International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Faizur Rahman A1, Priyank Hanuman Mhatre2

1Associate Professor, Department of Mechanical Engineering, CSI College of Engineering, The Nilgiris, Tamilnadu, India 2Senior Scientist, ICAR CPRS, The Nilgiris, Tamilnadu, India faizurmech@gmail.com and priyank.mhatre@icar.gov.in ***

Abstract – In hill terrain farming, potato harvesting is a challenging job due to bad weather conditions, frequent animal disturbances, and landscapes. In this paper, a potato harvester machine was designedand developed, especiallyfor hill terrain regions. It can be easily coupled with available farm power. It can harvest 0.15 hectares per hour. Manual harvestingandmachineharvestingwerecompared.Themajor factors considered in this paper were exposed potatoes, unexposed potatoes, damaged potatoes, time to complete the harvest, labour required in collecting plant debris, potatoes, and digging the soil. Approximately 64% of potatoes were damaged during manual harvesting compared to machine harvesting. Also, 48% of the cost was saved while using machine harvesting.

Key Words: Potato harvesting, Hill terrain farming, Potato soil separation, K2 chain attachment, Manual harvesting, Potato harvesting machine

Potato(Solanumtuberosum.L)isregardedasoneofthe mostimportantvegetablecropsthatmeetIndia'snutritional needs.Indiaisthesecond largestpotatoproducingcountry next to China. Potatoes are cultivated on 21.8 million hectaresofland,producing52.5millionmetrictonnesper year.Thereisaprojectionof711.5millionmetrictonnesby 2050. The weather and the climate are the greatest challengesfortheharvestingofpotatoes.Morethan90%of thepotatoesinIndiaareharvestedduringtheOctoberand March months that fall under short days in the northern hemisphere.Duetoshortdaytimeandlackofsunlight,the productivityofthepotatoesleadstoalowerpotentialyield.

IntheNilgiris,thepotatoesareharvestedfromFebruary toMarch. Small and marginal farmerscompromise onthe yieldandoptforanearlyharvestofpotatoes,whichresults ina30 40%lossinproductivity.Also,whileharvestingthe potatoeswitheitherhandtoolsormachines,thetubersmay getdamaged.Itwasobservedthatthegreatestpercentageof damagedtubersoccurredduetothegreatestimpactofthe working bodies of the harvester [1]. Potato harvesting technologiesneedmoreimprovementsinareaslikedigging, picking,andgrading.Thepotatoharvestingmachineisbased onfourbasicoperatingprinciples:reciprocating,conveying, rotating,andspinning[2].Thispaperpresentsthemethodof

conveying and separating the potato soil mass. Major parameterslikeexposedtubers,unexposedtubers,damaged tubers,machinefieldcapacity,fuelconsumption,andcostof harvesting operations were discussed [3]. Also, there is a need for more improvements in potato soil separation. A neatpotato soilseparatingmechanismwasdevelopedand classifiedthewholemechanismintoshearingarea,bending area,throwingarea,cleaningarea,andconveyingarea.Only 0.89%ofthedamagerateofpotatoeswasobservedinthis mechanism[4].Thedesignanddevelopmentofharvesting blades, gearboxes, and roller chain conveyors were the majorrolesplayedinthispaper.Theharvestingbladeangle and conveyor rod space were kept at 210 and 20 mm, respectively[5].

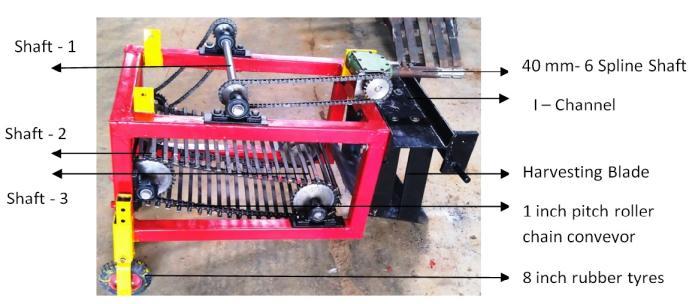

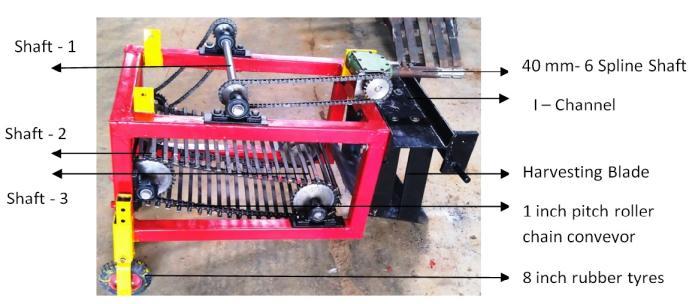

Thispotatoharvestermachine(PHM)canbeused forharvestingdifferentvarietiesofpotatoeslocatedinthe Nilgirisdistrict.Thismachinecanharvest0.15hectaresper hour.Thispotatoharvestermachine(PHM)consistsofthree main components. Harvesting Blade, Gear Box, and Chain Conveyor.Thismachineisconnectedwithatractorcapacity from18hpto30hpthroughthree pointhitchsystemsanda PTOunit.Theharvestingbladecontinuouslydigsthesoiland lifts the potato soil mass to the conveyor. Power was transferredfromthePTOshaftinthetractortothegearbox of the potato harvester machine, whereas the same was transferred to the conveyor through roller chain arrangements.So,thepotato soilmassgetsseparatedduring conveyingandthepotatoesfalltotherearofthemachine.All thepartsinthisharvestermachinewereeasilyreplaceable and economical for the farmers. The total weight of the machineis118kgandthemajorpartsofthemachineare markedanditisshowninfigure1.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

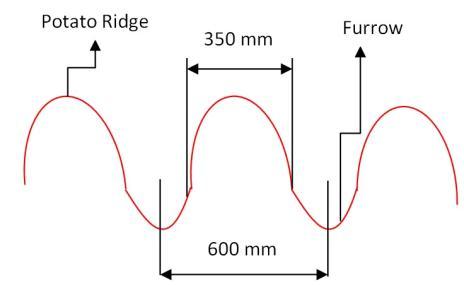

In Figure 2, it was shown that the furrows and ridgeswerethesizeofpotatoesplantedinthefield.So,the potatodiggingbladesweredevelopedaccordingly.

operatesat540rpm.Also,thespeedofthePTOshaftcanbe increasedthroughthetractorthrottleprocessdependingon the soil and harvesting conditions. A 4 inch by 20 tooth hardened steel sprocket wheel is connected to the output shaft of the gearbox. In shaft 1, 2 sprocket wheels with a diameterof4inchesofthesamesizearefixedthroughthe keyway.Onesprocketwheelofshaft 1isconnectedwiththe gearbox output shaft sprocket wheel and the other is connectedwithshaft 2sprocketwheelthrough1inchpitch rollerchains.

Fig -2:Schematicdiagramofthepotatoplantridgesand furrowsdistanceinthefield

Hardened mild steel plates and flats are used for fabricatingthe digging blades.To reduceweightanddrop the soil while digging, five laser cut slots are made in the diggingbladewithdimensionsof20mmwidthand200mm length,anditisshowninfigure3.Also,thebladeswerebent like a concave surface up to a depth of 4 inches to avoid potato cuts and enhance complete digging operations. Finally,diggingbladeswithdimensionsof400mmwide,8 mm thick, and 210 (blade angle) were fabricated. The I channelismadeupofmildsteelwithdimensionsof300mm inwidthand500mminlength,andisattachedtothedigging bladethroughfasteners.I channelwasusedtoconnectthese harvestingbladestothree pointhitchsystemsintractors. This harvest can be easily attached to the conveyor unit throughfasteners.

Fig 3:Potatoharvestingblade(a)I Channel attachedwithbladethroughfasteners(b)Lasercutslots providedinthebladetoreducethesoilload

A 1:1 right angle bevel gear box attached to this harvestermachinetorotatetheconveyorisshowninfigure 4. The 40mm hardened mild steel rod with 6 splines is attachedtothegearboxasaninputshaft.Thisinputshaftis connected with the tractor's Power Take Off (PTO) shaft through a PTO joint. Basically, the PTO shaft in a tractor

Thisconveyorisusedinthisharvestingmachineto conveythesoilandpotatomassfromthediggingbladeto the field. Also, it separates the soil and potatoes while conveying.Potatoeswillneverdropinsidetheconveyorgap becausethechaingapwasdesignedandfixedaccordingly. Here, K2 attachments with 1" pitch roller chains of 10m lengthareusedforconveyorfabricationanditisshownin Figure5.25mmmildsteelflatsof96numbersareusedto connect K2 attachments in the chain on both sides to performtheconveyingoperation.Initially,thesemildsteel flats are fastened using screws with lock nuts. After conductingmanytrialtests,itwasobservedthatscrewsand nutsweregettingloose,soflatswerereplacedbydiameter 12mmmildsteelrodsandtheywerewelded.Thisconveyor hastwoshafts,namelyShaft 2attherearsideandShaft 3at thefrontside.Adiameterof1inchmildsteelshaftof550 mmandadiameterof4inchhardenedsteelsprocketwheels of4numbersareusedintheconveyorsystem.P205Bearing unitsof6numbersareused.Furthermore,allbearingunits arehorizontallyadjustableviaslotsinthechannels.8inch rubber tyres of two numbers are used to support the harvestermachine,anditisplaced600mmwideinbetween accordingtothefurrowdistance.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3863

Fig - 4:GearboxfixedinPotatoharvestingmachineInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

TestPlace ICAR CPRS,Muthorai,Ooty

Tractor MitsubishiShaktiMT180D seriesminitractor

(a) (b) (c)

Fig 5:Conveyorunit(a)K2chainattachment(b)Side view(c)12mmdiametermildsteelrodweldedinK2 attachment

Detailsofthetestingparametersandspecifications are clearly indicated in Table 1. Figure 6 depicts the completionofalltrailrunsandfieldtestingatICAR CPRS, Muthorai,Ooty,TheNilgirisdistrict,Tamilnadu,India.

Hitching Threepointlinkage Soil SandyLoam

Moisture content(%) 7.6

Materials MildSteel&HardenedSteel

Trialruns 25

Factors Dimensionsofdiggerand thicknessofdiggingblade

Exposedpotatoes,Unexposed potatoes,Damagedpotatoes, Timetoharvest,Fuel consumption,Laboursrequired tocleantheplantdebris manualhoeandcollecting potatoes

Angle 210 FieldArea 330feet

Potatovariety KufriJyoti&KufriSwarna

Fig 6:Potatoharvestingmachineunderfieldtestingat ICAR CPRS,Ooty

Approximately 25 trial runs were conducted in a fieldwithhardsoilatanapproximatelengthof330feet.It was noted that 25 mm mild steel flats are missing and misalignedduetolooseningofscrewedfastenersrunningat highspeeds,anditisshowninfigure7.Also,somepotatoes remainunexposedwhiledigging.Inordertoovercomethe above mentioned problems, mild steel flats were welded permanently in the roller chain K2 attachments and the dimensionsoftheharvestingbladeswereslightlyalteredto digallthepotatoeswithoutanydamage.

Fieldtestsofthedevelopedharvestermachinewere comparedwithmanualharvestingusinglabourwithhand hoes.Twodifferentfieldplotsofthesamesize(1hectare) weretakenandcompared.Twoweeksbefore,aweedspray willbeusedtokillpotatoplantstocompletelyremovethe potatoes from the soil in dry conditions. At the time of harvesting,potatoplantswillbecompletelydriedandcanbe easily picked up by hand. So, two labours are required to clean the plant debris for a 1 hectare field in one hour. Finally,potatoeswereharvestedusingamanuallyoperated anddevelopedharvestermachine,andtheresultsareshown in Table 2. Few potatoes are left under the soil and two labours arerequiredtodigthesoilintwohourstocomplete 1hectareofland.Itwasalsonotedthatfewpotatoeswere cutanddamagedduringharvestingduetothematerialused and the speed of the conveyor. These cut potatoes can be storedandusedforseedingpurposes.Also,fourlaboursare requiredtocollectthepotatoesontheentireland andthe timeconsumedisaroundfourhours.

(a)

(b)

Fig 7. Variousremarksnotedaftertrialruns(a)25mm MildSteelFlatmissingduetoscrewjointfailure(b)25 mmMildSteelFlatmisalignedduetohighspeedrunning ofconveyor

Forthemanualmethod,eightlaboursarerequired perdaytocompletetheentirefield.Sixdaystocompletethe harvestDuringharvesting,laboursusehandhoestodigthe soil,andsomeofthepotatoeswillbedamagedduetotool material.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3864

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

FromTable3,itwasnotedthat48%ofthecostwas savedwhileusingthepotatoharvestermachine.Also,64% of potatoes were damaged during manual harvesting comparedwithpotatoharvestermachines.

–

PLOT 1 PLOT 2

Observation s

PotatoHarvesterMachine ManualMethod Results Cost inRs. Results Cost inRs.

Area Coveredin hectare 1 1

Description Manual Method Potato Harvester Machine

Cost difference inRs.

CostsaveinRs. 34100 17753 16347

Percentage of costsaving 48%

Total potatoes harvested 19.83 tonne

198 30 kg 18.79 tonne 18790 kg Exposed potatoes 90.80%

180 05.6 4kg 100 % 18790 kg Unexposed potatoes 6.20%

122 9.46 kg Nil Damaged potatoes 3%

594. 90 kg 8.30 % 1559.5 7kg

Timeto harvest 6hours30min 8hours/dayfor 6days

Fuel Consumptio nlitres/hour 3 1853 Nil Labours requiredto cleanthe plantdebris 2nos 1hour 1400 Nil Labours requiredfor harvesting usinghand hoe 2nos 2hour 2800 8nos 48 hours 3360 0

Labours requiredfor collecting potatoes fromthe field 4nos 4hour 1120 0 Nil

Miscellaneo us 500 500 TotalcostinRs. 1775 3 3410 0

A potato harvester machine is designed and developedespeciallyforhillterrainfarming.Theharvesting blade,gearbox,androllerchainconveyorarethethreemajor componentsusedtofabricatethepotatoharvestermachine. Inthismachine,K2chainattachmentson1inchpitchroller chain are used to fabricate the conveyor part. In the trial tests, it was noted that some potatoes were unexposed duringharvestingandafewmildsteelflatsgotmisaligned duetothespeedoftheconveyor. Harvestingthepotatoes wascomparedwithmanualandpotatoharvestermachines withthesame plotsize of1 hectare.Itwasnotedthatthe costofmanualharvestingandpotatoharvestingmachines wasRs.34100/ andRs.17753/ respectively.Nearly48%of thecostwassavedwhileusingapotatoharvestermachine, and 64% of the potatoes were damaged in manual harvestingcomparedtothepotatoharvestingmachine.

With great pleasure, we would like to extend our sinceregratitudeandthankstotheScienceandEngineering ResearchBoard(SERB)forsponsoringthisfundedproject under Teachers Associateship for Research Excellence (TARE)todevelopapotatoharvestermachineforhillterrain farming.

I again thank Indian Council of Agricultural Research(ICAR) CentralPotatoResearchInstitute(CPRI), Shimla, Himachal Pradesh and Central Potato Research Station(CPRS),Ooty,TheNilgirisinsupportingtodevelop the potato harvester machine and conduct the field experiments

[1] AlexeiSiberev,AlexandrAksenov,AlexeiDorokhovand Andrei Ponomarev (2019), “Comparative study of the forceactionofharvesterworktoolsonpotatotubers”. ResearchinAgriculturalEngineering,vol.65,pp.85 90. doi:https://doi.org/10.17221/96/2018 RAE.

[2] Dessye Belay (2021), “Design, Construction and Performance Evaluation of Potato Harvesters: A

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Review”.InternationalResearchJournalofEngineering andTechnology(IRJET),vol.8,pp.2747 2771.

[3] GamalEl DinMohamedNasr,MohamedNagiubRostom ,MohamedMorsyMohamedHussein,AhmedEl Fateh Farrag and Maher Fathy Attia Morsy (2019), “Development of suitable potato crop harvester for smallholdings”.AgriculturalEngineeringInternational: CIGRJournal,vol.21,pp.34 39.

[4] Bei Wu, Tianci Huang, Xuanxuan Qiu, Tianlin Zuo, Xiushan Wang and Fangping Xie (2021), “Design and ExperimentalStudyofPotato SoilSeparationDevicefor StickySoilsCondition”.AppliedSciences,vol.11,pp.1 21.doi:https://doi.org/10.3390/app112210959.

[5] K. C. Budhale, A. G. Patil, V. S. Shirole, S. S. Patil, R. S. DesaiandS.B.Salavi(2019),“Designand Development ofDigging&ConveyorSystemforSelf PropelledOnion Harvester”. International Research Journal of Engineeringand Technology(IRJET),vol.6,pp. 3304 3307.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3866