International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Abstract - Pervious concrete is a novel waytopavingthatis gaining popularity as a result of its environmental benefits. In addition to various other advantages, pervious concrete pavement allows storm water to permeate through the pavement, reducing or eliminating the need for additional control structures. As a result, it is seen as a greener alternative to typical asphalt and concrete pavementsystems. The purpose of this study is to provide an overview of pervious concrete and its use as a pavement.

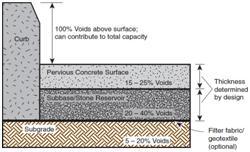

xPerviousconcretehasanopencellstructurethatenables waterandairtomovethroughit[1].Itismadeoutofgravel or stone, cement, water, and little or no sand. Pervious concreteisatypeofpavementthatisextensivelyutilisedas an ecologically friendly alternative to regular asphalt and concrete pavement. Figure 1 shows a typical portion of pervious concrete paving with open cell structures that enablestormwatertopassthroughthepavementandinto theunderlyingsoils.Asaresult,perviousconcretefunctions as a drainage system and aids in the protection of the pavement's surface and environment. When compared to typical asphalt and concrete pavements, it also offers significant structural, economic, and environmental advantages[2].Itcreatesadriersurfaceduringarainevent, makingthesesystemssaferfordrivers.Italsoproducesless noise than traditional systems, and it could eliminate the need for other types of stormwater treatment, such as retention ponds, which can be both expensive and impracticalinmanysituations.

Thefirsttimeporousconcretewasusedwasin1852inthe United Kingdom, when two dwellings were built out of gravelandconcrete.Porousconcretehascontinuedtogain favour in Europe as cast in place load bearing walls of multistoryhomesandprefabricatedpanels,owingtothelow cost of the cement employed. Pervious concrete became popular in the United States in the 1970s because of its permeabilityproperties[3].

Thousands of pervious concrete projects have been constructedintheUnitedStates,Europe,andJapanduring the last thirty years. Parking lots, sidewalks, pathways, tennis courts, patios, slope stabilisation, swimming pool decks,greenhousefloors,zooareas,shoulders,drains,nose barriers,frictioncourseforhighwaypavements,permeable

basedunderanormalconcretepavement,andlowvolume roads are some of the common applications for pervious concrete[4].Perviousconcreteisalsofrequentlyutilisedas a surface course for roadway applications in Europe and Japan, where porous concrete is a layer over the impermeablelayertoincreaseskidresistanceandminimise traffic noise. Because it retains rainfall and recharges the soil,itissuggestedforenvironmentalreasons[5].

Except for the proportions of materials, the fundamental constituentsofperviouscementconcretemixarerelatively similar to those of conventional cement concrete mix. Pervious concrete is made up of cementitious materials, water,coarseaggregate,andsometimesadmixtures,justlike conventional concrete, but it includes little or no fine aggregate.Togenerateasystemofhighporosityandlinked voids,asuitableamountofcementpasteisutilisedtocoat andbindtheaggregateparticlestogether.Theemptycontent rangesfrom15%to25%,withtheaveragebeingabout20%. [1]

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3251

Nitin Pal1 , Aman Bathla 2and Sanjeev Singh3 1,2,3 Departments of Civil Engineering, Geeta Engineering College, Naultha, Panipat Affiliated to Kurukshetra University, Kurukshetra , IndiaInternational Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Aggregates:Particles:Forperviousconcrete,theaggregate gradation is commonly made up of single sized coarse aggregatesorabinarycombinationofcoarseaggregates.The aggregatesizerangesfrom19to9.5mm[1].Theadditionof tiny amounts of fine aggregates (less than 10% of total aggregateweight)cangraduallyreducevoidcontentwhile increasingstrength.Perviousconcretehasbeenmadewith rounded and crushed particles, both standard and lightweight. Physical parameters of the aggregate, such as sizeandshape,haveasubstantialimpactonthepropertiesof pervious concrete [6, 7]. The size, shape, and gradation of aggregates havean impact on the compressive strengthof perviousconcrete.Uniformlygradedaggregatehasahigher compressive strengthand void ratio,and isalso better for fieldinstallationssinceitismoredifficulttoover compact [8].Accordingtocertainresearch,dolomiticaggregatesgive better compressive strength at higher porosity levels than equivalentlimestone/slagaggregatecombinations [9].For manyyears,recycledaggregatesfromdemolishedbuildings havebeenemployedinmanyregionsoftheworld[10].This methodisalsoenvironmentallybeneficial.

Cementitious materials:Portlandcements,mixedcements, slag cement, natural pozzolans, and fly ash are among the cementitious materials that can be employed. The total cementitious material content in the mixture is critical for compressive strength and void structure formation. Inadequate cementitious content might result in less aggregatepastecoatingandlowercompressivestrength.The idealcementitiousmaterialcontentvariesbyaggregatesize and gradation, but it usually falls between 260 and 415 kg/m3

Mix proportioning: The goal of pervious concrete mix proportioningistoachieveabalanceofvoids,strength,paste content, and workability. To determine optimal mix proportions using locally accessible components, experimentalbatchesmustbecreated[1].Whenitcomesto achievingthenecessaryporosityandstrength,thewater to cementitious material ratio (w/c) is crucial. A high w/c lowersthepaste'sadherencetotheaggregate,allowingitto flowandfillthegaps,asseeninFig.2.Aloww/cprevents proper mixing and uniform distribution of cement paste, lowering the concrete's final strength and durability. To provide adequate cement coating for the aggregates, the water to cementratioisalteredbetween0.28 0.40,whichis lowerthanintraditionalconcretemixes,wherethewater to cementratioistypicallybetween0.38and0.52[3].According tocertainresearch,a0.45w/cratioisexcellentforno fines concrete[11].

Dependingontheultimateuse,theaggregate to cementratio mightrangefrom4:1toashighas6:1.Theaggregate cement ratio utilised in construction applications typically varies from6:1to10:1,withstrengthsrangingfrom5MPato15 MPa.Concretestrengthisparticularlyimportantinpavement applications,andaggregate cementmixturesaslowas4:1 are employed to guarantee enough bonding between the

aggregateandcementtosustainthegreaterstresses.When comparedtootheraggregate/cementratiosof8:1and10:1,a 6:1aggregate/cementratiohadthemaximumcompressive strength,whichmightbeadvantageousforapavementthat required lowcompressivestrength butgood permeability. The smaller the coarse aggregate size, the higher the compressivestrengthand,atthesametime,thehigherthe permeabilityrate[7]. :

Khattabetal[12]lookedintotheeffectofmixproportions onthecharacteristicsofporousconcrete.Atotaloftwelve differentcombinationswerecastandtested.Sandwasused toreplace10%ofthecoarseaggregate.Slump,density,and compaction index tests were performed on new concrete Compressive strength, splitting tensile strength, flexure strength, permeability, and flow rate were all tested on hardened concrete. The inclusion of sand, as well as the usage of graded coarse aggregates and increased cement paste volume, all contributed positively to compressive, flexural,andcrackingtensilestrengths.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3252

Figure 2. Samplesofperviousconcretewithdifferent watercontents:(a)toolittlewater,(b)properamountof water,and(c)toomuchwater[3]International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Admixtures: Chemical admixtures can be added to a mixture to gain or improve certain qualities. A viscosity alteringadmixture,anairentrainingagent,andahigh range waterreducerwereutilisedasadditives.Theseadmixtures wereemployedtoenhancethebindingbetweenthecement and the coarse aggregate as well as the workability of the cement.Superplasticizersinperviousconcretecangreatly improve its strength. The low water content in porous concrete pavementmixturescausesthemtodryfast,thus retardersarealsoutilised.

Fly Ash: Fly ash can be used to replace up to 20% of the cementinperviousconcrete.Itimprovesthelowslumpmix's placementandfinishingproperties,aswellasitsworkability.

Perviousconcretehasalowercompressivestrength,better permeability,andalowerunitweightthanordinaryconcrete (approximately70percentofconventionalconcrete).

Density:Incomparisontotraditionalconcrete,whichhasa void ratio of around 3 5 percent, pervious concrete has a voidratio of15 40 percent, depending on theapplication. The large vacancy ratio results in a low unit weight of around70%ofthatofstandardconcrete[7].

Porosity / Permeability: The porosity of a specimen is definedasthevolumeofvoidsdividedbythetotalvolumeof the specimen. A water displacement method [13] can be usedtodeterminetheoverallporosityofperviousconcrete. Porosity should be between 15 and 25 percent [3]. The water to cementratioandcompactioneffortarealsofactors thatinfluenceporosity[1].Greaterporosities(alsoknownas voidcontentsandvoidratios)allowforhigherinfiltration rates but reduce compressive strength significantly. A falling headinstrumentdevelopedfromsoilstestingisused to determine the permeability of porous concrete, while variousmethodshavebeenused.Accordingtothefindings, permeabilityroseexponentiallyasthevoidratioincreased, andporousconcretewitha porosityoflessthan15%had limitedornopermeability[13].

Compressive Strength: Pervious concrete's compressive strength can range from 3.45 MPa to 27.58 MPa, whereas standard concrete's compressive strength typically varies from20.68MPato48.26MPa.Flexuralstrengthsofpervious concrete and conventional concrete typically vary from 1 MPa to 3.8 MPa and 4 MPa to 5.5 MPa, respectively [3]. Although porosity is the primary determinant of compressiveandflexuralstrength,aggregatesize,shape,and gradation can significantly influence pervious concrete strength[8].Thecompressivestrengthofporousconcreteis directlyproportionaltotheunitweightofthemix,andasthe unitweightgrows,sodoesthestrength.Accordingtocertain research,withtherightwater cementratioanddensification technique,strengthsofupto21MPamaybeachieved[14].

Using admixtures, however, pervious concrete strengths higherthanconventionaltraditionalconcretestrengthsmay beachieved,reachingupto55.16MPa[15].Thisisrelatedto the reduction of air spaces, which may result in a large reductioninpermeability.Becausethemajorpurposeofa porouspavementsystemistoobtainenoughpermeability forstormwatercontrol,compactingconcreteuntilitreaches adequatestrengthisnotalwaysapossibility,andabalance betweenstrengthandvoidratiomustbeestablished[14].

Durability: Perviousconcretehasa problemwithsurface durability. Even with adequate batching, handling, and curing,ravellingcanoccurinperviousconcrete.Thesurface durabilityofperviousconcretemaybetestedusingexisting ASTM test techniques [16, 17]. A laboratory test that evaluates the ravelling of pervious concrete has been developedformeasuringthesurfacedurabilityofpervious concrete [18]. Distress surveys were conducted on two distinct field locations as part of an examination into structuralperformance,andthedatawereutilisedtocreate a pavement condition index (PCI). The thicker pervious concretesections'highPCIratingsdemonstratedthat,when correctly planned, pervious concrete may be utilised for most "Residential" and many "Collector" roadways for averagedesignlifeperiodswhiledemonstratingsatisfactory structuralperformance[19].

Whenutilisingperviousconcrete,threedesignaspectsmust betakenintoaccount:

i) mixturedesign/proportioning,

ii) hydraulic design, which is comparable to stormwaterdetentionpondsandhasprogrammes and guidelines available from various national sources[20],and

ii) structuraldesign.

Structural pavement design: Any standard concrete pavementprocess(e.g.,AASHTO)[21]canbeusedtodesign perviousconcretepavements.PerviousPave,acompletetool createdbytheAmericanConcretePavementAssociation,may beusedtoproducebothstructuralandhydrologicaldesigns for pervious pavements [22]. There are currently no thickness guidelines for pervious concrete pavements, howevermanyparkinglotshaveperviouspavementsthatare 150mmthick,whereaslow volumeroadwayshavepervious pavementsthatarebetween150and300mmthick[1].The followingaretheconsiderationstoconsiderwhiledesigning perviousconcretepavements.

Subgrade and subbase.Acompositemodulusofsubgrade response, which accounts for the impacts of both the subgrade and the subbase, is commonly used to describe foundationsupport.Underpreviousconcretepavements,an

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3253

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

open gradedsubbaseistypicallyutilisedtoofferapathfor verticalwaterdrainageaswellasstoragecapacity.

Concrete flexural strength Concrete'sflexuralstrengthis an essential factor in the structural design of concrete pavements.Compressivestrengthsareoftenmeasured,and empirical relationships are used to determine flexural strengthsforuseindesign[3].

Traffic loading applications The majority of pervious concrete pavements are utilised in low traffic areas. The amount of traffic that a pervious pavement is expected to carryisgenerallyexpressedascomparable80kNsingle axle loadrepetitions.

Thestudydiscussedtherelevanceofperviousconcreteand its advantages as a sustainable pavement system that has been widely utilised for over 30 years for roadway applications in Europe, the United States, and Japan. The articleincludedawiderangeofperviousconcretequalities, including mix proportions, mechanical properties, environmentalconsiderations,andcost benefitanalysis.

When compared to other non pervious pavements, permeableconcretepavementoffersasignificantbenefitin reducingstormwaterrunoff.Perviousconcreteisasuitable materialforuseinpavementsbecauseofitshighwaterflow rateandlightweight.Thisfeaturehasledtotheincreased usageofperviousconcreteinmetropolitanareastoimprove storm water quality and reduce rainfall runoff. Pervious concrete's poor compressive strength, on the other hand, limits its use in areas with moderate traffic loads and volume. Because of its porosity, the material's strength is ratherlow.Thestrengthandabrasionresistanceofpervious concrete may be considerably improved by using appropriateaggregates,fineminerals,admixtures,organic intensifiers,andmodifyingtheconcretemixpercentage.It offers good qualities that may be used in road pavement applicationsdespiteitslowcompressivestrength.

Perviousconcretemixappearstobeaveryattractiveoption foruseasapavementmaterialinlow volumeroadwayssuch as local streets, pedestrian walkways, and driveways, and maybeinhighwaysinthefutureifmechanistic baseddesign techniquesareestablished,accordingtopublishedstudies. Based on prior study, it was discovered that there are various research gaps in the field. If these gaps are recognised and investigated, they can aid in the overall knowledgeofthematerialandcontributetotheformulation andimplementationofperviousconcretepavementdesign guidelines.

[1] American Concrete Institute (ACI) Committee 522, “ReportonPerviousConcrete”,ACI522R 10,American

Concrete Institute, Farmington Hills, Michigan, USA, 2010.

[2] Obla,K.H.,"PerviousConcrete AnOverview",Indian ConcreteJournal,August2010,pp.9 18.

[3] Tennis, P.D., Leming, M.L. and Akers, DJ., "Pervious Concrete Pavement", Engineering Bulletin 302.02, Portland Cement Association, Silver spring, MD; NationalReadyMixedConcreteAssociation,SkokieJL, 2004,pp.1 25.

[4] http:// www.perviouspavement.org, maintained by NationalReadyMixedConcreteAssociation (NRMCA), accessedOct20,2016.

[5] Fortes,R.M.,Merighi,J.V.,andBandeira,A.,"Laboratory studies on performance of porous concrete", 10th International Symposium on Concrete Roads, 18 22 September2006,Brussels,Belgium.

[6] Kevern, J.T., Schaefer, V.R., and Wang, K., "Mixture ProportionDevelopmentandPerformanceEvaluationof Pervious Concrete for Overlay Application", ACI MaterialsJournal,Vol.108(4),pp.439 448.

[7] Ajamu,S.O.,Jimoh,A.A.andOluremi,J.R.,"Evaluationof Structural Performance of Pervious Concrete in Construction",InternationalJournalofEngineeringand Technology,Volume2(5),May2012,pp.825 836.

[8] Crouch,L.K.,Pitt,J.,andHewitt,R.,"AggregateEffectson Pervious Portland Cement Concrete Static Modulus of Elasticity",JournalofMaterialsinCivilEngineering,Vol. 19(7),2007,pp.561 567.

[9] Cosic, K., Korat, L., Ducman, V., and Netinger, I., "InfluenceofAggregateTypeandSizeonPropertiesof PerviousConcrete",ConstructionandBuildingMaterials (Elsevier),Vol.78,2014,pp.69 76.

[10] Khalaf, F. M., and DeVenny, A. S., "Recycling of Demolished Masonry Rubble as Course Aggregate in Concrete: Review", Journal of Materials in Civil Engineering,Vol.16(4),2004,pp.331 340.

[11] Eathakoti,S.,Gundu,N.,andPonnada,M.R.,2015,"An InnovativeNo FinesConcretePavementModel",IOSR Journal of Mechanical and Civil Engineering (IOSR JMCE),Vol.12(5),2015,pp34 44.

[12] Khattab,E.A.,ElNouhy,H.A.andAbdel Hameed,G.D, "Assessment of Porous Concrete Properties as a FunctionofMixProportions",WorldAppliedSciences Journal,Vol.24(6),2013,pp.751 758.

[13] Montes, F., Valavala, S., and Haselbach,, L. M., "A New Test Method for Porosity Measurements of Portland

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Cement Pervious Concrete", Journal of ASTM International,Vol.2(1),2005,pp.1 13.

[14] Schaefer,V.R.,Wang,K.,Suleiman,M.T.,andKevern,J.T., "MixDesignDevelopmentforPerviousConcreteinCold Weather Climates", Final Report, National Concrete Pavement Technology Center, Iowa State University, Ames,IA,2006.

[15] Yang,J.,andJiang,G.,“Experimentalstudyonproperties ofperviousconcretepavementmaterials”,Cementand ConcreteResearch,Vol.33,No.1,2003,pp.381 386.

[16] ASTM.“Standardtestmethodforabrasionresistanceof concrete or mortar surfaces by the rotary cutter method.”C 944,AnnualbookofASTMstandards,ASTM International,WestConshohocken,PA,USA,1999.

[17] ASTM.“Standardtestmethodfordeterminingpotential resistance to degradation of pervious concrete by impact and abrasion.” C 1747, Annual book of ASTM standards,4(2),WestConshohocken,PA,USA,2011.

[18] Offenberg,M.,"ProvingPerviousConcrete'sDurability: AProposedTestMethod",ConcreteProducerMagazine, January2009

[19] Goede, W, and Haselbach, L. "Investigation into the StructuralPerformanceofPerviousConcrete",Journalof TransportationEngineering(ASCE),2011.

[20] Leming, M., Malcom, H., and Tennis, P., "Hydrologic Design of Pervious Concrete", Portland Cement Association.Skokie,IL,2007.

[21] Delatte, N, Mrkajic, A and Miller, D., "Field and LaboratoryEvaluationofPerviousConcretePavements", TransportationResearchRecord,2113,2009,pp.132 139.

[22] Rodden, R., "Structural and Hydrological Design of SustainablePerviousConcretePavements",Proceedings of the 2011 Annual Conference of the Transportation Association of Canada, Successes in the Pavement Industry,Edmonton,Alberta,Canada,2011

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3255