International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

1 Assistant Professor, S J College, Jaipur

2

2 Assistant Professor, Sir Padampat Singhania University, Udaipur ***

Abstract - TheIndustry5.0systemisanalogoustoasystem in which machines provide services and communicate information with products in real time. It offers numerous capabilitiesthataidinanysystem'sautomation,monitoring, and diagnostics. It is a process for transitioning from dominatingmachineproductiontodigitalmanufacturing.The Industry 5.0 standard must be thoroughly understood to achieveasuccessfultransformation,andadetailedroadmap mustbedevelopedandimplemented.Severalapproachesand conversationsarenowunderwaytoproduceroadmaps,some of which are discussed in this paper. Evaluating Industry 5.0 components and features is critical for defining the fundamental pillars of a concrete future manufacturing environment as well as a specific ranking position in India. Thisstudyaimstodescribe,examine,andcomparesomeofthe most promising existing methodologies for calculating nationalIndustry5.0readiness.

Key Words: Augmented reality and simulation, IoT, CII, CloudComputing,GCI.

Every moment in the world is changing so quickly due to human activity. The entire manufacturing and production flora and fauna are through a tremendous change with currentmodificationsintechnicaladvancements(Bagetal., 2021). The necessity to recognize and use modern manufacturingmechanismshasbecomeurgent.Thephrase 'Industry4.0'referstoasmartmechanisminwhichsmart digital devices are networked and communicate with raw materials,work in processitems,finishedgoods,machines, tools, techniques, automation, and robots (Chauhan et al., 2021; Esmaeilian et al., 2020). According to (Giovanni & Cariola, 2020), this industry is distinguished by its adaptability,efficientresourceutilization,andintegrationof customersandbusinesspartnersintothebusinessprocess. Industry 5.0 has proven its importance and necessity in several fields of human endeavor in recent times. Automation, machine learning, and deep learning are essential drivers of numerous technological innovations gaining traction in every area. Furthermore, the Japanese havetakenthisambitionfurtherbyincludingSociety5.0in the 5th Science and Technology Basic Plan. It is a human centred civilization that combines economic growth with socialproblemsolvingthroughasystemthatblendsonline and physical space. The evolution of society has been classified as a hunting society, an agricultural society, an

industrialsociety,aninformationsociety,andasuper smart society(Guptaetal.,2021;Kumar&Dadhich,2014).

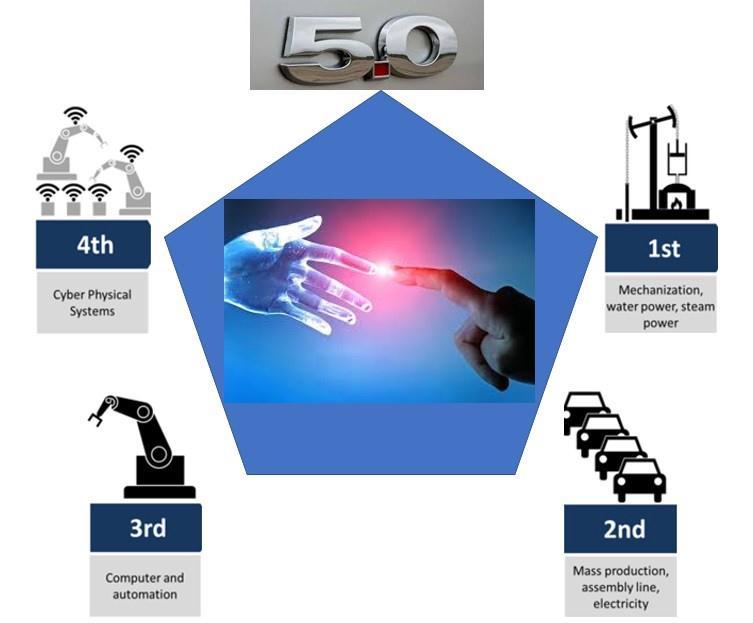

Smallandmedium sizedfirms(SMEs)arethebackboneof the economy in many nations since they generate jobs, convert goods and services, and ultimately contribute significantly to GDP (Dadhich, 2017a; Industry & What, 2016). The current industrial expansion has lasted many decades, and weare nowlivingin the age of Industry 5.0. GermansfirstproposedtheconceptofIndustry5.0in2011 (seefigure1).(Giovanni&Cariola,2020)discoveredthatthe firstindustrialrevolutionbeganinthelatterhalfofthe18th century.Thisreformwasdistinguishedbytheautomationof strandedmachineryandtheuseofsteampower.Thesecond phase, which began in the early twentieth century, is distinguishedbygrouplaborproductionbasedonelectrical energy.Thethirdstageoftherevolutionbeganinthe1970s, withthedefiningtraitsofscheduled productionashorein new internet related technology. Eventually, Industry 5.0 will includecharacteristicssuchasCyber Physical System production, which is based on big data and knowledge transformation(Dadhich,2017b;Guptaetal.,2021).Inthe recentpast,Industry5.0hasbeenassociatedwithbasketsof technologies and related patterns, such as real time manufacturing,IoT,augmentedreality,simulation,andsocial productadvancement(Kambleetal.,2018).

The current study fills the gaps by thoroughly reviewing researchpublicationsfromvariousjournalsandconferences ontheissueofIndustry5.0,makingiteasierforenterprises to prepare for the future. Organizational structure and procedure strengthen the favorable association between Industry 5.0 and IT adoption. Several studies have shown thattheexpansionofsustainablecorporateperformanceis dependentoninnovation,andIndustry5.0isoneofthem. Industry 5.0 elements are heavily influenced by modern conceptssuchasbigdata,automation,virtualreality,theAI ML DL,IoTandsmartfactories(Kannan,2021).

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

usingnewtechniquesandmeansofIndustry5.0todealwith theglobalmeltdown.

TheprimarygoalofthisresearchistoinvestigateIndustry 5.0 techniques to increase economic growth following a pandemic.Theresearchreportalsodivesintoanalyzingand summarizing readiness indices to reach a relevant conclusionwithanimportantguidelineforthedevelopment offurtheranalyses,namely,howIndustry5.0canalterthe economicgameplan.Thisworkalsoseekstointegratethe availableliteraturereviewsonthetopicandprovidethemin awaythatresearchersandacademicsmayfocuson,develop theirexpertiseonthetopic,andrecommendopportunities forfutureresearch

Fig 1:PhasesofIndustry5.0(Kannan,2021)

Thecurrentstudyisatheoreticalmodalbasedonsubstantial investigation using only secondary sources of knowledge. Journals, periodicals, annual reports, white papers, and novels are among the sources. The primary methodology employedinthisessayisthatofliteraryanalysis.

The economic ramifications of the epidemic are already havinganenormousimpactontheworld.Itistooearlyto predict how much worldwide economic damage Covid 19 willcauseinthecurrentsetting.Themomentumhasbegun insocialdistance,quarantine,lockdown,andworkingfrom home, but it will undoubtedly impede regular corporate growth on a vast scale (Kiraz et al., 2020; Kumar Naresh, Dadhich Manish, 2014). According to OECD estimates, the lockoutwilldirectlyimpactindustriesaccountingforupto one third of GDP in the main nations. Each month of containment will result in a 2% drop in the annual Gross Domestic Product. The tourism industry alone has seen a massivedrop,andmanyeconomiesaresensingthelooming recession. This is unavoidable, and there is a need to continue fighting the pandemic as international organizationsworktorestoreeconomicnormalcyasquickly aspossible.'Comingeventscasttheirshadowbeforethem' appearstobetrueinthecurrentglobalcrisesresultingfrom thispandemicoccurrence.Everybusinesswillexperiencea severebreakdown,particularlyretailandwholesaletrade, real estate services, automobiles, airlines, service sectors, agriculture,andassociatedbusinesses(Chauhanetal.,2021; da Silva Rabêlo & de Azevedo Melo, 2019; Dadhich et al., 2020).Asaresult,anoptimalsolutionmustbefoundusing well defined problems and their repercussions. It is also importanttoconsidertheconsequencesofthisepidemicby

TheprimarygoalofthisresearchistoinvestigateIndustry 5.0 techniques to increase economic growth following a pandemic.Theresearchreportalsodivesintoanalyzingand summarizing readiness indices to reach a relevant conclusionwithanimportantguidelineforthedevelopment offurtheranalyses,namely,howIndustry5.0canalterthe economicgameplan.Thisworkalsoseekstointegratethe availableliteraturereviewsonthetopicandprovidethemin awaythatresearchersandacademicsmayfocuson,develop theirexpertiseonthetopic,andrecommendopportunities forfutureresearch.

Big data is the data that is generated continually by everything in the current context. Every digital operation andsocialmediainteractiongeneratesamassiveamountof data.These data aretransmitted bysystems,sensors,and mobiledevicesovera cloud basednetwork infrastructure (Naresh Kumar, 2016). Big data is pouring in from all directions at breakneck speed, volume, and variety. To extract real value from big data, adequate processing capacity,analyticscapabilities,andinformationmanagement skillsarerequired.

Smart manufacturing aims to optimize production and product interactions by shifting from old methods to digitizedandautonomoussystems.Whenmanufacturingis defined as the multi phased process of making a product fromrawmaterials,smartmanufacturingisthesubsetthat usescomputercontrolandhighlevelsofadaptabilitytodo so.Itintendstousemoderninformationandmanufacturing technologiestoenablephysicalprocessflexibilitytofunction inahighlydynamicandglobalmarket(Dadhichetal.,2019). ThepurposeofaSmartFactoryistodevelopfullyflexible productionatthefastestpossiblespeed,whichnecessitates

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

acomprehensivetransformationfromtraditionalmethods toinnovativetechnologies.

Thecloudisutilizedforvariouspurposes,includingremote services,colormanagement,andperformanceevaluation.It has captured the attention of the information technology community, and its influence in other business areas will only rise. As technology advances, machines, data management,andfunctionalitywillcontinuetomigratefrom traditional ways to cloud based solutions (Bortolini et al., 2016; Dadhich, 2017a; Esmaeilian et al., 2020). The cloud enablesconsiderablyfasterthanstandalonesystemdelivery, quick updates, up to date performance models, and other delivery choices. The sector has experienced a significant shift toward using cloud solutions, which will continue to increaseandchallengeexistingdatastoragemethods.Cloud technologyisthemostbasiconlinestorageservice,offering operationalsimplicitythroughweb basedappsthatdonot require installation (Industry & What, 2016). Cloud computing lowers costs, decreases infrastructure complexity, expands the work area, safeguards data, and enablesinstantaccesstoinformation.Thesystemprimarily usesfourtypesofclouds:publiccloud,privatecloud,hybrid cloud,andcommunitycloud(Dadhichetal.,2022).

Itreferstocontinuouscommunicationbetweendevicesvia any channel, wired or wireless. Machine to machine communication can include industrial instrumentation, which allows a sensor to exchange data with application software (Esmaeilian et al., 2020; Rakesh Kumar Birda & Manish Dadhich, 2019). This type of communication was performed by having a distributed network of equipment transmitdatabacktoaninnermosthubforanalysis,which was then diverted to a personal computer. M2M is a technology that enables businesses to establish wireless connectivitybetweendatacentresandequipment.

The network is made up of physical devices, vehicles, and structures embedded with electronics, software, sensors, actuators,andnetworkconnectivity,allowingtheseitemsto facilitate and transform data. It has four key layers: Perception Layer, Network Layer, Support Layer, and ApplicationLayer(Chaârietal.,2016;Dadhichetal.,2021). IoTandIndustry5.0areconceptsthatarecloselyrelated. Moreeffectiveworkingenvironmentsaregeneratedbecause IoT enabledmanufacturingsystemsarelinkedtoweb based technologies.Thisalsoencouragesmajorstandardstoplaya role in creating new optimizations and tactics. ManufacturingsystemsbasedonIoTproducequicker,more optimistic,andfasterdecisionsthanthoseofcompetitors.

They are utilized to automate production procedures in various industries and are powered by the concept of the Internet of Things. This allows gadgets and computers to communicate with one another. The autonomous mobile machinecantransferresourcesacrosstheproductionfloor while avoiding obstacles, sharing with fleet mates, and identifying pickups and drop offs in real time (Kannan, 2021).Robotactionscanbecoordinatedandautomatedby connectingtoacentralserverordatabase,distinguishingit fromthehumaninterface.Theycancompletejobsquickly andintelligentlywithlittlehumanintervention(Kirazetal., 2020).

ARisatypeofrealityinwhichlivedirectorindirectviewsof actual real world environments are augmented with computer generated pictures. This technology underpins Industry 5.0 applications. The actual operations and simulation industries collaborated to create this new technology, which is critical to the industrial civilization. These strategies are extremely useful, particularly for designingproductsandmanufacturingsystems.Augmented realityisoneofthecutting edgetechnologiesincludedinthe Industry 5.0 movement, particularly in developing smart manufacturing functions. There have been some AR applications,primarilyinthefollowingfields.

Integrating digital and physical processes is a critical componentofIndustry5.0implementations.Theyinclude imagingandcontrolcapabilitiesinappropriatesystems.The ability of these systems to respond to any feedback generated is critical. They provide fast control and verificationofprocessfeedbacktoproducepredictedresults (Gupta et al., 2021). In general, a typical CPS in manufacturingmayfulfilthefollowingduties.

•Processcontrol.

•Usefulinvariousdisciplines,contributingtodevelopinga large scalesystem.

•Integratingseveraldisciplinesinvariousfields.

•Dealingwitheffectivereliability.

Robotscannowexecuteanywork,navigateanyterrain,and make decisions in the face of uncertainty. Recent advancementshaveresultedinstrategiesthatallowrobots to manage their surroundings. Artificial intelligence will contributetotheadvancementofrobotteamsworkingand collaborating to complete certain tasks assigned for a

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

specific destination. Some research is being conducted to promote robots, which can be useful in assisting with effective digital transformation (Kamble et al., 2018). Industry5.0ispredictedtoprovidenumerousbenefits,some ofwhichareasfollows:

•Increasedabilitytoinnovate.

•Simplesystemmultifunctiondiagnosticmonitoring.

•Highproductivityusingecologicallyfriendlyproducts.

•Increasedflexibilityatalowercost.

•Acceleratedproductdevelopmentwithnewbusinessand servicemodels.

• Decision making that is unbiased, real time, and knowledge based.

•Nationalinvolvementincontributingtotheeconomy.

Indiaisonthevergeofmassivereformsandisontrackto becometheworld'sthird largesteconomyby2030.Witha tech savvy and educated population, skilled workforce, a strong legal and intellectual property environment, and a strong commitment to controlled liberalization, India is a locationthatglobalinvestorscannotaffordtoneglect.From initial industrialization and the license system to liberalization and the current phase of global competitiveness, India's manufacturing segment has gone through various stages. Today, Indian manufacturing enterprises in various areas are expanding into global markets and becoming formidable global competitors (Sharma & Dadhich, 2014). Many are already among the most competitive in their respective industries. When it comestotheautomobilesector,theequipmentmakers,the government, and the customer all play important roles in definingtheindustry.Thefollowingareafewopportunities forIndiaintheFourthIndustrialRevolution:

Themanufacturingsectorcomprisesallareasofproduction andhumanresourcemanagement. Therevolutionfocuses primarily on productivity, producing with high accuracy using advanced machinery, and reducing production damage, time consumption, and human labor to a larger extent.ManufacturingprocessesaregivenpriorityinIndia duetotheirgreatercontributiontoGDP(ManishDadhich, ManvinderSinghPahwa,VipinJain,2021).

In today's world, the medical profession is equipped with cutting edgetechnologythatisutilizedtotreatawiderange of life threatening ailments. Damaged tissue, for example,

can be replicated using nanotechnology (Costa & Peixoto, 2020). Artificial Stimulated Cells, 3D printed Artificial Organs, Smart Inhalers, Precision Medicines, Health Wearables, and other recent medical advances include RoboticSurgeries,WirelessBrainSensors,andmore.

InemergingcountriessuchasIndia,transportationispoorly structured and unsafe. There is a significant possibility of improvingthetransportationsystemusingAlandIoT,such asoptimaltraffic,wheretheAIanalysestrafficpatternsto optimize and design routes based on peak traffic hours, maintenance,andconstructions(Dadhichetal.,2020).Using self drivingcarstoavoidaccidentsandtheuseofAlandIoT can contribute to cost savings while encouraging greater safetyandabettercustomerexperience(Singh,2021).

Agriculture is regarded as the backbone of the Indian economy.However,theagriculturesectorisgiventheleast emphasis in the current context due to a lack of sufficient understanding and advice about adopting Industry 5.0 methods.Asaresult,theincorporationoftechnologyhasled to a limited area of agriculture. Already, automated equipment is being employed in agriculture, saving both time and labor (Rakesh Kumar Birda & Manish Dadhich, 2019). Scientists and industry experts are developing and puttingtechnicalmeasuresinplaceintheagri sector.

• Humans are expected to contribute high value tasks to manufacturing policies in the next industrial revolution. Standardizationandlegalizationwillaidinthepreventionof major problems between technology, society, and enterprises.

• Senior members of society and stakeholders will find adjustingtothenewindustrialrevolutionconsiderablymore difficult

•Rapidandextremelyefficientmanufacturingmayresultin overproduction.

Transparencyinimplementationshouldalsobeconsidered.

•Wemustinvestigatehowethicalstandardscanbeincluded inautonomoussystems.

• In autonomous systems, there should be explainable ethicalbehaviorsolutions.

•Ethicalbehaviorinautonomoussystemsmustbeverified andvalidated.

•Criticalskillgapsinfuturemanagementandexecutivejobs, suchasCROs,mustbeaddressed.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Industry 5.0 is currently a new concept that depicts an evolutionofanewsetofsystems,bringingtogetherdigital, biological,andphysicaltechnologyinafreshandpowerful blend.Thesenewsystemsarebeingcreatedonthedigital revolution'sarchitecture.Governmentswillsimultaneously acquire new technological capabilities to expand their control over populations based on pervasive surveillance systemsandtheabilitytomanipulatedigitalinfrastructure. Many parallels and differences exist across the methodologies provided and studied in the Industry 5.0 readinessevaluationstudy.Theysharetheuseofrelatively simpleclusteringapproachesbasedonthestand byindex and production share. The discrepancies are in the indicatorsusedandtheevaluationmethodologiesused.The collectedresultsandanalysisoftheconcealed,notobvious information are of significant help to stakeholders in developing plans and policies to increase the readiness index.Theirin depthcomparisonandanalysiswillhighlight the merits and shortcomings of each option under consideration. India is rising to new heights, with the greatestdevelopmentintechnicalelementsandastronger position in practically every area. The preceding review provides insight into Industry 5.0 implementation and generates credible road maps to meet future difficulties, suchasCovid 19orotheradhocmeasures.Industry5.0isa collaborationbetweenmanandmachinethatmaycontinue togrowinallindustrieswhileallowingformorecreativity forabettersociety.

[1] Bag,S.,Yadav,G.,Dhamija,P.,&Kumar,K.(2021).Key resources for industry 4.0 adoption and its effect on sustainable production and circular economy : An empirical study. Journal of Cleaner Production, 281, 125233.https://doi.org/10.1016/j.jclepro.2020.125233

[2] Chaâri,R.,Ellouze,F.,Koubâa,A.,Qureshi,B.,Pereira,N., Youssef,H.,&Tovar,E.(2016).Cyber physicalsystems clouds: A survey. Computer Networks, 108, 260 278. https://doi.org/10.1016/j.comnet.2016.08.017

[3] Chauhan, C., Singh, A., & Luthra, S. (2021). Barriers to industry4.0adoptionanditsperformanceimplications : Anempiricalinvestigationofemergingeconomy. Journal of Cleaner Production, 285, 1 15. https://doi.org/10.1016/j.jclepro.2020.124809

[4] Costa, D. G., & Peixoto, J. P. J. (2020). COVID 19 pandemic:areviewofsmartcitiesinitiativestofacenew outbreaks. IET Smart Cities, 2(2), 64 73. https://doi.org/10.1049/iet smc.2020.0044

[5] DaSilvaRabêlo,O.,&deAzevedoMelo,A.S.S.(2019). Driversofmultidimensionaleco innovation:empirical evidence from the Brazilian industry. Environmental

Technology (United Kingdom), 40(19), 2556 2566. https://doi.org/10.1080/09593330.2018.1447022

[6] Dadhich,M.(2017a).Ananalysisoffactorsaffectingon online shopping behavior of customers. ZENITH International Journal of Business Economics & ManagementResearch, 7(1),20 30.

[7] Dadhich,M.(2017b).AnAnalysisofVolatilityofMacro Economic Variables on Gold Price. Pacific Business ReviewInternational, 9(12),21 25.

[8] Dadhich, M., Chouhan, V., & Adholiya, A. (2019). Stochastic pattern of major indices of Bombay stock exchange. InternationalJournalofRecentTechnologyand Engineering, 8(3), 6774 6779. https://doi.org/10.35940/ijrte.C6068.098319

[9] Dadhich, M., Chouhan, V., Gautam, S. K., & Mwinga, R. (2020).ProfitabilityandCapitalAdequacyApproachfor Measuring Impact of Global Financial Crisis Vis À Vis IndianBanks. InternationalJournalofAdvancedScience andTechnology, 29(4),2344 2365.

[10] Dadhich,M.,Hiran,K.K.,Rao,S.S.,&Sharma,R.(2022). ImpactofCovid 19onTeaching LearningPerceptionof Faculties and Students of Higher Education in Indian Purview. JournalofMobileMultimedia, 18(4),957 980. https://doi.org/10.13052/jmm1550 4646.1841

[11] Dadhich, M., Purohit, H., & Bhasker, A. A. (2021). Determinants of green initiatives and operational performanceformanufacturingSMEs. MaterialsToday: Proceedings, 46(20), 10870 10874. https://doi.org/10.1016/j.matpr.2021.01.889

[12] Esmaeilian,B.,Sarkis,J.,Lewis,K.,&Behdad,S.(2020). Resources,Conservation&RecyclingBlockchainforthe future of sustainable supply chain management in Industry 4.0. Resources, Conservation & Recycling, 163(December 2019), 105064. https://doi.org/10.1016/j.resconrec.2020.105064

[13] Giovanni, P. De, & Cariola, A. (2020). Research in TransportationEconomicsProcessinnovationthrough industry 4.0 technologies, lean practices and green supply chains. Research in Transportation Economics, April, 100869. https://doi.org/10.1016/j.retrec.2020.100869

[14] Gupta,H.,Kumar,A.,&Wasan,P.(2021).Industry4.0, cleaner production and circular economy : An integrative framework for evaluating ethical and sustainable business performance of manufacturing organizations. JournalofCleanerProduction, 295,1 18. https://doi.org/10.1016/j.jclepro.2021.126253

[15] Industry,G.,&What,S.(2016). Industry 4.0 : Building the digitalenterprise

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

[16] Kamble,S.S.,Gunasekaran,A.,&Gawankar,S.A.(2018). Sustainable Industry 4 . 0 framework : A systematic literature review identifying the current trends and future perspectives. Process Safety and Environmental Protection, 117, 408 425. https://doi.org/10.1016/j.psep.2018.05.009

[17] Kannan, K. S. P. N. (2021). Competencies of quality professionalsintheeraofindustry4.0 :acasestudyof electronicsmanufacturerfromMalaysia. International Journal of Quality & Reliability Management, Emerald Publishing Limited, 38(3), 839 871. https://doi.org/10.1108/IJQRM 04 2019 0124

[18] Kiraz, A., Canpolat, O., Ozkurt, C., & Tas, H. (2020). Computers & Industrial Engineering Analysis of the factors affecting the Industry 4.0 tendency with the structuralequationmodelandanapplication. Computers & Industrial Engineering, 150(10), 1 10. https://doi.org/10.1016/j.cie.2020.106911

[19] Kumar,N.,&Dadhich,M.(2014).RiskManagementfor InvestorsinStockMarket. EXCELInternationalJournalof MultidisciplinaryManagementStudies, 4(3),103 108.

[20] Kumar Naresh, Dadhich Manish, R. S. S. (2014). Determinant of Customers' Perception towards RTGS andNEFTServices. AsianJournalofResearchinBanking and Finance, 4(9), 253 260. https://doi.org/10.5958/2249 7323.2014.00960.2

[21] ManishDadhich,ManvinderSinghPahwa,VipinJain,R. D. (2021). Predictive Models for Stock Market Index Using Stochastic Time Series ARIMA Modeling in EmergingEconomy. AdvancesinMechanicalEngineering, 281 290. https://doi.org/10.1007/978 981 16 0942 8_26.

[22] NareshKumar,M.D.(2016).Ananalyticalstudyoflife insurance facilities provided by life insurance companies. SAARJ Journal on Banking & Insurance Research, 5(1),82 92.

[23] RakeshKumarBirda&ManishDadhich.(2019).Studyof ICT and E Governance Facilities in Tribal District of Rajasthan. ZENITH International Journal of MultidisciplinaryResearch, 9(7),39 49.

[24] Sharma,N.,&Dadhich,M.(2014).PredictiveBusiness Analytics: The Way Ahead. Journal of Commerce and Management Thought, 5(4), 652. https://doi.org/10.5958/0976 478x.2014.00012.3

[25] Singh, G. K. (2021). Impact Execution of Total Quality Management ( TQM ) on Operational Performance of Indian Cement Manufacturing Industry : A Comprehensive SEM Approach. Design Engineering, 8, 13538 13562.

https://doi.org/http://thedesignengineering.com/index .php/DE/article/view/6476

[26] Dadhich, M. et al. (2021) 'Determining the Factors InfluencingCloudComputingImplementationinLibrary Management System (LMS): A High Order PLS ANN Approach',LibraryPhilosophyandPractice,p.6281.doi: https://digitalcommons.unl.edu/libphilprac/6281.

[27] Bortolini,M.,Faccio,M.,Gamberi,M.,&Pilati,F.(2016). Multi objective design of multi modal fresh food distributionnetworks. InternationalJournalofLogistics Systems and Management, 24(2), 155 177. https://doi.org/10.1504/IJLSM.2016.076470

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal