International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

1

2

Abstract Inthis experimentalstudythe properties of high strengthconcretehas beenstudiedbyaddingwheatstrawash in different percentage to the weight of cement. The main objective of this experimental study is to find out the mechanical properties whichinclude(both7and28days)split tensile and flexural strengths of concrete mix. In this mix, In addition to normal materials, cement is replaced by optimum quantity to silica fumes (i.e. 7.5%), steel fibers (i.e. 1%). Then the cement content was replaced by wheat straw ash (WSA) with 5%, 10%, 15% respectively (by weight of cement). For this purpose, the experiments were carried out on M60, M70 and M80 grade of concrete. For all grades of concrete (i.e. M60, M70 & M80) we found that replacement of 5% cement with wheat straw ash gives maximum split tensile & flexural strength (both 7 & 28 days), however with even 15% replacement of cement by wheat straw ash we get all strengths within targeted range. Hence it can be concluded that a 15% replacement of cement with wheat straw ash is very useful both in increasing the strength properties, reducing the cost & dead load of structures and proper utilization of waste material and reducing the carbon emission.

Key Words: Steel Fibres, Silica fumes, High Strength Concrete, Split Tensile Strength, Flexural Strength, Wheat StrawAsh.

Concrete is very useful, construction material that can be used in various applications. In most of the construction concrete is the main material. When a structure is constructed,themostimportantconsiderationistomakeit safe,strongandeconomical.Also,themostimportantobject is to build a structure that is cost effective. Cement is the primary binding material in concrete, which provides strength and durability to the structure. Now a days, concreteismodifiedwiththeuseofseveraladditiveswhose primaryfunctionistoincreasetheconcrete'sstrengthand durability,suchasflyash,silicafume,andsteelfibres.These are the materials that enable concrete to provide greater strengthanddurability.RiceHuskAsh,sewagesludgeash and oil shale ash etc. are also new supplementary

cemetitiousmaterialthatimprovesstrengthanddurability ofconcrete. Other than these, wheat straw ash(WSA) has alsobeenfoundtobeanaffectivepozzolanicmaterial. Silicafumeisabyproductofthemanufactureofsiliconmetal orsiliconalloysinanelectricarcfurnace.Silicafumeshelpin theimprovementofconcrete'smechanicalpropertiesaswell asitsdurability.Thesedays,costandenvironmentalfactors areveryimportantineveryconstructionactivity.Ingeneral, theuseoffibersalongwithSilicaFumeinconcretehasbeen provedtobeenhancingthecharacteristicsofconcrete.Steel fiber reinforced concrete is a castable or sprayable composite material made up of hydraulic cements, fine aggregate & coarse aggregates and discrete rectangular cross sectionsteelfibersdistributedrandomlythroughout thematrix.Steelfibersmakeconcretestrongerbyreducing tensilecracking.

Wheat straw waste is a major agricultural by product obtained from wheat production, which causes environmentalpollutionbecausethefarmersburnitdirectly inopenfields. When wheat strawwasteis properlyburnt undercontrolledsituationitgivescementingpropertiesand thatcanbeusedassupplementarycementingmaterial.The resulting ash contains higher percentage of silica. The particles of ash are also finer as compared to cement, therefore it is considered as supplementary cementing material.Theadvantageofusingwheatstrawashinconcrete as cement replacement material in concrete has revealed thatWheatstrawashincreasescompressivestrengthwhen it was replaced by 5% cement. Researchers are also investigating on the durability aspects of concrete while using wheat straw ash as replacement material because durabilityisoneoftheimportantpropertiesofconcrete.It wasfoundthatdurabilityisimprovedduetothepozzolanic and filler property of Wheat Straw Ash in concrete. Additionally, researchers also utilizes wheat straw ash as filler material in concrete because of fineness of particles. Compressive strength of concrete is enhanced by the fine aggregateswhichwasreplacedbywheatstrawash.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Cement OPCcementgrade53isusedforthisexperimental studyvariouslaboratorytestwereconductedoncementand tabulatedinTable 1.Cementusedinthisstudywasfreefrom anylumpsandwasingoodcondition.

Table -1: Laboratorytestresultsconductedoncement

Specific Gravity 3.14

Setting Time (min)

Initial 33 Final 185

Fineness 97%

Consistency 32%

Soundness 1mm

Compressive strength (7 days) 39.83MPa

Compressive strength (28 days) 55.32MPa

FineAggregates Locallyavailableartificialsandwhichis passingthrough4.75mmsievewasused.SpecificGravityof fineaggregatesisfoundtobe2.75.WaterAbsorptionoffine aggregatewasfoundtobe1.21%.

Coarse Aggregates Angular Coarse aggregate is used with maximum size of 20 mm. Specific Gravity of coarse aggregatewasfoundtobe2.86.WaterAbsorptionofcoarse aggregatewasfoundtobe0.50%.

SilicaFume SilicaFumeisaby productresultingfrom the high purity quartz with coal in electric arc furnaces in manufacturing of ferro silicon and silicon metal. Main ingredientsofSilicaFumeissilicondioxidewhichisveryfine andsphericalinshape.SpecificGravityofSilicaFumeused wasfoundtobe2.25.

Steel Fibers Hooked end , long straight fibers with aspectratioof50areused.Thediameterandlengthofsteel fibersis1mmand50mmrespectively.Bundleofsteelfibers istakenfrommarketandcutaccordingtorequiredlength.

Wheat Straw Ash Wheat Straw ash is dark grey in colour.Thesmallsizedparticlesplaysanimportantrolein filling voids in the concrete, hence it produce dense and durableconcrete.Wheatstrawashhaspozzolanicproperties, means it can react with lime to form a cementanious compound.Specificgravityofwheatstrawashisfoundtobe 1.51.

Water Portablewaterisusedformixingaswellasfor curingpurposes.Waterusedforthisexperimentstudyisfree fromallimpurities.

SuperPlasticizers SuperPlasticizersishighrangewater reducer.Useofsuperplasticizersinconcretecanimprovethe mechanical properties ofconcrete. Inaddition to that, itis necessary to use super plasticizers in concrete because concrete need higher water contents, for proper mixing & compacting.

Theuseofwastemateriallikesilicafume,flyash,GGBS etc.inconcreteiscommonnowadays.Thisresearchaimsto use wheat straw ash which is an agricultural waste in concrete to make concrete economical and reduce the environmentalproblems.Inthisexperimentalstudywehave designed high grade concrete using agricultural waste. Followingaretheparametersofstudy:

Todesignhighgradeconcretenamely(M60,M70& M80)withoutanyadmixture.

Todeterminethesplittensileandflexuralstrength of concrete for getting the optimum dose of silica fume and steel fiber to be used in high grade concrete.

To replace cement with waste material like silica fume&wheatstrawash.Additionalstrengtheningis donebyaddingsteelfibers.

Todeterminethesplittensileandflexuralstrength (7&28days)ofconcreteusingtheoptimumdoseof silicafumeandsteelfiberwithvariouspercentage replacementofwheatstrawash(5%,10%&15%).

Costanalysisofnormalconcreteandconcretewith additives(silicafumes,steelfibersandWheatstraw ash).

Theingredientsusedinthestudynamelycement,fine & coarse aggregates, silica fume, steel fibers, wheat straw ash and water were collected from various sources. The laboratory tests on various ingredients wereconductedinthelaboratoryoftheinstitute.After testing of various ingredient the trial mixes of M60, M70 & M80 were designed using IS 10262 2019. To find the optimum dose of two different admixtures namely silica fume and steel fiber a trial studies on M60 grade of concrete was done. The percentage of silica fume used was 5%, 7.5% & 10% while the percentageofsteelfiberswas0.5%,1%&1.5%. After getting optimum doses of silica fume and steel fibers we prepared mix design for M60, M70 & M80 gradeofconcreteusingwheatstrawash.Inthiswork for M60, M70 & M80 grade concrete, cement is replacedbyoptimumdoseofsilicafumesi.e.7.5%by weightofcement,wheatstrawashisreplacedwith5%, 10%and15%byweightofcement&optimalquantity of Steel fibres i.e. 1% weight of cement was added additionally.Inthisstudyfirstlycalculatedquantities ofcement,sand,aggregates,water,silicafume,wheat straw ash, steel fibers and super plasticizers were weightedaccordingtothemixdesignratioof1:1.52:

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

2.82forM60gradeofconcretewithwatercementratio of0.28,mixdesignratioforM70gradeis1:1.59:2.94 with water cement ratio 0.29 and similarly for M80 graderatioofmixdesignis1:1.39:2.58withwater cement ratio 0.26. Cylinders (150 mm Dia. 300 mm height) and Beams (100 mm x 100 mm x 500 mm) werecastedandtestedincompressiontestingmachine attheageof7&28daystogetSplittensile&flexural strengthofconcrete

Determination of optimum dose of silica fumes and steel fibers:

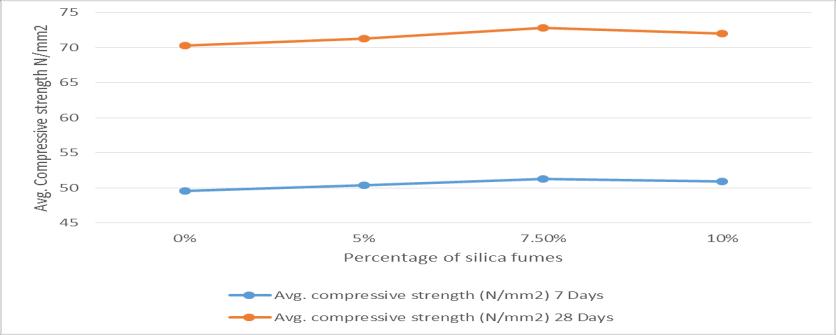

Table 2shows7&28dayscompressivestrengthofM60 gradeconcretefordifferentpercentageofsilicafumes.Figure 1showsthevariationincompressivestrengthofM60grade concretewithpercentageofsilicafumes

Table -2: Determinationofoptimumdoseofsilicafumes

S.No Silica fumes Avg. compressive strength (MPa)

7 Days 28 Days

1 0% 49.53 70.26 2 5% 50.35 71.32 3 7.50% 51.28 72.86

4 10% 50.93 71.97

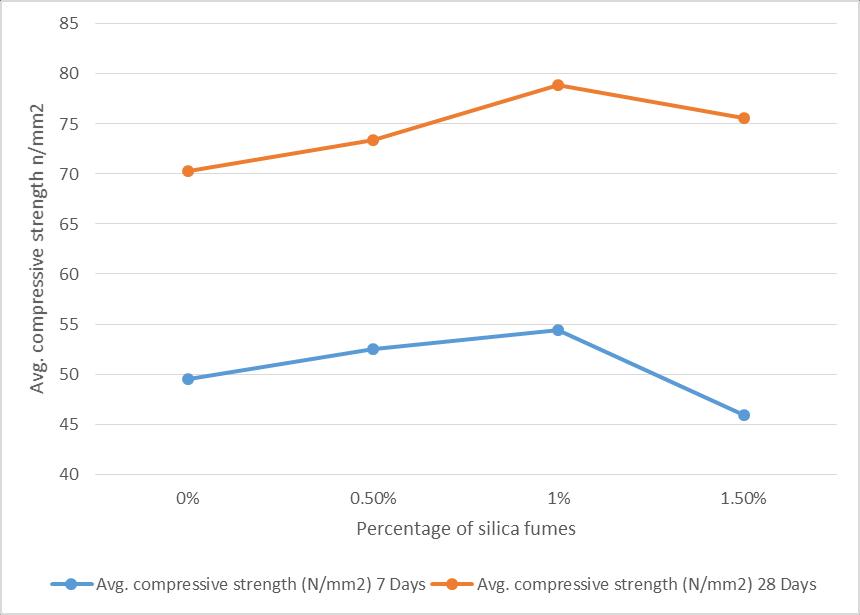

Table.3: Determinationofoptimumdoseofsteelfibers S.No. Steel Fibers Avg. compressive strength (MPa)

7 Days 28 Days

1 0% 49.53 70.26

2 0.50% 52.55 73.36 3 1% 54.42 78.92

4 1.50% 45.93 75.58

Fig 1: Variationincompressivestrengthfordifferent proportionsofsilicafumes

Table 3shows7&28dayscompressivestrengthofM60 gradeconcretefordifferentpercentageofsteelfibers.Figure 2showsthevariationincompressivestrengthofM60grade concretewithpercentageofsteelfibers

Fig. 2: Variationincompressivestrengthfordifferent proportionsofsteelfibers

Fromtheabovetables&curveswecanconcludethatthe optimumquantitysilicafumeis7.5%andsteelfibersis1%. Theseoptimumdoseofsilicafumes&steelfibersisaddedto dothefurtherstudyoneffectofwheatstrawashcanusein furtherexperimentalstudy.

Afterdeterminingtheoptimumdoseofsilica fumeand steel fibers, further study was conducted on replacing the cementwithwheatstrawash.Thepercentageofwheatstraw ashusedwas5%,10%&15%withthedesignedconcreteof M60,M70&M80cylindersandbeamswerepreparedand tested.

TheSplitTensileTestswereperformedonconcretecylinder of size 150mm Dia. And 300mm height as per IS (IS 5186 (1999)) by adding steel fibres (1%) and replacing cement withSilicafume(7.5%)anddifferentproportionsofwheat straw ash. The wheat straw ash replacement percentages were 5%, 10%, 15% by weight of cement. For each replacement level six cylinder were cast and cured. These number of number of cylinder were tested after 7 days of curingwhileremainingthreecylinderweretestedafter28 daysofusing.Finalstrengthwastakenbytheaveragevalue ofthreespecimens.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

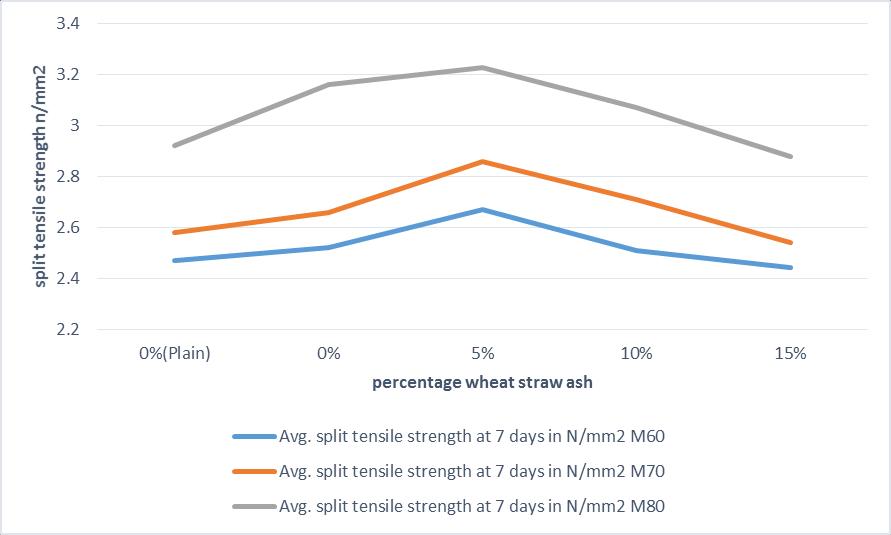

Table.4: Avg. split tensile strength at 7 days

S.No. Steel Fibres Silica fumes Wheat Straw Ash

Avg. split tensile strength at 7 days (MPa)

M60 M70 M80

1 0% 0% 0%(Plain) 2.47 2.58 2.92

2 1% 7.50% 0% 2.52 2.66 3.16

3 1% 7.50% 5% 2.67 2.86 3.23

4 1% 7.50% 10% 2.51 2.71 3.07

5 1% 7.50% 15% 2.44 2.54 2.88

Fig. 4: Variationofsplittensilestrength(28daysin N/mm2)withdifferentpercentageofwheatstrawash

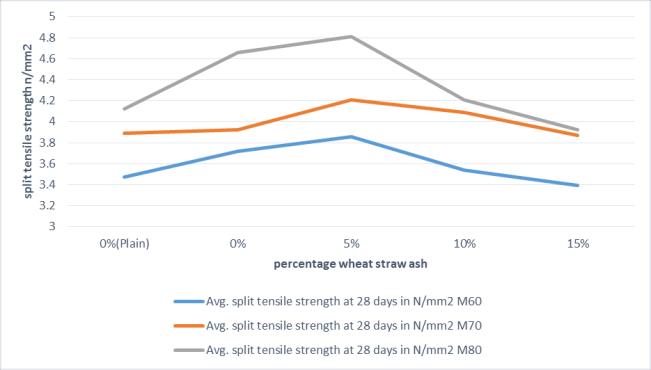

Table 5 shows the results of split tensile strength for differentgradesofconcretefordifferentpercentageofwheat strawash.Fig.4showsvariationinsplittensilestrengthof differentgradesofconcreteagainstthepercentageofwheat strawashat28Days.

Flexural strength Test:

Fig. 3: Variation of split tensile strength (7 days in N/mm2)withdifferentpercentageofwheatstrawash

Table 4 shows the results of split tensile strength for differentgradesofconcretefordifferentpercentageofwheat strawash.Fig.3showsvariationinsplittensilestrengthof differentgradesofconcreteagainstthepercentageofwheat strawashat7Days.

Table.5: Avg.splittensilestrengthat28days

S.No. Steel Fibres Silica fumes Wheat Straw Ash

Avg. split tensile strength at 28 days (MPa)

M60 M70 M80

1 0% 0% 0%(Plain) 3.47 3.89 4.12

2 1% 7.50% 0% 3.72 3.92 4.66

3 1% 7.50% 5% 3.86 4.21 4.81

4 1% 7.50% 10% 3.54 4.09 4.21

5 1% 7.50% 15% 3.39 3.87 3.92

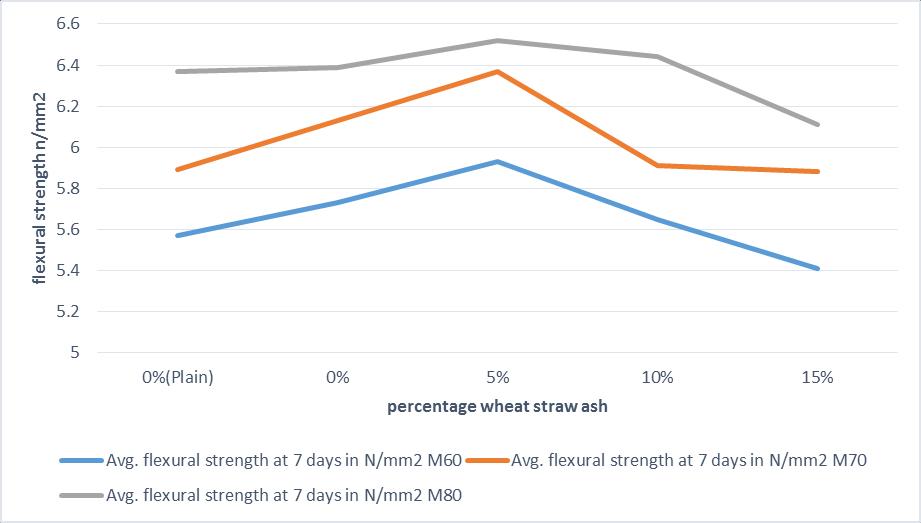

TheflexuralstrengthTestwasperformedonconcretebeam ofsize100mmX100mmX500mmasperIS(IS516 1959)by adding steel fibres (1%) and replacing cement with Silica fume(7.5%)withdifferentpercentageofwheatstrawash. The wheat straw ash replacement percentages were 5%, 10%,15%byweightofcement.Foreachreplacementlevel sixbeamswerecastandcured.Threebeamsweretestedat theageof7whiletheremainingweretestedafter28daysof curing.Finalstrengthwastakenbytheaveragevalueofthree specimens.

Table.6: Avg.flexuralstrengthat7days

S.No. Steel Fibres Silica fumes Wheat Straw Ash

Avg. flexural strength at 7 days (MPa)

M6 0 M7 0 M8 0

5.5 7 5.8 9 6.3 7 2 1% 7.50% 0% 5.7 3 6.1 3 6.3 9 3 1% 7.50% 5% 5.9 3 6.3 7 6.5 2

1 0% 0% 0%(Plain)

4 1% 7.50% 10%

5.6 5 5.9 1 6.4 4

5 1% 7.50% 15% 5.4 1 5.8 8 6.1 1

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

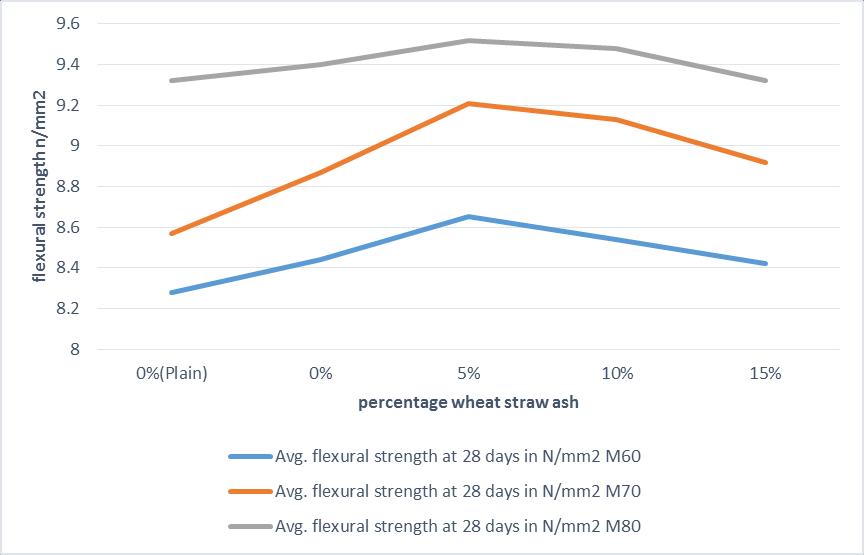

gradesofconcreteagainstthepercentageofwheatstrawash at28Days.

Cost Analysis:costanalysisisdonebycomparingcostof conventionalconcreteandconcretewithdifferentadditives. TheCostAnalysisofconcreteisdoneasperthemarketrates andscheduleofRatesbyCentralPublicWorksDepartment, 2021.

Table.8: CostestimateofNormalConcreteforM60 gradeconcrete

S. No. Particular Quantity Units Rate (Rs) Amou nt

Fig. 5: Variationofflexuralstrength(7daysinN/mm2) withdifferentpercentageofwheatstrawash

Table 6showstheresultsofflexuralstrengthfordifferent gradesofconcretefordifferentpercentageofwheatstraw ash. Fig. 5 shows variation in flexural strength of different gradesofconcreteagainstthepercentageofwheatstrawash at7Days.

Table.7: Avg.flexuralstrengthat28days

S.No. Steel Fibres Silica fumes Wheat Straw Ash

Avg. flexural strength at 28 days (MPa) M60 M70 M80

1 0% 0% 0%(Plain) 828 8.57 9.32

2 1% 7.50% 0% 8.44 8.87 9.4

3 1% 7.50% 5% 8.65 9.21 9.52

4 1% 7.50% 10% 8.54 9.13 9.48

5 1% 7.50% 15% 8.42 8.92 9.32

1 Cement 9.3 bag 330 3069

2 Fine Aggregates 0.709 Cubic meter 900 635.4

3 Coarse Aggregates 1.312 Cubic meter 1400 1836.8 Total 5541.2

Table.9: CostestimateofConcreteforM60gradeusing Wheatstrawash,silicafumes&SteelFibers

S. No. Particular Quantity Units Rate (Rs) Amount

1 Cement 7.2076 bag 330 2378.51

2 Fine Aggregates 0.709 Cubic meter 900 635.4

3 Coarse Aggregates 1.312 Cubic meter 1400 1836.8

4 Silica Fume 34.87 Kg 5 174.35

5 Wheat StrawAsh 69.75 Kg 0 0

6 Steel Fibers 4.65 Kg 50 232.5

7 NetCost 5257.56

Fig. 6: Variationofflexuralstrength(28daysin N/mm2)withdifferentpercentageofwheatstrawash

Table 7showstheresultsofflexuralstrengthfordifferent gradesofconcretefordifferentpercentageofwheatstraw ash. Fig. 6shows variation in flexural strength of different

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Table.10: CostAnalysisforM60gradeconcrete

1 CostofNormalConcrete 5541.2

2 Costofconcreteusingsilica fume,wheatstrawashand steelfibers

5257.56

3 Percentageincostofsavingper m3 ofconcrete 5.39%

Similarly,wehaveperformedthecostanalysisforM70& M80gradeconcreteandweconcludedthat

• Percentagesavingperm3ofconcreteforM70was4.98%.

• Percentagesavingperm3ofconcreteforM80was5.63%.

Fromabovecostanalysiswefoundthatreplacementof cementwithwheatstrawash,silicafumeandsteelfiberscan beeconomical&environmentalfriendlyformassconcrete work.

Followingaretheconclusions

The optimum percentage of silica fume and steel fiberforthedesignofdifferenthighgradeconcrete isfoundtobe7.5%and1%respectively.

Althoughat5%replacementofcementwithwheat straw ash, maximum split tensile and flexural strengthisobtained,butevenat15%replacement of cement with wheat straw ash the achieved strengths are more than the targeted strength. Hence to achieve maximum economy, it is recommendedtouse15%wheatstrawash.

concrete” 29th Conference on OUR WORLD IN CONCRETE & STRUCTURES: 25 26 August 2004, Singapore.

[3] Santhi A.S., et al. (2011) “Study on Strength DevelopmentofHighStrengthConcreteContainingFly ash and Silica fume” International Journal of EngineeringScienceandTechnology2011.

[4] Roy, D. K. (2012) “Effect of Partial Replacement of Cement by Silica Fume on Hardened Concrete” International Journal of Emerging Technology and AdvancedEngineering,2(8),472 475.

[5] SabaleV.D.,etal.(2014)“StudytheEffectofAdditionof SilicaFumeonPropertiesofHighStrengthConcrete” International Journal of Engineering Research & TechnologyVolume3issue1,2014.

[6] ChoudharyS.,etal.(2014)“StudyOfHighPerformance Concrete” Journal of Civil Engineering and EnvironmentalTechnologyVolume1,2014.

[7] QiangZ.,etal.(2014)“Effectofrapestrawashandsilica fumeadmixtureonconcreteperformance” Journalof HunanAgriculturalUniversity(NaturalSciences),2014, 40(3):334 336.

[8] Pandit R.D. & Wadekar A.P. (2015) “Study of High StrengthFibreReinforcedConcretebyusingTwoTypes ofFibres” IJREST2015.

Apartfromeconomicalpointofview,itisobserved that,replacementofcementwithwheatstrawash, silica fume and steel fibers can be economical & environmentalfriendlyformassconcretework.It will not only reduce the consumption of cement, which will be ecofriendly but will also solve the problemsofdisposalofwheatstrawash.

[1] Al AkhrasN.M.,Abu AlfoulB.A.(2002)“Effectofwheat straw ash on mechanical properties of autoclaved mortar” journalofCementandConcreteResearch32 (2002)859 86.

[2] Perumal,K.,Sundararajan,R.(2004)“Effectofpartial replacementofcementwithsilicafumeonthestrength and durability characteristics of High performance

[9] KumarA.,etal.(2015)“PartialReplacementofCement inM 30ConcretefromSilicaFumeandFlyAsh” SSRG InternationalJournalofCivilEngineering,3(5),40 45, 2015.

[10] Hamiruddin N.A., et al. (2018) “Effect of steel fibre contentwithhighstrengthfibrereinforcedconcreteon compressive behavior” AIP Conference Proceedings 2030,020049(2018).

[11] Zheng Y.,etal.(2018)“Mechanical PropertiesofSteel Fiber Reinforced Concrete by Vibratory Mixing Technology” Advances in Civil Engineering Volume 2018.

[12] Hamiruddin N.A., et al. (2018) “Effect of Steel Fibre ContentswithHighStrengthFibreReinforcedConcrete” International Journal of Advances in Scientific

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

ResearchandEngineering(Volume4, Issue3March 2018).

[13] Shar I.A., et al. (2019) “Use of Wheat Straw Ash as Cement Replacement Material in the Concrete” InternationalConferenceonSustainableDevelopmentin CivilEngineering2019.

[14] KhanM.S.,etal.(2019)“AStudyofPropertiesofWheat Straw Ash as a Partial Cement Replacement in the ProductionofGreenConcrete” UWJournalofScience andTechnologyVol.3(2019)61 68.

[15] Yanxia Ye, et al. (2020) “Experimental Study of High StrengthSteelFiberLightweightAggregateConcreteon MechanicalPropertiesandToughnessIndex” Advances in Materials Science and Engineering Volume 2020, ArticleID5915034.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3625