International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

1MTech student, Dept. of Mechanical engineering, Technocrats Institute of Technology & Science, Bhopal, MP, India

2Professor, Dept. of Mechanical Engineering, Technocrats Institute of Technology & Science, Bhopal, MP, India

3 Professor, Dept. of Mechanical Engineering, Technocrats Institute of Technology & Science, Bhopal, MP, India ***

Abstract Nanofluids have demonstrated their capacity to work on the thermal conductivity of base liquids and heat transfer in heat exchangers and other devices. The heat exchanger consists of a hollow shell, a single tube, and a flower baffle plate. The baffle plates are placed inside the shell side of the heat exchanger. The angle of the plate affects the pressure drop, fouling of the heat exchanger as well as the heat transfer rate. The nanofluid of carbon nano tubes (CNTs) is introduced as cold fluid to increase the heat transfer rate as CNTs has higher thermal conductivity. Double distilled water is used to prepare the nanofluid and sodium dodecyl sulphate is used as a surfactant to increase the stability of the nanofluid. The objective of this research is to enhance the rate of heat transfer of the shell and tube heat exchanger (STHX) by using nanofluids CNTs. The model of heat exchanger is modelled by using SOLIDWORK 2020 and ANSYSFLUENT 2020 to run the simulations. The temperature at the outlet of the tube side and shell side and pressure drop of the heat exchanger are calculated and plotted graphically. The results shows that the nanofluid has higher heat transfer rate than the combination of nanofluid and flower baffle plates.

Key Words: Shell and tube heat exchanger, Nanofluids, Carbon nanotubes, Flower baff le plates, Convective heat transfer coefficient.

Heatexchangerisamechanicaldevicethatreusestheheat energypresentintheworkingfluid.Theshellandtubearea versatileheatexchangerduetoitsflexibilityindesignandis commonlyusedinmanyindustriesforcoolingofturbineand compressor, oil industries, for refrigeration and air conditioning, etc.Theshell andtubeheat exchangerhasa bundleoftubesencasedwithinashell.Thebaffleplatesare one of the important barriers located within the shell to create turbulence which will increase the rate of heat transferandalsoprovidesupporttothelengthsofthetube. Baffleplatesusedintheshellandtubeheatexchangermay belongitudinalflowbaffles,impingementbaffles(usedfor theprotectionofbundlewhenenterwithhighvelocity)and orificebaffles.Shinde(2017)[1]didaninvestigationonshell and tube heat exchanger with continuous helical baffle. Different helix angle was taken into consideration and investigatedmathematicallybymodellinghelicalbaffleon shell and tube heat exchanger for various mass flow and

inlettemperatureconditions.Resultssuggestthatthehigher helixangle(30°,38°,and50°)addstolowerheattransfer andlowerpressuredrop,andwithlowervalueofhelixangle (21°,19°and10°)higherwillbethepressuredropandheat transfer.Mahenndran(2019)[2]studiedtheshellandtube heat exchanger with conventional single plates and new designed baffleplateswere designed andcompared using SOLID WORKS. The performance of both the baffles were also analysed. The results suggested that the overall performance of the conventional model is more efficient thanthesegmentalbaffleplateheatexchanger.Chen(2020) [3]investigatedtheimpactofthebafflepatternontheheat transfer and mass flow rate of shell and tube heat exchangers. Different types of baffle plates were used includingtri flowerbaffle,poreplate,rodbaffle,segmental and pore baffle, and segmental baffle. To analyze the hydrodynamicsandheattransferattributesofthefiveheat exchangers, a water water heat transfer system was constructed. The outcomes show that the shell side heat transfer coefficient of the tri flower baffle and pore plate bafflewerepredominant.Wang(2011)[4]experimentally investigated the flower baffle heat exchanger and the original segmental baffle heat exchanger. The outcomes recommend that, under similar conditions, the general exhibitionoftheflowerbafflewas20 30%higherthanthat ofthesegmentalbaffleheatexchanger.Youetal.(2012)[5] investigated the numerical modeling, experimental validationofheatexchangerandflowresistanceontheshell sideofa shell andtubeheat exchanger withflowerbaffle. Theworkshowsthatthemodelwaseconomicandeffective in the thermal hydraulic design and analysis of a whole device.Geeteetal.(2021)[6]workedonashell spiralheat exchanger.Theperformanceofconstructedheatexchanger forvariousflowratesand temperatures(inlet)ofhotand coldfluidsshowsthatthehighestachievableeffectivenessis 0.988. Kunwer et al. (2020) [7] did a comparison on the selected STHX with segmental and helical baffles, which shows that pressure drop in helical baffle was low as comparedtothesegmentalbaffle.Differentnanofluidswere usedtoenhancetheperformanceoftheheatexchanger.The nanofluidconsistedofnanoparticlesandabasefluid.Liuet al.’s(2011)[8]experimentalinvestigationresultsshowthat nanofluids with a low concentration of carbon nanotube (CNT), CuO and Cu had higher thermal conductivity than baseliquids.Singh(2020)[9]experimentallyvalidatedthat CNT has higher coefficient of thermal conductivity up to

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3201

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

3000 6000 W/m K when contrasted with other solid particles.Consequently,itcouldbeconceivablethatalower concentration of CNT would give better thermal conductivity. CNT nanofluid has higher heat transfer upgrade up to 13% when contrasted with nanofluids of alumina,ethyleneglycolandwaterat0.25vol%.Theyfound thattheheattransfercoefficientofCarbonnanofiber(CNF) nanofluid increased up to 3.39W/m2K at 0.6wt%. Venkataramanetal.(2019)[10]studiedthatCNTnanofluid has unique properties that makes them suitable in heat transfer applications. Carbon nanotubes (CNTs) pulled in huge interest because of their novel blend of properties includinghighmechanicalstrength,highaspectratio,large surfacearea,highelectricalandthermalconductivity,which makethemreasonableforawidescopeofuses.Almanassra etal.(2019)[11]conductedastudyonstabilityandthermal conductivity of water/CNTs nanofluid using a different surfactant.Theresultobtainsexperimentallyoftheshelland tube heat exchanger exhibit increments in rate of heat transfer with the convergence of CNT up to 65%, with an increaseinpressuredropofaround15%utilizing0.5wt.% of CNT. The pumping power computations demonstrated that the necessary ability to give a same measure of heat withtheuseofnanofluidsis33%ofthatneededforwater. Moorthy & Srinivas (2016) [12] studied about the anticorrosive properties and improved heat transfer properties of carboxylated water based nanofluids. The stabilityofnanofluidwasgreaterwithcarboxylatedwater ratherthannormalwater.Vivekanandanetal.(2020)[13] conductedanexperimentalandcomputationalfluiddynamic analysisonhelicalcoilheatexchangerwithflowerbaffles. Theanalysiswasdoneinbetweenthecounterandparallel flowheatexchangerbyvaryingtheflowratesofthehotand coldfluid.Theresultssuggestedthattheheattransferratein counterflowishigherthanthatinparallelflow.

From the above mentioned research, we see that STHX is versatileandcanbemodifiedaccordingtotheneedwithout compromisingtheperformanceoftheheatexchanger.The counter flow heat exchanger has a higher rate of heat transferthantheparallelflowheatexchanger.Further,the flower baffle plates give lower pressure drop than other baffleplate.Nanofluidsformedwithalowerconcentrationof carbonnanotubesgivebetterheattransferratethanother nanofluid and the pumping power required is lesser than water which decreases the energy required to pump the nanofluidintheheatexchanger.

Inthiswork,themassflowrateisvaryingforhotwaterto find the one which has a higher rate of heat transfer and higher convective heat transfer coefficient keeping the pressuredropasminimumaspossible.

The analysis was divided into two parts, first, the designing of the STHX with flower baffle and second, the thermalanalysisontheSTHX.

For the design, the model of STHX and flower baffle is done on different platforms. The STHX are designed on ANSYS 2020, and the flower baffle is designed on SOLIDWORKS2020.Thentheflowerbaffleisimportedonthe ANSYS2020platformforfurtheranalysis.

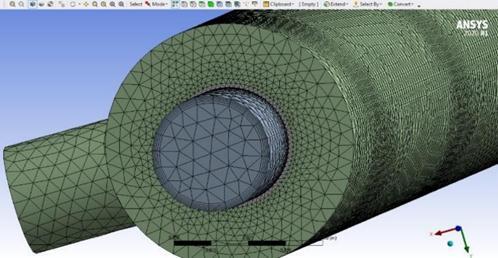

Themeshingwasdonebytakingthemodelasak epsilon turbulent model as shown in Fig.1. Geometry has been meshedwithanelementsizeof10mm.Convergencecriteria for the different parameters are different. For continuity equation,1.0e 05isused,forvelocitiesinalldirections1.0e 05isused,forenergyequation1.0e 08isusedandforkande 1.0e 05 is used. To reach the convergence value fast, relaxationvalueassignedtopressureis0.3whilekand∈is 0.7andtemperatureis0.9.Theinletofboththefluidismass flowinletandoutletaretakenaspressureoutlet.

Allthedimensionsaretakeninmillimeters(mm).Theouter andinnerdiameterofthetubeis43and40,respectivelyand theshelldiameteris84.Thelengthoftheheatexchangeris 1000.Theheatexchangerisdesignedasacounter flowheat exchangerandtheinletandoutletforthecoldfluidis40in diameterandextrudedfor50mmfromtheshellsurface.The baffleplatesaremountedonthetubeinahelicalpath.For thelengthof1000mm,52flowerbafflesaremountedonthe tube. The helix angle for the flower baffle is 0° and its thicknessis5mm.

Thematerialoftheheatexchangerisaluminum.

Theinlettemperaturewastakenas300Kforcoldfluidand 353Kforhotwater.

The hot fluid is water, and the cold fluid is nanofluid CNT (Carbonnanotubes)withwater(doubledistilled)asabase fluid.

Theanalysisisperformedandcomparedwithandwithout the effect of the flower baffle for all cases. The different temperaturevaluesareobtainedbytakingtheaverageofthe

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

valuesobtainedat10equallydistantpositionsonthemodel. Differentparametervaluesarenotedfromthepost analysis.

Nanofluiddensity(ρnf):

ρnf =1001kg/m3

Nanofluidspecificheat(Cpnf): Cpnf =4100J/kg K

Nanofluidviscosity(μnf): μnf =0.025×10 3 kg/m s

Nanofluidthermalconductivity(Knf): Knf =12.647W/m K

Performed analysis of the STHX using nano fluid and flowerbaffleisasfollows:

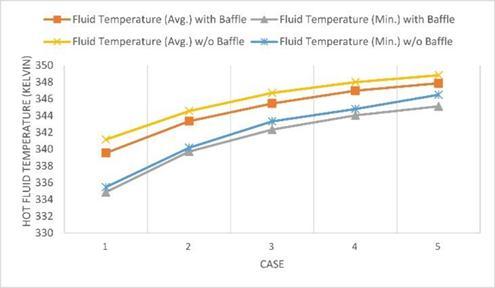

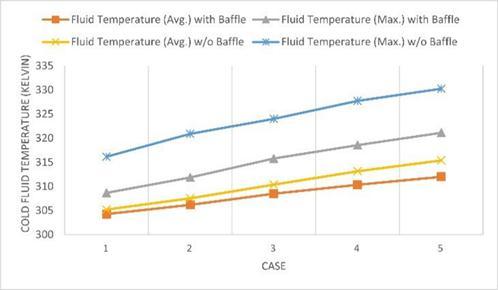

For the case of cold fluid, the average and maximum temperature obtained with nanofluid is higher than that obtainedwiththeuseofflowerbaffleasshowninFig.2.This isduetothehigherthermalconductivityofthenanoparticles ofCarbonnanotubespresentinananofluid.

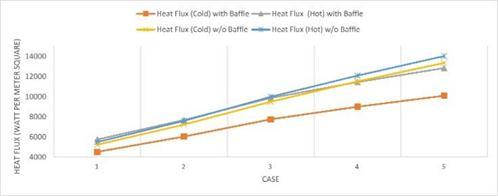

Thenanofluidgiveshighvalueofheatfluxforhotandcold fluid due to the higher thermal conductivity of Carbon nanotubes, which increases the difference in the wall and fluidtemperaturetherebyincreasing theoverallheatflux, whereasintubesideoftheSTHXforthecaseof1 1lpmand 1 2lpmthecombinationofflowerbaffleandnanofluidgives higher heat flux value. But for remaining cases nanofluids havehigherheatfluxvalueasshowninFig.4

Inthecaseofhotfluid,thedifferenceintemperatureofhot fluidismorewiththeuseofflowerbafflebecausetheflower baffles are the extension of the tube acting as fins and extractsmoreheatfromthehotfluidasshowninFig.3.

Fig -4: Heatfluxforhotandcoldfluidforallcases

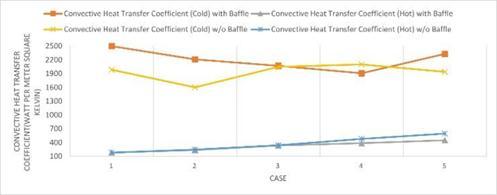

It has been observed that the maximum convective heat transfercoefficientinthecaseofflowerbaffleandnanofluid obtained is 2497.57 W/m2K in the cold side of the heat exchangerfortheflowrateof1lpmonboththecoldside andthehotside.Inthecaseofhotfluid,5lpmhasahigher convectiveheattransfercoefficientof450.04W/m2K.The caseof1 5massflowrate(llpmonthecoldsideand5lpm onthehotside)showsasatisfyingresultwithaconvective heattransfercoefficientof2330.05W/m2Konthecoldside and450.04W/m2Konthehotsideoftheheatexchanger.

Intheanalysisonlywithnanofluid,themaximumconvective heattransfercoefficientisobservedinthecaseof1 4mass flowratei.e.,1lpmonthecoldsidewhichis2100.45W/m2K and4lpmonthehotsidewhichis480.65W/m2K.Butwecan also see that the maximum convective heat transfer coefficientforthehotsideisobtainedfortheflowrate5lpm givingavalueof595.25W/m2KasshowninFig.5.

Fig 5: Convectiveheattransfercoefficientforallcases

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3203

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

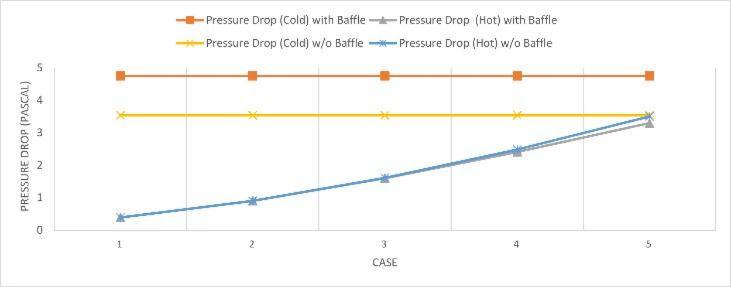

Thepressuredroponthecoldsideisgreaterthanthatinthe caseofnanofluid.Thecoldsidegivesapproximatelyconstant pressure drop at a constant flow rate i.e., ranging from 4.750608Pato4.750597Painall5cases.Whileinwithout flowerbafflecasethevalueofpressuredropisconstanti.e., 3.54Pa. So, from here we can conclude that the pressure drops in the case of shell and tube heat exchanger with flowerbaffleandnanofluidarelargerthanwithoutflower baffleonthecoldside.Pressuredropforallcasesisshownin Fig.6.

Materials Today 21, 419 (2020) https://doi.org/10.1016/j.matpr.2019.06.380

[3] J.Chen.Experimentalthermal hydraulicperformances ofheatexchangerswithdifferentbafflepatterns.Energy 205 (2020). https://doi.org/10.1016/j.energy.2020.118066

[4] Y.Wang.Experimentalinvestigationofshell and tube heat exchanger with a new type of baffles. Heat and Mass Transfer 47, 833 (2011). https:// doi 10.1007/s00231 010 0590 x

[5] Y.You,A.Fan,S.Huang,W.Liu.Numericalmodelingand experimental validation of heat transfer and flow resistance on the shell side of a shell and tube heat exchangerwithflowerbaffles.InternationalJournalof Heat and Mass Transfer 55, 7561 (2012). http://dx.doi.org/10.1016/j.ijheatmasstransfer.2012.07 .058

Fig -6: Pressuredropsinshellandtubeside

Thenanofluidgiveshigherheatfluxwiththeincreaseinthe differenceinmassflowrateofhotandcoldfluid,whereas the combined effect of flower baffle and nanofluid gives a higherconvectiveheattransfercoefficientforcoldfluid.

Itisevidentthatinthecaseofflowerbafflewithnanofluid, keeping the flow rate of 1 lpm and 5 lpm on cold and hot side, respectively, gives satisfying results with a pressure drop of4.75Paonthecoldside,and with nanofluid 1lpm and4lpmoncoldandhotsiderespectivelygivessatisfying resultwithapressuredropof2.48Paintubeside.

The combined effect of flower baffle and nanofluid CNT decreasesthepressuredroponthecoldsidewithaconstant mass flow rate, whereas in the case of the hot side the pressuredropsincreaseasthemassflowrateincreases.

Aboveresultsindicatethatwithlow pressuredrop intube sideCNTnanofluidgiveshigherheatflux.

[1] S.Shinde.Numericalandexperimentalanalysisonshell side thermo hydraulic performance of shell and tube heat exchanger with continuous helical FRP baffles. Thermal Science and Engineering progress 5, 158 (2018).https://doi.org/10.1016/j.tsep.2017.11.006

[2] J. Mahendran. Experimental analysisof shell and tube heatexchangerusingflowerbaffleplateconfiguration.

[6] A. Geete. Entropy, Exergy and Entransy Analyses on Fabricated Shell and Spiral Tube Heat Exchanger. JournalofTheInstitutionofEngineers(India)SeriesC 102,897(2021).https://doi.org/10.1007/s40032 021 00686 8

[7] R.Kunwer&S.Pandey.Comparisonofselectedshelland tubeheatexchangerswithsegmentalandhelicalbaffles. ThermalScienceandEngineeringProgress20,(2020). https://doi.org/10.1016/j.tsep.2020.100712

[8] M.S.Liu.Enhancementsofthermalconductivitieswith Cu, CuO, and carbon nanotube nanofluids and applicationofMWNT/waternanofluidonawaterchiller system. Nanoscale Research Letters 6, (2011) https://doi.org/10.1186/1556 276X 6 297

[9] K. Singh, S. K. Sharma, S. M. Gupta. An experimental investigation of hydrodynamic and heat transfer characteristics of surfactant water solution and CNT nanofluid in a helical coil based heat exchanger. Materials Today 43, 3896 (2021) https://doi.org/10.1016/j.matpr.2020.12.1233

[10] A.Venkataraman,E.Victoria,Y.Chen&C.Papadopoulos. Carbon Nanotube Assembly and Integration for Applications. Nanoscale Research Letters 14, (2009). https://doi.org/10.1186/s11671 019 3046 3

[11] W.Almanssra.An experimental studyonstabilityand thermal conductivity of water/CNTs nanofluids using differentsurfactants.JournalofMolecularLiquids304, (2020).https://doi.org/10.1016/j.molliq.2019.111025

[12] C.V.K.N.S.N.Moorthy&V.Srinivas.CorrosionandHeat Transfer Characteristics of Water Dispersed with Carboxylate Additives and Multi Walled Carbon Nano

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3204

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Tubes Journal of The Institution of Engineers (India) SeriesC97,569(2016).S

[13] M. Vivekanandan, R. Venkatesh, R. Periyasamy, S. Mohankumar & L. Devakumar. Experimental and CFD investigationofhelicalcoilheatexchangerwithflower baffle. Materials Today 37, 2174 (2021). https://doi.org/10.1016/j.matpr.2020.07.642

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3205