International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

1DR. JANARTHANAN M Assistant Professor Level II, Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamanagalam, Erode, Tamil Nadu, India. 2,3students, Department of Textile Technology, Bannari Amman Institute of Technology, Sathyamanagalam, Erode, Tamil Nadu, India. ***

Abstract - An Aditya Birla Fashion and Retail Limited is one of the largest apparel manufacturer and retailer in India manufacturing top brands like Louis Philippe, Allen Solly, Peter England, Van heusen and export brands like Superdry, Mar co polo etc. The garment industry is constantly working to enhance production and garment quality in order to compete in such a crowded market. The productivity of the clothing industry determines its long term viability and profitability. A variety of procedures are carried out at various locations during the garment manufacturing process. Because of the operators to obtain the desired results, all of these activities must be coordinated, scheduled, and completed on time, productivity. In industries, many practises and procedures are used to increase production. Almost every garment company uses time study as one of the most effective tools for optimising output rate. This article examines the production process of shirt. which we have investigated the time spent on each phase of the process.

Key Words: Garment Industry, checked shirts, feature line, checks repeat, pinning, spreading, ready cut, block cut, CAD

Thisstudyisconductedinthecuttingsectiontoidentifytheareasthatneedstandardizationandimprovement.Observedthat Productionofshirtswithversatiledesignstakeplaceintheproductionfloor.Oneofthechallengingandimportantaspectinthe processofmanufacturingofcheckedshirtsistomaintainthefeaturelinematchingthroughoutthegarment.Thelinematching isveryimportantforshirtpartslikepocket,frontplaquette,bothsleevepanels,sleeveplaquetteandyokepanels.Forthisline matchingaspectmeasuresshouldbemadeinthefirstprocessofgarmentmanufacturingknowsasfabricspreadingorlaying. Themainfactorplaysamajorroleinthislinematchingarethechecksandstripedrepeatsinthefabricrolls.Thisrepeatvaries from roll to roll which is a challenging thing. For this issue the clubbing to rolls based on the repeat size difference was proposedbyusingwhichwecanmakeCADmarkersforeachrepeatclubs.Thisimplementationwillautomaticallyreflectin perfectfeaturelinematchingandincreaseinreadycutpercentage.Thegarmentmanufacturinginvolvesmanyprocesseslike cutting,fusing,sewingandfinishing.Andforalltheabove mentionedprocessesthereareseparatedepartmentsatAdityaBirla FashionandRetailLimited.

Fabricstore

Trimstore

CAD

Cutting

Sewing

Finishing

AmongthesedepartmentsourprojectdealswithCADandCuttingdepartmentswhichisknownastheheartofthefactory.

Themainobjectiveofthisimplementationistoachieveperfectmatchingoffeatureline acrosstheshirtparts.Forthisthe perfectpininglaystyleshouldbefollowed.Pinninglaystyleisperformedonpintablewhichisabout4metersinlengthand1.8 metersinwidthwhichconsists42pinsarrangehorizontalandverticalacrossthetable.Inpinningstyleoflayingthefabricis spreadoverthetablebypinningthefabricoverthepinonthetablebythewaythefeaturelineisaccurate.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal |

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Thedeviationoccurswhenalayrequires50pliesbuttherollno.1canonlyproduce30pliessoforthenext20pliesrollno.2 shouldbeused.Inthiscaseiftherepeatsizebetweenthetworollsismorethan3mmthendeviationinfeaturelinematching willoccur.

Heretherepeatwiseclubbingofrollswilleliminatethedeviationinmatchingoffeatureline.

Firstthefabricwillbeissuedtothefabricstore.

Wherethefabricinspectioniscarriedoutandfabricinspectionreportismade.Thefabricinspectionreportis madebytakingaswatchfabricfromeachroll.

Thefabricinspectionreportcarriesdetailslike

Fabricshrinkagevalue

Shadevariationtype(csvornoncsv)

Rolltorollrepeatvariationincheckedfabric

Fabricvisualinspectionreport

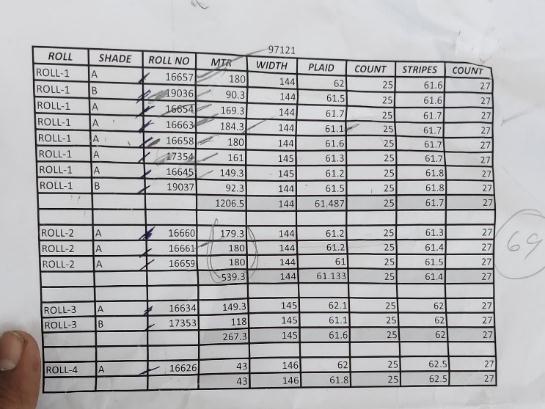

Thentherollsareshadewisesegregatedandtherolllistismade.

Afterthisthenewlyimplementedrepeatwisegroupingofrollsneedtobecarriedout.

Afabricswatchof80cmfromeachrollistakenandtherepeatsizesaremeasured.Fabricrollswithrepeatsizes within3mmdifferenceareclubbedtogetherintherolllist.

ThenthefabricinspectionreportalongwithrolllistcontainingshadeandrepeatclubbingisissuedtotheCAD department.

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Repeatwisegroupingisclubbingofrollsinasingleworkorderwithsimilarrepeatsize.Thisprocessshouldbecarriedout infabricstoreandthisreportshouldbedonealongwiththefabricinspectionreport.

Forchecksshirtsthematchingoffeaturelinewithpartslikepocket,frontplaquette,yoke,bothsleeves,sleeve plaquetteisimportant.

Forthispurpose,checksfabricislayusingaspecialmethodcalledpinningwhichisperformedonapinningtable.

Pinningtableis4meterslongtablewith1.8metersoflengthwhichconsistsof42pinsarrangeverticallyand horizontallyoverwhichthefabricsarefabricsarelaidbypinningthefeaturelineoverthepins.

Thishelpsinmismatchingofthefeaturelinesamongthepliesinalay.Therepeatsizewillvaryfromrolltoroll,so evenifthefollowofpinninglaystylewillnotgiveperfectmatchingoffeaturelinesandthiswillreducethe percentageofreadycut.

CADdepartmentanalysesthefabricinspectionreportconsideringfactorslikefabricshrinkage,width,csvornoncsvshade andpreparesmaker.

Nowastherollsarerepeatwiseclubbed,themarkercanbemadewiththeaveragerepeatsizementionintherolllistfor eachclub.CADdepartmentwillalsoaddthepre plannedlayingcolumntothecutplanwhichwillreducethenon value addedactivitiesandhelpsinincreasingproduction.Thisalsohelpsinendbitfabricstandardization.

Marker1 1 1 2 1.74 1.76 80.84 2 0.81 3.5 0 Marker2 1 1 4 1.32 1.34 81.41 4 1.63 5.3 Marker3 1 1 2 18 3.01 3.03 81.29 36 14.63 54.2 Marker4 2 2 16 2.69 2.71 83.38 32 13.34 43.0 Marker5 1 1 2 60 2.89 2.91 82.92 120 49.75 173.4 Marker6 1 1 6 1.43 1.45 80.63 6 2.42 8.6 Marker7 0 0.02 0 0.00 0.0 Marker8 0 0.02 0 0.00 0.0 Marker9 0 0.02 0 0.00 0 Marker10 0 0.02 0 0.00 0 Marker11 0 0.02 0 0.00 0 Marker12 0 0.02 0 0.00 0

Marker13 0 0.02 0 0.00 0 Marker14 0 0.02 0 0.00 0 Marker15 0 0.02 0 0.00 0 Marker16 0 0.02 0 0.00 0 Marker36 0 0.02 0 0.00 0

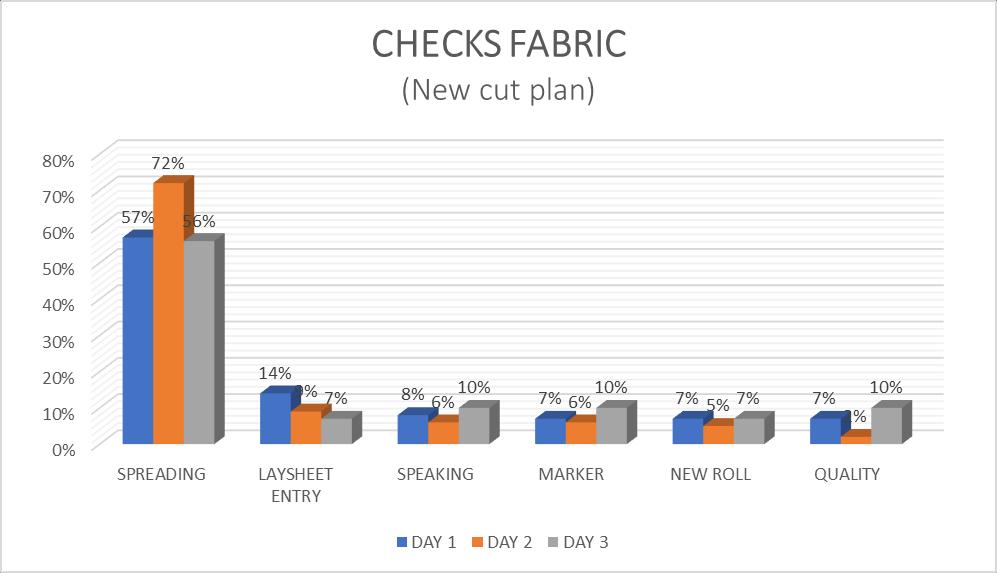

Fig 2: Newcutplan

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

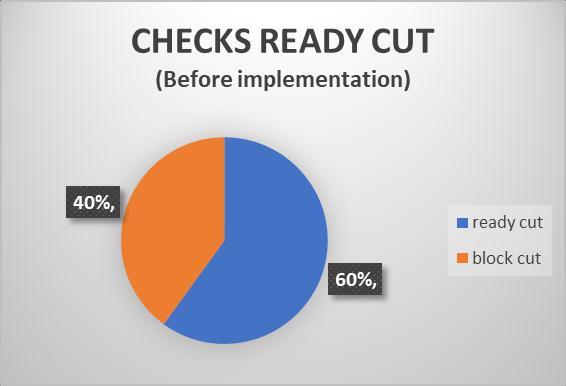

Fig 4: Checksreadycutbeforeimplementation

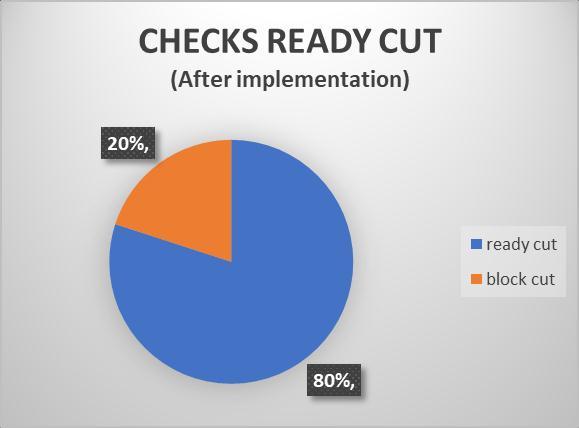

Fig 5: Checksreadycutafterimplementation

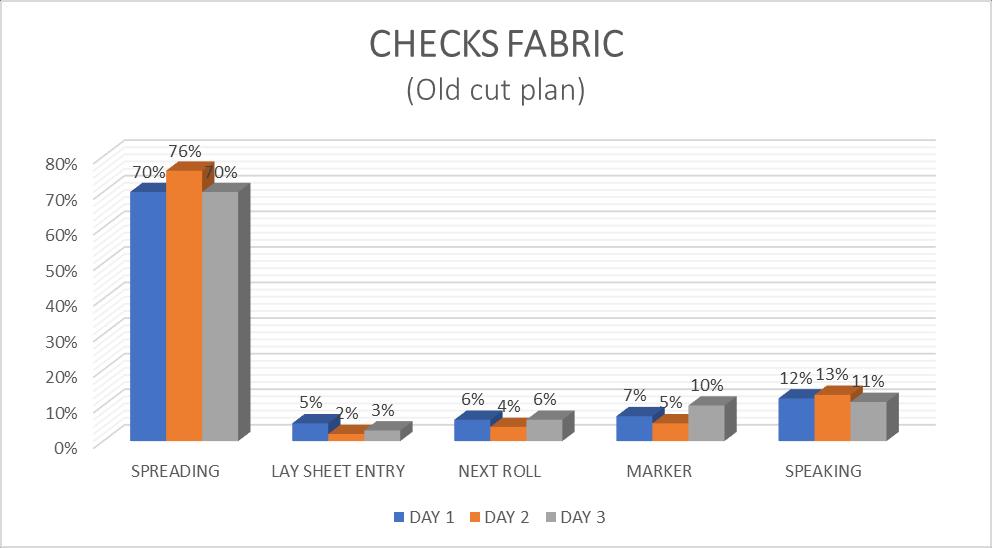

Fig 6: Timestudywitholdcutplan

2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Fig 7:Timestudywithnewcutplan

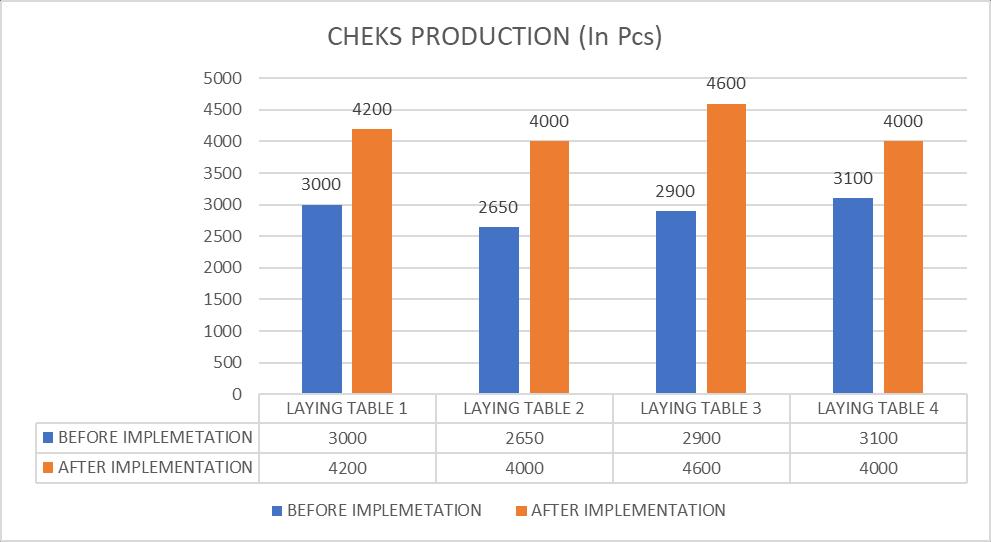

Afterimplementationofthisrepeatwisegroupingofrolls.Thefeaturelinematchingisperfectinlayswhichincreasetheready cutpercentageby20%from60%to80%.Thisimplementationisalsoafirststepforcheckedfabriccuttinginautocutter.

Fig 8: Productionimprovement

1. Khatun,Murshida.ApplicationofIndustrialEngineeringTechniqueforBetterProductivityinGarmentsProduction, InternationalJournalofScience,EnvironmentandTechnology,Vol.2,No6,2013,1361 1369.

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

2. Price, JohnWH., Industrial Engineering: Important for Managementin Australia, Fourth InternationalConference onEngineeringManagement,1994:Preprints.InstitutionofEngineers,Australia,1994.

3. HaqueAhasanul,LeadtimemanagementinthegarmentsectorofBangladesh:anavenuesforsurvivaland growth, EuropeanJournalofScientificResearch,Vol.33(4)2009,617 629.

4. KaderShahidul,andMaeenMdKhairulAkter,Analysisofthefactorsaffectingtheleadtimeforexportofreadymade apparelsfromBangladesh

5. DrPKhanna:Workstudy,timeandmotionstudy,DhanpatRaiandSons,NewDelhi,(pp21 31).[2]F.M.Gryna,J.A. DeFeo,“QualityPlanning&AnalysisforEnterpriseQuality”,TataMcGrawHill,Edition,2008

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal

6. https://www.researchgate.net/profile/MadhuriKakde/publication/326534061_Enhancing_Efficiency_and_Productivit y_of_Garment_Industry_by_Using_Different_Techniques/links/5b52d891a6fdcc8dae345688/Enhancing Efficiency and Productivity of Garment Industry byUsing Different Techniques