International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072

1. G H Raisoni

***

Abstract:

In this paper, design and development of a wheel solar sprayer for spraying solution on vegetable crops and other crops is depicted. The major goal istoreducetheamountofwork required byfarmerstocarrythe backpack sprayerandtodevelop and build a solar operated wheel sprayer that can spray pesticides on vegetable crops. The developed wheel sprayer is analyzedanditsperformanceevaluatedanditistestedatGHRaisoniUniversitySaikheda.Thelandchosenhadlateriticsoil, and testing is done on an area. The wheel rotates when the operator pushes the handle of the produced wheel sprayer forward. The operator's push force is eventually transformed to pressure energy, and the fluid is sprayed. When the wheel sprayer drives forward, the pump reciprocates, causing the working fluid to flow through the boom assembly and out the nozzle. The theoretical field capacity, actual field capacity, and field efficiency of the created wheel sprayer are determined duringtheperformanceevaluation.Thesolaroperatedpesticidesprayerisfoundtobeportable,havealargetankcapacity,be costeffective,easytouse,andhaveashortsprayingtime.

Keywords:Sprayer,Wheel,Solar,3DCADmodel,Automation

India is claimed to be an agriculture based country, with 75 percent of the population directly or indirectly dependent on farming. Nonetheless, our farmers continue to cultivate in the same traditional methods they have for centuries . There is a need for growth in this sector, particularly in terms of fertilizer and pesticide spraying techniques, because spraying in the traditional manner necessitates more effort and time. The agricultural sector must be modernized in order to meet the food demands of a growing population and fast industrialization. On many farms, productivity falls as a result of delayed sowing, incorrect pesticide and fertilizer distribution, harvesting, and other factors. Insufficient electricity supply for farms and low levels of farm mechanization are two of the key factors for decreased production. Mechanization eliminates all of the issues that lead to low output (Miller et.al, 2004). It saves time and effort while ensuring a more even distribution of resources. It decreasestheamountofinputrequiredforabetterresponsewhilealsopreventinglossesandwaste.Asaresult,agricultural implementsareusedmoreefficientlyandatalowercost.Plantprotectioniscrucialforincreasingacrop'syield.Agricultural pestscausesignificantcropdamageandareamajorproductivitybottleneck.Asaresult,effectiveplantprotectionisrequired toreducelossesandensurethatallotherproductioninputsareutilizedtotheirfullpotential.Chemicalpestmanagementhas proventobequiteeffective, butitmustbehandledcarefully,usedinrationeddoses,andsprayedcorrectly.Astheonlyfully mechanizedfarmingoperation,specializedequipmentisrequiredforchemicalapplication.Pesticidesprayingisanimportant partoffarming.Thegoalofpesticideapplicationistokeepthepestundercontrol.Toavoideconomicagriculturalproduction loss, the pest population must be controlled to a bare minimum of biological activity. The objective of pesticide application besides keeping the pest population under check should also be to avoid pollution and damage to the non targets. These herbicides,pesticides,andfertilizersareappliedtoagriculturalcropswiththehelpofaspecialdeviceknownas"Sprayer".The sprayer provides optimum performance with minimum efforts. The invention of a sprayer, pesticides, fertilizers, bring revolutionintheagricultureorhorticulturesectoraswellasenablefarmerstoobtainmaximumagriculturaloutput.Machines previously developed for chemical application include the knapsack sprayers, tractor boom sprayers and ultra low volume sprayers (Liu, 2008). Spraying chemicals to protect crops against pests, illnesses, and weeds is done with a variety of equipmentrangingfromlargetractor mountedsprayerstohand operatedknapsacksprayers(Matthews,2008).

Because of its versatility, cost, and design, small scale farmers are highly interested in manually lever controlled knapsack sprayers.However,thissprayerhasseverallimitations,suchastheinabilitytosustainadequatepressure,whichcanresult in back strain. However, this equipment can lead to chemical misapplication and inefficient pest management, as well as

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072

pesticide loss due to dribbling or drift during application. Furthermore, due to their design and operation, the quality of a number of these sprayers, as well as their ability to precisely and efficiently administer pesticides, is of great significance Spray deposition is influenced by spray application technique. Spray dispersal varies greatly depending on sprayer design. Anothersortofsprayerisonethatrunsonexpensivefuel,suchasdieselorgasoline.Onedisadvantageofapetrolsprayer is the necessity to purchase fuel, which raises the sprayer's operating costs; it also causes greater vibrations and noise, which irritatesthefarmer.During theswingofknapsack sprayers'lanceoperation,Apesticidesprayerhastobeportableandwith an increased tank capacity as well as should result in cost reduction, labor and spraying time. In order to reduce these problems, there isa number of sprayers introduced in the market, but these devices do not meet the above problems or demands of the farmers. Today we use various spraying and seed sowing technologies involving use of electrical energy, chemical energy of fuels. This fact makes us know that how large content of energy is getting used at such places where mechanical energy can be used instead of direct energy sources. In markets battery operated and fuel operated pesticide sprayer are available. But this requires some external source of energy and increases cost of production. In conventional methods,thepesticidesprayerismountedonthebackwhichcausesbackpainandalsoimpropersprayingofpesticides.The heavytankcontainingpesticideiscarriedbythefarmerandrequiresalotofhumaneffortsforspraying(Ahmadetal.,2018). Inviewoftheaboveconstraints,amanuallyoperatedwheeldrivensprayerwasproposedwhichismainlydesignedtoreduce humaneffort.Itisfocusedonsprayingpesticidesatmaximumrateinminimumtimebyusingwheeloperatedmechanism.The targetofusersissmallerindustriesandsmallgardens.Usuallygardenerswillusethemanualknapsacksprayerthatisheavy andneedtocarryontheirbacktodosprayingsession.But,proposedwheelsprayerneedsonlyaforwardpushtooperateitin field. Besides this, with a single operator, the proposed wheel sprayer can apply spray solution on both sides of its forward motion.Sothatthetimetakenisless,moreareacanbecoveredandeffortislessthanthatofnormalknapsacksprayer.

Towardsthisobjectivethefollowingcontributionsofthispaperinclude

i. Todesignanddevelopasolaroperatedmulti purposewheelsprayersuitableforsprayingchemicalsandfertilizerson vegetablecrops.

ii. Tofabricateawheelsprayer.

iii. Toanalyzetheperformanceofthedevelopedwheelsprayer.

Inthischapter,previousresearchonwheeloperatedsprayersandothercharacteristicsisreviewed.Underthecorresponding areas, a quick review of work done pertinent to various facets of the current development is provided. Also specified is a reviewofstudiesrelatingtotheparametersofthechosencrop.

"Solar Sprayer An Agriculture Implement" is developed by Joshua et al. (2010). The notion and technology of using non conventionalenergyforallkindsofdevelopmentoperationsisbecomingincreasinglypopularthesedays.Agricultureisoneof the primary areas where there are several applications. Solar energy is used to dry agricultural products as well as for irrigation and pumping well water in rural settlements without electricity. Solar sprayers can be used to spray pesticides, fungicides,andfertilisers,amongotherthings,utilisingthistechnology.Thisstudyexplainshowa'PowerSprayer'thatisnow inuseandrunsonfossilfuelsmaybeturnedintosolarsprayersthatdonot. The"Multiplepowerprovidedfertilisersprayer" isdevelopedbyRaoetal.(2013).Theypresentedasystembasedonamodifiedmodelofatwo strokepetrolengine powered sprayer, whichreducesthe challengesassociated with existing powersprayers,suchasoperatingcosts, fuel changes, andso on. The technologyis put to the test and compared to theoretical chargingtimes. Intheagricultural sector, farmers typically utilise the traditional method of spraying crops with a backpack sprayer. This is time consuming and expensive, and human wearinessisahugeissue.

The methodsused in thedesign,development,andtestingofthe wheel sprayeris brieflyoutlined in thischapter. The key components of a wheel sprayer's design specifications and methods are presented. The created wheel sprayer's costanalysisisalsodetailedhere.

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072

3.1.1

ThefieldischosennearGHRaisoniUniversitySaikheda.Thefieldchosenhadlateriticsoilwithexcellentdrainageand sunlightasshowninFig.1.

A field with dimensions of 15000 x 10000 mm is chosen, and 10 rows of continuous furrows with 1000 mm spacing are ploughed.ChilliseedlingsfromtheUjwalavarietyaretransplantedatadistanceof500mmbetweenplants. Fig.2depictsthe fieldsetupfortestingthenewlybuiltwheelsprayer.

Fig.2Layoutofthechillifield

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072

Ujwalaisahigh yieldingbacterial resistantcultivar.Theplantis650mmtallonaverage.Tapeisusedtomeasurethefield measurements. Seeds are planted in the nursery, and seedlings are moved to the main field after one month. The chilli varietyUjwalaisgrownontheplayingfieldthischillicropisgrownatGHRaisoniUniversity

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072

The evolved wheel sprayer'shandleispushedforward bytheoperator.Thegearsprocketattachedonthewheel revolvesat thesamespeedasthewheel.Themotionofthedrivingsprocketistransferredtothedrivensprocketviathechaindrive.On either side of the same shaft, the driving sprocket and connecting rod are placed. With the help of the crank and connecting rod mechanism, the rotating motion of the shaft is turned into the reciprocating motion of the pump. The piston pump's reciprocating motion creates the required pressure for spraying the spray solution via the nozzles. Because the wheel, sprockets,andchainareallbicycle style,thepumponlysprayswhentheoperatormovesthecreatedwheelsprayerforward. The piston pump reciprocates as the wheel sprayer travels forward, causing the spray solution to discharge via the boom assemblyanddropletstobesprayedontheplantsurfacebythespraynozzles.

CAD,orcomputer aided designand drafting(CADD),is a designandtechnical documentationtechnologythatautomatesthe traditional drawing process. CAD software is used to increase designer productivity, improve design quality, and improve designefficiency.

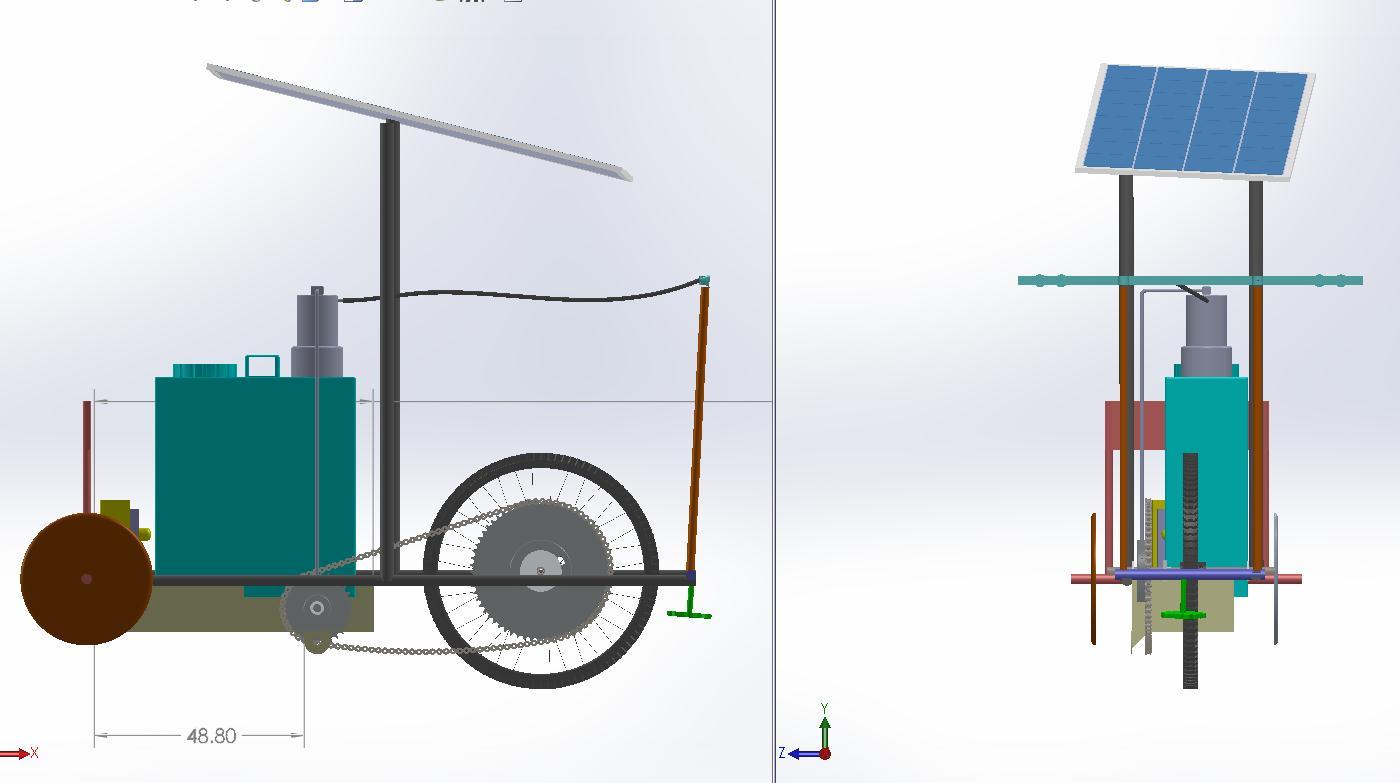

The drawing is created using the SolidWorks software as shown in Fig. 4 and manual sketches based on the design criteria. SolidWorksisusedtocreatethetopview,frontview,andsideviewofthedesignedwheeloperatedsprayer.

Fig.4.showsadrawingofawheelsprayerwithmeasurements.

WeightofTank=4.6kgx9.8=45.08N

Frameismadeofmildsteelbarsofthickness31mmwhichcanbeeasilywelded.Itcansupporttheloadandtaketheweightof thetankeasily.

Restoftheframeisdesignedconsideringitsstrength,stabilityandergonomics.

Lengthofframe=Centredistancebetweentwosprockets+wheelradius+framehandlelength+excesslength `=470+240+500+210

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

=1420mm

MaximumHeightofframe=500mmMaximumWidthofframe=580mm

Totalweightofframe=16.5kg=161.7N

Thereforetotalweightofthecompleteassembly=21kgTotalloadontire=161.7+45.08=206.78N≈207NTherefore,

Forcerequiredformotionofwheel=�×W

�=0.45forsandyloam

Totalforce(F)=0.45×207=93N

Totaltorquetobeappliedatthehandle=r×Fr heightofframe=500mm

Therefore,totaltorque=0.5×93 =46.5Nm

Distancebetweentwoplants=1.64feet=500mm.Noofplantscoveredbyonerotationofwheel=3 50×3=1500mm 150=2πr r= r=240mm

Diameterofwheel=480mm

Forthiswheeldiameter,awheelrimof420mmdiameterisconvenientlyfittedinit.Therpmofthewheel(N)ismeasuredas 27rpm. Weknow, =0.679ms 1 or2.44kmh 1Weknow, Therefore, = = =30mm

Aspectratio(%)= = =75%

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3393

International Research Journal of Engineering and Technology (IRJET) e ISSN:2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN:2395 0072

Thewheeloperatedsprayer,whichconsistsofapistonwithonlyonesideengagingthefluidbeingdisplaced,worksbestwith asingleactingreciprocatingpump.

Requireddischarge;

forsingleactingreciprocatingpump

Speedofpiston=21rpmD=diameterofpiston=60mmL=Lengthofstroke=50mm

Where,A=Areaofpiston= =2826mm2

Thesolaroperatedmultipurposewheelsprayeriscreatedwiththepurposeofsprayingsolutionsonvegetablecrops. A primary frame, wheel, chain, sprayer, and sprockets, as well as a shaft, bearing, sprayer tank, piston pump, solar panel, battery, motor, boom, and three nozzles, make up the designed wheel sprayer. Two sprockets are employed, one driven (16 teeth, 70 mm diameter) attached to the shaft and the other a larger diameter driving sprocket (32 teeth, 140 mm diameter) connected to the wheel. A high pressure power spray hose with a working pressure of 150 200 kgf cm 2 is installed to transportliquidsprays fromthetank tothesuction endoftheboom. Withinthemechanismof thiswheel sprayer,thereare two sorts of motion transmission. The chain drive transmits rotational motion between two sprockets. The connecting rod converts the rotary motion of the crank derived from the chain drive into reciprocating motion of the piston. Spray fluid is dischargedonchilliplantswhenthesprayerismovedforward.Thenozzledischargerateofthewheelsprayeriscalculatedas 0.907Lmin 1 whendoingperformanceevaluationon9rowsofthefield.Thetheoreticalfieldcapacityis0.244hah 1,butthe actualfieldcapacityis0.206hah 1.Thefieldefficiencyofawheeledsprayerisdiscoveredtobe84.5percent.Thepurposeof the rate analysis and cost calculation is to assess the economic feasibility of the produced wheel sprayer. The overall cost of thewheelsprayerfabricationisestimatedtobeRs.5100/ Toincreasefieldcapacity,thenumberofnozzlesintheboomcan beraisedfromthreetosix.Slidingslotswithnutandboltarrangementcanbeusedtomodifytheheightofthesprayboomin relationtothecropheight.

M.A.Ahmad,S.H.Borkar,andS.D.Ghatole.2018.ReviewtheMulti NozzlePesticideSprayerPumpthatismanuallyoperated. 7(3):223 227inInternationalJournalofInnovativeResearch,Science,andTechnology.

A.Bhashkar,S.Tiwari,andP.Vajpayee,2020 Designandmanufacturingofamulti nozzlewheelspraypump,International JournalofEngineeringScienceandResearchTechnology.

Joshua,R.,Vasu,V.,andVincent,P.2010. Int. J. Sustain. Agric. 2(1):16 19.SolarSprayer AnAgricultureImplement.

G.Q. Liu, G. Zhang, and J. Li. 2008. The Pearl River estuary and the nearby South China Sea have a unique source and distributionofairorgano chlorinepesticides.InternationalJournalofEnvironmentalScience,29(12),3320 3325.

G.A.Matthews,1992.PesticideApplicationMethods, New York: Longman Scientific and Technical, 2nd edition,405p

M.A.Miller,B.L.Steward,andM.L.Westphalen.2004.Theimpactofmultimodefour wheelsteeringontheperformanceof sprayermachines.47(2):385 395,AmericanSocietyofAgriculturalEngineer.