments of capacitor cell balancing methods in the literature[8,9,10,11].

Therefore,inthisstudy,weemphasizeonusingMATLAB SIMULINK software for control technique used for cell balancing to reduce the balancing time for each cell in battery pack to attain the responses (charge discharge, variationofSOCofeachcell,etc).Further,wecanalsostudy toimplementordoaco simulationofproposedtechniquein SimulinkwiththevehiclemodelinAVLCruise.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Therearemanybatterycellsavailablebutconsideringthe specific energy of lithium-ion batteries, most of the automobilesuselithium-ioncellstodevelopabatterypack. Based on the required output capacity we can design the batterypack.Foranelectricvehicleveryhighvoltagerating is required and the battery pack required is thereby of highercapacity.

Thishigh-poweroutputcanbeobtainedbyconnectingcells in series and parallel. The power rating of the battery dependsonthetotalterminalvoltageofthebattery.Thisis givenbythebelowrelation:

P=U*I

Where;U=Voltage I=Current.

(NOTE-Highercurrentacrossthecircuitgenerateshigher thermal heat so one has to consider optimum value for voltageaswellforthecurrent rating.Also,anappropriate cooling system has to be considered for heat dissipation acrossthebatterypack.)

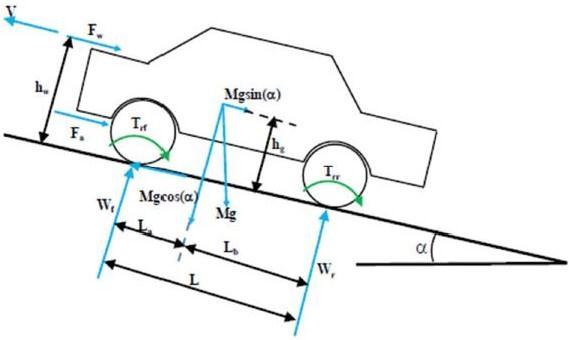

Thevehicle'spropulsionunitgeneratestheforcerequiredto propelthevehicleforward.Thisforceassiststhevehiclein overcomingresistivefactorssuchasgravity,airresistance, and tire resistance. To find the longitudinal performance characteristicsofacarweneedtoconsiderfirsttheforces acting on it while traveling in a straight line. The major externalforcesactingonatwo axlevehicleare

1.AerodynamicresistanceRa 2.RollingresistanceRrofthefrontandreartiresRrfand Rrr 3.DrawbarloadRD 4.GraderesistanceRG,(Wsinθ)

5.TractiveeffortofthefrontandreartiresFfandFr(Fora rear wheel drivevehicle,Ff=0,whereasforafront wheel vehicle,Fr=0).

Totalaerodynamicdragactingonthevehicleisgivenby: Where: V=CarVelocity ρ=AirDensity Cd=DragCoefficientAf=FrontalArea

Rolling Resistance acting on vehicle due to tyre is composedprimarilyof 1. Resistancefromtiredeformation 2. Tirepenetrationandsurfacecompression 3. Tireslippageandaircirculationaroundwheel 4. Widerangeoffactorsaffecttotalrollingresistance Totalrollingresistanceactingonthevehicleduetotyreis:

Totalgradientresistanceactingwhileclimbingtheslope Is Acombinationofthelaboveforceswillgiveusthetotal forceactingonthevehicleatthatconstantspeed.

TotalVehicularResistanceatConstantVelocity:

Powerratingrequiredbythemotorcanbegivenas: MotorPowerRequired=Ftr*V(Vehiclespeedinm/s)

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

Motor has to develop a torque that is required by the vehicle based on the resistive forces acting on it. Power outputofthemotorwillbedeterminedbyconsideringthe losses.Belowisthetotalpowerdevelopedbythemotor.

Netpowerinputprovidedbythemotorisgivenbybelow relationwhichwillaccountforthelosses.Thispowerwillbe furthertransferredtothedrivetrain.

Where, The total energy required by the motor can be determined by integrating the power that the motorhas developed.

BasedoncalculationT=27.35Nmat393.206RPMUsing motor catalogue motor selected is PM BLDC 2000W,48V,4200RPM

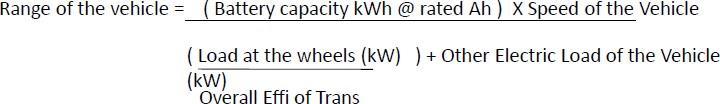

Therangeofelectricvehiclesbasedonthebatterycapacityis givenbytherelation: Table 1 Importantparameters

Power(W) Torque at Wheel (Nm) Motor RPM Required

4505.49288 17.23523379 686.4820798 10015.59941 38.31349909 686.4820798 15524.02921 59.38535025 686.4820798 21029.10605 80.44437509 686.4820798 26529.15475 101.4841653 686.4820798 32022.50162 122.4983185 686.4820798 37507.47505 143.4804401 686.4820798 42982.40594 164.4241451 686.4820798 48445.62827 185.3230604 686.4820798 53895.47957 206.1708265 686.4820798 59330.30146 226.9610992 686.4820798 64748.44011 247.6875522 686.4820798 70148.24677 268.3438783 686.4820798

Motor Torque (Nm) Accessory Load(W) Battery Capacity (kWh) 4.854995434 600 7.65823932 10.79253495 600 15.92339911 16.72826768 600 24.18604381 22.66038735 600 32.44365908 28.58708883 600 40.69373212 34.5065686 600 48.93375243 40.41702538 600 57.16121257 46.3166606 600 65.37360891 52.203679 600 73.5684424 58.07628914 600 81.74321936 63.932704 600 89.89545219 69.77114146 600 98.02266016 75.58982487 600 106.1223702

Table 3 - Calculations

Based on the above calculation it is found that the capacityofbatteryrequired isaround8kWh ontheplain roadwhenthevehicleisrunningataspeedon50kmph.And thatontheroadwith12 adegreegradientbatterycapacity requiredisequivalentto100kWh.But in the actual road drivingscenariowedon’tdriveatconstantspeedratherit depends on thedrivingcondition due to which theoretical calculatedcapacityistohigh.Hencetodeterminethe

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

performancewesimulatethevehiclemodel inAVLCruise softwareorinMATLAB.Wecanconsiderthemeanvelocity of the driving cycle and calculate the power and capacity requiredusingtheabovecalculations.

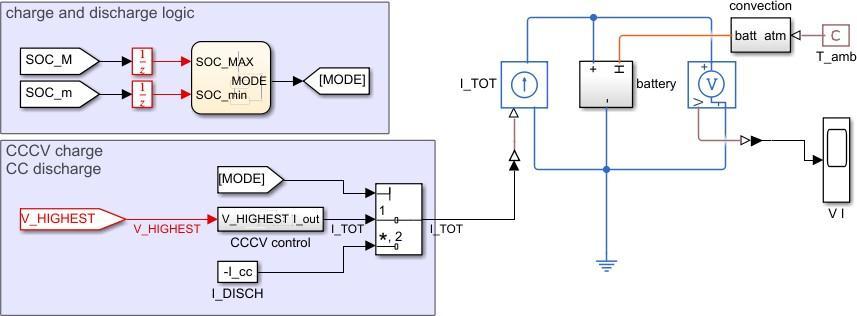

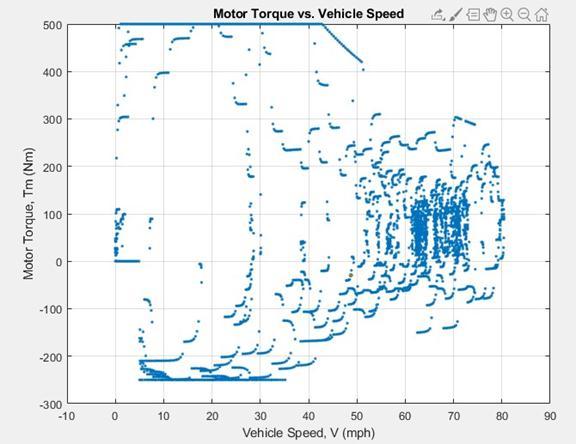

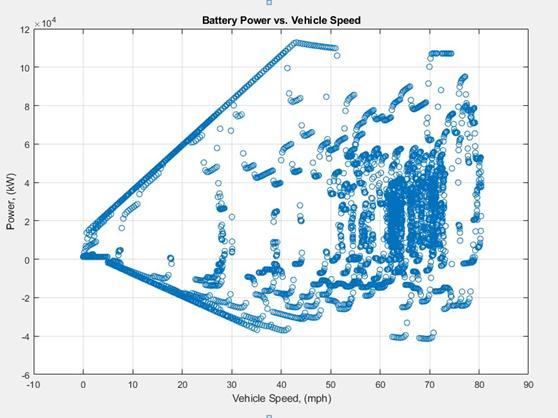

Chart2showsallthepointsatwhichmymotorisoperating at.Fromfigurewecantellthatatspeedof25 35mphmotoris operating a lot. Graph also helps to decide the size of the motorbasedontheworkingpointdistribution.Ifpointsare running out from the Torque line means we need to have largermotorforthatparticulardrivecycle Fig 2 SimulinkModel

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

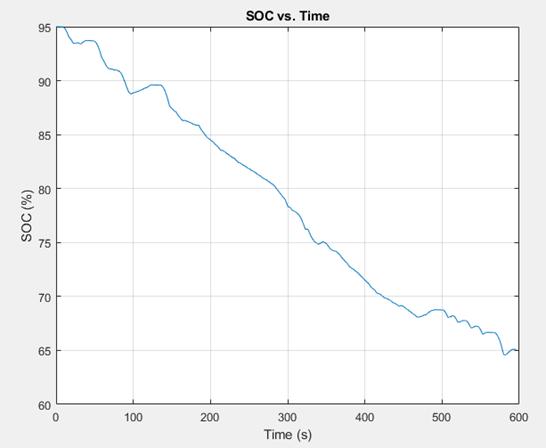

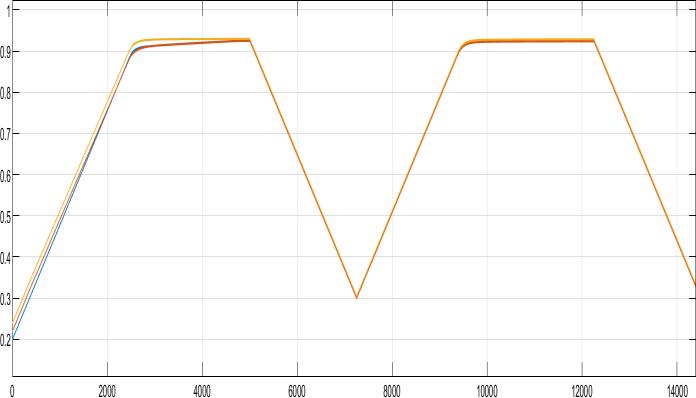

Based on the results obtained it can be seen that time requiredforthebalancingis6000seconds.Oncethecellsare being balanced based on the discharger logic battery will starttodrainandcyclerepeatsforgiventimespan.

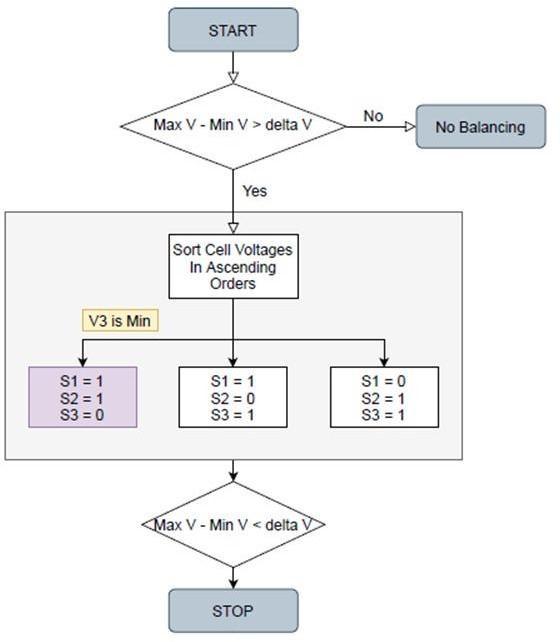

Instateflowdiagram,operationsarecarriedoutbasedon the current state of the system and based on the logic providedsystemgoesintothenextstate.Thisconceptcanbe easilyunderstoodfromtheflowchartgiveninfig.15.System will be continuously monitoring the state of charge and voltage of each cell within the battery pack. When in the differencebetweenthemaximumVoltage

andtheminimumVoltageisgreaterthan 2%itsassumed that cells are imbalanced and balancing protocol will be executed ad system will go into balancing state. Now the system will monitorVoltage of each cell and based on the logicprovideditwillarrangethecellin ascendingorderon theirvoltages.Fromtheflowchartabovelet’sassumethat cell1hasthelowestvoltage(orsaySOC)inthiscaseother twocellsshouldbedischargedunlessanduntiltheirSOCis equivalenttothethirdcell(approximateErrorof2%).For this to happen system will ON the switch 2 and switch 3 whichwillconnectcell1andcell3toshuntresistorwhichis connectedinparalleltocell.Theresistorwilldischargethe cellbygivingoutchargeinformofheat.Meanwhilesystem willkeepcheckingtheSOCdifferenceoncethedifferenceis below2%balancingsequencewillstopandalltheMOSFET willonOFFstate.

It is very important for BMS to be well maintained for batteryreliabilityandsafety, properstatemonitoringand evaluation,andfunctionalcellbalancingandchargecontrol. Duetothesereasons,thereisaneedforBMSoptimizationfor EVs to increase the reliability of BMS and optimize Ev’s powerperformance.Fromthispaper,wecanconclude with thefollowingpoints

Active balancing was continuous whereas passive balancingwasnotcontinuousandthetimetakenat higherSOCisveryhigh.

Costingofpassivebalancingcouldbeveryhighfor thelargerbatterypackandthecostdoesnotjustify thebalancingtimerequired.

By adopting different active balancing techniques anddifferentcontrollogicwecanfurtherreducethe balancing time and hence increase the overall life andperformanceofthebatterypack.

Inthefuture,wecanimplementordoaco simulationofthe proposed technique in Simulink with the vehicle model in AVL Cruise for validating the effect of techniques used in BMS

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 06 | Jun 2022 www.irjet.net p ISSN: 2395 0072

[1](Emadi,June2088),"Powerelectronicsandmotordrives in electric, hybrid electric, and plug in hybrid electric vehicles,"IEEETrans.Ind.Electron,vol.55.pp.2237 2245, June2008.

[2] Stuart A. T., and Zhu W., “Fast Equalization for Large Lithium Ion Batteries”, IEEE Aerospace and Electronic SystemsMagazine,Vol.24,pp.27 31,2009.

[3] Zhang X., Liu P., and Wang D., “The Design and Implementation of Smart Battery Management System Balance Technology”, J. Convergence Information Technology,Vol.6,No.5,pp.108 116,May2011

[4] Cao J., Schofield N., and Emadi A., “Battery balancing methods:Acomprehensivereview”,IEEEVehiclePowerand PropulsionConf.,VPPC08,pp.1 6,2008.

[5]DaowdM.,OmarN.,VanDenBosscheP.,andVanMierlo J.,“Passiveandactivebatterybalancingcomparisonbased onMATLABsimulation”,IEEEVehiclePowerandPropulsion Conf.,VPPC2011,pp.1 7,6 9Sept.2011

[6]KutkutN.H.,WiegmanH.,DivanD.M.andNovotnyD.W., “Designconsiderationsforchargeequalizationofanelectric vehiclebatterysystem”,IEEETrans.IndustryApplications, 35(1),Jan.1999.

[7] Moore, S. and Schneider, P., “A Review of Cell EqualizationMethodsforLithium IonandLithiumPolymer BatterySystems,”SAETechnicalPaper2001 01 0959,2001, doi:10.4271/2001 01 0959.

[8]WestS.,andKreinP.T.,“Switched CapacitorSystemsfor Battery Equalization”, IEEE Modern Techniques and Technology(MTT2000).ProceedingsoftheVIInternational Scientific and Practical Conference of Students, Post graduatesandYoungScientists,pp.5759,2000.

[9]PascualC.,andKreinP.T.,“Switched CapacitorSystem for Automatic Series Battery Equalization”, IEEE Applied PowerElectronicsConf.andExpo.,pp.848 854,1997.

[10] Baughman A. C., and Ferdowsi M., “Double Tiered Switched Capacitor Battery Charge Equalization Technique”,IEEETrans.IndustrialElectronics,Vol.55.pp. 2277 2285,2008.

[11]Sang HyunP.,Tae SungK.,Jin SikP.,Gun wooM.,and Myung JoongY.,“ANewBatteryEqualizerBasedonBuck boostTopology,”IEEE7thInt'lConf.PowerElectronics,pp. 962 965,2007