International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Abstract The purpose of this research was to see how Non Woven Coir (NWC)/coir fiber combined with black cotton soil in sub grade affected the results. Black cotton soil combined with coir fiber in varied percentages of 0.15 percent to 0.75 percent is used for this purpose. In another example, soil was mixed with NWC ranging from 0.15 to 0.75 percent and sand ranging from 3 to 15%, and the qualities of the soil were assessed. The study's findings showed that NWC may be built on soft ground, has more stability when restricted than other soil fills, has little long term settling, and can also be utilized as a stabilizing agent. When NWC and sand were added to black soil, the CBR increased almost linearly.

Expansive soils are particularly troublesome due to their proclivityforsubstantialvolumefluctuationsasaresultof changes in moisture content. The soil is regarded as undesirable for construction material due to its great flexibility,severeswelling,shrinkage,andlowstrengthwhen wet(Chen1988;DifandBluemel1991;Zemenuetal.2009; Terzaghietal.2010;MokhtariandDehghani2012;Meshram etal.2013).Duetoalackofappropriatesoil,largefinancial investments are necessary for the building of highways, canals,andembankments.ThesoilofBlackCotton(BC)is veryvast.Soilstabilisationcanbeaccomplishedinavariety ofways. Theyincludethecohesivenon swellingsoillayer (Kattietal.1983),thesandcushionmethod(Satyanarayana 1969), chemical stabilisation (Estabragh et al. 2014), bio enzymes (Lopez Lara et al. 1999), the deep soil mixing method (Madhyannapu et al. 2009), and the mixing of variousadditivessuchaslime,cement,flyash,stonedust, and so on (Cokca 2001; Mishra et al. 2008, Mathur et al. 2012;PhanikumarandSharma2004;Sridharanetal.2006; Agarwaletal.2016Emeetal.2016).Becauseofthemixing problem,thedepthneedstobestabilised,andtrustworthy resultsarenotproduced,thepresentmethodshavelimited application.Asaresult,therehasyettobeproducedasingle, adaptablesolution.

Non Woven Coir (NWC)/coir fibre is used to solve this problem,sinceitprovidesthebulkofthemassandimproves the soil's strength. It has been discovered to be the finest optionforsubgradeorsubbaseinpavement.Coirfibreisa natural, biodegradable, fast binding, low cost, environmentallybeneficial,andnon pollutingsubstancethat can be practically replaced by any current polymeric alternative(Meshrametal.2013).Theaimofpresentstudy is to improve CBR of black cotton soil by using NWC and sand.

Naturalgeotextileshavenotgainedpopularity,despitethe fact that India generates enormous amounts of coir fibre, which may be used for geotechnical and transportation engineeringpurposes.Theabilityofcoirgeotextilestofulfil variousrolesinordertoimprovetheengineeringbehaviour ofblackcottonsoilisdemonstrated(Meshrametal.2014). To boost the shearand tensile strength ofsoil, ithas been combined with randomly scattered fibres (Maher and Ho 1994; Ziegler et al. 1998). Kumar and Devi (2011) investigatedtheuseofneedlepunchednonwovengeotextiles constructed of coir and jute fibre, as well as the CBR reinforcement ratio value of the geotextiles sub grade achieved by CBR testing. The soil's CBR has improved becausetothenonwovengeotextiles.

KumarandRajkumar(2012)investigatedtheperformanceof woven and nonwoven geotextiles, determining the reinforcement ratio based on the CBR load penetration relationship of soft subgrade gravel and soft subgrade geotextiles gravel, respectively, for woven and nonwoven geotextiles. The incorporation of woven and nonwoven geotextilesimprovestheperformanceofthereinforcement ratioestablishedusingtheCBRstrengthtest.

Shankar and Chandrasekhar (2012) investigated the most generally used additives for stabilising lithomarge clay utilisingsandandcoir,suchassand,cement,pondash,andso on.Thegeotechnicalqualitiesofclaywerefoundtoimprove withvariedamountsofsandandcoiradditions.

The current work focuses on increasing the CBR of black cottonsoil,whichisemployedasasubgradematerial.The first stage involved determining the soil index characteristics, compaction, and CBR values. The soil is mixedwithNWCinvariouspercentages(0.15percent,0.30 percent,0.45percent,0.60percent)inthesecondstep,and thencompactionandCBRvaluesarecalculated.Inthethird stage, OMC MDD and CBR values were evaluated in soil mixed with NWC and sand in which NWC was mixed in different percentages viz. 0.15 percent, 0.30 percent, 0.45 percent,0.60percent,and0.75percentandsandwasmixed indifferentpercentagesviz.3percent,6percent,10percent, 12percent,and15percent.TheNWCwasspreadatrandom withBCsoilandsand.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3256

Mohd Shehzad1 , Aman Bathla 2and Sanjeev Singh3 1,2,3 Departments of Civil Engineering, Geeta Engineering College, Naultha, Panipat Affiliated to Kurukshetra University, Kurukshetra , IndiaInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Thematerialsusedintheinvestigationconsistof (a) Blackcottonsoil, (b) Sand, (c) Non wovencoir.

The Atterberg limit test (IS: 2720 (Part 5) 1985), Specific gravitytest(IS:2720(Part3) 1980),CBR(IS:2720(Part16) 1987), Free swell test (IS: 2720 (PART XL) 1977), and Standardcompactiontest(IS:2720(Part7) 1980)wereused toassessthephysicalcharacteristicsoftheclay.Thesoilis classed as CH (clay of high plasticity and compressibility) accordingto(IS:1498 1970).

The test results were examined, and Table 1 shows a summaryofthephysicalparametersofthesoil.Aexample paragraphfromtheIrjetTemplate.Evenifabbreviationsand acronymshavebeendefinedintheabstract,definethemthe firsttimetheyareusedinthetext.IEEE,SI,MKS,CGS,sc,dc, andrmsareexamplesofabbreviationsthatdonotneedtobe specified.Abbreviationsshouldonlybeusedinthetitleand headingsiftheyareunavoidable.

LiquidLimit(%) 55 PlasticLimit(%) 37 PlasticityIndex(%) 18 SpecificGravity 2.72

OptimumMoistureContent(%) 27

MaximumDryUnitWeight(kN/m3) 1.40 SoakedCBR(%) 1.80 FreeSwellIndex(%) 33

Sieveanalysis,specificgravity(IS2720 Part3(Sections1): 1980),andminimumandmaximumdryunitweighttest(IS: 2720 (Part 14) 1983) were performed on the sand in the laboratory.

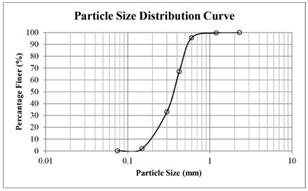

Figure 1 depicts the sand particle size distribution curve, whileTable2listsothersignificantparameters.Accordingto theclassificationsystem,thesandisclassifiedasSP(poorly graded sand) (IS: 1498 1970). Particle Size Distribution Curvewasusedtocategorisethesoil(IS:1498 1970).D10, D30,andD60values(i.e.particlesizeequivalentto10,30, and60percentfinercorrespondingly)weredetermined.

Chart 1:ParticleSizeDistributionCurveforSand

Table

Particlesizecorrespondingto10%finer,D10 (mm) 0.19 Particlesizecorrespondingto30%finer,D30 (mm) 0.29 Particlesizecorrespondingto60%finer,D60 (mm) 0.40 CoefficientofUniformity,CU 2.10 CoefficientofCurvature,CC 1.10 SpecificGravity,G 2.67

MaximumDensity,γmax(kN/m3) 16.46 MinimumDensity,γmin(kN/m3) 14.16

PhysicalpropertiesofNWCareshowninTable3.

Table 3 PhysicalPropertiesofNWC

PROPERTY VALUE

Length(mm) 15 280 Density(g/cc) 1.15 l.4 Tenacity(g/tex) 10.0

Breakingelongation(%) 30.0 Diameter(mm) 0.1 1.5

Rigiditymodulus(dynes/cm2) 1.8924 Swellinginwater(diameter) (%) 5.0 Moistureat65%RH(%) 10.5 Specificgravity 1.15 Young’smodulus(GN/m2) 4.5

To complete the intended investigation on CBR of black cottonsoil,twosetsofexperimentswereconducted.NWC wasrandomlymixedwithBCsoilinonetestseries,whileBC soilwascombinedwithNWCandsandinanother.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3257

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

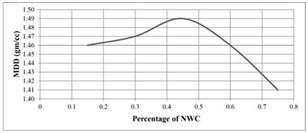

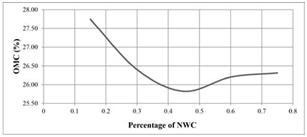

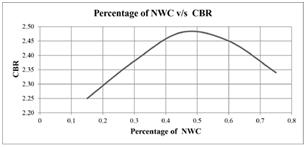

0.15percent,0.30percent,0.45percent,0.60percent,and 0.75 percent NWC were mixed with soil in various percentages.ForthevaryingpercentagesofNWCindicated inFig.2toFig.4,thesamplesweretestedforOMC,MDD,and CBR.

(b) Tests on Soil Mixed with NWC and Sand

NWC was incorporated in various percentages in BC soil, including 0.15 percent, 0.30 percent, 0.45 percent, 0.60 percent,and0.75percent.SandnwasmixedwithBCsoilin various amounts, such as 3 percent, 6 percent, 10%, 12 percent,and15%,asindicatedinTables4to8.

ForvariedpercentagesofNWC,thesamplesweretestedfor OMC,MDD,andCBR.

Table 4 CBRValueforBCSoilMixedwith0.15%NWCand VaryingPercentageofSand

Soil Mixed With NWC and Sand OMC (%) MDD (gm/ cc) Soaked CBR (%)

Soil,0.15%coirand3% sand 22.10 1.410 2.23

Soil,0.15%coirand6% sand 20.59 1.438 3.12

Soil,0.15%coirand10% sand 19.77 1.557 4.31

Chart 2:VariationofOMCwithPercentageofNWC (mixedinBCsoil)

Soil,0.15%coirand12% sand 18.54 1.579 4.98

Soil,0.15%coirand15% sand 16.87 1.610 5.24

Table 5 CBRValueforBCSoilMixedwith0.30%NWCand VaryingPercentageofSand

Soil Mixed with NWC and Sand OMC (%) MDD (gm/ cc) Soaked CBR (%)

Soil,0.30%coirand3% sand 23.30 1.520 2.35

Soil,0.30%coirand6% sand 22.44 1.535 3.20

Chart 3:VariationofMDDwithPercentageNWC(mixed inBCsoil)

Soil,0.30%coirand10% sand 20.87 1.555 4.49

Soil,0.30%coirand12% sand 19.34 1.580 5.12

Soil,0.30%coirand15% sand 17.73 1.610 6.40

Table 6 CBRValueforBCSoilMixedwith0.45%NWCand VaryingPercentageofSand

Soil Mixed with NWC and Sand OMC (%) MDD (gm/ cc) Soaked CBR (%)

Soil,0.45%coirand3% sand 24.40 1.620 3.35

Soil,0.45%coirand6% sand 23.22 1.635 4.20

Soil,0.45%coirand10% sand 21.79 1.664 5.49

Chart -4:VariationofCBRwithPercentageNWC(mixedin BCsoil)

Soil,0.45%coirand12% sand 20.28 1.680 6.12

Soil,0.45%coirand15% sand 18.30 1.710 7.40

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3258

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Table 7 CBRValueforBCSoilMixedwith0.60%NWCand VaryingPercentageofSand

Soil Mixed with NWC and Sand OMC (%) MDD(gm/ cc) Soaked CBR (%)

Soil,0.60%coirand3% sand 23.21 1.540 2.25

Soil,0.60%coirand6% sand 22.41 1.600 3.10

Soil,0.60%coirand10% sand 20.77 1.670 4.39

Soil,0.60%coirand12% sand 19.32 1.690 5.02

Soil,0.60%coirand15% sand 18.53 1.720 6.31

Table 8 CBRValueforBCSoilMixedwith0.75%NWCand VaryingPercentageofSand

Soil Mixed with NWC and Sand OMC (%) MDD(gm/ cc) Soaked CBR (%)

Soil,0.75%coirand3% sand 23.27 1.520 2.28

Soil,0.75%coirand6% sand 22.40 1.532 2.93

Soil,0.75%coirand10% sand 20.83 1.551 4.44

Soil,0.75%coirand12% sand 19.37 1.579 5.07

Soil,0.75%coirand15% sand 18.60 1.597 6.34

Onthebasisofresults,theeffectofBCsoilmixedwithNWC andsandonOMC,MDDandCBRisgivenbelow:

It was discovered that when coir was combined with soil, OMCinitiallyreducedandthengrewbeyondacertainpoint. Becausecoirwassoakingwater,MDDroseatfirstandthen droppedafteraspecificthreshold.Becausemorevoidswere produced, OMC dropped and MDD rose as the sand % increased.

When BC soil was combined with 0.45 percent NWC, the maximumCBRvaluewasdiscoveredtobe2.48percent,and afterthat,theCBRvaluefellbecausecoirbreaksdownand cannotbearloadbeyondacertainpoint.Becausesandtook more weight than dirt, the CBR value increased as the proportionofsandincreased.

Basedonresults,themultiplelinearregressionmodelswere developedforpredictionofCBR:

(a) ForNWCmixedwithBCsoil CBR= 1.89 0.018OMC+3.16MDD+35.97C (R2 =98%)

(b) ForNWCMixedwithBCsoilandsand CBR= 12.03+0.42OMC+2.17MDD 0.76C+ 0.48S (R2 =94%)

Where,

CBR=CaliforniaBearingRatioin%,OMC = Optimum Moisture Content in %, MDD = MaximumDryDensityingm/cc,C=NonWovenCoircontent in%,S=Sandcontentin%.

1. The addition of nonwoven coir to BC soil improved the soil's characteristics. The optimal nonwoven coir content wasfoundtobe0.45%.Inthis example,CBR increases by 67.8%whencomparedtovirginsoilCBR.

2.SoilqualitiesincreasewiththeadditionofsandtoBCsoil andnon wovencoirmixes.

3.Forvaryingpercentagesofsandandnonwovencoir,the CBRvaluesteadilyincreases.

[1] Agarwal, A., Muley, P., and Jain, P.K. (2016). “An ExperimentalandAnalyticalStudyonCaliforniaBearing Ratio of Lime Stabilized Black Cotton Soil.” Electronic JournalofGeotechnicalEngineering,21(20),6583 6599.

[2] Chen, F. H. (1988). “Foundations on Expansive Soils.” ElsevierScientificPublishingCo.,Amsterdam.

[3] Cokca, E. (2001). “Use of Class C fly Ashes for the Stabilization of an Expansive Soil.” Journal of Geotechnical and Geoenvironmental Engineering, 127 (7),568 573.

[4] Dif,A.E.,Bluemel,W.F.(1991).“ExpansiveSoilsUnder CyclicDryingandWetting.”Geotech.TestingJournal,14 (1),96 102.

[5] Eme,D.B.,Nwofor,T.C,andSule,S.(2016).“Correlation Between the California Bearing Ratio (CBR) and Unconfined Compressive Strength (UCS) of Stabilized Sand Cement of the Niger Delta.” SSRG International JournalofCivilEngineering,3(3),7 13.

[6] Estabragh, A. R., Rafatjo, H., and Javadi, A.A. (2014). “Treatment of an Expansive Soil by Mechanical and ChemicalTechniques.”GeosyntheticsInternational,21 (3),233 243.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3259

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

[7] Indian Standards. (1970). “Classification and Identification of Soils for General Engineering Purposes.” IS 1498, First Revision, Reaffirmed 2007, NewDelhi,India.

[8] IndianStandards. 1977“IndianStandardMethodsof Test for Soils: Determination of Free Swell Index of Soils.”IS2720(PartXL),NewDelhi,India.

[9] Indian Standards. (1980). “Indian Standard Code of PracticeforMethodsofTestforSoils:Determinationof Specific Gravity of Fine Grained Soils.” IS 2720 (Part 3/section1),NewDelhi,India.

[10] Indian Standards. (1980). “Indian Standard Code of PracticeforMethodsofTestforSoils:Determinationof Water Content Dry Density Relation Using Light Compaction.”IS2720(Part7),NewDelhi,India.

[11] Indian Standards. (1983). “Indian Standard Code of PracticeforDeterminationofDensityIndexofCohesion LessSoils.”IS2720(Part14),NewDelhi,India.

[12] Indian Standards. (1985). “Indian Standard Code of PracticeforMethodsofTestforSoils:Determinationof Liquid Limit and Plastic Limit.” IS 2720 (Part 5), New Delhi,India.

[13] Indian Standard (1987). “Methods of Test for Soil Laboratory Determination of CBR”. IS2720 (Part 16), SecondRevision,Reaffirmed2002,NewDelhi,India.

[14] Katti,R.K.,Bhangle,E.S.andMoza,K.K.(1983).Lateral Pressure of Expansive Soilwith and without Cohesive Non SwellingSoilLayerApplicationstoEarthPressures ofCrossDrainageStructuresofCanalsandKeyWallsof Dams (Studies of K0 Condition). Central Board of IrrigationandPower.TechnicalReport32,NewDelhi, India.

[15] Kumar, P. S., and Devi, S. P. (2011) “Effect of Needle Punched Nonwoven Coir and Jute Geotextiles on CBR Strength of Soft Sub Grade”. ARPN Journal of EngineeringandAppliedSciences,6(6),114 116.

[16] Kumar, P. S., and Rajkumar, R. (2012). “Effect of GeotextilesonCBRStrengthofUnpavedRoadwithSoft SubGrade”.ElectronicJournalofGeotechnicalEngg.,17, 1355 1363.

[17] Lopez Lara,T.,Zepeta Garrido,J.A.,andCastario,V.M. (1999). “A Comparative Study of the Effectiveness of DifferentAdditivesontheExpansionBehaviorofClays.” Electronic Journal of Geotechnical Engineering, 4(5), paper9904.

[18] Madhyannapu,R.S.,Puppala,A.J.,Nazarian,S.,andYuan, D.(2009).“QualityAssessmentandQualityControl of DeepSoilMixingConstructionforStabilizingExpansive

Subsoils.”JournalofGeotechnicalandGeoenvironmental Engineering,136(1),119 128.

[19] Maher, M. H., and Ho, Y.C. (1994). “Mechanical PropertiesofKaolinite/FiberSoilComposite.”Journalof GeotechnicalEngineering,120(8),1381 1393.

[20] Mathur, S., Swami, R.K., and Arun, U. (2012), “Lime/Cement Stabilisation for Soil and Granular Materials.”NationalWorkshoponNon Conventional Material/Technologies,NRRDA,NewDelhi,56 74.

[21] Meshram, K., Mittal, S.K., Jain, P.K., and Agarwal,P.K. (2013). “Application of Coir Geotextile in Rural Roads ConstructiononBCSoilSubgrade”.InternationalJournal of Engineering and Innovative Technology, 3(4), 264 268.

[22] Meshram, K., Mittal, S.K., Jain, P.K., and Agarwal,P.K. (2013). “Application of Coir Geotextile for Road Construction:SomeIssues”.Oriental

[23] Meshram, K., Mittal, S.K., Jain, P.K., and Agarwal,P.K. (2014).“CBRImprovementofExpansiveBlackCotton Soil Using Coir Geotextile”. NICMAR Journal of ConstructionManagement,XXIX(III),45 50.

[24] Mishra,A.K.,Dhawan,S.,andRao,S.M.(2008).“Analysis of Swelling and Shrinkage Behavior of Compacted Clays.”Geotech.Geol.Eng.,26,289 298.

[25] Mokhtari,M.,andDehghani, M.(2012).“Swell Shrink Behavior of Expansive Soils, Damage and Control.” Electronic Journal of Geotechnical Engineering, 17, 2673 2682.

[26] Phanikumar, B.R., and Sharma, R. S. (2004). “Effect of FlyashonEngineeringPropertiesofExpansiveSoil.”J.of GeotechnicalandGeo environmentalEngineering,130 (7),764 767.

[27] Ravi Shankar, A.U., and Chandrasekhar, A. (2012). “Experimental Investigation on Lithomarge Clay StabilizedwithSandandCoir.”IndianHighways,40(2), 21 31.

[28] Satyanarayana,B.(1969).“BehaviourofExpansiveSoil Treated or Cushioned with Sand.” Proc., 2nd National ConferenceonExpansiveSoils,Texas,308 316.

[29] Sridharan,A.,Soosan,T.G.,Jose,B.T.,andAbraham,B.M. (2006). “Shear Strength Studies on Soil Quarry Dust Mixtures.”GeotechnicalandGeologicalEngineering,24, 1163 1179.

[30] Terzaghi, K., Peck, R. B., and Mesri, G. (2010). “Soil MechanicsinEngineeringPractice.”JohnWiley&Sons, Inc.,U.K.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3260

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

[31] Zemenu,G.,Martine,A.,andRoger,C.(2009).“Analysis of the Behaviour of a Natural Expansive Soil Under CyclicDryingandWetting.”Bull.Eng.Geol.Environ.,68 (3),421 436.

[32] Ziegler, S., Leshchinsky, D., Ling, H. I., and Perry, E.B. (1998). “Effect of Short Polymeric Fibers on Crack Development in Clays.” Soils and Foundations, 38 (1), 247 253.

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3261