International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

USE OF SAWDUST IN CONCRETE

1,2,3 UG Student, Department Of Civil Engineering, Alard College Of Engineering And Management, SPPU, Pune, India

4 Assistant Professor, Department Of Civil Engineering, Alard College Of Engineering And Management, SPPU, Pune, India ***

Abstract - The construction industry is one of the main sectors in India, and the need for building materials such as cement, sand, natural stones, bricks, steel, has increased over the last two decades. In the future years, the demand for building materials will expand as the overall value of planned projects in India rises. 16 percent of the nation's working population is supported by the construction industry. The purpose of this research is to observe and examine the compatibility of sawdust, as waste material, in concrete block using various tests, and to determine the optimal mix for concrete block based on the compressive strength of concrete cubes. We trying to find out sawdust can be used for modified concrete mix or exceeded all of the strength requirements. To identify max value of replace sand with sawdust for 30%, and any quantity in excess would damage the quality of M20 grade concrete. To find the value compressive strength to replace out and decrease the amount of sand in concrete.

Key Words: Concrete blocks, sawdust, strength, construction material, light-weight, Building construction

1.INTRODUCTION

ThebuildingindustryisoneofthelargestindustriesinIndia andthereisagrowingdemandforbuildingmaterialsinthe last two decades, such as cement, sand, construction material etc. The demand for the construction material is going to increase in coming years as the total value of projects planned in India is Around 16 per cent of the nation'sworkingpopulationdependsonconstructionforits employment. Thisexpectedoverallgrowthisseenasaclear indicationofaprosperingmarketforconstructionmaterials.

To meet this demand, building material suppliers have exploited natural resources. This has led government agencies to enforce stringent laws in maintaining natural resources for a livable future Further, this has motivated many researchers to adopt a concept of recycling waste materials into an inventive building material to meet the largedemandofconstructionmaterials.Brickshavebeena majorconstructionandbuildingmaterialforayears

Conventional bricks are produced from clay with high temperature kiln firing or from ordinary Portland cement concrete.Miningoperationsforobtainingtheclayareenergy

intensive,adverselyaffectthelandscape,andgeneratehigh levelofwastes.

1.1 SAWDUST CONCRETE

The concrete is made by addition of sawdust is called as sawdustconcrete.Inthistypeofconcrete,theDrySawdust isusedtoreplacethefineaggregateandSawdustAshcanbe usedtoreplacesmallquantityofthecement.Alongwiththat woodchipscanbeusedtoreplacecoarseaggregates.

1.2 BENEFITS OF SAWDUST CONCRETE

• Sawdustconcreteismadeofecologicallypurestuff.

• SawdustConcretecontrolsinteriorhumiditylevel.

• SawdustConcreteisfrostproof.

• Sawdust Concrete is favorable thermal and soundproofingcharacteristics

• SawdustConcreteislightweight.

• Itiseconomicalalternativetoconventionalbuilding concretemethodandmaterial.

• Duetomaterial’sinertnaturetowardscementand other aggregates, it does not react with any ingredientsofconcreteandsteel.

• Attheendofitsoriginalservicelife,concretecanbe crushedandreusedasaggregatefornewconcrete continuingthecycleofenvironmentalbenefits.

2. METHODOLOGY

Thematerialidentificationwasdoneforthemodificationof sawdust.TheSawdustwastheselectedmaterial.Afterthat the material was collected from various sawmills and furnitureshopsinpune.Thematerialqualitywaschecked withthehelpofsieveshakingandthematerialretainedon 4.75 mm and passing through 425 micron was discarded. ThemixdesigncalculationforM20gradeconcretewasdone and the sand proportion of that was replaced 10%, 20%, 30%byweightwithsawdust.Theslumpconetesthelpedin deciding the water cement ratio of the sawdust modified concrete.Afterthatcubewerecastedandcuredfor28days.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Onesetofcubesweretestedon7thdayandremainingcubes were tested on 28th day. The results were observed and recordedinresultssectionofthepaper.

2.1 MATERIAL AND MIX PROPORTIONS

Materials that were used in this study were; ordinary Portland cement, Sand, Coarse aggregate, sawdust (generatedfromthemechanicalprocessingofvariousraw woods in the saw mill industries), It was sieved and the material passing through 4.75 mm and retaining on 425 micronsusedwithoutanypre treatment.Concreteusedfor thisstudywaspreparedusingmixratioof1:1.5:3(C:S:A) anda water tocement ratio of 0.54; whilebatchingofthe materialswasdonebycombinationofvolumeandweight batching due to the remarkable differences in the specific gravities of cement, sand and sawdust. The homogenized mixturewasthenintroducedinto150mm×150mm×150 mmmetalmolds;theconcretede moldedafter24hourand cured,thecompressivestrengthtestwasperformedafter7 daysand28days.

2.2 PROCESS

• Thequantitiesestimationofregularmixdesignof M20gradeconcretewasusedtocreateBlankcubes for M20 grade concrete. Further the sand portion was weighed and percentagewise replacements weredoneintherespectivemixdesigns.

• The size of Sawdust and the sand which it was replacingwasinthesamerange.

• Throughout the experiment, same material was usedforcubecasting.Toavoiderrorsoccurringdue tovaryingmaterialpropertyandquality.

• Thequantityofsawdustusedtoreplacethesand, wascalculatedbasedontheremovalbypercentage weight. The quantity of sand removed will be satisfiedbytheadditionofsameweightofsawdust. The percentage of sawdust replaced are taken as 10%,20%and30%.

2.3 TEST CONDUCTED FOR MIX DESIGN

Trialformixdesignwasdonebyweightusingmixratioof 1:1.5:3 and water cement ratio of 0.54% for the concrete production

M20 Grade Concrete Volume =0.054

Cu m (W/C Ratio = 0.54)

Table 1: Trialmixdesign

10% modification with saw dust

20% modification with saw dust

30% modification with saw dust

DryRatio 154 154 154

Sand(Kg) 816 725 635 Saw Dust (Kg) 0.907 1814 27216

Aggregate (Kg) 1512 1512 1512 Water(Kg) 435 435 435

TheVolumeofconcretethatwascreatedforonesetofthe cubemouldfillingwas0.0135Cu.m.

2.4 TEST METHODS

Testthatwascarriedoutinthisresearchandtherespective standardsusedwere:

• Particlesizedistribution

• Slumconetest

• CompressiveStrength

• BallTest

• SoundnessTest

2.5 MATERIAL TESTING

Particle size distribution (Total sample weight = 300 grams) Itwassievedandthematerialpassingthrough4.75 mm and retaining on 425 microns used without any pre treatment.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

3. RESULT AND DISCUSSION

CONCRETE TESTING

SlumpconeTest (10%modificationofsawdustwithsand)

Sr no Water/CementRatio Slumpvalue

1 0.2 NoSlump

2 0.4 NoSlump

3 0.5 TrueSlump

4 0.6 TrueSlump 5 0.7 ShearSlump

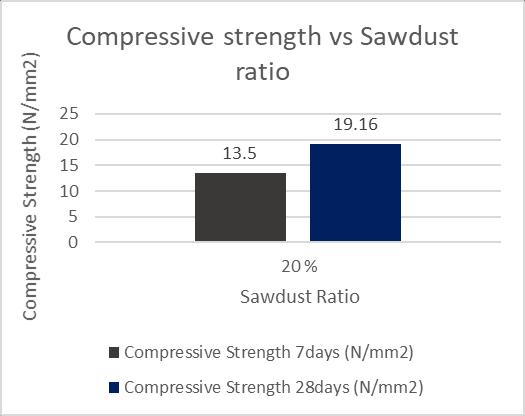

Compressiontestingofmodificationofconcretewith sawdust20%(Curingdays=07&28)

Sr no Water/CementRatio Slumpvalue

(20%modificationofsawdustwithsand) (30%modificationofsawdustwithsand)

1 0.2 NoSlump 2 0.4 NoSlump 3 0.5 TrueSlump 4 0.6 TrueSlump 5 0.7 ShearSlump

Sr no Water/CementRatio Slumpvalue

1 0.2 NoSlump

2 0.4 NoSlump

3 0.5 TrueSlump

4 0.6 ShearSlump

5 0.7 Collapse

COMPRESSIVE TESTING

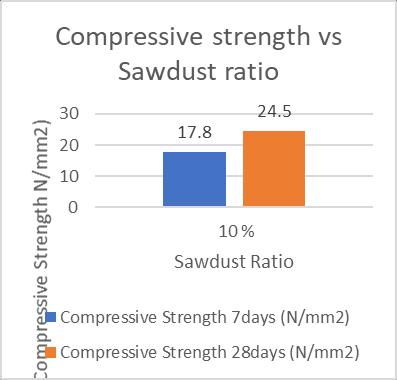

Compressiontestingofmodificationofconcretewith sawdust10%(Curingdays=07&28)

Sawdust Ratio(%) Compressive strength7days N/mm2

Compressive strength28days N/mm2

10 17.8 24.5

SawdustRatio (%) Compressive strength7days N/mm2

Compressive strength28days N/mm2 20 13.5 19.16

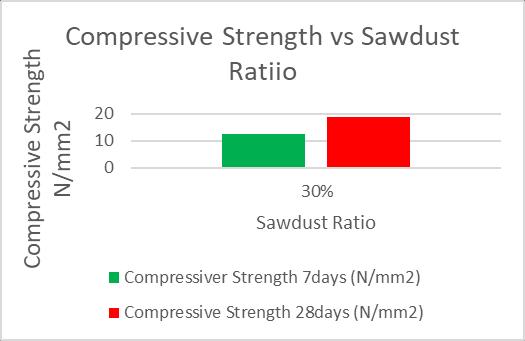

Compressiontestingofmodificationofconcretewith sawdust30%(Curingdays=07&28)

SawdustRatio (%)

Compressive strength7days N/mm2

Compressive strength28days N/mm2 30 12.6 18.7

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

4. APPLICATION OF SAWDUST

1. Sawdustwasusedpartiallyreplacementforsandin concreteproduction.

2. Sawdust concrete mix for residential building structuralmembersuchascolumn,beam,slaband foundationandplasteringarealsoelicited.

3. Amajoruseofsawdustisforparticleboard.

4. Sawdust is used in the manufacture of charcoal briquettes.(Henryford)

5. Sawdust has been used for cultivation of greenhousevegetablesandstrawberriesinbag.

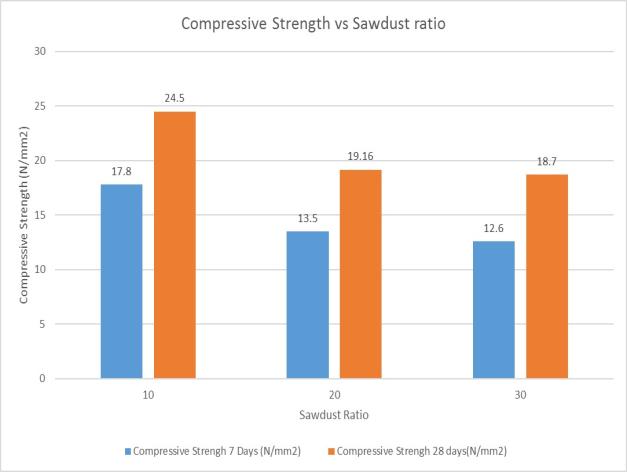

Compressiontestingofmodificationofconcretewith sawdust10%,20%&30%(Curingdays=07)

Sr.no Sawdust Ratio CompressivestrengthN/mm2

1. 10 17.8 2. 20 13.5

3. 30 12.6

Compressiontestingofmodificationofconcretewith sawdust10%,20%&30%(Curingdays=28)

Sr. no Sawdust Ratio CompressiveStrength(N/mm2)

1. 10 24.5 2. 20 19.16 3. 30 18.7

6. Spreadingsawdustaroundthebaseofyourgarden plantscanpreventweeds,helpretainmoistureand keeprootscooler.

5. CONCLUSION

The sawdust modified concrete was observed to be performing excellent in terms of the strength criteria. The observed maximum value to replace sand by sawdust was observed to be 30% any excess amount will degrade the quality of M20 grade concrete. The sawdustawastematerialwasobservedtobeasuitable materialtoreplaceandreducetheusageofsandinthe concrete.

6. REFERENCE

• K. Ambiga and P. Meenakshi (2015), “Studies on StrengthofconcretebyPartialReplacementofsand with Sawdust”, International Journal of Advanced EngineeringResearchandStudies.

• Sourabh G. Sable and S.B. Walke (2015), “Experimental Investigation on Properties of Concrete for Partial replacement of Brick Ballast Aggregate”, International Journal of Emerging TechnologyandadvancedEngineering.

• P. Sri Chandana and Shaik Ahamad Myauddin (2015),“Experimentalstudyonstrengthofconcrete by partial replacement of Fine aggregate with SawdustandRobosand”,InternationalJournaland MagazineofEngineering,Technology,Management andResearch.

• K. Gopinath, K. Anuradha, R. Harisundar and M. Saravanan (2015), “Utilization of Sawdust in CementMortarandCementConcrete”,International Journal of Scientific Research, Volume 6, Issue 8, August2015.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

• MahmudAbubakarandAbayomiAfolayan(2013), “Partial replacement of Sand with Sawdust in ConcreteProduction”,ConferencePaper,May2013.

• Prof.R.SathishKumar(2012),“Experimentalstudy onthepropertiesofconcretemadewithalternate construction materials”, International Journal of ModernEngineeringResearch,Vol.2,Issue5,Sept Oct.2012.

• M. Mageswari and B. Vidivelli (2009), “The use of sawdust ash as fine aggregate replacement in Concrete”,JournalofEnvironmentalResearchand Development,Vol.3,No.3,January March2009.

• S.Acharya,U.Neupane,andS.Adhikari,“Strength OptimizationofSawdustConcretethroughCement Variation Strength Optimization of Sawdust Concrete throughCement Variation,” Proceedings Of 8th Graduate Conference, vol. 8, pp. 730 736, 2021.