International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Highlighting Key Gas 4.0 Distribution Business Processes A Greek Case Study

Nikolaos A. Panayiotou1, Vasileios P. Stavrou2 and Konstantinos E. Stergiou31Professor, National Technical University of Athens, School of Mechanical Engineering, Section of Industrial Management and Operational Research, Greece, Athens, Zografos Campus, 15780, panayiot@central.ntua.gr

2Researcher, National Technical University of Athens, School of Mechanical Engineering, Section of Industrial Management and Operational Research, Greece, Athens, Zografos Campus, 15780, vstavrou@central.ntua.gr

3Researcher,National Technical University of Athens, School of Mechanical Engineering, Section of Industrial Management and Operational Research, Greece, Athens, Zografos Campus, 15780, stergiouke@mail.ntua.gr ***

Abstract The paper highlights key business processes in the Natural Gas distribution sector which can adopt Gas 4.0 andaccompanyingInformationTechnologysolutions.AGreek Natural Gas distribution company was selected as a case study. A project team formulated by researchers, company’s process owners and key users identified 155 business processes, 44 of which were highlighted as candidates for redesign based on the Gas 4.0 approach. The analysis identified four business process groups with high Gas 4.0 potential: End User and User Management, Project and Network Management, Infrastructure Network Maintenance and Infrastructure and Network Operation. The enabling technology recognized was a Customer Relationship Management system integrated with smart metering equipment, a Project Management system for network expansion integrated with a Document Management System and a Predictive Maintenance application integrated with sensors and actuators for network monitoring, utilising Machine Learningalgorithms. All the collecteddata fromthe networkwasdesignedtoberoutedtoaControlRoom,usinga NetworkMonitoringapplication.Theidentificationofthekey business processes that can benefit from Gas 4.0 is going to guide redesign initiatives and corresponding technology solutions,increasingorganizationalefficiencyandminimizing costs.

Key Words: Gas4.0,GasMidstreamSector,SmartGrid,Gas Distribution, Pipeline Maintenance, Business Process Management,Industry4.0.

1. Gas 4.0 Concept and Key Characteristics

As a concept, Gas 4.0 is considered a sectoral division of Industry4.0focusedontheNaturalGassector,havingthree major areas of activity (upstream, midstream and downstream) [1,2,3,4]. Industry 4.0 was introduced in Germany in 2011, as the country was trying to gain a strategic competitive advantage over its key industrial competitors [5, 6]. Industry 4.0 allows companies to implementthedigitalredesignofitsprocessesbasedona variety of technologies. More specifically, each company willingtoadoptIndustry4.0concept,canchoosefromapool

of options regarding IT (Information Technology), productionorsupplychaintechnologiesinordertomeetthe needs of its customers. Any company that aims to be prepared for the adoption of Industry 4.0 should develop specific components regarding the modernization of its processes and equipment. Interoperability, Virtualization, Decentralization,Real time Operation, Service Orientation and Adaptability / Scalability can be defined as main principlesduringthemajorimplementationsteps[7].

InternetofThings(IoT)andCyberPhysicalSystems(CPS) are probably considered the most critical components of Industry4.0[8].CyberPhysicalSystemscanbedefinedas industrial automation systems, integrating innovative functionalities through network in order to enable connection of the operations of the physical reality with computingandcommunicationinfrastructures[9].Examples ofCPSincludesmartgrids,autonomousautomobilesystems, medical monitoring systems, industrial control systems, robotics,andautomaticpilotavionics.IoTcanbedefinedas a global network infrastructure based on standard and interoperablecommunicationprotocolswherebothphysical and virtual ‘things’ have identities, physical attributes, virtual personalities, intelligent interfaces, and are seamlesslyintegratedintotheinformationnetwork[10].In other words, IoT refers to the billions of physical devices around the world that are connected to the internet, all collectingandsharingdata.AccordingtoGTAI[9],IoThas been revolutionizing many existing systems, and is consideredtobeakeyenablerforIndustry4.0[6,11,12]. Moreover, key tools such as big data [13, 14] and digital twins play a key role in the success of Industry 4.0. Especiallythedigital twin[15,16]usesreal worlddata in order to create simulations which can predict the way a process will perform in a future or an unpredictable situation.

InIndustry4.0,theterm“Industry”isexpandedandrefersto theoverallvaluechain[5].Intheutilitiessector,Ιndustry4.0 can be applied in a variety of cases. Utilities include companies operating in the Natural Gas sector, implementing a number of innovative solutions, such as

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Cyberphysical Systems and Internet of Things. Under this perspective,Industry4.0technologiesandtoolsareapplied withrelativesuccessintheGasindustry.Anewconcept,Gas 4.0 has been put on the agenda as an instantiation of Industry4.0andgainedgroundamongbusinessesintheGas industry [4]. Although the gas sector has some special characteristics, the profit from the reengineering and digitalization of processes in upstream, midstream or downstreamsectionspushesmanyindustrycompaniesto adoptsimilarpractices[17].

Morespecifically,intheNaturalGassector,Industry4.0has significantresearchandpracticalinterest[18].Theresearch interestfocusesonallthestagesoftheNaturalGassupply chain,emphasizingondistributiontofinalconsumers[18]. Special equipment, tools and assets are used, aiming to integrate digital technologies with the equipment already usedandthecompany’sprocesses.DigitalizationintheGas sectorincreasestheindustryproductivity,usingIoT,cloud computing, industrial internet of things, artificial intelligence, and blockchain [19]. It is highlighted that NaturalGasasaproductisclassifiedas"nonintelligent"asit cannot add embedded information or connectivity to it. There are, however, a number of Natural Gas companies which are involved in the extraction or distribution of NaturalGas(whichmeansthatthemainproductdiffers).Gas 4.0cancompletelychangethestatusquooftheNaturalGas industry, bringing huge benefits and accelerating the digitization and intelligentization. However, Gas 4.0 as a conceptisstillinitsinfancy[4].

Thepaperaimstohighlight keybusinessprocessesinthe NaturalGasdistributionsectorwhichcanadoptGas4.0and accompanyingInformationTechnologysolutions.Thiseffort willaidbothindustryandtheresearchcommunityinorder to apply Industry 4.0 technologies in a gas distribution company.Inthefollowingparagraphs,ananalysisofmain Gas4.0businessprocessestakesplace,focusingonaNatural Gas Distribution Network Operator operating in Greece (whichispracticallythearticle’scasestudy).Section2ofthe paperprovidesashortliteraturereview,analyzingmainGas 4.0toolsidentifiedintheliterature.Section3presentsthe methodological approachfollowedinordertoanalyzethe businessprocessesofthecompany.Section4analyzesthe main business processes in which Gas 4.0 can be utilized. Finally,Section5providestheconclusions,theimplications andthelimitationsoftheresearchpresentedinthearticle.

2. Technologies Involved in Gas 4.0

In the midstream sector, equipment and gas network are usually controlled by a control room using appropriate software, sensors and actuators [5]. Design and implementationofthecontrolroominordertoimplement datacollection,integrationanddecisionmakingprocesses arebasedinahumanmachineinterface.

Inmostcases,thecommunicationbetweenthecontrolroom, thepipelineequipmentandsmartmetersisperformedusing apipelinesurveillancesoftware[5].Differenttechnologies andtoolsareusedinordertoestablishthecommunication betweenthecontrolroomandthenetworkpointsofinterest [20].Nowadays,the most preferredsolutionis todevelop opticalfiberbasednetworks[21].Onthecontrary,wireless technologyprovidesasecureandhighspeedconnectionfor sendingandreceivingahugeamountofinformation[5].In addition,satellitenetworksare usedinsomecasesdue to longdistancecoverage[4].Inalltheabovementionedcases, specificequipmentisinstallednexttothepipelinenetwork, which receives signals related to the condition of the network, while intervenes whenever deemed necessary, receivingtheappropriatecommandsfromthecontrolroom (through the use of sensors and actuators). This way, detection of malfunctions is possible, and after proper processing respective maintenance systems or supply interactionsareactivated[22].

The smart meter is an advanced energy metering device whichcanbeeasilyintegratedwiththerestGas4.0network equipment.Itsmainactivityistoobtain information from the end usersandmeasurethegasconsumption,providing addedinformation to the gas company and/or thesystem operatorforbettermonitoringandbilling[5].Smartmeter supports bidirectional communications between the end usersandthecontrolroom. Inaddition,smart meter has the ability to disconnect and reconnect gas supply remotely, while it can be used in order to monitor and control the users’devices[23].Smartmetersalsoincrease company’s flexibility, as consumption changes lead to distribution grid load alterations [4]. Operation can be implemented in a number of different ways. Automated Meter Reading (AMR), allows gas companies to remotely readtheconsumptionrecordsandmainstatusinformation fromcustomers’sites.AMRcanalsodetectoutageortamper. The next generation of AMR (AMR Plus) exports hourly data from points of interest, taking daily consumption measurements, while it sends outage notifications to the controlroom.However,AMRpotentialislimited,duetoits one waycommunicationcapabilities.Forthisreason,many utility companies moved towards Advanced Metering Infrastructure (AMI). AMI provides gas companies with bidirectionalcommunicationabilities.AMIsystemsallowgas companiestoperformgridcontrolandmanagement,remote emergencyshutdownincaseofdangerorleakage,manage time based rates and implement remote smart meter programmingandgasqualitycontrol.

Specialemphasisshouldbegiventothenetworksecurity,as in the past there have been numerous attempts from external sources in order to interfere in the gas network softwareanddataandcreateseriousproblems[24,25].In ordertoimprovenetworksecurity,blockchaintechnologies can be used, allowing data transparency [26, 27, 28]. In addition,AugmentedReality(AR)isworldwiderecognized

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

asoneofthepillarsofIndustry4.0andGas4.0[29,30,31]. ARtechnologycouldassistinthetrainingofexpertworkers inrealconditions,beforetheimplementationoftheactual operation.Moreover,PreventiveMaintenancewiththeaidof machinelearningisakeyparameterinordertoreducecosts and downtime within a production unit, improving the overallexperienceofgascustomers,improvingoperational safety[32,33].

The support of employees through digitization and Information Systems introduction can offer a significant contributiontogasdistributioncompanies,improvingtheir productivityincollaborationwithGas4.0tools.Oneofthe main aims of digitalization is considered the creation of digital filescontainingmaterialsandequipment, based on principles of automation and digitization. In addition, the collaboration betweensensors,actuatorsandInformation Systemsincreasespipelinesefficiency.Gascompaniesaimto integrate the abovementioned data with maintenance Information Systems, in order to enhance maintenance monitoring.CustomerRelationshipManagementsystemsare also used in order to establish communication with company’sstakeholders[34].EnterpriseResourcePlanning andDocumentManagementSystemscanalsohelpinternal communication(businessprocessesandexistingworkflows handling). Moreover, the introduction of Business Intelligence systems ensures vertical communication betweeninformationsystemsandautomationsindifferent levels of Information Systems architecture, utilizing cloud technology and Internet of Things (IoT) philosophy InformationSystemsaimtooperateinconjunctionwithGas 4.0 in a single framework in order to optimize business processes,customerserviceandcostsavings[35].

IntegrationbetweenGas4.0andBusinessProcessconcepts isconsideredcritical forthe operationofGasDistribution companies. A range of modeling tools is used for the completerecordingofprocessesandfortheintegrationof appropriate technologies [36]. Some researchers [35, 37] proposed a complete Industry 4.0 architecture, aiming to reflect the unified way in which business processes, Information Systems and automations operate. In the followingchapters,acaseregardingPublicGasDistribution Networks(DEDAS.A.)ispresented,analyzingthecompany’s BusinessProcessesspecificneedsandintroducingnewGas 4.0 technologies, giving particular emphasis on smart pipelines,operation,maintenanceandmetering.Themain goalistocorrelatespecificbusinessprocesseswithspecific Gas4.0tools,inordertodemonstrateinpracticetheadded valueofGas4.0inthemidstreamsector.

3. A Methodology for Highlighting Key Gas 4.0 Business Processes

DEDA S.A. (Public Gas Distribution Networks) is a newly establishedcompany,aimingtooperateastheDistribution NetworkAdministrator(inMediumandLowPressure)for

Natural Gas in Greek Territory. Development of the gas network, monitoring of the distribution process, network maintenance and connection of new customers to the network are DEDAS’s main priorities. DEDA is aiming to coverthewholecountryinthenextfewyears.

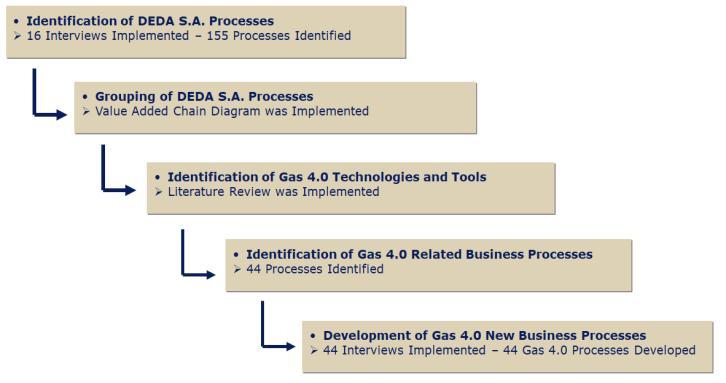

The methodology followed consists of a series of distinct steps.Atthebeginningoftheprocess,themainconcernwas theidentificationandgroupingofDEDAS.A.processes,with theaidofthecompany’sprocessowners.16personaland groupinterviewstookplace,involving11DEDAemployees (processowners),resultinginaValueAddedChainDiagram (VACD). As a next step, a literature review took place in ordertoidentifyGas4.0technologieswhichcouldapplyand improveDEDA’sbusinessprocesses.Theliteraturereview focused exclusively on the Natural Gas industry, trying to identify technologies that could be used. Subsequently, business processes in which Gas 4.0 techniques could be adoptedwereidentified.Literaturereviewandinterviews’ results were combined in order to identify candidate businessprocesses.Finally,anefforttookplacewiththeaim ofplanningthefuturesituationregardingthe44 business processeswhichhavebeenidentified.44personalandgroup interviewstookplace,involving25DEDAemployees(senior executivesandcompanyofficers).Intotal,60personaland groupinterviewstookplace.Figure1depictsthesuggested methodological steps to be followed regarding the methodologydevelopment.

Fig -1:MethodologyforHighlightingandReengineering KeyGas4.0DistributionBusinessProcesses

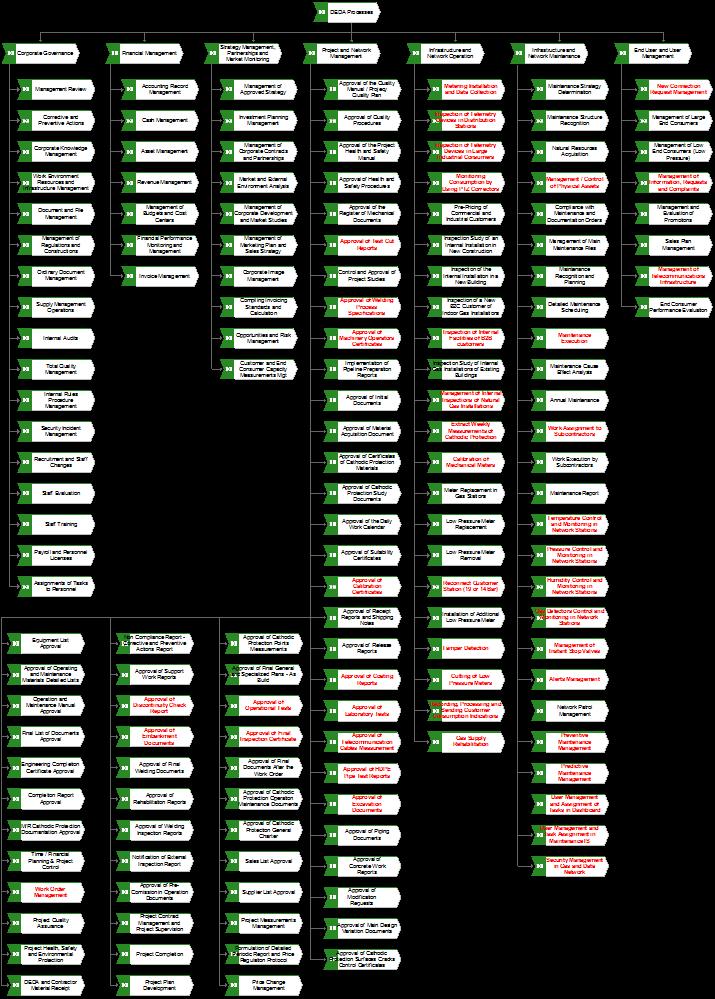

Asatotal,155processeshavebeenidentified,dividedinto7 processgroups,asfollows:

•CorporateGovernance(17processes)

•FinancialManagement(7processes)

•StrategyManagement,PartnershipsandMarketMonitoring (10processes)

•ProjectandNetworkManagement(65processes)

•InfrastructureandNetworkOperation(22processes)

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

•InfrastructureNetworkMaintenance(26processes)

•EndUserandUserManagement(8processes)

ThecorrespondingValueAddedChainDiagramisdepicted inFigure2.Theliteraturereviewresultsarepresentedinthe second chapter of the article. As regards the forth step, a totalof44processeswerefoundinwhichGas4.0concepts and technologies could be used in an integrated way. In order to understand the nature of DEDA’s Business Processes, as well as their improvement possibilities, a BusinessProcessManagementarchitecturewascreated.The views ofthearchitectureanalysishavebeendetectedand categorizedasfollows[15]:

•Organization View: It encompasses the organizational structureofthecompanyaccordingtoemployees’positions anditsallocationindepartments.

•ProcessView:Itcomposesoftheprocesses,sub processes andactivitiesoftheorganization.

•Information Systems View: It depicts the Information Systems used by the company as well as the applications includedinthemandtheirinterconnections.

•Industry 4.0 and Internet of Things View: It analyzes the utilization of automations in the operations of semi autonomous functions using sensors, actuators and tele communicationnetworks.

•Documents/Files View: Recording and classification of significantdocumentsandfilesfortheBusinessProcesses operationareincludedinthisview.

•Rules/LegislationView:Itreferstothebusinessrulesand lawswhichinfluenceorganizationprocessesandshouldbe noteddown.

•Risks/ControlsView:Itincludesriskslistingaccordingto theircategoryandtheirimplicationsinbusinessprocesses.

•Products/Services/CustomersView:Itcontainstheanalysis ofproductsandservicesprovidedbytheorganizationand the approaches on the basis of which its main customer categoriesareserved.

Depending on the views described, ARIS (Architecture of IntegratedInformationSystems)wasdecidedtobeusedas the business process modeling architecture. ARIS was selected not only because it completely encompasses the views which have to be included in the analysis, but also because it can be completely understandable and easily accessiblebyDEDA’semployees.

4. Incorporation of Gas 4.0 in DEDA’s Business Processes

ConcerningtheidentificationofBusinessProcessesinwhich Gas4.0technologiescouldbeused,atotalof44 processes werefound.EachprocesswasanalyzedwiththeaidofARIS architecture using BPMN (Business Process Model and Notation) diagrams, while specific additional architecture diagrams were implemented, in case it was deemed appropriate. 44 interviews with DEDA employees were conductedinthisstageofthemethodology.Theprocesses identifiedarehighlighted(bothinboldandwithredcolour) inFigure2.

Fig 2:DEDAValueAddedChainDiagram

The Business Process analysis indicated that the main processesofDEDAfocusonthegasnetworkconstruction(at least until the network is fully developed), the network maintenanceandoperation,aswellasthefinalconnectionof userstothenetworkandcustomerservice.Thisleadstofour business process groups that could be radically improved (ProjectandNetworkManagement,InfrastructureNetwork Maintenance, Infrastructure and Network Operation, End UserandUserManagement).Alltheproposedinnovations,

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

automationsandInformationSystemsshouldbeintroduced aroundtheseprocessgroups.

4.1 Project and Network Management group of processes

Project and Network Management group of processes is considered critical regarding the Natural Gas network, especiallyforDEDA,whichaimstoexpanditsnetworkand servea largeramountofcustomers.Atthistime, network expansionprojectsarebeingcarriedoutinalmosttheentire Greek territory. However, the management of these processes faces a number of intractable problems. For example, the processes are implemented without using Information Systems, and there is no possibility to utilize datafrompastcompletedprojects.Inordertoimprovethe existing situation, a number of processes related to the developmentofthecompany'snetworkwillbereengineered (Selection of Contractors, Management of Bid Evaluation, ProjectTimeManagement,ProjectSupervisionandContract Management,PayApprovals,DeliveryofMaterials,Project Completion, Work Orders Management) using a Project ManagementInformationSystemsupportedbyaDocument andWorkflowManagementsystem.

Itshouldbehighlightedthatallthecompany’sprojectsare implemented with the aid of subcontractors, while the companyislimitedtoamanagerialandsupervisoryrole[2]. Thelifecyclemanagementofsubcontractor’scontractswill beimplementedthroughthenewappropriateInformation System. This system has the main aim to monitor the progressofthecompany’sprojects,correctingandupdating schedules. At predefined time windows, the system deals withtheapprovalofpaymentsregardingsubcontractors(in collaborationwiththeInformationSystemsofthefinancial department of the company). For this reason, special attentionwaspaidinordertolinktheprojectmanagement procedures with corresponding financial processes regarding the issuance of invoices, through an existing InformationSystem. The wholeinterface isgoing toserve both the materials procurement and subcontractor’s payments, in an integrated and IT supported way. In addition,thesystemicrolesforallthestakeholdersinvolved in Project and Network Management processes were defined.Standardizationofallthedocuments(electronicor not) existing in the abovementioned processes also took place, as well as configuration of the corresponding automatedworkflows.

An additional crucial factor during the project implementationisthesupplyofprojectmaterials.DEDAis responsible for the materials procurement, which are subsequentlytransportedtotheprojectsiteinorderto be used by the subcontractors. Through the appropriate Information System, the project materials are selected (basedonpriceandspecifications)withmethodsthatmay differ depending on the case (open tender, closed tender,

reverseauction)[2].Asregardstheprojectcompletionstep (which is the final step of the projects), the Project Management Information System aids in the project final control,sothatboththecompanyandthesubcontractorsare guaranteedthattheprojectmeetsthespecifications ofthe initialcontract.

Anumberofinterviewswiththeprocessowners(whowill be the future Project Management Information System users)wereconductedinordertomoreaccuratelyrecord therequirementsandfunctionalspecificationsofthesystem. As thecompany'sNatural Gasnetwork isgoing to expand considerably, the reengineering of Project and Network Managementprocesseswiththesimultaneousintroduction ofaProjectManagementInformationSystemareconsidered criticalfactors.Theseparameters,alongwiththetrainingof subcontractorsonthenewprocesses,specifyasecureand sustainableway,allowingthecompanytoproceedsafelyto thenextimplementationsteps.

4.2 Infrastructure Network Maintenance Group of Processes

Infrastructure Network Maintenance can be implemented either in a preventive or in a predictive way. In the reengineeredprocesses,whichwillbebasedontheGas4.0 techniques, real time network status will be monitored throughthecontrolroomandpossiblemalfunctionswillbe detected. The Control Room will be the heart of the data transmission“to”and“from”thenetworkpointsofinterest, communicatingwithsensors,actuatorsandsmartmeters, through the operation of a parallel data network. The Control Room will be based on a Network Monitoring application,inordertomonitorpipelinespointsofinterest andendusersinformation,takingtheappropriatedecisions. The Network Monitoring application will operate in close cooperation with the communication network (and the corresponding equipment), based on wireless technology (LoraWan protocols). Wireless systems will transmit information from the metering devices and the entire networkinfrastructuretotheControlRoom.

The Network Monitoring application will be closely associated with a Predictive Maintenance application. Predictive Maintenance application is going to utilize the wirelessnetwork(placedatvariouspointsofthepipeline) enabling the company to predict the time remaining until failure.Predictivemaintenancealsoinvolvestherepairingof the machinery in order to keep it working longer. The applicationwillbebasedonMachineLearningtechniques, supportingbusinessneeds.TheaimofMachineLearningis to construct a predictive maintenance model containing multiple variables. Based on Machine Learning, the applicationwillbeabletoidentifyequipmentcondition,and proceedwithpredictivemaintenanceprocesses.Incaseof equipmentfailure,thecompanyhastoproceedwithreactive maintenance,whichmeansthatthereplacementcostwould bemuchhigher,aswouldbethereplacementtime.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Incombinationwithpredictivemaintenance,theNetwork Monitoring application can also support preventive maintenance processes. In this way, a preventive maintenance program is exported, in order to carry out specific maintenance tasks related to different network equipment.Theabovementionedprogramcouldassistthe companyinordertosaveresourcesduringthemaintenance process. Moreover, the use of long term data is going to assistduringthelifespan estimation ofthemanufacturing equipment.

Restorationofgasnetworkleakagesoroutages,causedby malfunction or malware, is also considered a difficult situation which usually takes much longer than expected. Especiallyiftheproblemoccursduringthesummermonths whenthereisnohighdemandforNaturalGas,thenitcanbe identifieddaysorevenweeksafteritsoccurrence.Although "standard"repairtimeshavenotbeencalculated,theyare certainly not considered satisfactory. In the reengineered process, based on the use of sensors along the entire network,theleakagelocationisquicklyidentified.Incaseof emergency,avehiclemaybesentandtransmitimagefrom the damage area so that appropriate personnel and equipment can be dispatched. All data are stored in the NetworkMonitoringapplicationimplementedinthecontrol room.

Finally,itshouldbehighlightedthatInfrastructureNetwork Maintenance processes are usually carried out in collaborationwithsubcontractorswhoundertakepartofthe workassigned.Subsequently,trainingofsubcontractorsin the new improved processes is a matter of particular importance.Nevertheless,andincontrasttotheProjectsand Network implementation, the company's strategy is to become independent from subcontractors in the field of maintenance.Inthiscontext,alltheprocessesimplemented exclusivelybysubcontractorsarereengineeredinorderfor thecompanytoacquiretheappropriateknow how,andto be able to perform the necessary activities with its own means.

4.3 Infrastructure Network Operation Group of Processes

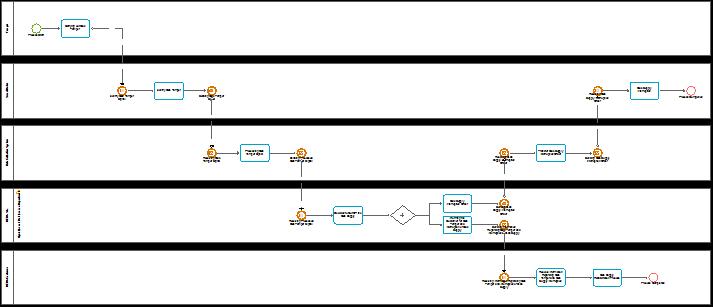

As regards the Infrastructure and Network Operation processes which are reengineered involving Gas 4.0 techniques, they concern a number of measuring devices whicharedeployedalongthenetwork.Anumberofmetrics are monitored by the control room in real time, using appropriate sensors. Both the consumption measurement process and the customer life cycle process will be monitoredandsupportedbyacorrespondingInformation System. This Information System will manage all the availableinformationregardingthestatusofeachcustomer (orpotentialcustomer),whileitcantransmitdatafromone business department to another in order to complete the requiredactions.Inaddition,theinstallationofnewsmart metering equipment is taking place in order to exchange

information between the final consumers and the control room of the company. A smart secure gateway will be installed in the metering system of the clients in order to ensure data transmission. Smart meters are going to facilitate and automate the Consumption Management Process, while reducing the costs involved. These smart meters also undertake a number of other processes (leak detection,gastamperdetection).Thereengineeredtamper detectionprocessisdepictedinFigure3,asanexample:

Fig 3:DEDATamperDetectionProcess

A critical part regarding the network operation is the measurementofgasqualitythroughtelemetryequipment. For this purpose, a series of detectors (pressure, temperatureandhumiditydetectors)areplacedinspecific andpreselectedpointsofthenetworkinordertotransmit data to the control room, measuring the gas quality. In a similarway,gasconsumers(andespeciallylargeindustrial consumers)arerequiredtocomplywithcertainstandards regardinggasquality.Indoordetectorsareinstalledinorder tocollectdatafromindustrialcustomerfacilities,whilethey sentdatatothecontrolroominordertocontroltheproper facilityoperation.

As a final step, after the provision of services, DEDA's invoicing process takes place. The invoicing process is managedthroughanintegratedInformationSystemwithfull visibility, while employees have the ability to monitor invoices throughout their life cycle. When the accounting department receives an invoice, this typically follows an approval process, while the invoice is matched with a purchase order or contract. The integrated Information System streamlines this workflow by scanning invoices, while all approvals are implemented through the system. Onceinvoicesareapproved,theyarestoredonthecloudfor easyaccessatalaterdate.

4.4 End User and User Management Group of Processes

Finally, in the End User and User Management group of processes,thepotentialcustomersexpresstheirinterestin order to be connected to DEDA’s network. In case gas networkisavailableinthecustomer’sarea,theconnection canbeimplemented.Inaddition,thegroupincludesasetof technicalandmanagerialprocesseswhichfacilitateboththe connection of new customers and their consumption measurementatpredefinedtimewindows.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

In the current situation, the abovementioned group of processes requires constant effort from the part of the company and a huge workload to be processed. The automationoftheprocessleadstoresourcesavingswhich couldbeplacedtoothercompany’sprocesses.AnewCRM (CustomerRelationshipManagement)softwareisgoingto handlenewconnectionrequests,inordertobecompleted smoothly. The same CRM software is going to handle stakeholder’scomplaints,inordertohaveaunifiedviewof thecustomer'sbehaviorduringtheirlifecycle.

Specializedtechniqueswereimplementedinordertoensure vertical communication of all the company’s Information Systems,displaythewholeavailableinformationinasingle pointandfacilitatedecisionmaking.Verticalcommunication willbesecuredusingaBusinessIntelligencemodule,using cloud technology and Internet of Things philosophy. It is highlightedthattechnologiesadoptedbyDEDAS.A.arenot theonlyGas4.0technologieswhichcanbeappliedinagas distribution company. On the contrary, there is a high probabilitythatDEDAisgoingtoadoptadditionalGas4.0 technologiesinthenextmaturitysteps,inordertofurther improveitsefficiency.

5. Conclusions

The reengineering and modernization of companies activatingintheutilitiessectorwiththeaidofIndustry4.0 tools and techniques are steadily gaining ground. In the DEDA’s case, through the reengineering using Gas 4.0 techniques and technologies, critical business processes wereenhancedwithautomationequipmentandΙΤsolutions. Gas 4.0 has the potential to increase business processes’ efficiency and effectiveness, aiding in rational decision making.EndUserandUserManagement,Infrastructureand Network Operation, Infrastructure Network Maintenance, Project and Network Management are major Natural Gas distributionactivityareasaroundtheGas4.0concept.

Gas 4.0 use in DEDA’S business processes affects a wide groupofstakeholders.DEDAwillhaveanundeniablebenefit asGas4.0reengineeringwill allowthecompanytoutilize state of the arttechnologiestoprovidehighqualityservices toitscustomerswitheconomicalandsustainableway.Butin reality, the results of these improved services are finally reaped by both customers and the customers of DEDA customers, who are the end users of Natural Gas. ImprovementofservicesprovidedtoDEDAcustomerswill offerthepossibilityofafasterandmoreaccuratepricingto final consumers, recording at the same time a number of otherconsumption parameterswhichareimportantto all networkusers.Inaddition,efficientgashandlingcanbring multipleeconomicbenefitstothewholeindustrybutalsoto other industries, multiplying the benefits for the national economy. Further, the issue of the safe operation of the networkandthepossibilityofimprovedpreventiveoreven predictivemaintenanceorimmediateinterventionincaseof

problem (due to damage, accidental events or deliberate actions)isaparameterthataffectsthegeneraleconomicand socialactivityofthecountry.

The contribution of Gas 4.0 in process groups such as Infrastructure Network Maintenance, Infrastructure and NetworkOperationandProjectandNetworkManagement becameimmediatelyevident.Theeffectivemonitoringand control of the gas network through the control room implementation,utilizingautomations(sensors,actuators, smart meters) in line with Gas 4.0 philosophy, pushesthe companytowardsa “doing morewithless” philosophy. In otherwords,thecompanyreducesmaintenancecostswhile increasingautomation,digitalization,safetyandsecurity.

IncollaborationwithGas4.0technology,theintroductionof supportiveInformationSystems(acollaborativeCustomer RelationshipManagement,aProjectManagementSystem,a Document and Workflow Management system, a Network Monitoring Application and a Predictive Maintenance Application) proved to play a key role in order to achieve fullyintegratedBusinessProcesses.AsCRMwasthekeyto bring the company closer to the other stakeholders, the ProjectManagementsoftwarefacilitatedthemonitoringof network projects. The Network Monitoring application providescompleteintegrationwithPredictiveMaintenance application, coordinating and facilitating Network MonitoringandNetworkMaintenance.

Asregardsresearchlimitations,itshouldbeemphasizedthat the study refers to a Natural Gas company, and more specificallytoacompanywhichoperatesintheNaturalGas distributionsector.Inthecaseofacompanyoperatingina different sector, different tools should be selected, as the company’s business process may differ significantly. It should also be highlighted that DEDA S.A. has as its main activitytooperateastheNaturalGasDistributionNetwork Administrator,inMediumandLowPressure.Corresponding companies may need to adopt different tools and methodologiesiftheyactivateindifferentfossilfuelssuchas oil,oriftheimplementationtakesplaceinhighpressure.The case study took place is a company operating in Greece, a marketwithspecificcharacteristics(suchaslowmaturity). Special attention should be given to the market maturity issue, and different tools are about to be selected for a similarcompanyinadifferentcountry.Incasetheresultsof theresearchhavetobeappliedtoanothersimilarcompany, a detailed study of the company’s processes must have preceded(asitwasmentionedinthemethodologychapter).

Suchstudiesareconsideredveryimportantfortheresearch community,astheycanobtainaclearpictureregardingthe industry development. On the other hand, industry executives can obtain specialized knowledge regarding specificissues,suchasbusinessprocessreengineeringand theintroductionofIndustry4.0technologiesintoindustrial businessprocesses.Inthefuture,particularattentionshould

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

bepaidtoothersectionsofthegassector,asthemidstream section is currently attracting the main research effort. Businesses in the gas industry, in whatever section they belongto,andinordertoreapthebenefitsofGas4.0,should putbusinessprocessesatthecenteroftheirdesign,tryingto adapt the appropriate tools. In addition, the evaluation of any redesigned process based on the Gas 4.0 and the correspondingtoolsshouldbebasedonacarefullydesigned evaluation process, in order for the adoption of the new processtobringthedesiredresults.

ACKNOWLEDGMENTS

«Acknowledgment: Thisresearchhasbeenco‐financedby theEuropeanUnionandGreeknationalfundsthroughthe Operational Program Competitiveness, Entrepreneurship and Innovation, under the call RESEARCH CREATE INNOVATE(projectcode:T1EDK 01825)».

REFERENCES

1. I.S. Korovin, M.G. Tkachenko, “Intelligent oilfield model”,ProcediaComput.Sci.,2016,101,pp300 303.

2. O.Elijah,P.A.Ling,S.K.A.Rahim,T.K.Geok,A.Arsad,E.A. Kadir, M.Y.A. Abdulfatah, “Survey on Industry 4.0 for the Oil and Gas Industry: Upstream Sector”, IEEE Access,2021,Vol9,pp144438 144468.

3. W.Z. Qin, “Intelligent process manufacturing an efficient way to upgrade traditional refineries”, Petroleum&PetrochemicalToday,2016,Vol24,pp1 4

4. H.Lu,L.Guo,M.Kun,“OilandGas4.0era:Asystematic review and outlook”, Computers in Industry, 2019, Vol111,pp68 90

5. N.Panayiotou,V.Stavrou,K.Stergiou,“IdentifyingKey BusinessProcessesThatCanBenefitfromIndustry4.0 intheGasSector:ThePublicGasDistributionCasein Greece”,InB.Lalicetal.(Eds):APMS2020,IFIPAICT, pp373 380,2020.

6. L.D.Xu,E.L.Xu,L.Li,“Industry4.0:stateoftheartand future trends”, International Journal of Production Research,2018,Vol56,No8,pp2941 2962

7. Cleverism,“Industry4,0:Definition,Design,Principles, Challenges, and the Future of Employment, 2017, availableonline:https://www.cleverism.com/industry 4 0/(accessedon10/05/2022)

8. N.Panayiotou,V.Stavrou,K.Stergiou,“Reengineeringof the New Customer Gas Connection Process Utilizing Industry4.0Technologies,TheGreekCaseofPublicGas Distribution Networks S.A”, ISCSIC, Amsterdam, Netherlands,September25 27,2019

9. R.Y.Zhong,X. Xu, E. Klotz, S.T.Newman, “Intelligent Manufacturing in the Context of Industry 4.0: A Review”,Engineering,2017,Vol3,Νο5,pp616 630.

10. R. Kranenburg, “The Internet of Things: A Critique of Ambient Technology and the All seeing Network of RFID”, Network Notebooks 02, 2007, Institute of NetworkCultures,Amsterdam

11. T.R.Wanasinghe,R.G. Gosine,L.A.James,G.K.Mann,O. IdeSilva,P.J.Warrian,“TheInternetofThingsintheOil andGasIndustry:ASystematicReview”,IEEEInternet ofThingsJournal,2020,vol7,no9,pp8654 8673.

12. W.Z.,Khan,M.Y.Aalsalem,M.K.Khan,M.S.Hossain,M.A. Atiquzzaman, “Reliable internet of things based architecture for oil and gas industry”, 19th InternationalConferenceonAdvancedCommunication Technology(ICACT),IEEE,2017,pp705 710

13. E.Haidy, “UnleashingIndustry4.0Opportunities:Big Data Analytics in the Midstream Oil & Gas Sector”, International Petroleum Technology Conference, Dhahran,KingdomofSaudiArabia,January2020

14. T. Nguyen, R.G. Gosine, P.A. Warrian, “Systematic reviewofbigdataanalyticsforoilandgasindustry4.0”, IEEEaccess,2020,Vol8,pp61183 61201.

15. Y.N.A.Imamverdiyev,“Conceptualmodelofdigitaltwin fortheoilandgasindustry”,ProblemsofInformation Technology,2020,pp41 51.

16. T.R. Wanasinghe, L. Wroblewski, B.K. Petersen, R.J. Gosine,L.A.James,O.DeSilva,P.J.Warrian,“Digitaltwin fortheoilandgasindustry:Overview,researchtrends, opportunities,andchallenges”,IEEEaccess,2020,Vol8, pp104175 104197.

17. K.Georgiou,N.Mittas,I.Mamalikidis,A.Mitropoulos,L. Angelis,“AnalyzingtheRolesandCompetenceDemand for Digitalization in the Oil and Gas 4.0 Era”, IEEE Access,2021,Vol9,pp151306 151326

18. M.L. Montanus, “Business Models for Industry 4.0: Developing a Framework to Determine and Assess ImpactsonBusinessModelsintheDutchOilandGas Industry”,2016,DelftUniversityofTechnology,Faculty ofTechnology,PolicyandManagement

19. C.Toma,M.Popa,“IoTSecurityApproachesinOil&Gas Solution Industry 4.0”, Informatica Economica, 2018, Vol22,No3,pp46 61

20. M. Faheem, S.B.H. Shah, R.A. Butt, B. Raza, M. Anwar, M.W. Ashraf, M.A. Ngadi, V.C. Gungor, “Smart grid communication and information technologies in the perspective of Industry 4.0: Opportunities and

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3822

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

challenges”, Computer Science Review, 2018, Vol30, pp1 30.

21. J.Ramsay,L.Noble,G.Lockyer,M.Alyan,A.AlShmakhy, “Addressing the Limitations of Oil and Gas 4.0 Surrounding Distributed Fiber Optic Data Streams”, Abu Dhabi International Petroleum Exhibition & Conference,AbuDhabi,UAE,November2021

22. N.Qarabash,S.Sabah,H.Qarabash,“Smartgridinthe contextofindustry4.0:anoverviewofcommunications technologies and challenges”, Indonesian Journal of Electrical Engineering and Computer Science, 2020, Vol18,No2,pp656 665.

23. J.Zheng,D.W.Gao,L.Lin,“Smartmetersinsmartgrid: an overview”, Proceedings of the green technologies conference,2013,p57 64

24. S.Mehdiyev,T.Fataliyev,“Industry4.0:TheOilandGas Sector Security and Personal Data Protection”, International Journal of Engineering and Manufacturing(IJEM),2020,Vol2,pp1 14

25. J.R.Dancy,V.A.Dancy,“Terrorismandoil&gaspipeline infrastructure:Vulnerabilityandpotentialliabilityfor cybersecurityattacks”,ONEJ.,2017,Vol.2,No.6,p.38.

26. H. Lu, K. Huang, M. Azimi, L. Guo, “Blockchain technology in the oil and gas industry: A review of applications,opportunities,challenges,andrisks”IEEE Access7,2019,pp41426 41444

27. S.B. Rane, Y.A.M. Narvel, “Re designing the business organization using disruptive innovations based on blockchain IoT integrated architecture for improving agility in future Industry 4.0.”, Benchmarking: An InternationalJournal,2021,Vol28,No5,pp1883 1908.

28. M.Javaida,A.Haleema,P.P.Singhb,S.Khanc,R.Suman, “BlockchaintechnologyapplicationsforIndustry4.0:A literature based review”, Blockchain: Research and Applications,Vol2,No4,2021.

29. A.K.Saroha,A.B.Pal,“Industry4.0:ApplicationsinOil and Gas Industry”, Handbook of Smart Materials, Technologies,andDevices:ApplicationsofIndustry4.0, 2021,pp.1 27,SpringerInternationalPublishing.

30. F. Bruno, L. Barbieri, E. Marino, M. Muzzupappa, L. D’Oriano, B. Colacino, “An augmented reality tool to detectandannotatedesignvariationsinanIndustry4.0 approach”, The International Journal of Advanced ManufacturingTechnology,2019,Vol105,No1,pp875 887.

31. G.M. Santi, A. Ceruti, A. Liverani, F. Osti, “Augmented Reality in Industry 4.0 and Future Innovation Programs”,Technologies,2021,Vol9,p.33

32. Y.N.Pandey,A. Rastogi,S.Kainkaryam,S.Bhattacharya, L.Saputelli,“TowardOilandGas4.0.MachineLearning intheOilandGasIndustry”,2020,Apress,Berkeley,CA.

33. H. Nordal, I. El‐Thalji, “Modeling a predictive maintenance management architecture to meet industry 4.0 requirements: A case study”, Systems Engineering,2021,Vol24,No1,pp34 50

34. S.Merlin,“SmartutilitiesandCRM:Thenextphaseof customermanagementinutilities”,JournalofDatabase Marketing & Customer Strategy Management, 2010, Vol17.

35. N. Panayiotou, K. Stergiou, V. Stavrou, “The Role of Business Process Modeling & Management in the Industry 4.0 Framework”, INAIT 2019 Industry 4.0 andArtificialIntelligenceTechnologies,Cambridge,UK, August19 20,2019

36. J.R. Rehse, S. Dadashnia, P. Fettke, “Business process managementforIndustry4.0 Threeapplicationcases in the DFKI Smart Lego Factory”, It Information Technology,2018,Vol60,No3,pp133 141

37. T.V. Alexandrova, V.G. Prudsky, “On the conseptual model of oil and gas business transformation in the transitional conditions to the Industry 4.0”, Scientific papersoftheUniversityofPardubice,2019,SeriesD, FacultyofEconomicsandAdministration

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal