International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

1, 2, 3, 4 Students in Mechanical Engineering Dept, SNJB’s Shri.H.H.J.B. Polytechnic, Chandwad, Nashik (MS),423101

5Lecturer in Mechanical Engineering Dept. SNJB’s Shri.H.H.J.B. Polytechnic, Chandwad, Nashik (MS),423101 ***

Abstract: This project emphasis on design and fabrication of the automatic bike stand. The side stand is usedfor supporting the parked motor cycle if the rider may forget to retract the side stand before riding, then the undistracted stand hitting the ground and affected the rider’s control during the turn. stand is important component of bike because stand help to keep the bike upright. But most of the time accidents happen because of stand is down. At such time our automatic bike stand project will helps to reduce accidents, because the stand is automatic, now a days a sensor is used for ensure that stand condition and stand retracting. The motor cycle standconsists of metallic rod in this project in simple words we retrieve this metallic rod automatically it will go up and down automatically. this all the system are works using bikes DC battery power. In this system we also used mechanical and electronic components because this system is based on mechatronics. In this system also included sensors motor with gear box indicators safety switches for control the stand position all the system operated by Arduino microcontroller. This system works using bike operating positions/conditions

Key Words: Automatic Bike Stand, Stand Position, Sensor, Microcontroller.

Inalloverworldeverywheremotorcycle isused.Theside standplaysmajorrollwhilethevehicleisinrestposition. Butithassomedisadvantagestakesplaceaswhilethedriver startingthemotorcycle,theremaybepossibilityofforgetto releasethesidestandthiswillcausedtounwantedtroubles

Whilethetwo wheelersareconcerned,accidentsoccurdue toridingthevehicleinhighspeed,ignorestousehelmets, doesnotmaintainsthespeedlimitandforgetstolifttheside standwhileridingthevehicles.Thesearethemajorsource for accidents, forgetting to lift the side stand causes huge accidents.Wehavedevelopedanewtypeofsidestandwhich is automatically retracting the side stand through some mechanical and electronic arrangement and it also have some advance feature. In this system microcontroller, Displacement, Vibration Sensor with a dc battery is used. Through the sensor, sensor sense the rotation of the key from OFF position to ON and sends the signal to the microcontroller which is actuate the dc motor which is causedthedisengagethestandfromtheroad.

Intheoverviewofliterature,thepaperrelatedtothestudyof theactualbikestandproject.

The new system “AUTOMATIC SIDE STAND RETRIEVE SYSTEM”istobeDesignedbasedontheworkingprincipleof bikes. Since all bikes transmit power from Engine to rear wheelbymeansofchaindrive.Sincethedesignsetupistobe keptinBetweenchaindrive,thensetup(Sprocket)rotates andsidestandgetretrievesAutomatically.Thissystemcan be implemented in all types of bikes by changing small variationinsizeandcostofthissystemalsoverylowandso it will not affect the economic level also while compare to othersystem(K.DEVENDRANATH)2012.

Based on the working principle of two wheeler (i.e the powerisgeneratedintheengineandittransmitspowerto the pin ion and makes it to rotate. The pinion transmits power to the rear wheel pinion and makes the vehicle to move).Thisisthebasicprinciplefollowedinalltypesoftwo wheelers, based on this “automatic side stand retrieve

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

system” works. The whole construction of this system is simple and efficient. The arrangement and position of componentsmakesthesystemtofunction.Eachandevery component has its own property and responsibility. The power obtained from the chain drive is transmitted to the appropriatecomponentwithoutpowerloss.Thesystematic designofsystemismadeinordertoconsumeonlyverylow amount of power initially for few seconds to retrieve the stand. Then the power consumption doesn’t occur after retrievingthestand(RanjeetPokharel)2014

Now a day’s sensor is used for ensure that the stand is in Releasedcondition.Themotorcyclesidestandconsistsofa Metallicrodandhelicalspringwhichisoffsetfromthecenter. Somesidestandretractsautomaticallywhenthemotorcycle is Lifted up the support some other are fit with electrical interlocks,Warningdevicesorspecialretractingmechanism. InthispaperThereispossibilitytoreducetheevidentwhich istakesplacebytheSidestandAutomaticstandispresently in use and quite successful. Although it has certain disadvantages.Automaticstandispresentlyinuseandquite successful.(VishalSrivastava),2014

Thisautomation is related to thelimitswitch. Thesystem usesthetwo limitswitchwhichisplacedtwoplacesofstand. When the limit switch is actuated, the stand will automatically place. If another limit switch is actuated the sidestandwillautomaticallyreturnstotheinitialposition.

When limit switch is actuated, the signal is passed to the microcontrollerfromthelimitswitch.Themicrocontroller savesthedata andactuatestherelay.Thisrelayisusedto actuate the motor. Thus, by the stand is placed. If another limit switch is operated this sends the signal to the micro controller. So, this actuates the relay thus the motor is operatedandthestandisreturntotheinitialposition.Inthis project, a novel method of automatic bike stand is been designed and developed for motorcycle bike drivers. As everyoneintoday’sworldisridingbikeitisessentialtotake careofunwantedtroubles.Eachandeverybikeshouldhave automaticbikestand.(ShubhamBagul1),2017.

To avoid this problem, we do the project practically for “Automatic Side Stand Lifting Mechanism System”. This project is based on simple mechanism. This mechanism operatedbythetotalmanuallymeansonthefeetpowerof rider.So,itisnotrequiredanyexternalpoweranditismore economical also easily installable in bike. In our India 20 22%accidenthappenedduesidestandwhichisnotremoved by the rider after starting a bike. For preventing that problem,weinstalledthismechanism.Itdoesnotdisturbthe Performance of the vehicle. And it is different than other Mechanism.Othersystemrequiresbatterypowerorchain Powerbutitisnotrequiringanyexternalpower.Moreover,it Should be economical for every class of society. It is new Product it will promote employment and vast field

development for new engineer in day period. (Aniket Gulhane)2017.

So,wehaveMadetheprojectof“AutomaticSide StandLifter for Two Wheeler” is to be designed based on the working principle of Bikes. This mechanism is operated manually means on the Feet power of rider. After starting the bike immediatelyWhentheriderputsthefirstgear,thesidestand liftsAutomatically.Theobjectiveofthisprojectistoprovide the rigid and safety mechanism without changing in any standarddesignofbike.Itdoesnotdisturbtheperformance ofthevehicle.Anditisdifferentthanothermechanism.Other systemrequiresbatterypowerorchainpowerbutitisnot required any external power. (Associate Professor R. Selvendran)2019.

WeDesignedbasedontheworkingprincipleofbikes.Since allbikestransmitpowerfromenginetorearwheelbymeans ofchaindrive.

The project of automatic bike stand is carried to achieve someoftheobjectiveslike:

To develop actual implementation setup of automatic bikestand

Toavoidaccidentsindailylife. Itdecreaseshumanefforts.

Accidentoccursduetostandatdownposition. Loadtestcarriedoutonstand

The starter consists of a microcontroller circuit used to monitor the starter and then operate the stand sliding mechanism.Thestandconsistsofamotorizedsystemused to operate the stand. The circuit monitors the starter, on starting the bike the side stand is operated by the motor usingashafttoslidefromaverticalpositiontoahorizontal position. On turning off the key in other direction to lock bikethesystemmovesthemotorizedstandshaftinopposite direction so as to move the stand in a direction perpendicular to the bottom frame rod which rests the motorbikeonsidestand.Thus,wehaveafullyautomated sidestandsystemformotorbikes.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

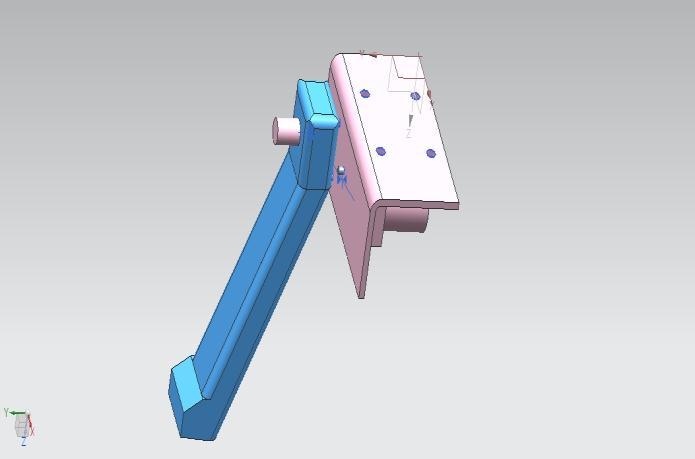

Fig.6.3:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

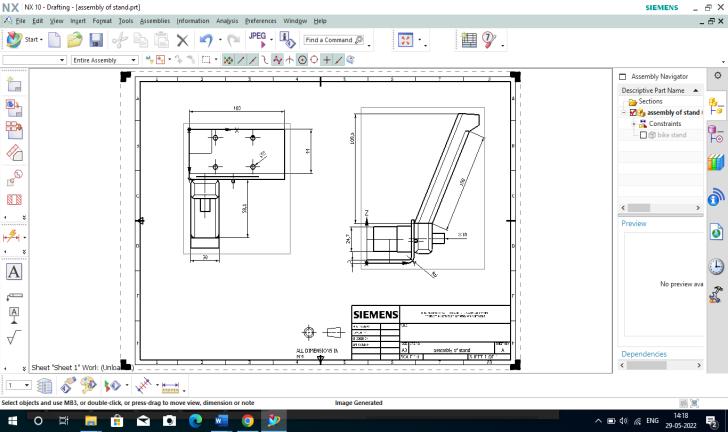

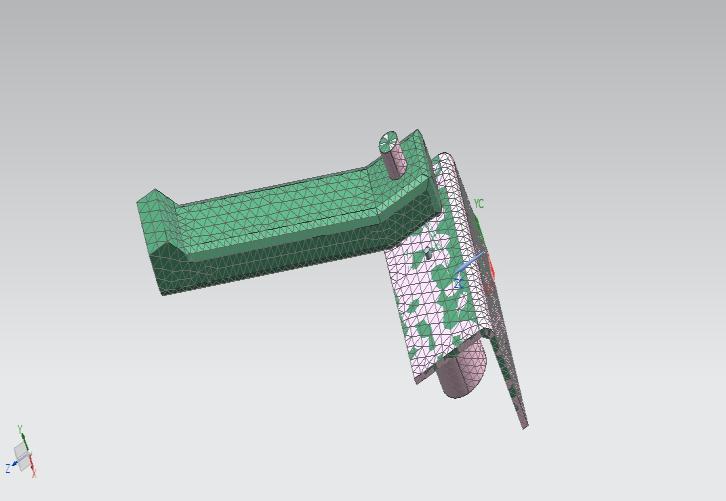

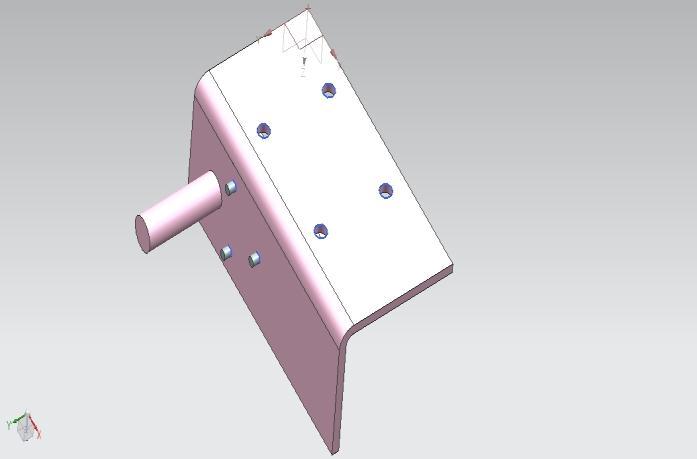

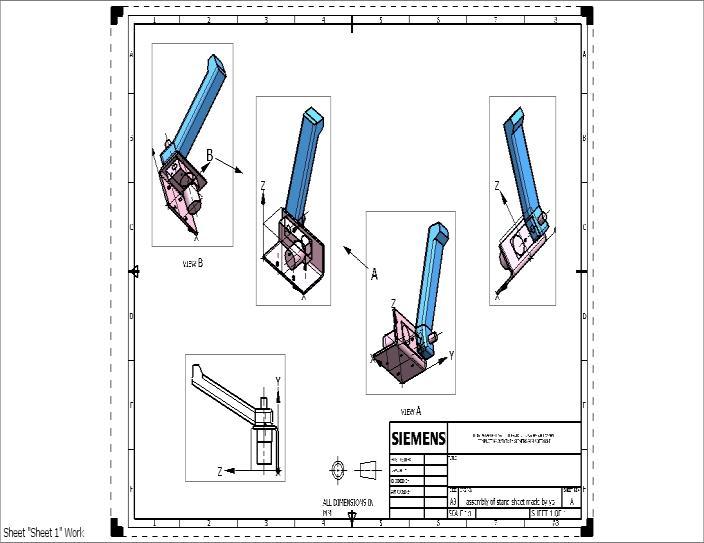

Fig.6.7: AssemblyviewofStand

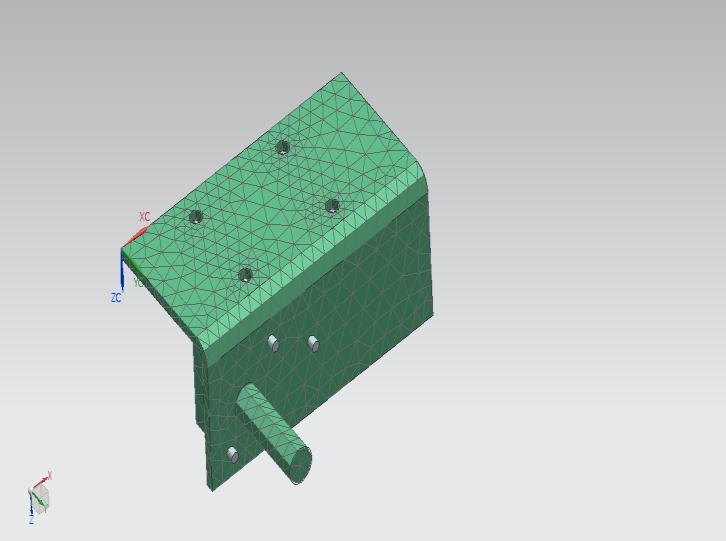

First, she took the angle plate and attached it to the bottomofthechassispipeofthebike.

Taking the second rubber packing, they stuck the packingtothechassispipe

HetooktheClampandappliedtherubberpackingtothe chassispipeofbike

Nowtaketheboltandputthewasherinitandtakethe boltandputitintheangleandclamholes.Tightenthe boltswithnuts&standassemblydone.

Therestofthemicrocontrollercircuitwedidn't Havespaceinthebikesowefittedittothebikebumper.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Fig.8.2.1AssemblyinProcess

Fig.8.2.2StandWelding

StartingfromtheignitionswitchThengivethesupplyyou've receivedtothepeoplewhoneedit.indicatorWethengiveit to the microcontroller box with the indication. with the assistanceofasupplycircuitcontrollerAfterthesupplygoes into the micro controller, the supply goes to the detector sensor.Afterthedetectorsensordetectstheactivityofthe bike, the next control unit will be activated. After this process,theindicatorwillindicatethatthemicrocontroller isfullyactivatedItwillthenbedistributedtothesensorsset aside by the supply manifold the sensors mounted on the side of the bike will then detect the position of the bike’s handle.Alltheactivitiesofthehandlewillgotothismicro controllerthenthemotorrunningcircuitwillbeturnedon andfromtherethesupplymotorswillgotothegearboxand themotorwillrun.Afterthemotorruns,thestandwilltakea momentandmovetoapositionaboveorbelowthestand.

It by an observation that the side stand retrieve by mechatronicbasedcircuitisbetterthanmechanicalmethod ofstandretrievingItcanreduceriskofaccidentscausedby unremovalofsidestanddefinitelythissystemcouldbeused inalltypetwowheelersthisprojectcouldbearevolutionin automobileindustrybecauseitprovidesasolutionforthe problemwearefacinginourdailylifeRunningabikewith sidestandinitsupliftmaycreatesproblems, butwiththe helpofourprojectsolvethisproblem.

Wewouldliketoexpressourspecialthanksofgratitudeto our project guide Prof. Shailesh S. Parkhe and project coordinator Dr. G.D. Shinde also HOD of Mechanical Engg. Dept. Prof. D.V. Lohar for their valuable guidance and supportwhilecompletingourprojectwork

1. (K.DEVENDRANATH)(12KQ1A0323)M.M.SRINIVAS (12KQ1A0328) P. RAJASEKHAR (12KQ1A0338) G. VINAY KUMAR (12KQ1A0313) V. SRIKANTH (122Q1A0345)(AUTOMATICSIDESTANDRETRIEVING SYSTEMFORTWOWHEELERS.SubmittedtoJawaharlal NehruTechnologicalUniversity,Kakinada)2012

2. (Vishal Srivastava), Tejasvi Gupta, Sourabh Kumar, Vinay Kumar, Javed Rafiq, Satish Kumar Dwivedi)( Automatic Side Stand . International Journal of Engineering and Advanced Technology (IJEAT)ISSN: 2249 8958,Volume 3,Issue 4,April2014)2014

3. Shubham Bagul1, Nikhil Dhake2, Deepak Mengal3, Padmakar Jadhav4, Ms. Divya R. Dhagate5, Prof. Sunil M.More6) (AUTOMATIC BIKE STAND . Third Year ElectricalStudents,5,6AssistantProfessor,Department ofElectricalEngineering,GuruGobindSinghPolytechnic Nashik,Maharashtra,India)2017K.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

4. Aniket Gulhane1, Ganesh Gawande2, Bhagwat Gawande3, Shraddha Dhule4, Chaitanya Deshmukh5 (FabricationofAutomaticSideStandLiftingMechanism )2017

5. 5. Associate Professor R. Selvendran.M.E., (Ph.D.)UG Scholar AnlinJP,MohamedAshikN,MohamedRiyasK (DesignandFabricationofAutomaticSideStandLifter for Two Wheeler . Department of Mechanical Engineering,Hindusthan Institute of Technology.Coimbatore,Tamilnadu,India.)2019

6. 6.P.Vijay1/S.Vinobalaji2/DysonBruno3(Automatic Side Stand Retrieving System for two Wheelers) UG students, Department of Mechanical Engineering Assistant Professor, Department of Mechanical EngineeringPSNACollegeofEngineering&Technology, Dindigul)2019

7. 7 V. CHANDRIKA, Asst. Prof P.S.C.M.R.C.E.T chandrikakishore26@gmail.com T. ASHOK, student P.S.C.M.R.C.E.Tmech.eng.ashok@gmail.comSK.JILANI, student P.S.C.M.R.C.E.T Jilanishaikindianarmy@gmail.com V. HARISH, student P.S.C.M.R.C.E.T harishvikkurthi@gmail.com )( AUTOMATIC BIKE SIDE STAND RETRIEVE SYSTEM) 2020.

8. 8. Ravi Pratap Singh, 2Ritu Raj,3Rupesh Kumar Verma,4Yashveer Yadav,5Nilesh Singh 1Assistant Professor, 2,3,4,5Student 1Mechanical Engineering 1Institute Of Technology & Management Gida Gorakhpur (DESIGN AND FABRICATION OF AUTOMATICSIDESTANDFORTWO WHEELER)2020

Mr. Sachin J. Ugale Student in Mechanical Engineering Dept. SNJB’S Shri.H.H.J.B. Polytechnic, Chandwad,Nashik(MS)423101

Mr. Yogesh R. Pawar Student in Mechanical Engineering Dept. SNJB’S Shri .H.H.J.B. Polytechnic, Chandwad,Nashik(MS)423101

Mr. Harshal B. Deore Student in Mechanical Engineering Dept. SNJB’S Shri .H.H.J.B. Polytechnic, Chandwad,Nashik (MS)423101.

Mr. Saurabh D. Patil Student in Mechanical Engineering Dept. SNJB’S Shri .H.H.J.B. Polytechnic, Chandwad,Nashik (MS)423101