A STUDY ON DEMOLISHED CONCRETE WASTE AS PARTIAL REPLACEMENT OF COARSE AGGREGATE IN CONCRETE

Ajit M. Kadam 1 Rohan B. Patil2 , Harshal R Jadhav3 , Aditya S. Jadhav 4 Aditya Y. Salunkhe5 Kanipnath G. Yantal6

Ajit M. Kadam 1 Rohan B. Patil2 , Harshal R Jadhav3 , Aditya S. Jadhav 4 Aditya Y. Salunkhe5 Kanipnath G. Yantal6

1Professor,

2,3,4,5,6Diploma

Abstract - Concrete is the second most used construction material in the world. Here concrete is made from composition of cement, fine aggregate (sand), coarse aggregate and demolished concrete waste generated from demolished construction. Demolished concrete aggregate is replaced as coarse aggregate in concrete. Use of demolished concrete waste as coarse aggregate in concrete leads to reduce construction cost and also it helps to reduce the percentage of coarse aggregate.

In this project we have study on partial replacement of demolished concrete waste as coarse aggregate in concrete. Demolished concrete can be reused or recycled, by crushing it to specific size., cleaned so that we can use it in mixture as coarse aggregate in fresh concrete.

In this study 20% and 25% replacement for coarse aggregate by demolished concrete aggregate for M 30 mix is done. Compressive strength result for that demolished aggregate concrete are obtained and these results are comparable with conventional concrete.

Key Words : Steel slag, fine and coarse aggregate, partial replacement. Concrete, demolished concrete waste, cement, fine aggregate, coarse aggregate, replacement, compressive strength, Comparison M 30 mix.

1. INTRODUCTION

As we know that concrete is construction material which is mostly used in construction activities. The worldwide production of concrete is 4.4 billion tons annually and the demand for concrete is continuously rising. So that we not only find alternative for coarse aggregate but also provide solution for demolished concrete waste management. Simultaneously we try to reduce construction cost by using demolishedwaste.

In this project we have study on partial replacement of demolished concrete waste as coarse aggregate in concrete. Demolishedconcretecanbereusedorrecycled,by crushing it to particular sizes, cleaned it to remove unwanted debris from mixture, and it is reused as coarse aggregate in fresh concrete.

Demolished aggregate concrete helps to reduce landfill

crowding by reusing it. And it also saves more resources from beingusedtocreatefreshconcrete. We are going to compute tests like compressive strength test, specificgravitytest,Crushingvalueofaggregate,sieveanalysis test,mixdesign.

2. OBJECTIVES

[1] Toreduceconcretewasteascoarseaggregate infreshconcrete.

[2] To use concrete waste in order to reduce constructioncost.

[3] Touse concrete wasteas partial replacement forcoarseaggregate.

[4] Comparative study of ordinary concrete and recycledconcrete.

3. SCOPE

[1] To completely replace aggregate by concrete waste.

[2] To reduce landfill crowding by reusing demolishedconcreteascoarseaggregate.

[3] Touseconcretewasteaspartialreplacementfor coarseaggregate.

4. APPLICATIONS

A. Demolishedaggregateconcreteisusedwhere higher strengthisnotrequired.

B. Thisconcretecanbeusedoutdoorseating,decorative screen, outdoor bar, flower bed and many outdoor furniture.

C. Demolishedaggregateconcretemaybean alternative toconventionalconcrete.

5. MATERIALS USED

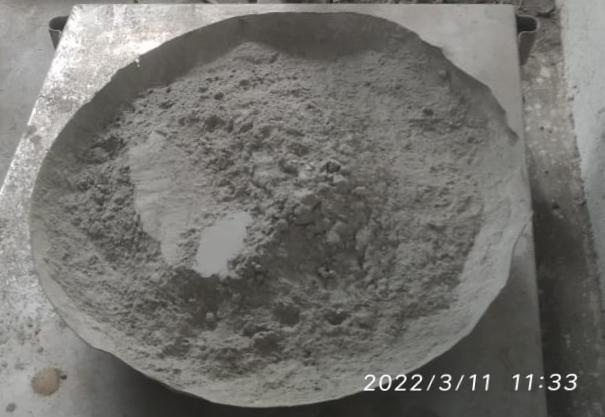

5.1 Demolished concrete aggregate:

5.4

Coarse aggregate:

Fig.

4. CourseAggregate

Fig. 1. DemolishedConcreteAggregate

It is waste generated after demolishing any building or other structures. Demolished concrete can be reused or recycled, bycrushingittospecific sizes.cleanedsothat we canuseitinmixtureascoarseaggregateinfreshconcrete.

5.2

Cement:

These are the particles that are greater than fine aggregate and retain on 4.75mm sieve. For preparation of concrete we tooksizeof20mmaggregate.

5.6

Water:

Fig. 5.

Fig. 2. Cement

Cement is binder material used in construction. It is mixed with fine aggregate to make mortar which is used in masonry work or mixed with sand and coarse aggregate to makeconcrete.

5.3 Fine aggregate:

Water

ThewaterusedforexperimentswaspotablewaterFresh portablewaterfreefromorganicmatter.Itistransparent fluid.Itshouldnotcontainanydustparticlesandwillbe clean.

6. METHODOLOGY

Actual Procedure of Concrete Block Casting

6.1 Preparing material for concrete

ThematerialofM30gradeconcreteofratio1:1.48:2.46was collected and stored to an temperature of 27 ±3 degree Celsius. Also our waste product i.e. Demolished concrete aggregatewasbrought.WatercementratioforM30gradeof concrete we used is 0.42 for maintained for good workabilityofconcrete. 6.2 For 20% replacement:

Fig. 3. FineAggregate

Itisthecrushedsandwithmostparticlespassingthrough sieve of 4.75 mm and retain on sieve of 0.075mm. It is washedandproperlygraded.

6.4

Volume: 09 Issue: 05 | May 2022 www.irjet.net p-ISSN: 2395-0072

Fig.

7 ConcreteMixing

Mould preparation:

Weusedthemouldofcastironforcastingofconcreteblock. Thenwecleanedit.Andthenoileditsinnersurfaceforeasy removalofconcreteblock.

6.5

Fig. 6 MouldPreparation

Concrete mixing

We preferred hand mixing because of there is small work. The process is done on the rectangular pan until a homogenousmixisobtained.Cementisproperlymixedwith trowel to avoid lumps. And the water is added as per mix design.

Chart 3:Materialrequiredforconcretemixing

6.6

Casting of

specimen Afterconcretemixingthespecimeniscastedof15cm×15cm in cast iron mould and properly compacted in order to preventhoneycombingformation.

6.7

Compaction

Compaction is done with tamping bar of dimension of diameter 16mm and height of 0.6m. Compacting is done with min 35 strokes in all parts of mould for proper compaction.

Fig. 8. Compaction 6.8 Vibration Vibratingofspecimenisdoneonvibratingtable.Andthisis doneforremovingairvoidsinthespecimen.

Fig. 9. Compaction

Volume: 09 Issue: 05 | May 2022 www.irjet.net p-ISSN: 2395-0072

6.9 Curing

Thenthespecimenisstored inmoistairfor24hours. Then blocksareremovedfromthespecimeniskeptsubmergedin clearfreshwaterforduringfor3days,7days,28days.

7.2 Selection of water cement ratio

Maximum W/C ratio required for M30 grade concrete is takenfromtableno.5ofIS456. MaximumW/CforM30is0.45 AdoptedW/CforM30is0.42

7.3 Selection of water content –

Maximumwatercontentfor20mmaggregatesizetoachieve slumpof50mmisreferredfromtableno.2ofIS10262. 186Lofwaterrequiredtoget50mmslump.

7.4 Calculation of cement

Fig. 10. Compaction

6.10 Testing of blocks

Compression test is carried out after 3days, 7days, and 28daysofcuring.Andresultswereobtained

Cementrequired=Watercontent/(W/Cratio) =186/0.42 =442.85Kg

7.5 Calculation of fine aggregate and coarse aggregate

Fromthetableno3of IS10262for20mm,fineaggregateof zone2

Ratioofcourseaggregate=0.62

Ratiooffineaggregate=1 0.62=038 Forcoarseaggregate(C.A)

Fig. 11. Compaction

7. Mix design for M30 grade concrete:

Ingredien ts Ceme nt Fine Aggrega te

Coarse Aggrega te

Wate r Chemic al

Quantity 422.8 5 658.37 1090.60 186 NA Ratio 1 1.48 2.46 0.42 NA

Chart 4:MixdesignforM30

7.1 Target mean strength =30+1.65×5 =38.25N/mm2 Thevalueofstandarddeviation(S)istakenfromtableno. 8ofIS456

Ca = 1090.60 kg/m3 Forfineaggregate(F.A) Ca = 658.37 kg/m3

7.6 Proportion for M30

Ingredien ts Ceme nt Fine Aggrega te

Coarse Aggrega te

Wate r Chemic al

Quantity 422.8 5 658.37 1090.60 186 NA Ratio 1 1.48 2.46 0.42 NA

Chart 5:ProportionforM30

MixratioforM30concreteis1:1.48:2.46

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3551

8 TESTS ON MATERIAL AND CONCRETE BLOCK Testsperformedonmaterials

8.1 Specific gravity of aggregate

Specific gravity of aggregate is an test carried out on aggregate to find strength of aggregate. It is the the ratio of weight of aggregate to weight of water with equal volume. Anditrangesbetween2.5to3.0 :

Fig. 14. Sieveanalysis

9. Test Performed on Concrete blocks:

9.1

Compressive strength:

Fig. 12 Specificgravity

8.2 Crushing value of aggregate

It is the resistance of an aggregate to compressive load. Crushingvalue ofaggregate indicatesstrengthofaggregate. This test is is carried out on aggregate to achieve high qualityofpavement.

It is the characteristics strength of concrete. It is the ability of concrete to resist load without any failure like crack or deflection Usually, a compressive testing machine (CTM) is used to perform compressive strength on concrete block. After air drying the concrete block, the strength must have tobeknownforthemoreapplicationoftheconcreteblocks. Fig. 15. Sieveanalysis

Fig. 13. Crushingvaluetest

8.3 Fineness modulus

It is an index number that indicates of particles in coarse aggregate. It also indicates fineness or coarseness of aggregate.

N/mm

N/mm

Days TestResults Compressive strength Average

3rd day 22000kg 9.59 9.59 22500kg 9.81 21500kg 9.37 7th day 35000kg 15.26 15.62 37000kg 16.13 35500kg 15.47 28th day

12.

47500kg 20.71 21.07 48500kg 21.14 49000kg 21.36