International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Sanjay P R 1, Mr.Ramesh.S2

1M. Tech Student, Dept. of Structural Engineering, NCET, Bengaluru.

2Assistant Professor, Dept. of Civil Engineering, NCET, Bengaluru, Karnataka, India. ***

Abstract self compacting concrete (SCC) addresses an achievement in .solid exploration. SCC is an exceptionally flow able, non isolating .solid that can spread in to put, fill the formwork an exemplify the support with no mechanical vibration for union. SCC was initially evolved at the University of Tokyo, Japan during the year 1986 by Prof. Okamura and his group to improve the nature of development and furthermore to defeat the issues of faulty workmanship. A model of SCC for underlying applications was first finished in 1988 and was named ''HighPerformance.concrete'', andlater proposed as ''Self Compacting HighPerformance.concrete''. A board of trustees was framed to examinethepropertiesofSCC, remembering a crucial examination for functionality of .concrete , which was done at the University of Tokyo by Ozawa and Maekawa.

SCC addresses perhaps the most exceptional headway in .solid innovation during the most recent decade. Because of its particular properties, which are accomplishedbytheamazing coordination of deformability and isolation opposition, SCC may add to a huge improvement in the nature of .solid designs and open up new fields for the use of .concrete . The utilization of SCC offers numerous advantages to the development practice the disposal of the compaction work brings about diminished expense of arrangement, a shortening of the development time and in this way in an improved efficiency. The use of SCC likewise prompts a decrease of clamor during projecting, better working conditions and the chance of extending the setting time in downtown territories. Different benefits of SCC are the improved homogeneity of the .solidand the phenomenal surface completion without blowholes or other surface deformities, becauseoftheadvanced blendofthe individual parts of the solid blend.

Key Words: self compaction concrete, compression loading on specimens.

ThecurrentsituationrequestsIDofsubstitutematerialsfor stream sand for making of .concrete. Likewise these days relievingisamajorissuesoweattemptedself restoring,by supplantingcoarsetotalbylightweighttotal.Thedecisionof

substitutematerialsforsandin.concretereliesuponafew factors like their accessibility, cost, actual properties, compound properties, synthetic fixings and so on for lesseningtheexpenseof.cementandfurthermoretofulfill the need. Locally accessible waste materials, for example, silica seethe, rice husk,saw dust,squashedstone powder, earthenwarescrap,lakedebriscanbeutilizedassubstitute materials.Weutilizedfakelightweighttotal,wereLWAwas drenchedfor24hoursandafterwardutilizedin.concrete

While inspecting the characteristics of silica smoke and Quarry Dust it becomes obvious that if both are utilized together,themisfortuneinstrengthbecauseofonemightbe halfwayrefutedbytheimprovementinfunctionalitybrought aboutbytheincorporationoftheother.Thisundertakingis intendedtodecideifsuchadvantagescouldbeacquiredby the utilization of these two materials together, and to evaluatesuchadvantages.Positiveoutcomeswillpromptthe chance of utilizing two side effects in enormous amounts, whilelesseningtherelianceoncompoundadmixtures

Theaimsofthisexperimentalstudyareasfollows,

To describe every one of the elements of Self Compacting.concretecontainingdistinctiveextent ofQD,LWAandsteadyrateSilicaseethe.

TodecidethestreampropertiesbydirectingSlump stream,T50droopstream,J ring,V pipe,U Boxand L boxandtrackeddownthatthequalitiesareinside thecutoffpointsrecommendedbyEFNARC

To decide the diverse strength boundaries of the Self Compacting.concreteincontrastwithNSC

Basalt fines, regularly called Quarry or Crushed stone powder are side effects of the creation of .solid totals by pulverizingofrocks.

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

QuarryDust(QD)whichisforthemostpartconsideredasa waste material causes an ecological burden because of removal issue. The expansion of Quarry Dust to typical .concrete blends is restricted due to its high fineness. ConsequentlyQuarryDustisutilizedasanoptionincontrast tocommonsandanditsconsequencesforthestrengthand functionalityofSCCareexplored.TheexpansionofQuarry Dust to new .solid builds the water interest and subsequently the concrete substance for given usefulness and strength prerequisite anyway possible advantages to utilizingQuarryDustistheexpensehaving,onthegrounds thatthematerialexpenseshiftsrelyinguponthesource

Itisexceptionallypermeablelightweighttotal.Itsthickness isroughly0.25g/cm3.Itisnormallylightshadedandclearair pocketdividers.Lightweighttotal.concretewithshutdesign hasbeenutilizedeffectivelyforunderlyingpurposessincethe latenineteenthcentury.Lightweighttotal.concretehasclear benefitsofahigherstrength/weightproportion,betterstrain limit, lower coefficient of warm extension, and prevalent warmthandsoundprotectionqualitiesbecauseofairvoids existedinlightweighttotal(LWA)Theupsideoflightweight totalisitsdiminishedmassandimprovedwarmandsound protectionproperties,whilekeepingupsufficientstrength. The decreased weight has various benefits, remembering diminished interest for energy during development. The diminishedselfweightofLWCdecreasethegravityloadand seismic inertial mass prompting decreased part sizes and establishment powers. Totals assume a significant part in cementandtheyrepresent60to75percentofthecomplete volumeof.cementandinthiswayaffectthediversematerial properties.Notwithstandingtheirjobaspracticalfiller,totals help control the dimensional strength of concrete based materials,whichmightbeconsideredtocompriseofasystem of concrete glue with moderately huge shrinkage developmentscontrolledbythetotalparticles

Silicarageareultrafinenonglasslikesilicacreatedinelectric circularsegmentheaterasaresultofthecreationofnatural silicon or compounds containing silicon and comprises of round particles with a normal molecule measurement of 150nm.Itisnormallyadimhuedpowder,fairlylikePortland concrete.Itisotherwisecalledminiaturesilica,isashapeless (non glasslike)polymorphofsilicondioxide,silica.Thecrude materialsare quartz,coal,and woodchips. Thesmoke that outcomesfromheateractivityisgatheredandsoldassilica smolder. Maybe the main utilization of0this material is as a0mineraladmixture0inconcrete.

Table 1: Chemical Composition of Silica Fume

SL.No. Constituents Quantity(%)

1 Sio2c 91.03m

2 Al2O3c 0.39m 3 Fe2O3c 2.11m 4 CaOc 1.5m 5 LOI 4.05mm

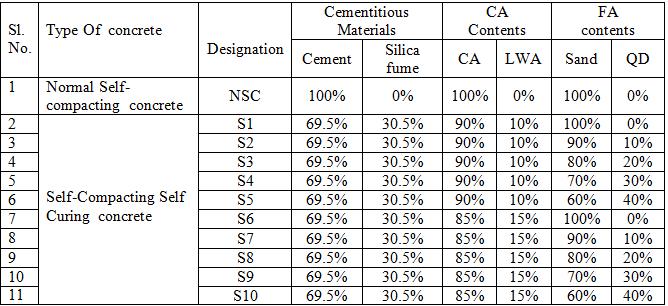

Table 2: detailsofselfcompactingselfcuringsolidand normalselfcompactingsolidconsideredforstrength boundaries

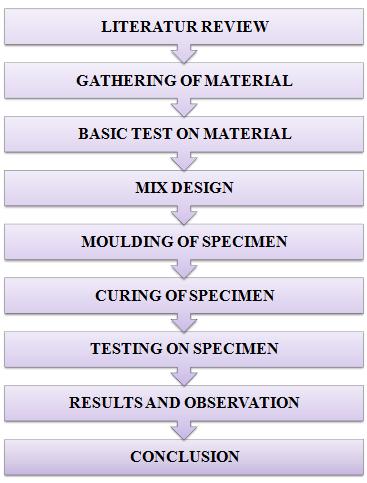

Chart 1:Methodology

International Research Journal of Engineering and Technology (IRJET)

e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

At each ideal relieving periods 7, 28, 56days examples of typical .concrete are removed from water and dried and afterward tried for compressive strength. The S .solid 3D shapes are additionally tried for 7, 28, 56days. The 3D squaresaretriedin200Tlimitpressuretestingmachineto getthecompressivestrengthofconcrete.

5.1 Compressive Strength of S1-S10 concrete

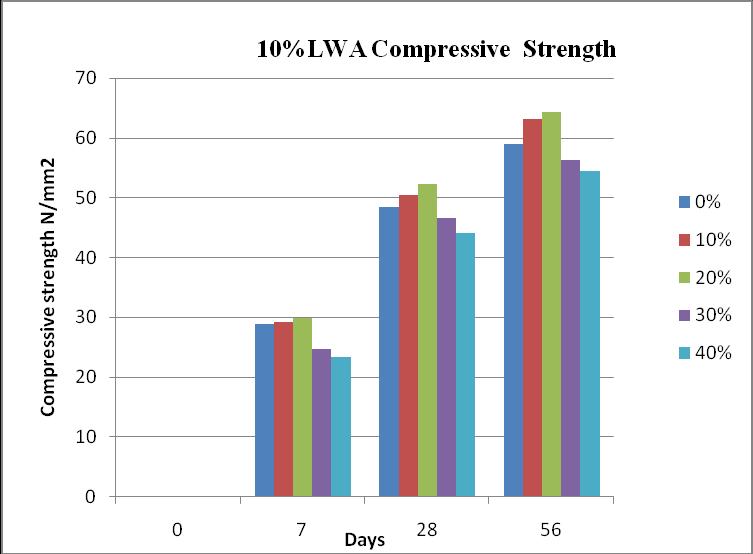

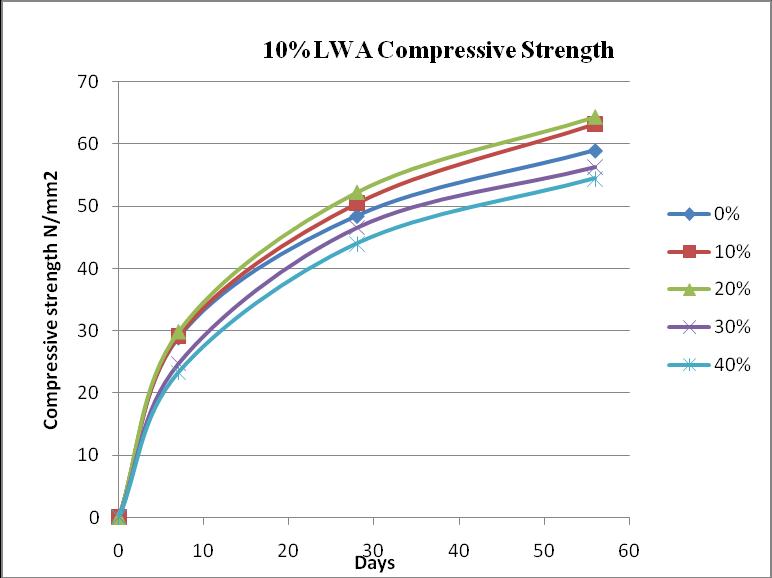

For10%LWAReplacement

Designation QD Replacement 7Days 28Days 56Days

S1 0% 28.88 48.44 58.95

S2 10% 29.1 50.45 63.2 S3 20% 29.79 52.2 64.29 S4 30% 24.7 46.55 56.3 S5 40% 23.3 44 54.45

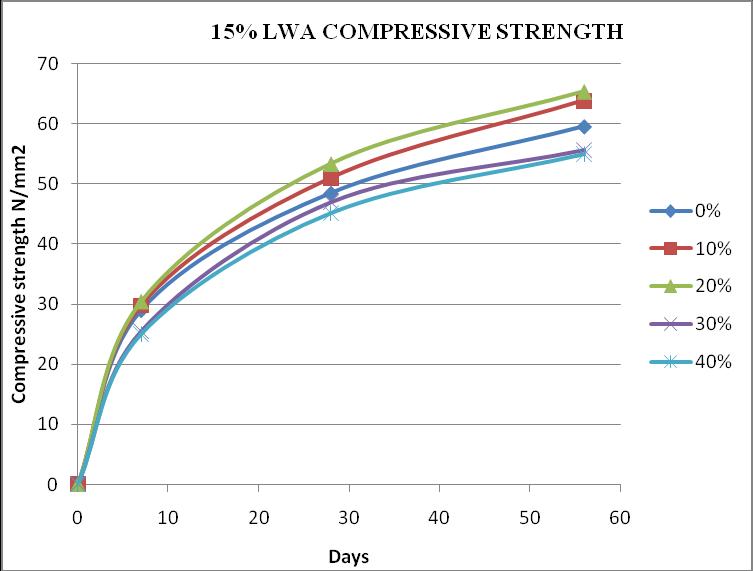

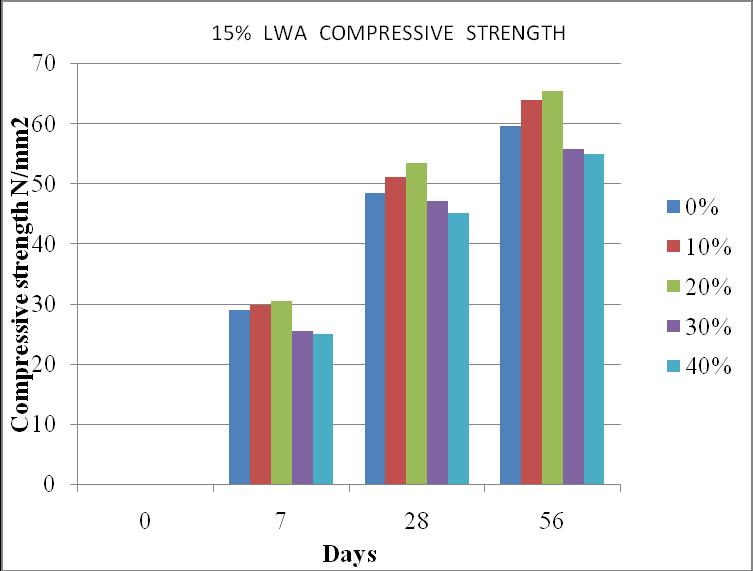

For15%LWAReplacement

S6 0% 28.96 48.45 59.54 S7 10% 29.8 50.98 63.87 S8 20% 30.4 53.32 65.34 S9 30% 25.5 47 55.69 S10 40% 24.99 45.1 54.9 NSC 0% 28.33 47.85 57.4

5.2 Compressive strength of self compacting self relieving .concrete and Normal self-compacting concrete

Sl. No Designation Averageof3cubesstrength,N/mm2 atdifferentages 7Days 28Days 56Days 1p NSC 1 1 1 2p S1 1.02 1.01 1.03 3 S2 1.03 1.05 1.10 4 S3 1.05 1.09 1.12 5 S4 0.87 0.97 0.98 6 S5 0.82 0.92 0.95 7 S6 1.02 1.01 1.04 8 S7 1.05 1.07 1.11 9 S8 1.07 1.11 1.14 10 S9 0.90 0.98 0.97 11 S10 0.88 0.94 0.96

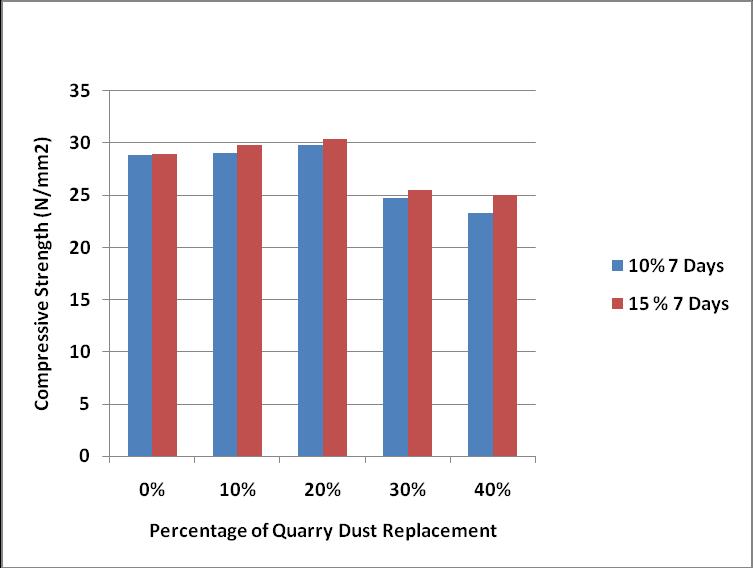

Chart 2:CompressivestrengthComparisonofS1 S5and S6 S10for7days

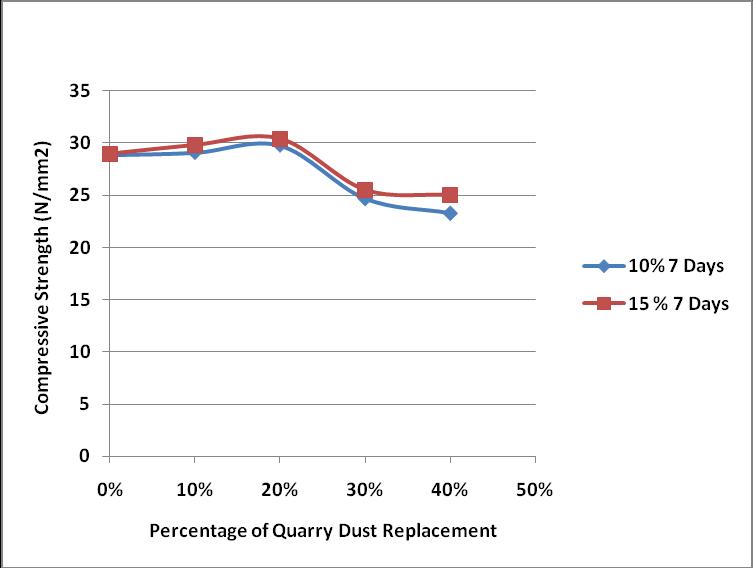

Chart 3:CompressivestrengthComparisonofS1 S5and S6 S10for7days

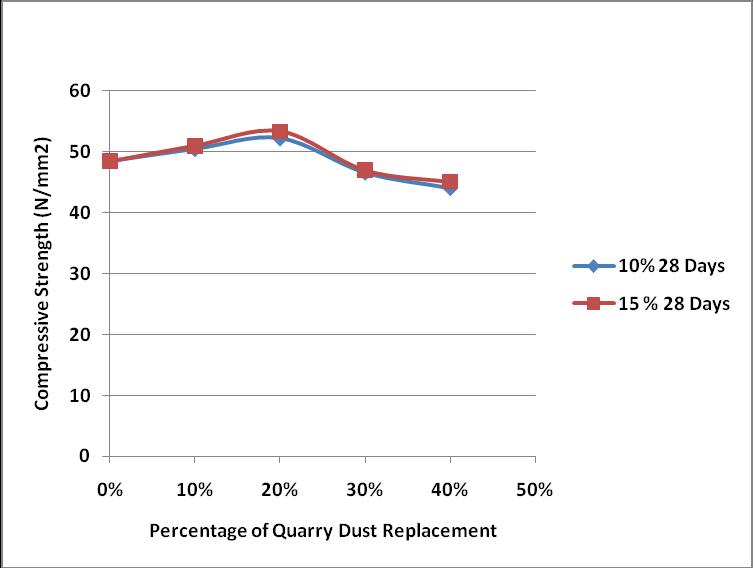

Chart 4:CompressivestrengthComparisonofS1 S5and S6 S10for28days

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

Chart 5:CompressivestrengthComparisonof S1 S5andS6 S10for28days

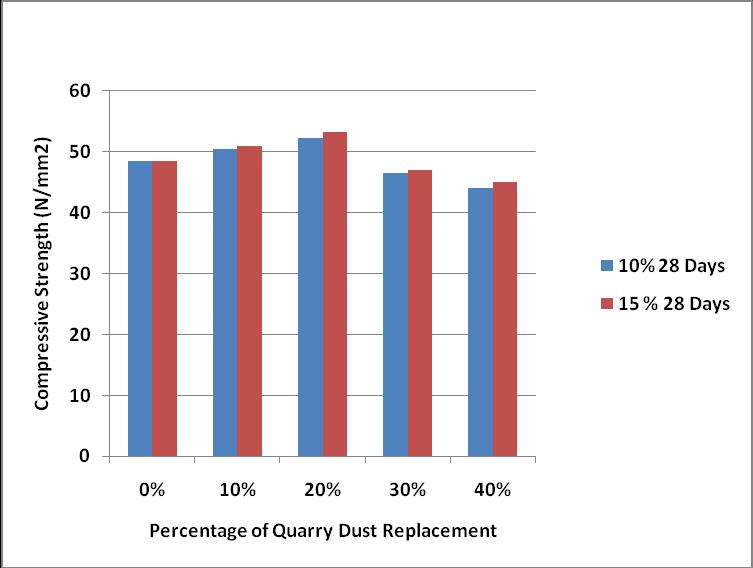

Chart -8:CompressivestrengthComparisonof S1 S5concrete

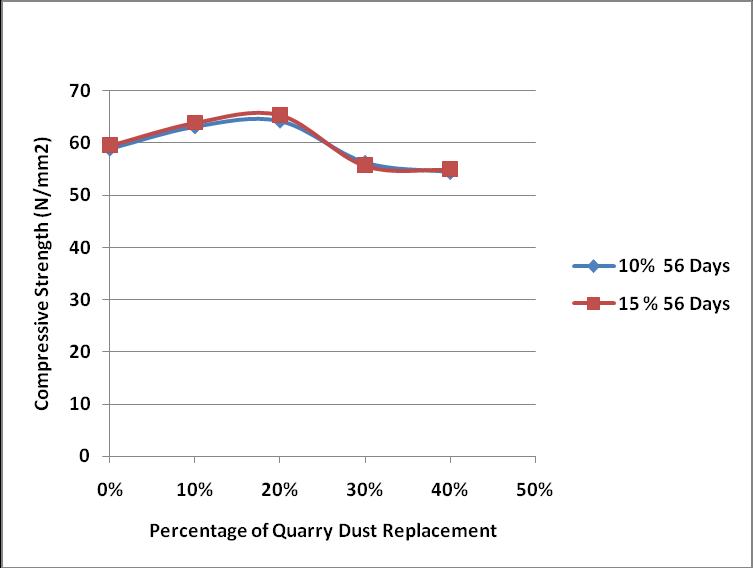

Chart 6:CompressivestrengthComparisonof S1 S5andS6 S10for56days

Chart 9:CompressivestrengthComparisonof S1 S5concrete

Chart 7:CompressivestrengthComparisonof S1 S5andS6 S10for56days

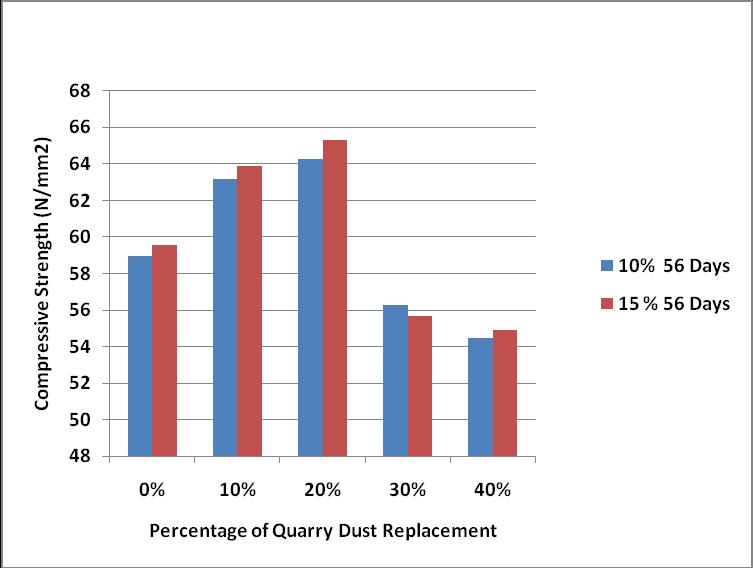

Chart 10:CompressivestrengthComparisonof S6 S10concrete

2021, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3192

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072

3) Durability concentrates on self compacting and self relieving.concrete.

4)Forknowingthereasonableconductinflexure,shearand pressure tests on model quarry dust part like shafts and segmentssizesportrayingthatutilizedoveralldesignsmust bedonetolearntheirexhibition

1) LiberatoFerrara,Yon DongPark,SurendraP.Shah “Amethodformix designof fiber reinforcedself compacting .concrete ” Cement and .concrete research,march2017,pp.957 971

Chart -11:CompressivestrengthComparisonofS6 S10 concrete

In light of the consequence of this investigation, the accompanying end are drawn It is feasible to fabricate an underlying light weight total concrete with low thickness and high self combining attributes (flow ability, deformability,self compactabilityandsoundness)utilizing neighbourhood delivered materials. There is a huge expansioninthecompressivestrengthandsplitrigidityfor boththe.solidwhensandissupplantedbyquarrydustupto 20%.Silica moulder was seen to improve the mechanical propertiesofSCC.Itcanbe inferredthatoneselfrestoring wasnearlyjustaboutascompellingastheordinaryrelieving technique.Theoutcomesrecommendthatself relievingcan be embraced in restoring of self compacting .concrete especially difficult to reach spaces of .solid constructions. This restoring strategy can likewise help where .solid executiondetailsaresignificant.Itcanlikewisebeinferred thatif20%sandissupplantedbyquarrydustin.concrete,it won'tjustdecreasetheexpenseof.concreteandyetwillsave huge amount of characteristic sand and will likewise diminishthecontaminationmakebecauseoftheremovalof thisquarrydustonimportantfruitfulland.

ClearlythereareasyetnumerouspartsofutilizationofSilica moulder, quarry residue and light weight total in .cement and RCC which are yet to be concentrated before it is normalized.Comingup next isa rundownofthepotential zones where future catalyst examination might be coordinated.

1) Investigate to concentrate on mechanical properties of concretebyutilizingLightweighttotalstructuredistinctive industrycanbeutilized.

2)Investigationstoconsidershrinkageandbondproperties ofself compactingandself relieving.concrete.

2) Selvamony C, Ravikumar M. S, Kannan S. U, Basil Gnanappa S “Development of high strength self compacted self curing .concrete with mineral admixtures” International journal on design and manufacturingtechnologies,Vol.3,No.2,july2019

3) TayyebAkram,ShazimAliMemon,HumayunObaid “Production of low cost self compacting .concrete using bagasse ash” Construction and building materials,2019,pp.703 712

4) SelcukTurkel&AliKandemir“Freshandhardened propertiesofSCCmadewithdifferentaggregateand mineral admixtures” JOURNAL OFMATERIALSIN CIVILENGINEERING,OCTOBER2018pp.1025 1032

5) M.M.Ranjbar,M.HosseinaliBeygi,I.M.Nikbin,M. Rezvani, A. Barari “Evaluation of the strength variation of normal and light weight self compacting.concrete infullscalewalls”materials andtechnology,2017,pp.571 577

6) MD NOR ATAN & HANIZAM AWANG “ The compessiveandflexuralstrengthofself compacting .concrete using raw rice hush ash “ journal of engineering science and technology, vol.6, 2018 pp.720 732

7) ShazimAliMemon,MuhammadAliShaikh,Hassan Akbar “Utilization of Rice Husk Ash as viscosity modifying agent in Self Compacting .concrete ” Construction and building materials” 2018, pp.1044 1048

8) Prakash Nanthagopalan, Manu Santhanam “Fresh and hardened properties of self compacting .concrete produced with manufactured sand “Cement&.concrete composites,2019pp.353 358

9) Dr. Gamal Elsayed Abdelaziz “A study on the performance of lightweight self consolidated .concrete”.“Cement&.concrete composites,2018 pp.353 358

International Research Journal of Engineering and Technology (IRJET) e ISSN: 2395 0056

10) H. A. F. Dehwah “Corrosion resistance of self compacting .concrete incorporating quarry dust powder, silica fume and flyash” construction and buildingmaterials,2018,pp.277 282

11) Rafat Siddique, Paratibha Aggarwal, Yogesh Aggarwal “Influence of water/powder ratio on strength properties of self compacting .concrete containing coal fly ash and bottom ash” Constructionandbuildingmaterials,2016,pp.73 81

12) Iliana RodríguezViacava,AntonioAguado deCea, Gemma Rodríguez de Sensale “Self compacting .concrete of medium characteristic strength” Constructionandbuildingmaterials,2012,pp.776 782

13) Yu.Q.L,Spiesz.P,Brouwers.H.J.H“Developmentof acement basedlightweightcomposite”.

14) Mucteba Uysal “Self compacting .concrete incorporatingfilleradditives:performanceathigh temperature”Constructionandbuildingmaterials, 2012,pp.701 706

15) JacekKwasny,S.M.ASCE,MohammedSonebi,Susan E. Taylor, Yun Bai, Kieran Owens and William Doherty “Influence of the Type of Coarse LightweightAggregateonPropertiesofSemilight weight Self Consolidating concrete ” Journal of MaterialsinCivilEngineering,2012,pp.1474 1483

16) Patel manishkumar Dahyabhai & PROF. JayeshkumarR.Pitroda“Self curing concrete:New technique for .concrete curing” Journal of international academic research for multidisciplinary, vol.1, Issue 9, October 2013, pp.539 544

17) K. S. Johnsirani, Dr. A. Jagannathan & R. Dinesh Kumar “Experimental investigation on self compacting .concrete using Quarry dust” International journal of scientific and research publications,vol3,issue6,June2013

18) U. N. Shah & C. D. Modhera “A state of Art Self compacting concrete with various industrial waste”Indianjournalofresearch,vol:2issue:7,july 2013,pp.167 169

19) Ms. Priyanka P. Naik & Prof. M. R. Vyawahare “ Comparative study of effect of silica fume and Quarry dust on strength of self compacting .concrete “ International journal of engineering research and applications, vol. 3, may june 2013, pp.1497 1500

20) Ahmed S. D. AL Ridha “The influence of size of lightweightaggregateonthemechanicalproperties ofself compacting.concrete withandwithoutsteel fiber” International journal of structural and civil engineeringresearch,vol.3,2014,pp.54 68

Volume: 09 Issue: 05 | May 2022 www.irjet.net p ISSN: 2395 0072 © 2021, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page3194