International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Omkar S. Kalase1, Adityara B. Dange2, Shubham P. Thorat3 , Adil A. Jamadar4, Pranil S. Patil5

1,2,3,4,5 Diploma Student, Department of Civil Engineering, Rajarambapu Institute of Technology, Rajaramnagar, India ***

Abstract - Duetotheriseindemandinsteelstructuresin recentyears,therearenumberofsoftwarethatareavailable inengineeringfieldfordesignofsteelstructures.

Thisstudydealswithcomparisonofmanual methodsand softwaretofindtheaccuratedesignofthestructure.Inthis studythedesignoftrussisfirstdonebymanualcalculation andsecondbytheuseofSTAAD Pro.

Theresultsobtainedarethencomparedtoobtainthebest andmostefficienttrussforsteelstructure.

Key words: Design, Analysis, Fink Truss, Design, STAAD PRO, Steel take off

Inallpartsoftheworldsteelindustryisrisingrapidly.Steel roof trusses have a broad range of application in industry involving of good load transfer mechanism without negotiatingwiththestructuralappearance.

Nowadays,numberofapplicationsoftwareareavailablein marketfordesignsincivilengineeringfield.software’sare developedonbasisofadvancedanalysiswhichincludesthe effectofloads,earthquakeeffectsetc.inthepresentwork,to studytheefficiencyofcertaincivilengineeringapplication softwareanattemptwasmade.

The study of this paper reviews to analysis and design of steel member /section to be used in construction of steel structure, and its comparative study of properties using softwareandmanualcalculations

1.Todesignaneconomicaltruss. 2.Tostudythepropertiesofdesignedtruss.

3.TocomparetheresultsofdesignoftrussfromSTAADPRO andmanualcalculations.

Increase the load carrying capacity of truss without optimizingthematerialsused

Modification in design methods which help in easy designofTruss

Decrease the materials and change in design used withoutoptimizingtheloadcarryingcapacityoftruss.

4. MANUAL DESIGNS

4.1 Methodology in Manual design 1]Trussconfiguration 2]LoadsConfiguration 3]Memberforces 4]Reactions 5]Resultants

4.2 Description of data in manual design

Riseoftruss 1/4ofspan

Self weightofPurlins 318N/m

Roofing

Asbestoscementsheet(dead weight =171N/m2)

HeightofBuilding 11M

C/CSpacingoftruss 8M

WidthofBuilding 16M

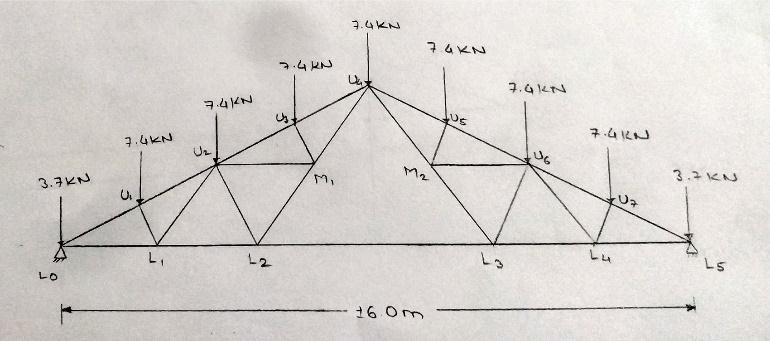

4.3 Truss Configuration

LetɑBetheInclinationofTheRoofwithTheHorizontal Tanɑ=4/8=½ ɑ=26o34’ =26.566o

LengthOftheRafter =

LengthOfEachPanel=8.94/4=2.235M

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

=6700/2=3350N=3.35KN

AssumeWeightofBracing=12N/M2 DeadWeightofAcSheetSheets=171N/M2 Self WeightofPurlin=318N/M2 =318x8=2544N

PanelLength=2.235m

ThePanelLengthinPlan =2.235Cos260 34’=2.00m.

LoadOnEachIntermediatePanelDuetoDeadLoad =(12+171+110)X(8X2)+2544=7232N ≌7.4KN

LoadOnEndPanelPointsoftheRafter =7.4/2=3.7KN

ɑ=26o 34’=26.566o

AssumeNoAccessProvidedtoTheRoof.TheLiveLoadIs ReducedBy20N/M2

ForEachOneDegreeAbove10o Slope LiveLoad=750 20X(26.566 10) =418.68N/M2

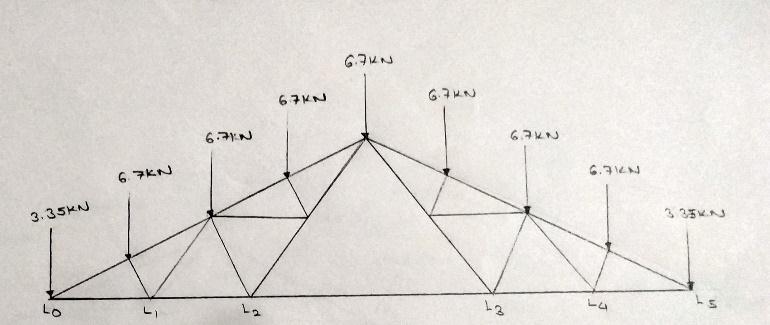

TheLoadOnEachIntermediatePanel =418.68*8*2 =6698.88N=6700N=6.7KN

TheLoadOnEachPanelPoint

ExpectedTheLifeoftheIndustrialBuildingis50Years andTheLandisPlainandSurroundedbynumberSmall Building

K1 = 1.0

K2 = 0.89

K3 = 1.0 Vb = 47 M/S

Design Wind Speed Vz =K1 *K2 *K3 *Vb = 1.0*0.89*1.0*47

Design Wind Pressure, Pd = Vz 2 =0.6*41.832=1049.8N/M2

HeightOfBuildingColumnAboveGroundLevel,H=11m

WidthOfBuilding,W=16m

InThisPresentExampletheRoofAngleΑIs26.566oFor WhichtheCoefficientsAreTabulatedBelow

TheValuesofCoefficientCpeforVariousConditionsinThe TableHaveBeenCalculatedbyTheInterpolationfor AppendixXvIs800 PartIII

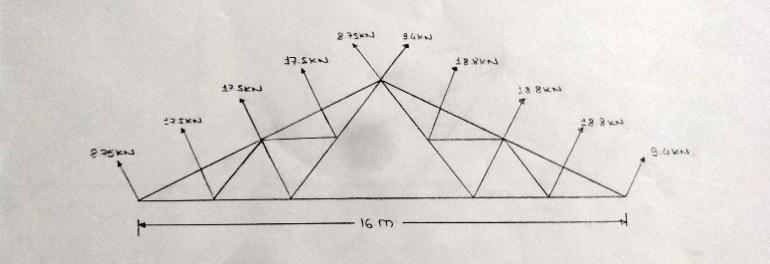

1) Windward Side

F1 = = ( 0.8 0.2) X 1.05 X (8 X 2.235) = 18.77≌ 18.8kn

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

F2 = 18.8/2 = 9.4 KN [ Intermediate Panel Points]

2) Leeward Side

F3 = = ( 0.731 0.2) X 1.05 X (8 X 2.235) = 17.48≌ 17.5kn

F4 = 17.5/2= 8.75 KN [Intermediate Panel Points]

Horizontalcomponent = 75.2sin 26.566o = 33.63 KN →

Nethorizontalcomponent = 33.63 31.30 = 2.33kN →

Horizontalforceateachfaceshoe = 2.33/2 = 1.165kN →

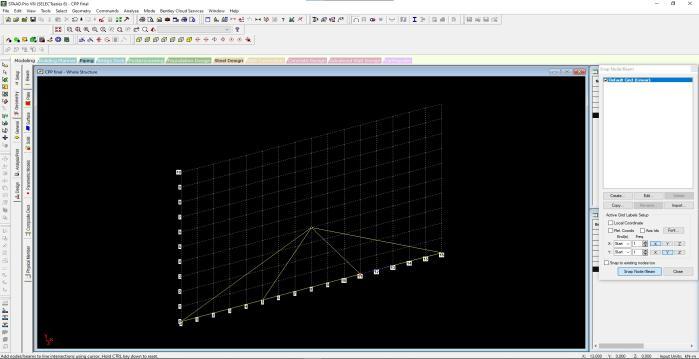

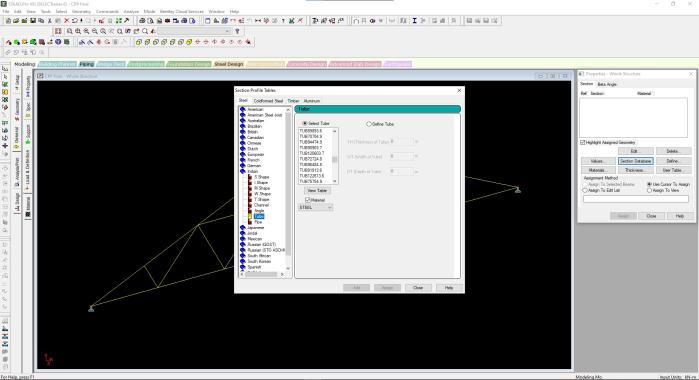

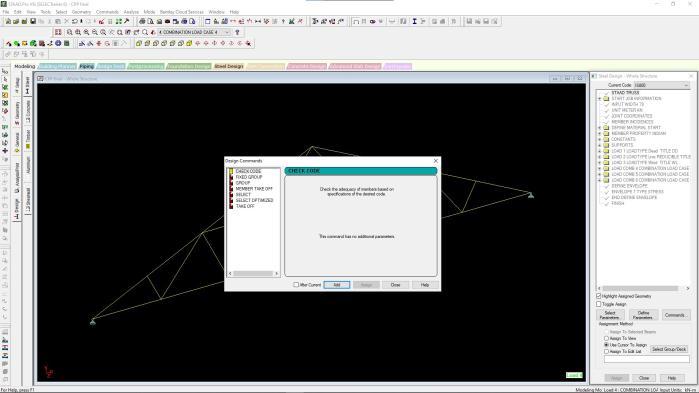

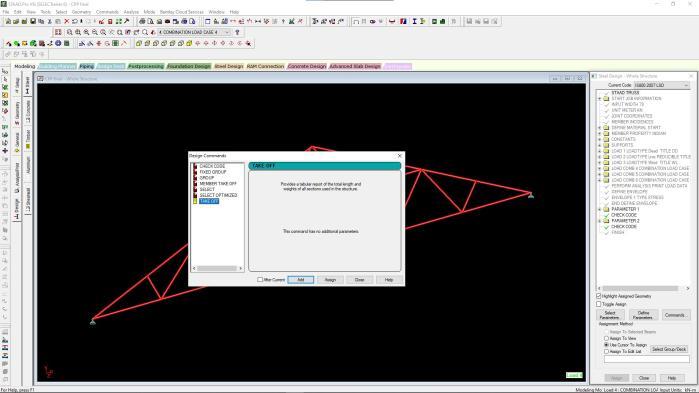

MethodologyusedindesignonSTAAD

1]Snapnode/beam

2]Supports

3]Properties

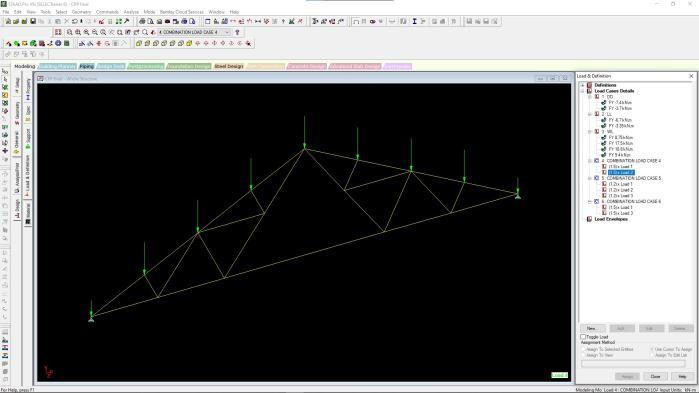

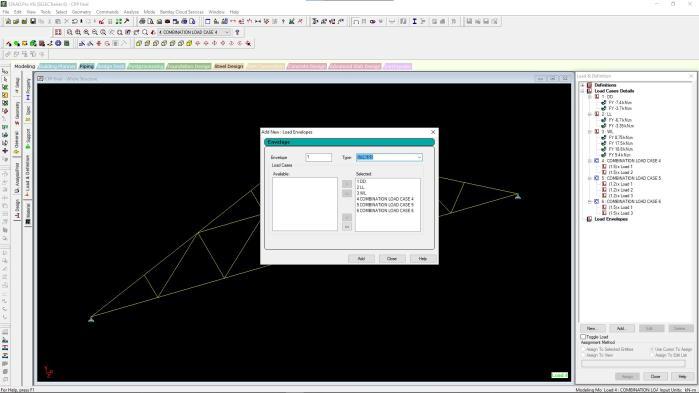

4]Loading[DL,LL,WL]

5]LoadEnvelope

6]SteelDesign ApplyIScodes

Thetrussissymmetricalandtherefore,thedeadloadand live reactions will be the same on both supports but the reactions due to wind load will be different on the two supports

Dead Load Reaction

Taking Moment at Lo 7.4 X 2 + 7.4 X 4 +7.4 X 6 + 7.4 X 8 + 7.4 X 10 + 7.4 X 12+ 7.4 X 14 + 3.7 X 16 = R15 X 16

Rl0 = 29.6KN

By Symmetry, Rl0 = Rl5= 29.6KN

Taking Moment at L0 6.7 X 2 + 6.7 X 4 +6.7 X 6 + 6.7 X 8 + 6.7 X 10 + 6.7 X 12+ 6.7 X 14 + 3.35 X 16 = R15 X 16

Rl0 = 29.6kn

By Symmetry, Rl0 = Rl5= 29.6 KN

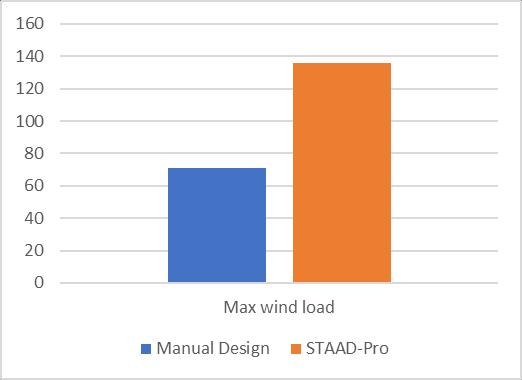

Force: 70.0 KN

Verticalcomponent = 70.0 cos 26.566o =62.60kN ↑

Horizontalcomponent = 70.0 sin 26.566o =31.30 KN ←

Force:75.2kN

Verticalcomponent = 75.2 cos 26.566o = 67.26 KN ↑

7]SteelTake off 8]Analysisofloads

9]Results

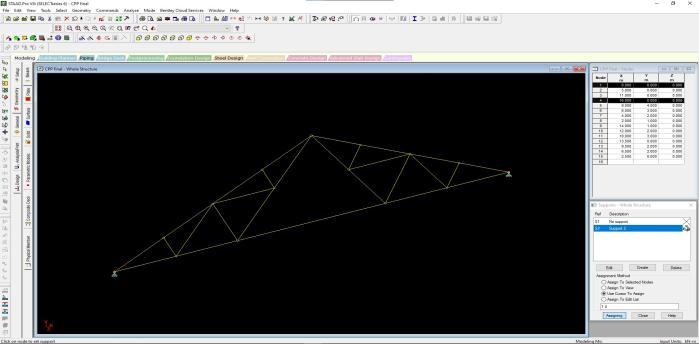

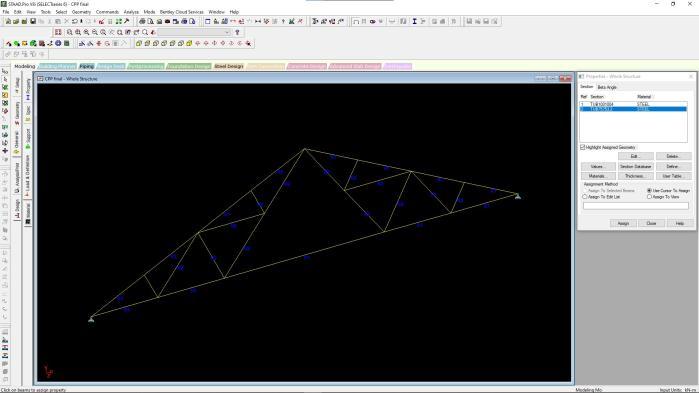

STAADDesign:

Use of figures has been done to explain the design process

Figno5AssigningNode/beam

FigNo.6AssigningSupports

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056 Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

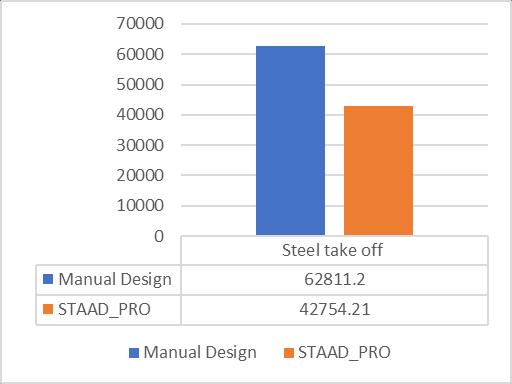

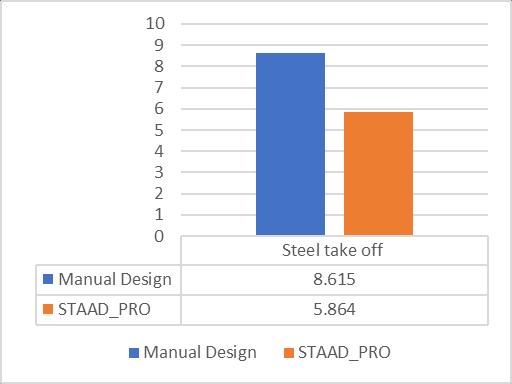

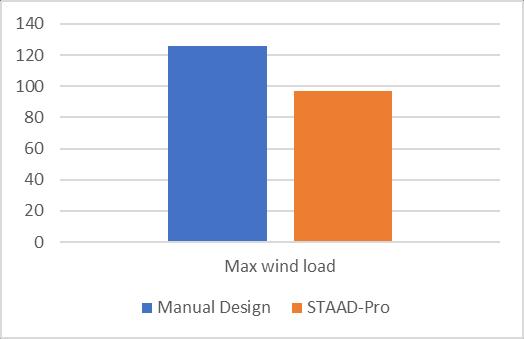

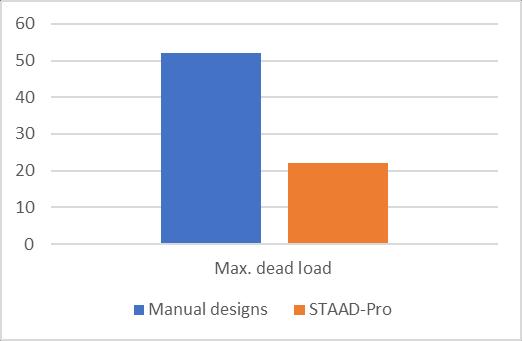

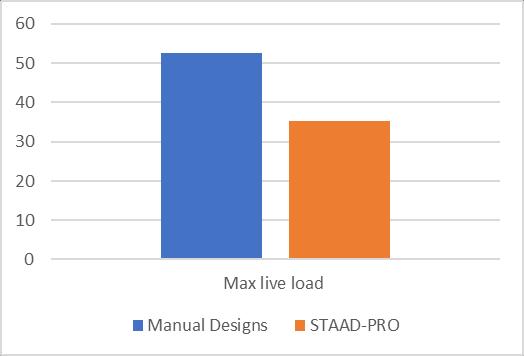

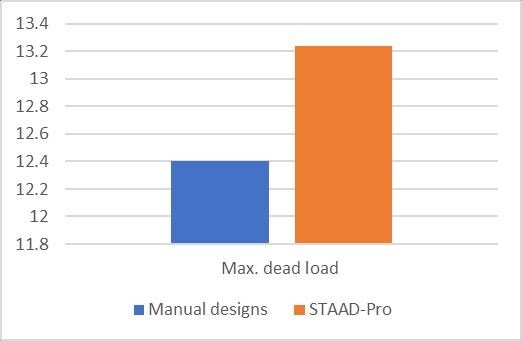

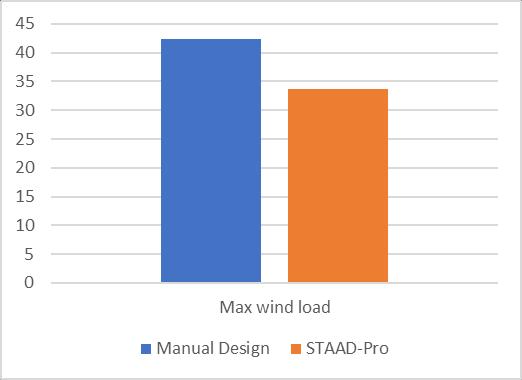

1. Fromtheaboveresultsweconcludethattheaxial forcesinMANUALDESIGNaremoreascomparedto STAAD PRO.

2. From the above results we conclude that the STAAD PROismoreeconomictouseaslessforces arerequired.

3. From the above results we conclude that STAAD PRO model is more economical and suitable for buildingaslessmaterialarerequiredascanresista greaternumberofforcesthanmanualdesign